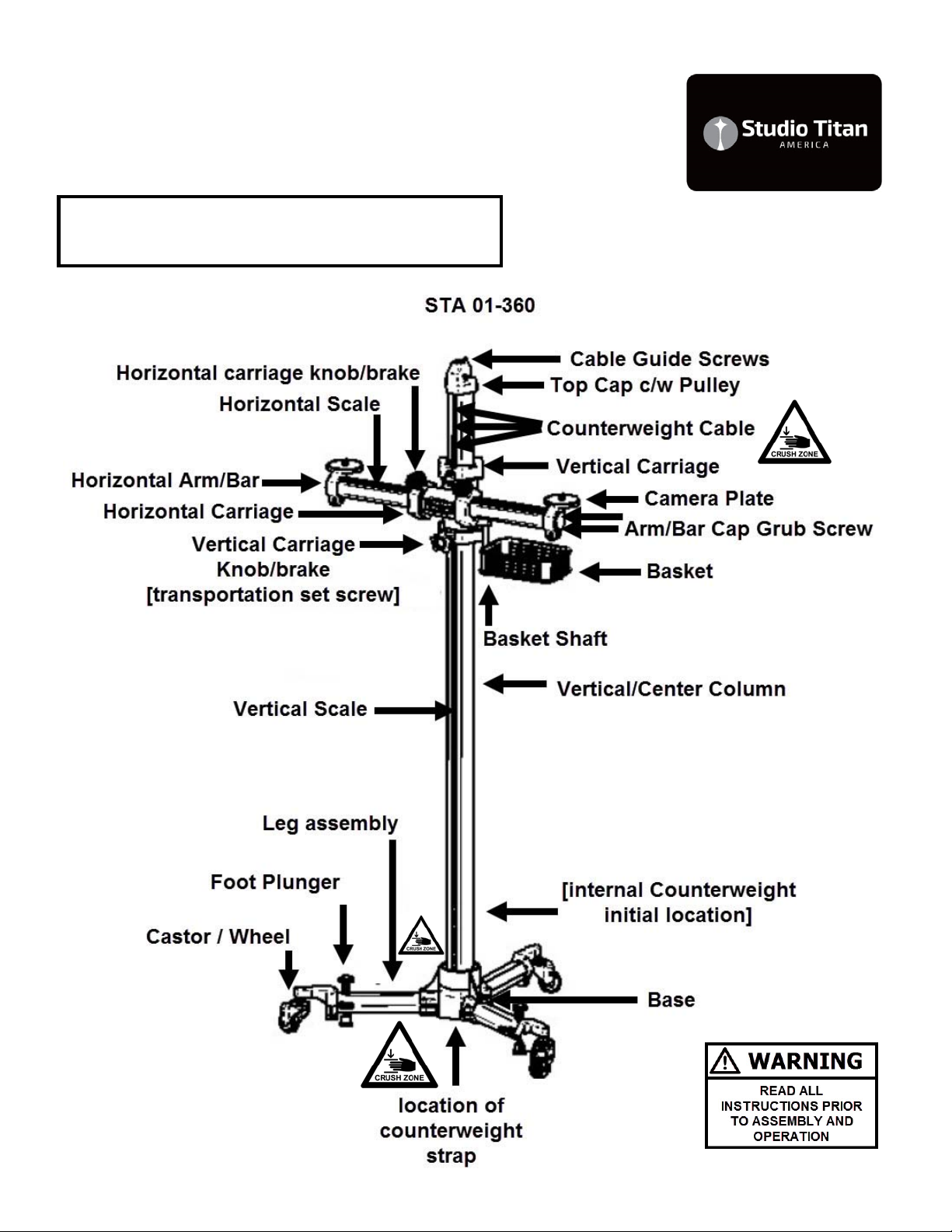

Studio Titan STA 01-360 User manual

Other Studio Titan Camera Accessories manuals

Studio Titan

Studio Titan STA 06-105 User manual

Studio Titan

Studio Titan STA 01-380 Series User manual

Studio Titan

Studio Titan STA 01-350R-MK2 User manual

Studio Titan

Studio Titan STA-C01-360 User manual

Studio Titan

Studio Titan STA 01-397 U User manual

Studio Titan

Studio Titan STA 01-350MK2 User manual

Studio Titan

Studio Titan STA 01-360MK2 Series User manual

Studio Titan

Studio Titan STA-01-398 User manual

Popular Camera Accessories manuals by other brands

Mophie

Mophie power boost mini user manual

GAZ

GAZ lomain KGL P Series Installation, operation and maintenance instructions

Lee Filters

Lee Filters ProGlass IRND Instruction booklet

Olympus

Olympus Camedia B-HLD10 instructions

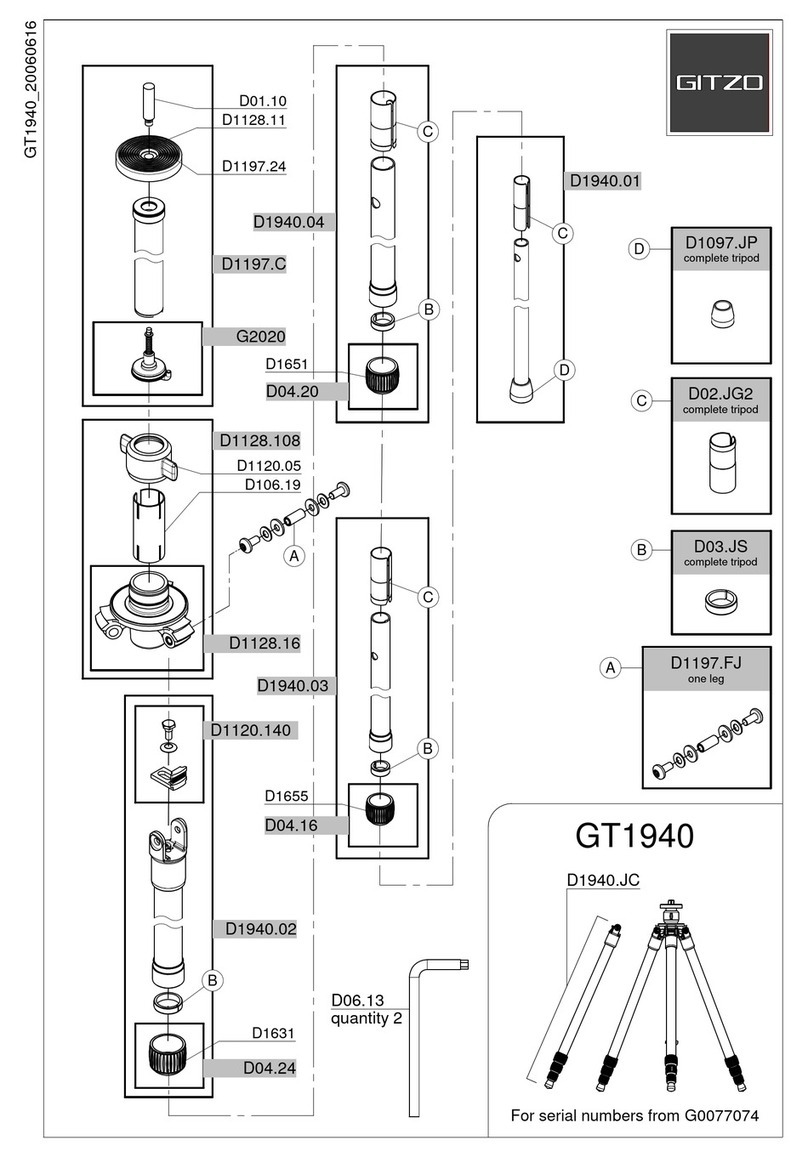

Gitzo

Gitzo GT1940 parts list

Foto Walser

Foto Walser Walimex Radio Flash Trigger Set Duo Copy of Instruction Manual