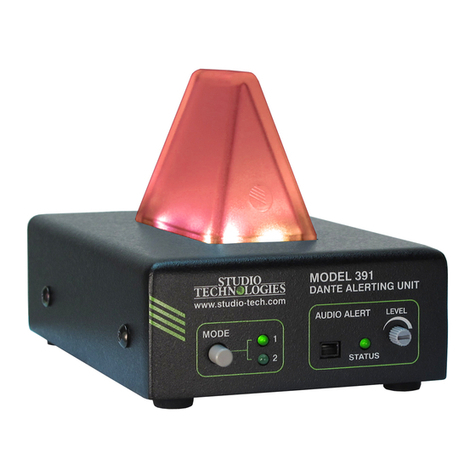

Issue 5, November 2014 Model 233 User Guide

Page 8 Studio Technologies, Inc.

voice-over applications. The fourth mode

provides a hybrid function, supporting

both push-to-talk and tap-to-enable/tap-to-

disable operation. This operation is similar

to that found in many broadcast intercom

system user stations.

The two buttons associated with the talk-

back functions can be configured to oper-

ate from either of two modes. One of the

modes supports a “push-to-talk” function.

This is typically used for on-air broadcast

applications. The other mode provides a

hybrid function, the operation of which is

discussed in the previous paragraph. The

hybrid mode is especially useful when the

Model 233 is used in a production-support

application.

The main button mode configures how the

main output, when it is in the “latched” on

state, responds to talkback activity. One

choice momentarily turns off the main

output when talkback is active, returning

the main output to the on state when the

talkback function has ended. The other

choice “unlatches” the main output in

response to a talkback function.

Cue Sources

The Model 233 supports the connection

of up to four external audio sources, each

of which can be selected for routing to the

stereo headphone output. The sources

are line input 1, line input 2, intercom

channel 1, and intercom channel 2. Each

source can be individually assigned to the

left channel, the right channel, or both the

left and right channels. This allows a wide

variety of stereo and mono headphone

mixes to be created.

For application flexibility, two line-level

audio sources can be connected to

the Model 233. Possible signal sources

include off-air receivers, wireless IFB

systems, and audio consoles. The con-

nected signals can be from two indepen-

dent sources, or could be from a stereo

audio feed such as would be associated

with a broadcast music event. Two level

trim potentiometers, located on the bottom

of the unit, allow signals with wide nominal

audio levels to be cleanly interfaced.

Audio signals associated with a single-

or dual-channel intercom system can

be routed to the headphone output. The

Model 233’s intercom interface is com-

patible with standard party-line intercom

systems from manufacturers such as

RTS™ and Clear-Com®. A broadcast-type

IFB (interrupted foldback) circuit can also

be connected to the intercom input. This

“listen only” signal is often found in televi-

sion broadcast applications.

Sidetone

The Model 233 includes an integrated

sidetone function that allows the output

of the compressor circuit associated with

the microphone preamplifier to be routed

to the stereo headphone output. This pro-

vides a confidence signal to the user, al-

lowing them to hear exactly what is being

sent to the main and, if desired, talkback

outputs. This sidetone signal can be a

critical element when creating an effective

communications environment.

In on-air television and radio broadcast

settings the Model 233 user’s own micro-

phone audio signal is typically returned

to the headphone output by way of a cue

audio source. But there are cases where

this signal is not available, such as when

“mix minus” cue feeds are utilized. This

type of cue feed includes everything but

the user audio, a requirement when sig-

nificant time delays, typically associated

with satellite transmission systems, are