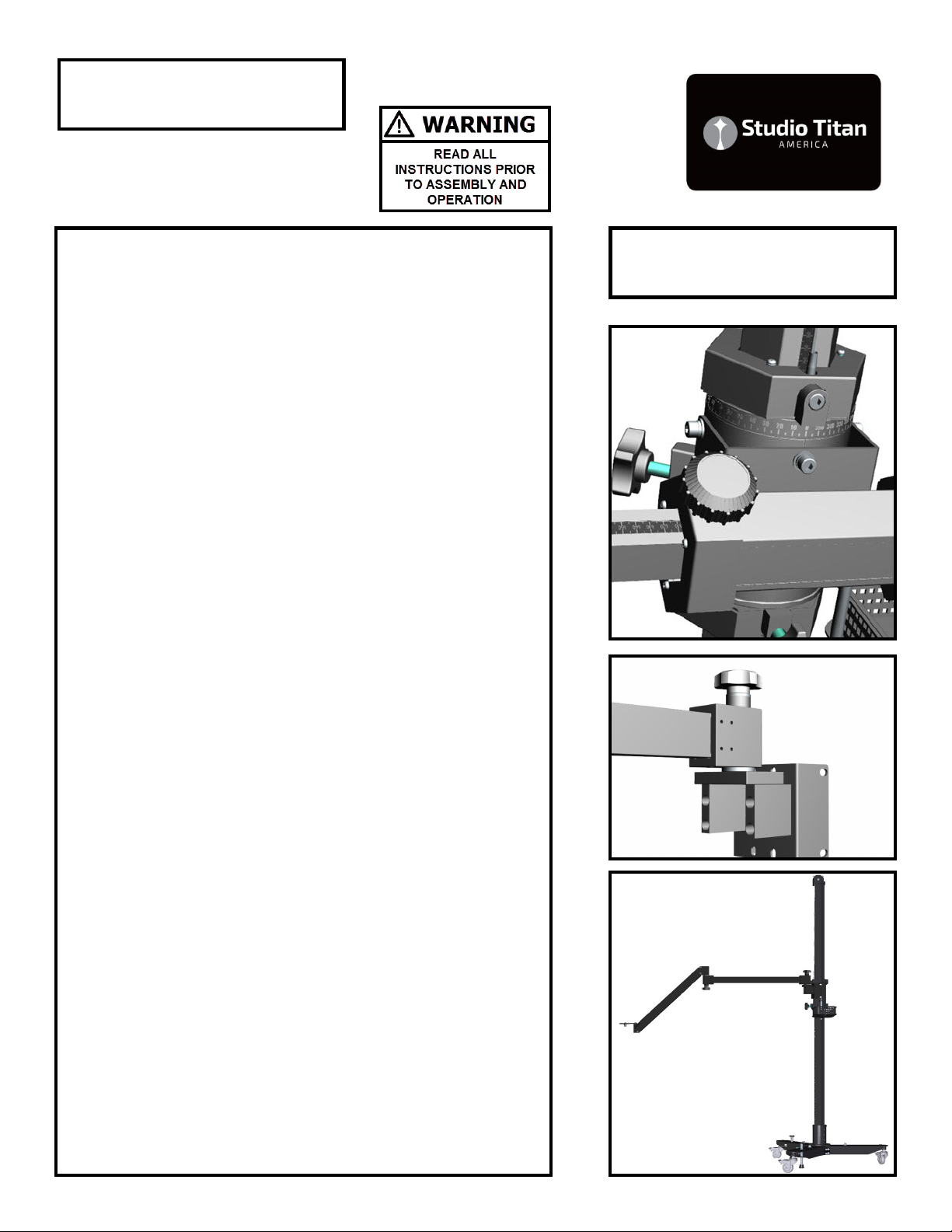

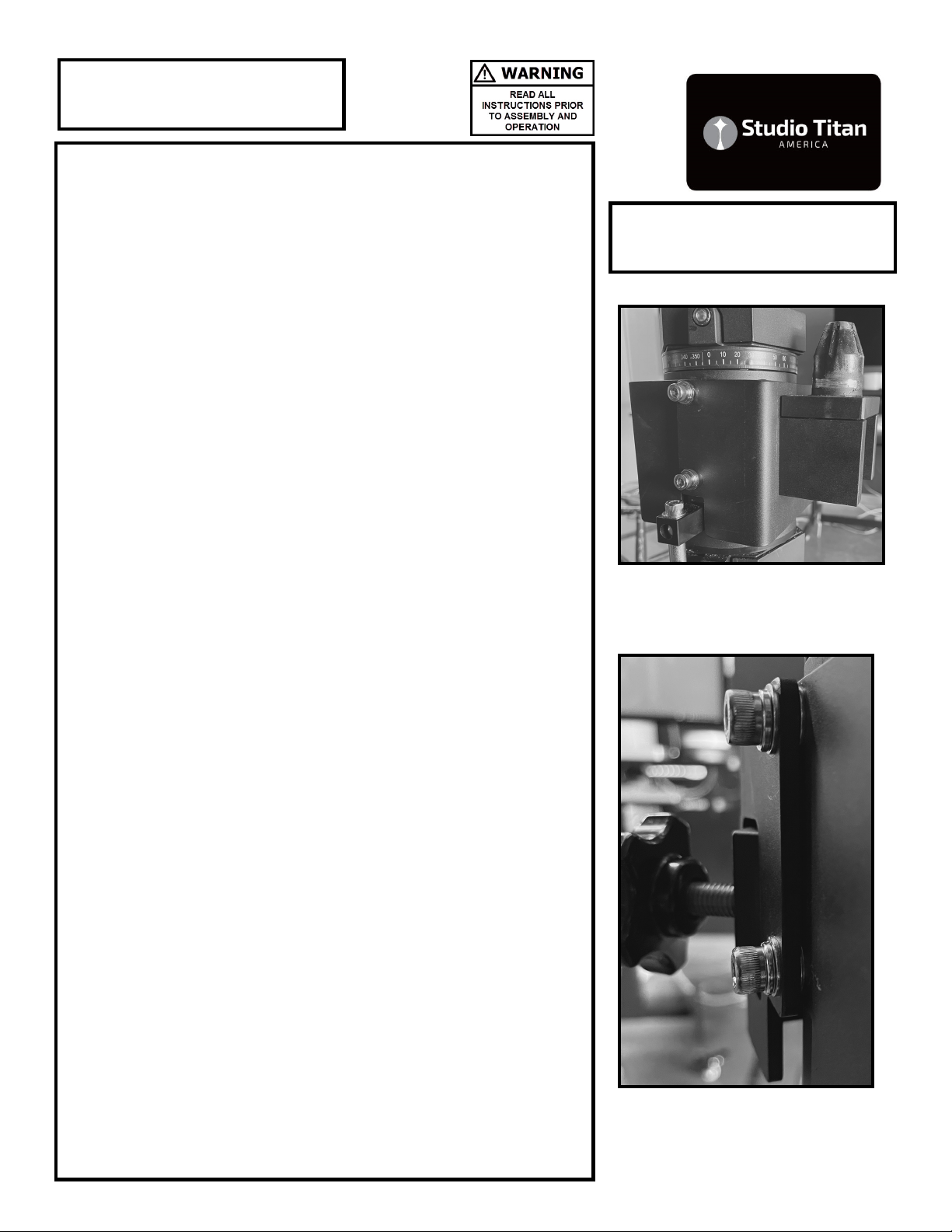

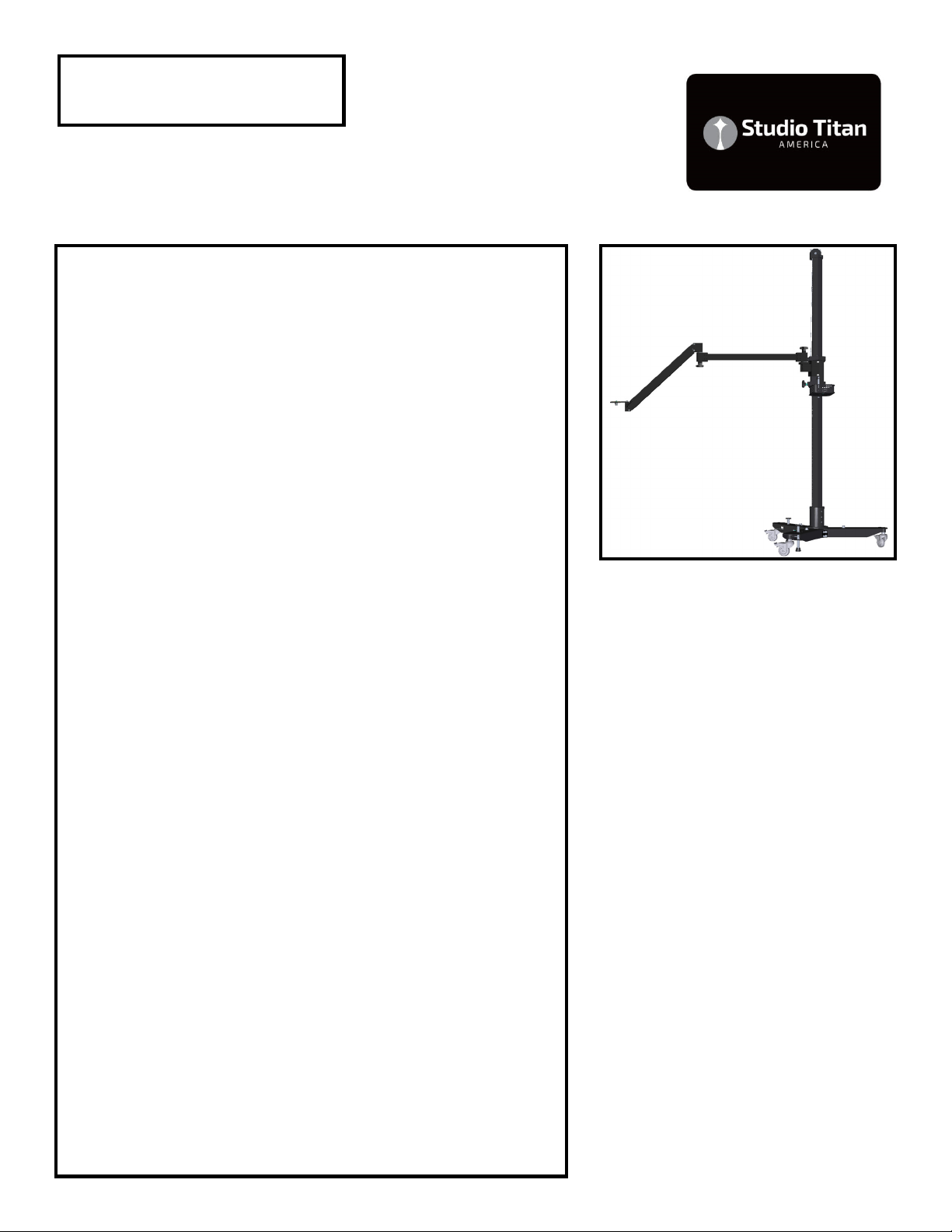

Studio Titan STA 06-105 User manual

This manual suits for next models

1

Other Studio Titan Camera Accessories manuals

Studio Titan

Studio Titan STA 01-360 User manual

Studio Titan

Studio Titan STA 01-350MK2 User manual

Studio Titan

Studio Titan STA 01-397 U User manual

Studio Titan

Studio Titan STA 01-360MK2 Series User manual

Studio Titan

Studio Titan STA 01-350R-MK2 User manual

Studio Titan

Studio Titan STA-C01-360 User manual

Studio Titan

Studio Titan STA-01-398 User manual

Studio Titan

Studio Titan STA 01-380 Series User manual

Popular Camera Accessories manuals by other brands

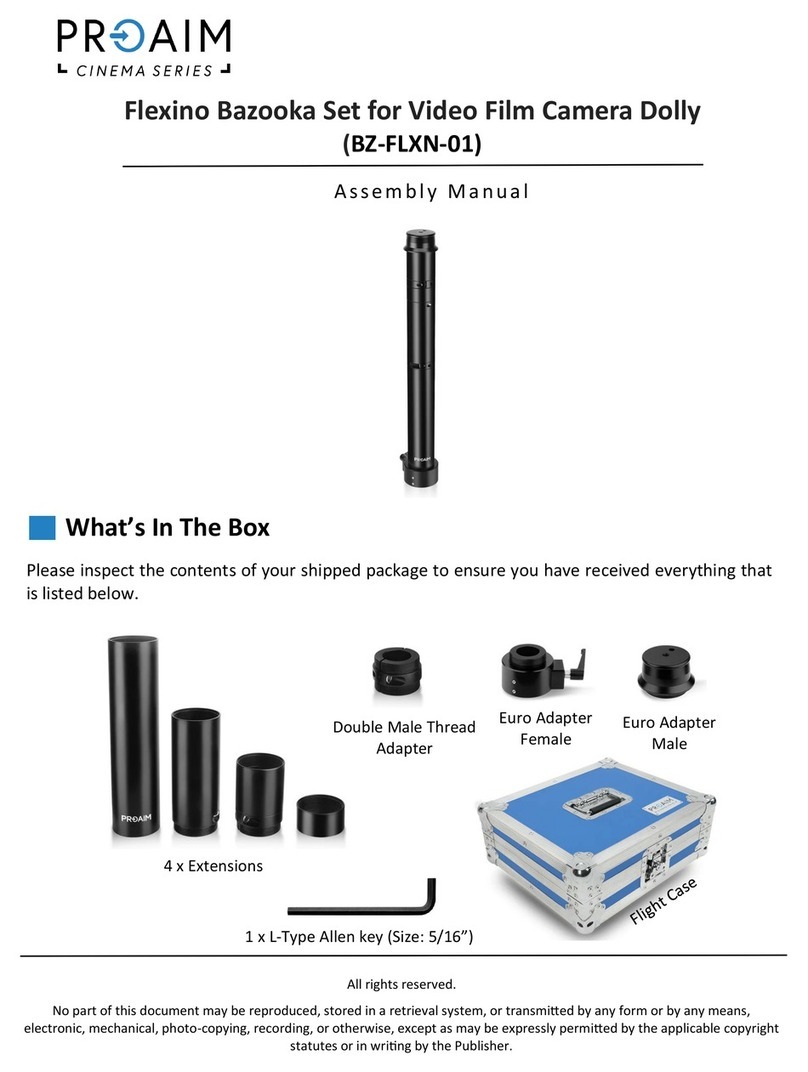

PROAIM

PROAIM Bazooka BZ-FLXN-01 Assembly manual

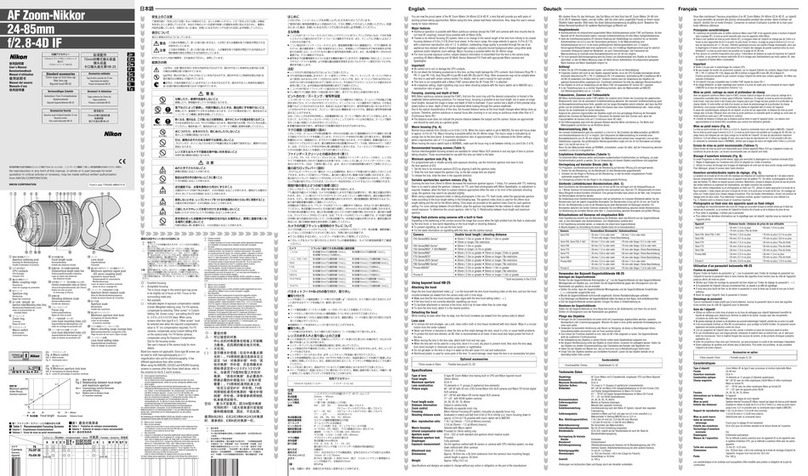

Nikon

Nikon AF Zoom-Nikkor 24-85mm f/2.8-4D IF user manual

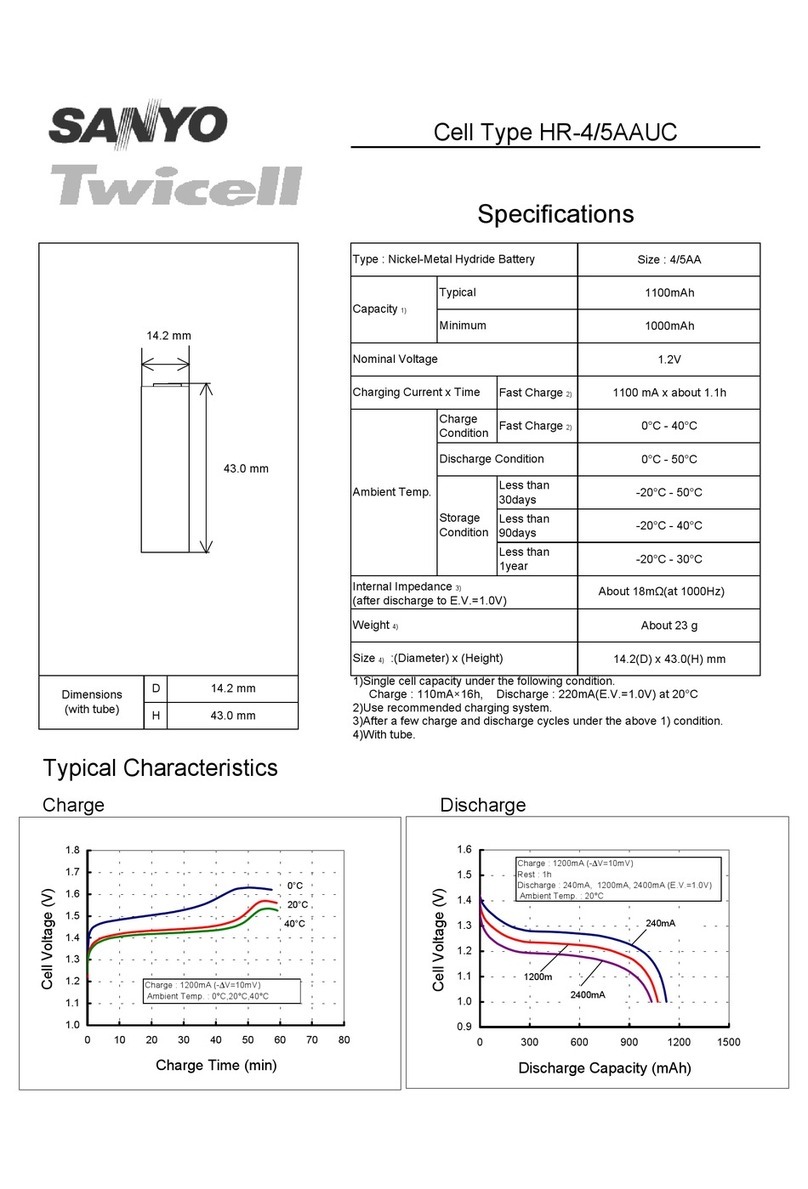

Sanyo

Sanyo Twicell HR-4/5AAUC Specifications

Dragonfly Energy

Dragonfly Energy Battle Born BBGC2 installation guide

EnerSys

EnerSys PowerSafe SBS XC Series Operation guide

Stiga

Stiga BT 20 Li 2.0 S Operator's manual