JABSCO 37202-2712 User manual

Other JABSCO Water Pump manuals

JABSCO

JABSCO 30510-0 Series User manual

JABSCO

JABSCO 30520-1 Series User manual

JABSCO

JABSCO ITT 36600 Series User manual

JABSCO

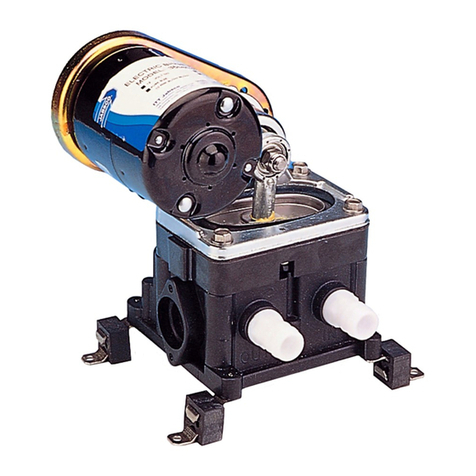

JABSCO 29200-0120 User manual

JABSCO

JABSCO 31595-009 User manual

JABSCO

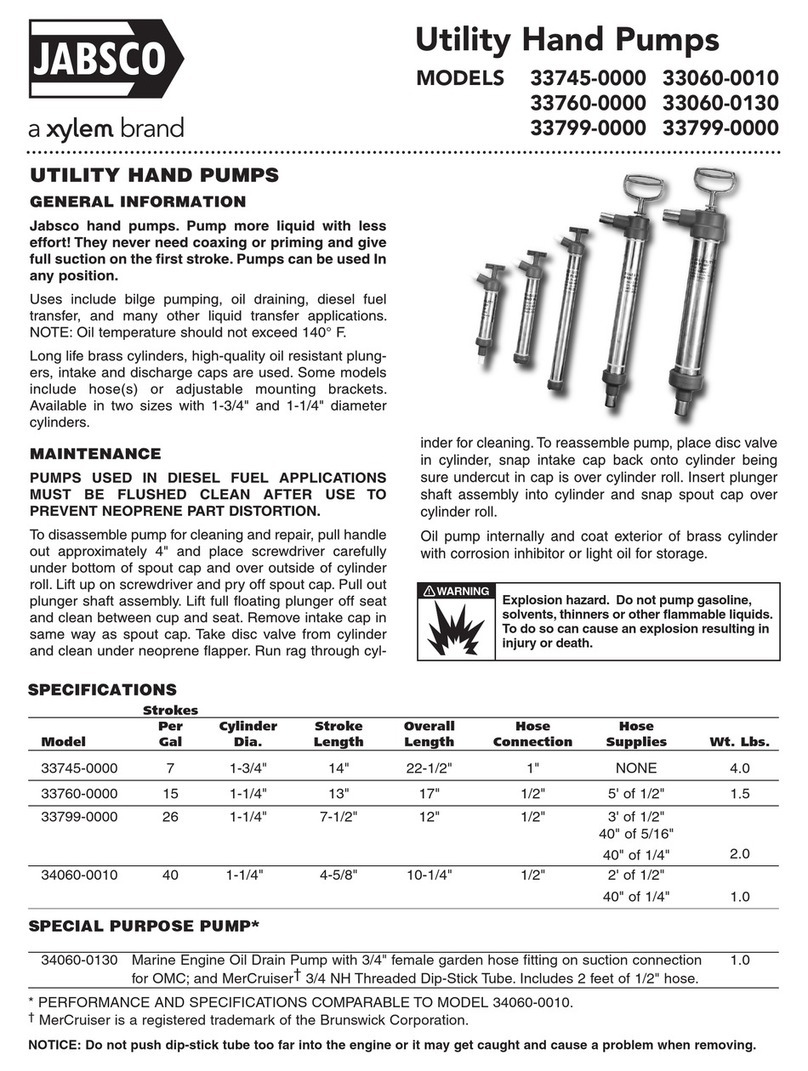

JABSCO 33745-0000 User manual

JABSCO

JABSCO 30510-0 Series User manual

JABSCO

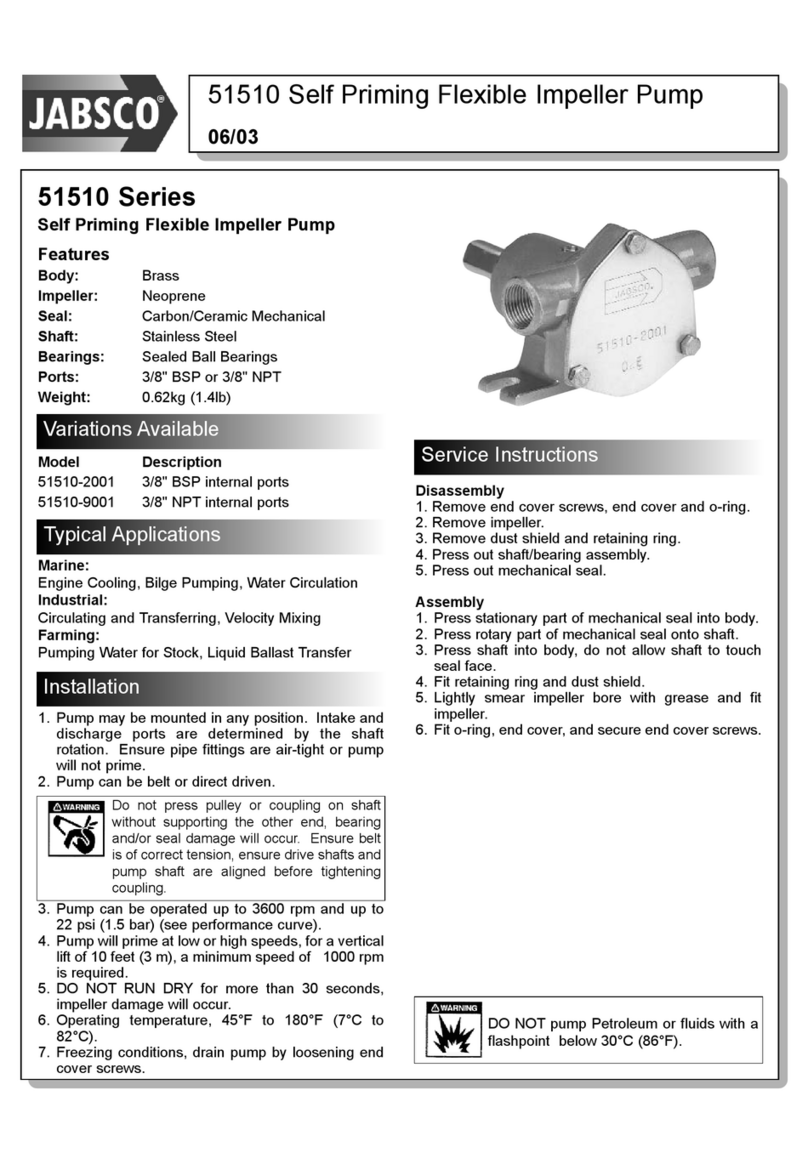

JABSCO 51510 Series User manual

JABSCO

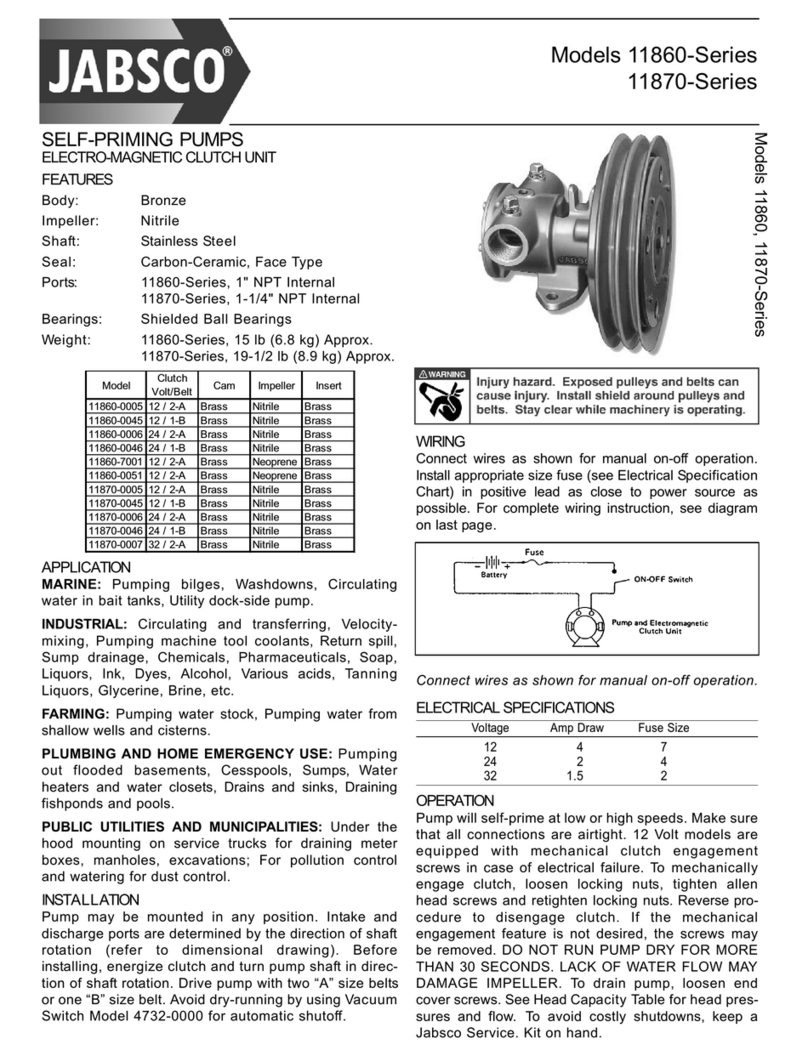

JABSCO 11860-0005 User manual

JABSCO

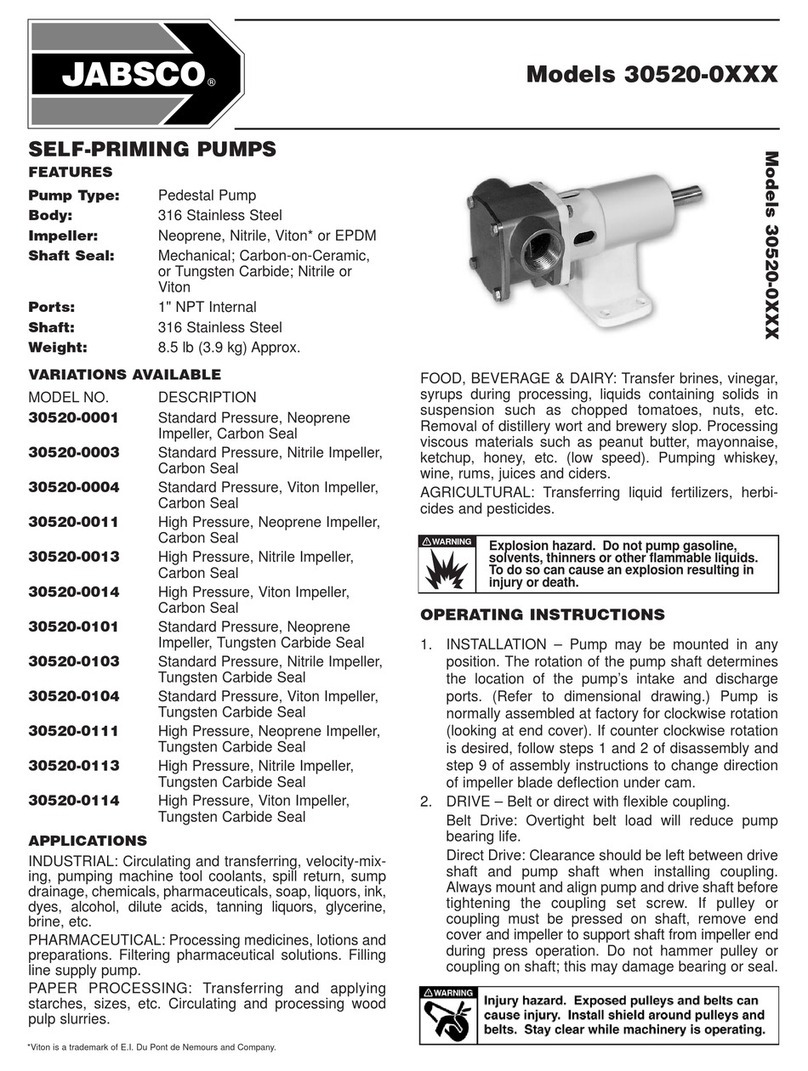

JABSCO 30520-0001 User manual

JABSCO

JABSCO 36600-0000 User manual

JABSCO

JABSCO 52700 User manual

JABSCO

JABSCO 30570-0 Series User manual

JABSCO

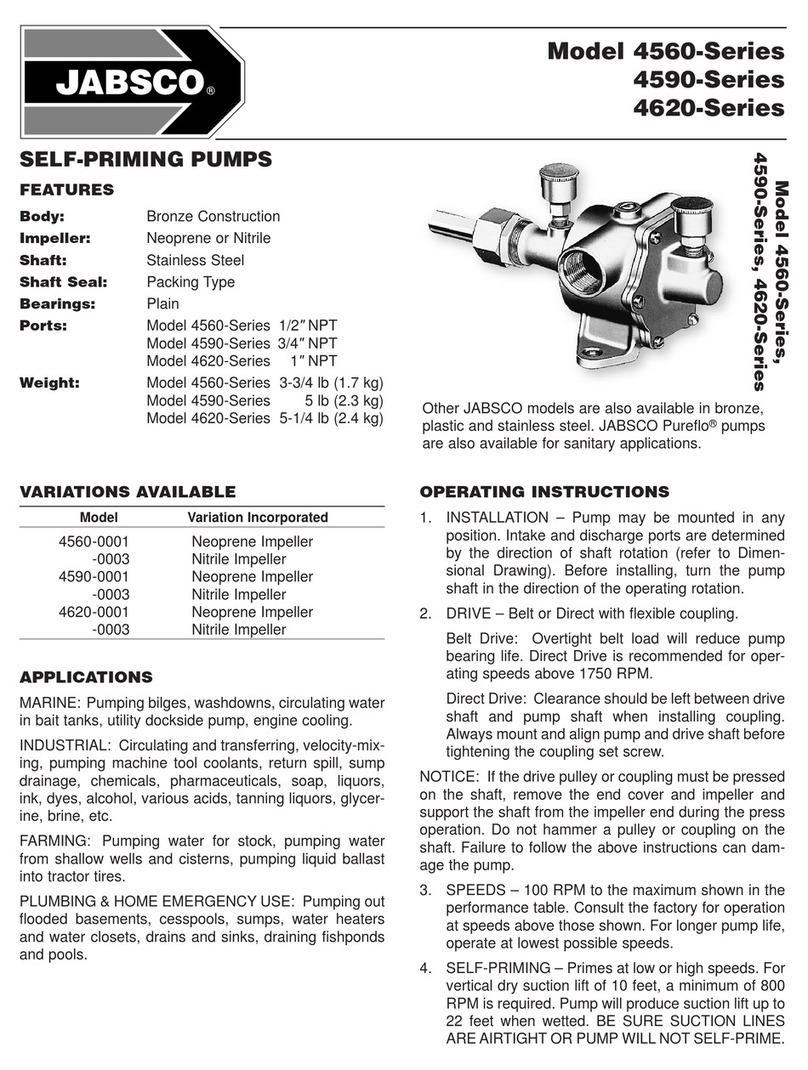

JABSCO 4560 Series User manual

JABSCO

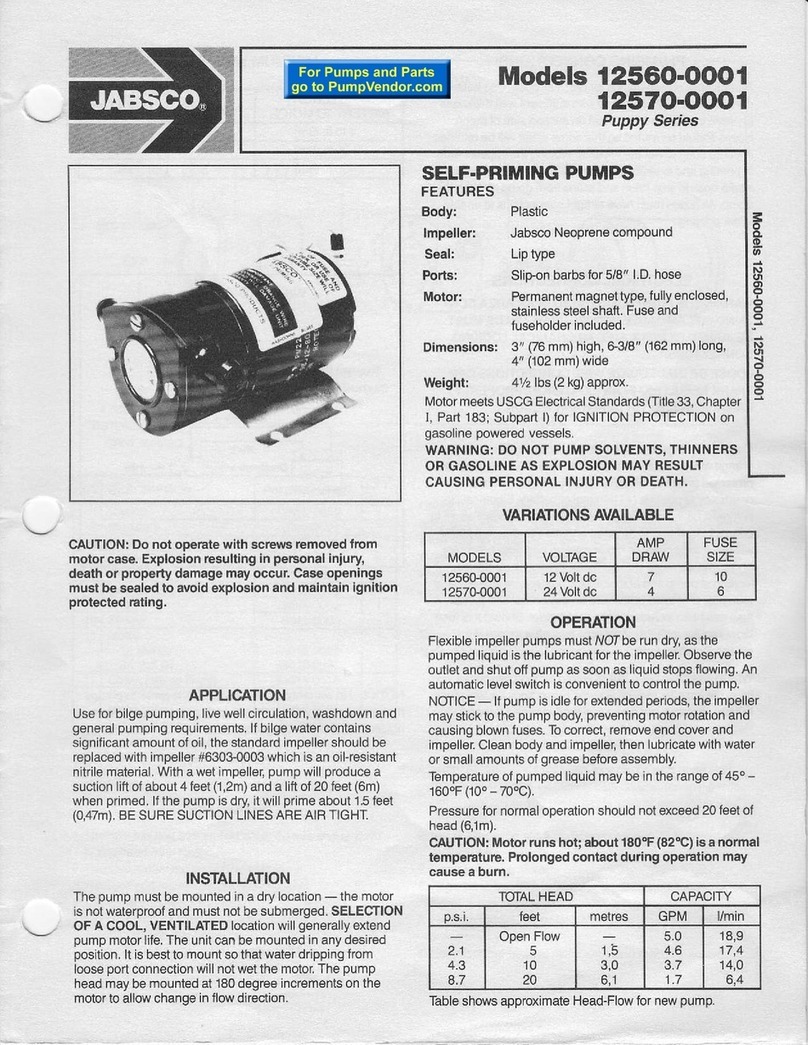

JABSCO Puppy 12560-0001 User manual

JABSCO

JABSCO 30520-310 User manual

JABSCO

JABSCO VR050-2022 User manual

JABSCO

JABSCO 30510-3 Series User manual

JABSCO

JABSCO 36680-2 Series User manual

JABSCO

JABSCO 37202-2 User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual