Studio Titan STA-C01-360 User manual

STA C01-360 1

CAUTION: Use supplied leather work gloves and safety glasses when handling the box, when

opening the box and when assembling the product.

HAZARD: Strapping is under tension and can jump when cut. Strapping and Buckles, rotec-

tive Edging, lastic Walls, lastic Caps and roduct Components and parts should be handled

with care. Work slowly, use extra caution to avoid any sharp edges.

Additional Tools may be Required: The essential tools are included. The following tools

are recommended to be on site: Box Cutter, Scissors, Screw Driver, Plyers or djustable

wrench, Metric Hex / llen Key set.

STA C01-360 2

Transit Damage:

Each package is inspected prior to being shipped from the

warehouse to insure that is in perfect condition. The column

shipping boxes are constructed using extra thick cardboard.

Some packaging includes engineered plastic walls, end caps

and banding. The columns are packed using engineered plas-

tic walls and in dense foam to protect and absorb energy

from reasonable drops and impacts. The column packaging is

designed and drop tested from approximately 5 feet [1.5 Me-

ters] without sustaining any internal damage. The packaging

is crush tested using a 660lb [300kg] weight placed along the

long side of the box without sustaining any internal damage.

If handled without care the boxes will show signs of transit

damage. Wearing work Gloves, while following the Assembly

Steps, carefully inspect the contents inside the boxes. Specifi-

cally the Vertical center column top cap pulley should be se-

curely fastened to the top of the Vertical center column as

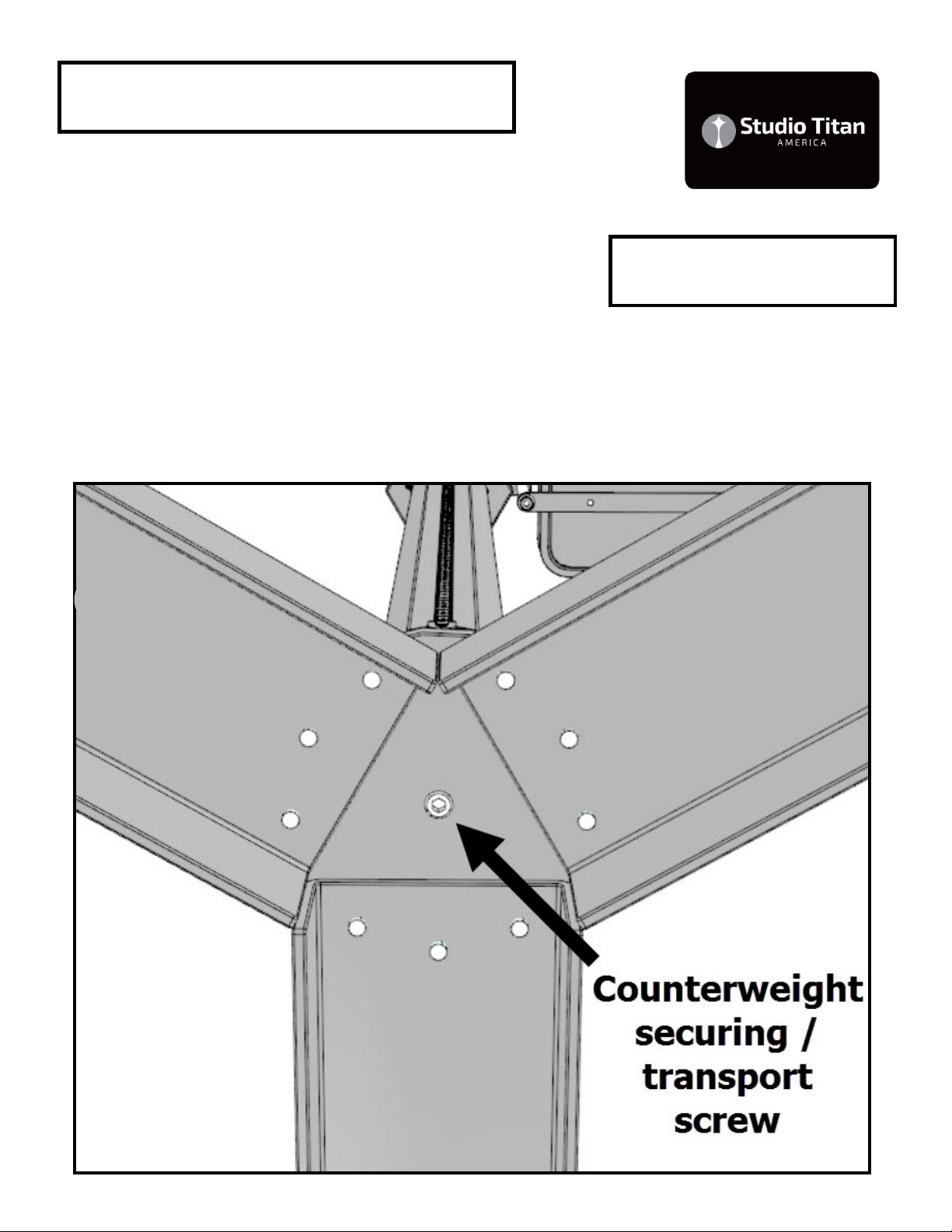

shown on the [component identification] page. In the base,

the transportation counterweight securing / transport screw

should be secured to the counterweight. As illustrated in Dia-

gram E. If anything seems unusual, !!!STO !!! Send images

to: in-

[email protected] for a second opinion. If there are

damaged OR Loose parts, do not assemble the stand, you

may injure yourself. If the damage is noticeable such as

cracks or loose or broken parts contact your dealer for ex-

change. If the damage is minor or cosmetic and does not

compromise the safe assembly or operation of the stand send

images of the parts that are affected to:

[email protected]. Arrangements will be made to

provide you with replacement parts to restore the stand to

new condition.

STA C01-360 3

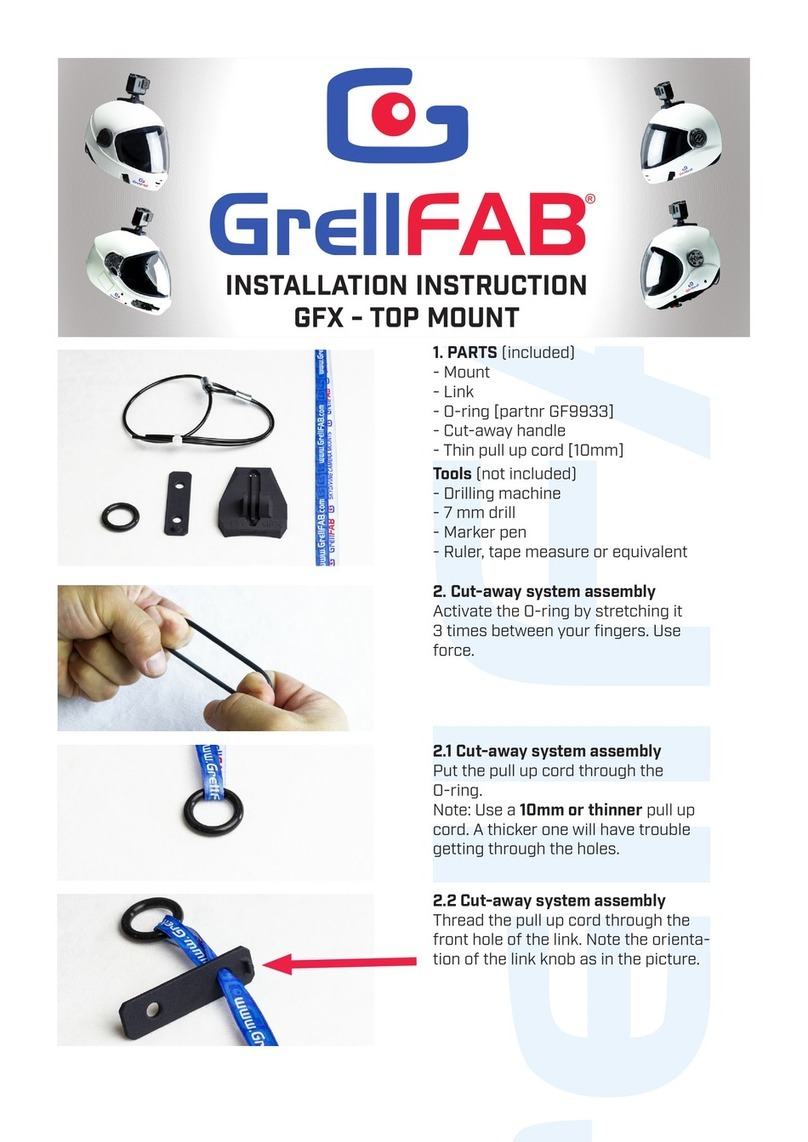

Product Nameplate / Label is located on the vertical column assembly.

The label information is indicated below:

STUDIO TITAN AMERICA

No.[Model Number] - [Manufacture Date]

Im orted by / Im orte ar

STEPHANIE MCNEIL CORPORATION

250 Augusta Ave, Suite 204

Toronto, ON M5T 2L7 CANADA

Manufactured in / Fabrique en

SOUTH KOREA

Label examples are indicated below:

STA C01-360 4

Intended use:

This product is intended for use by professional

and commercial photographers in a studio envi-

ronment with a high ceiling. The wheels are

designed to be used indoors on a floor that is

smooth, hard, flat and unobstructed. The Studio

Stands with internal counterweight are designed

to be used at all times with a load (Camera or

laptop shelf or both). CAUTION: This product

is not recommended for use by hobbyists or in a

household environment with a low ceiling or

carpeted floors. Carpeting or pitted surfaces are

not recommended because of the increased roll-

ing resistance which can cause the stand to tip

over. If the surface is not ideal, the stand must

be moved with CAUTION, very slowly, using

both hands one at the top and the other at the

bottom to steady the stand in order to prevent

the stand from tipping over. If the surface is not

ideal, lower the load to waist level before mov-

ing the stand. We also recommend the use of a

sandbag or weight attached at the base when

conditions are not ideal to prevent tipping over.

Ultimately it’s the users responsibility to under-

stand how the stand operates and to use the

stand within its specification limits, as intended

to insure their own safety and the safety of

their equipment. It is also recommended to use

a short tether cable to secure the camera to the

stand in the event that the head, head plate,

attachment stud or camera adapter plate comes

loose or fails. Some assembly is required, we

recommend using an assistant during the initial

product assembly. lease read all documenta-

tion prior to assembly.

STA C01-360 5

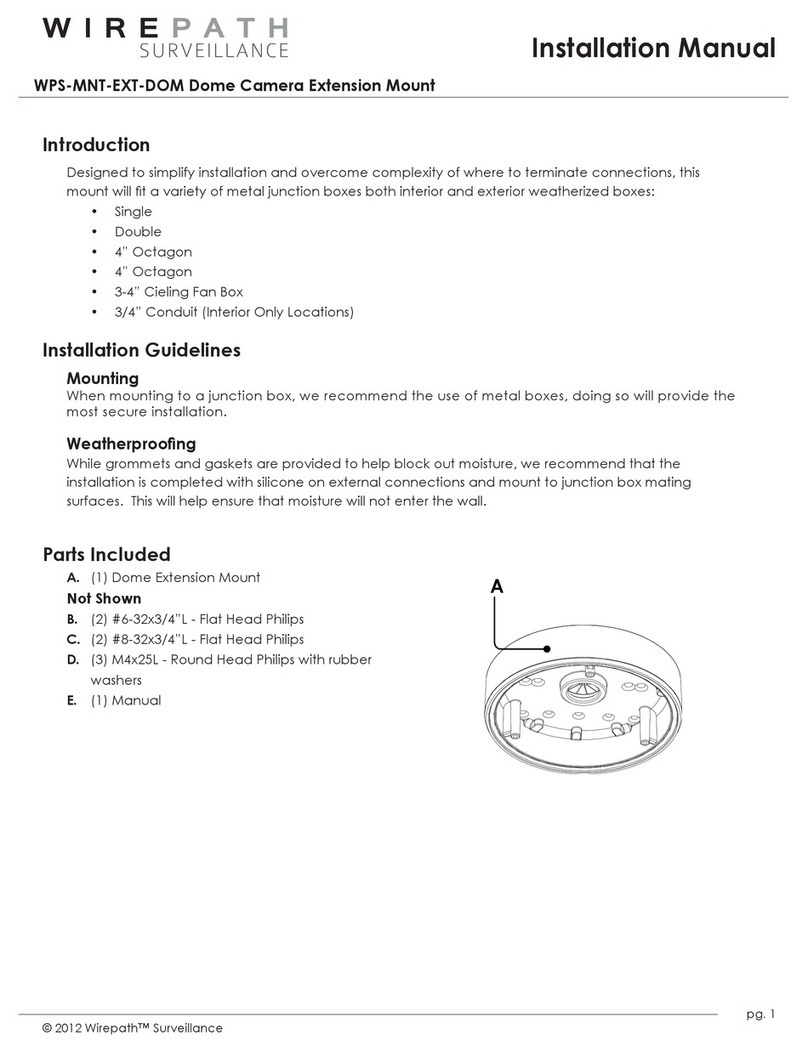

Component Identifi ation: STA-C01-360

STA C01-360 6

Component Identifi ation: STA C01-360

Diagram: D

STA C01-360 7

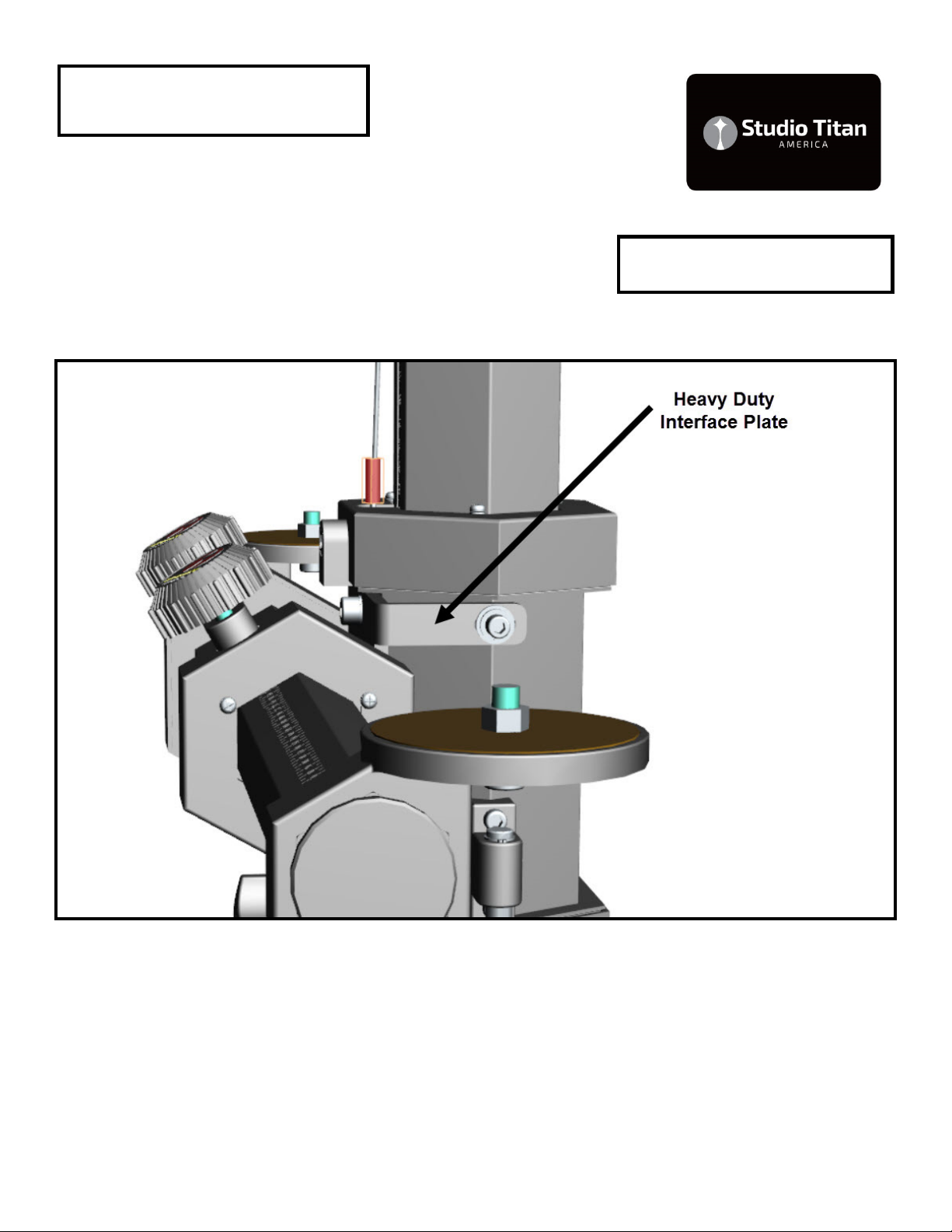

Component Identifi ation:

HD Interfa e Plate

STA C01-360 8

! CAUTION ! Cross Threading Components:

Cross-threading omponents during assembly is not overed under war-

ranty.

Cross-threading is a term that des ribes damage that is aused when a

misaligned s rew or knob thread is for ed into a threaded hole. When this

o urs, threads are damaged and are no longer apable of proper opera-

tion. The remedy is repla ement or repair of the damaged omponent/s.

AVOID ross-threading of mounting s rews and knobs during assembly us-

ing this easy to follow pro edure:

While standing in front of and looking into the threaded hole. Pla e the

s rew or knob thread against the threaded hole. Using one hand, hold the

thread between your fingers. With the other hand hold the hex key like a

pen il or pla e your index finger in the enter of the knob. Align the s rew

or knob with the hole as indi ated in the pi ture with the he kmark be-

low. Slowly turn it ounter- lo kwise or left, several turns, until you hear a

li k or feel the start of the thread. Then pro eed slowly, turning lo kwise

or right, gently using only finger for e to tighten the s rew or knob. If you

feel in reased resistan e, the threads are not aligned, remove and start

pro edure from the beginning again.

STA C01-360 9

Component Identification: TA C01-360

Diagram: E

STA C01-360 10

Assembly Steps:

1. Wearing gloves and together with your Assis-

tant…….. lace the Column Box [long rectangular

box] flat on floor. lace some packing materials

on the floor. Do not stand the Vertical/Center

Column vertically. Remove and Lay the Vertical/

Center Column flat on the floor. Under the Base,

Visually inspect and Confirm that the Counter-

weight securing transport screw is present which

secures the counterweight during transportation.

Do NOT remove the Counterweight securing /

transport screw until advised in the set-up in-

structions. Confirm the bolt is present and pro-

ceed to step 2 with assembly. If NOT, then:

If Counterweight securing / transport screw is

NOT present, the counter weight is loose and can

move inside the column. Do not stand the column

vertically. Stop the SET-U and Contact us for

further instructions. lease email:

info@studiotitanamerica.com with the best phone

number to reach you. We normally respond with-

in 24hrs, during weekdays.

STA C01-360 11

Assembly Steps:

2. Attach the three Leg Assemblies to the base.

[See Diagram: A] The Hex Key tool is supplied

and three fasteners are supplied attached to each

Leg Assembly. Use the supplied Hex Key tool to

tighten the nine fasteners by hand.

3. Wearing Gloves, remove the counterweight se-

curing / transport SCREW [See Component Iden-

tification STA C01-360 Diagram ]

4. Locate and identify the counterweight cable.

[See Component Identification STA C01-360 Dia-

gram ]

!!!CAUTION!!! AVOID CONTACT WITH THE

COUNTERWEIGHT CABLE AT ALL TIMES. CAU-

TION MUST USED TO AVOID INCHING YOUR

FINGER DURING SET-U AND NORMAL O ERA-

TION. The counterweight cable may become

frayed during transportation or normal use. When

frayed, stop using the stand and immediately re-

place the cable. Cable strands that separate may

become sharp.

Diagram: A

STA C01-360 12

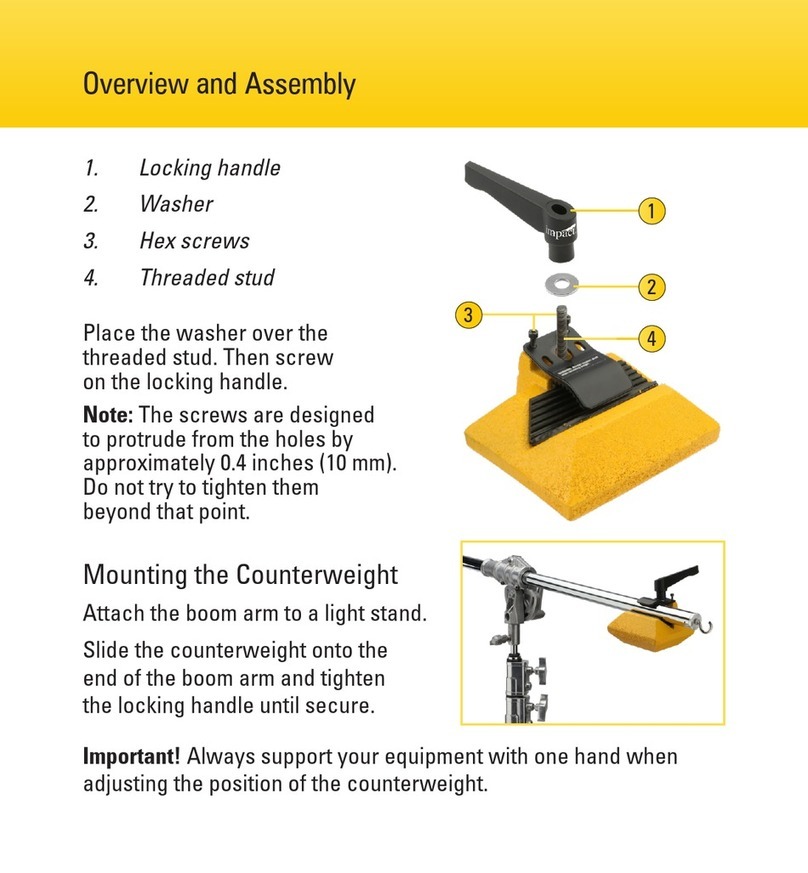

Assembly Steps:

5. Together with your Assistant…Wearing Gloves

…..Carefully, Slowly raise and lift until the Verti-

cal/Center Column is standing freely on its

wheels.

6. Locate the M8 Hex Wrench. Refer to section

“Cross Threading Components.” Remove the four

M8 x 20 screws from the Vertical carriage. Two

M8 screws from the front and one from each side.

[DIAGRAM: B indicates the screw locations] Lo-

cate the Horizontal Arm/Bar Carriage Assembly.

[See Component Identification STA C01-360 Dia-

gram] Together with your assistant. Have your

assistant hold the Horizontal Arm/Bar Carriage

Assembly in place while you fasten it with the

four M8 x 20 screws. Note the order. [screw,

spring washer and then flat washer] Hand tight-

ening with the Hex Wrench is recommended. If

you have a torque wrench tighten the M8 screws

to 45Nm or 33 lb/ft. not more.

7. Locate the M6 Hex Wrench. Refer to section

“Cross Threading Components.” Locate the loose

Vertical / Brake Knob. Locate the location of Verti-

cal Carriage / Brake Knob See [Transportation Set

Screw] [See DIAGRAM: D]. With the M6 Hex

Wrench FIRST Remove the transportation set

screw and THEN replace with Vertical Carriage /

Brake Knob. Turn the Vertical Carriage /Brake

Knob fully Clock Wise to secure the vertical car-

riage in the upper most or “parking position.”

Diagram: B

Diagram: B

STA C01-360 13

Assembly Steps:

8. Locate two M8 Hex wrenches. Locate the Bas-

ket. Locate the Basket Shaft. [See Component

Identification STA C01-360 Diagram] Refer to sec-

tion “Cross Threading Components.” With the first

M8 hex key hold the M8 screw at the top of the

Basket shaft. With the second M8 hex key loosen

the M8 screw at the bottom of the Basket shaft.

Attach the Basket to the Basket Shaft. Note the

order of fastener connection: [Screw , Flat washer,

Basket late, Flat Washer]. [See: DIAGRAM: C]

9. CAUTION: [Only with the Horizontal Arm/Bar in

the upper most positon “parking position”.] Slowly

release the Vertical Carriage Knob/brake by turning

it Counter Clock Wise. This will release the vertical

carriage allowing it to travel freely up and down

the Vertical Center / Colum. Confirm that the Verti-

cal Carriage is free to move in both directions while

using both hands to hold the Horizontal Arm/Bar.

Turn the Vertical Carriage Knob/brake fully Clock

Wise to secure the vertical carriage.

10. Locate the Two Horizontal Carriage Knob/

Brakes. [See Component Identification STA C01-

360 Diagram] Turn the Horizontal Carriage Knob/

Brake Counter Clockwise to release and confirm

that the Horizontal Arm / Bar is free to move left

and right.

STO SET-U — Read below— GO TO STE 11 If

anything seems unusual or if the vertical carriage

is not moving freely up or down. Stop Set-up and

send a few images of the stand to:

info@studiotitanamerica.com for assistance.

Diagram: C

STA C01-360 14

Use & Maintenan e Steps:

11. HAZARD: Stop and take a moment to under-

stand the effect of the counterweight. HAZARD:

The counterweight forces the vertical column to

travel towards the top of the Studio Stand. With-

out a load [Camera, laptop, etc.] on the horizontal

Arm/Bar it travels towards the top of the stand.

HAZARD: Use the stand with a load [Camera, lap-

top, etc.]. Always securely “ ark” the Vertical

Carriage by Turning the Vertical Carriage Knob/

brake fully Clock Wise before and after re-

positioning or before the stand is unloaded

[removing Camera, laptop, etc.].

12. HAZARD: Work in such a way so your always

standing behind or in front of the stand. Keep

clear of the Horizontal Arm/Bar and accessories.

Take extra notice of your body position when you

are releasing the Vertical Carriage Knob/brake.

With your free hand apply a downward force to

the Horizontal Arm/Bar Simultaneously as you re-

lease the Vertical Carriage Knob/brake.

13. Storage: When not in use, store with Vertical

Carriage in the upper most “ arking osition”. Re-

view this manual with all Studio personnel prior to

operating the Studio Stand.

14. Re-tighten all fasteners AGAIN. Re-tighten

fasteners after the first shoot. Tighten yearly.

STA C01-360 15

Theory of Operation:

A studio stand is used by professional and com-

mercial photographers to capture images accu-

rately with repeatability. It provides a rigid and

stable platform essential for High Resolution Sen-

sors used in DSLR, Medium Format and Large

Format cameras and imaging systems. A studio

stand reduces vibrations that are present when

shooting hand held. Reduced vibration increases

image sharpness. It enables the photographer to

focus on subject matter and image composition

instead of hand holding the camera. It provides

creative shooting options using heights and an-

gles that are unachievable when hand holding a

camera. It provides the foundation stone that

enables the photographer to develop their own

technical workflow. As the workflow evolves to

include advanced imaging practices, the results

can be seen as sharper images.

With an adjustable camera head the user can ac-

curately set up the camera to maintain camera to

subject flatness of field in both the vertical and

horizontal planes of travel. The flatness of field is

maintained as the user moves the stand both ver-

tically and horizontally eliminating perspective dis-

tortion.

Shooting tethered with an optional accessory /

laptop shelf, reduces floor cabling and allows the

photographer to immediately confirm both focus

and lighting. A Studio Stand reduces user fatigue.

The internal counter balance offsets the weight of

the camera and computer. Allowing the user to

easily move the camera and computer up and

down and left and right using only one hand.

This promotes good body ergonomics which can

prevent tennis elbow.

STA C01-360 16

Tip Over Hazard:

Caution must be used when moving the stand to

prevent tip over. Move the stand slowly and avoid

uneven surfaces as well as low and high level ob-

jects. Additional caution must be used when the

Horizontal arm with load (Camera or Laptop Shelf)

is used in the upper area above the midpoint of the

stand.

Counterweight Hazard:

The Horizontal Arm/Bar is connected to a counter-

weight located inside the Vertical Center/

Column. Caution must be used at all times when

using the Horizontal Arm/Bar. The Vertical Carriage

Knob/Brake must always be tightened to lock the

Horizontal Arm/Bar in place. Without a load on the

Horizontal Arm/Bar it can travel upwards. When

releasing the Vertical Carriage Knob/Brake stand

clear of the arms path of movement, firmly hold

the Horizontal Arm/Bar applying pressure down-

wards. Stand back to avoid contact with the Hori-

zontal Arm/Bar when unloaded. Do not remove the

load when the Vertical Carriage Knob/Brake knob is

released or turned CCW. Unless repositioning the

Vertical Center/Column intentionally the Vertical

Carriage Knob/Brake must be fully engaged (turned

fully clockwise). Store with Vertical Carriage in the

upper most “ arking osition.”

STA C01-360 17

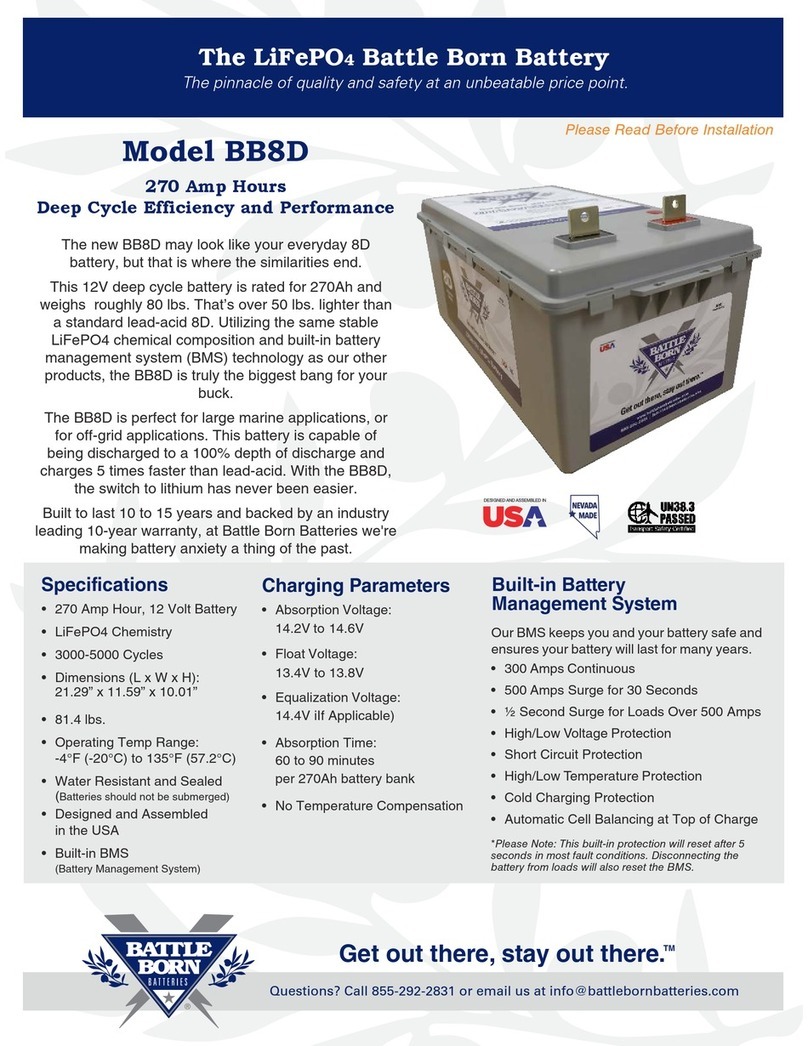

STA C01-360 Spe ifi ation & Dire tions

for Materials Re y ling

• Total Height : 203cm / 79.92 in

• Working Height Maximum : 176cm / 69.29 in (measured

from Camera Plate to floor)

• Working Height Minimum : 61cm / 2 in (measured from

Camera Plate to floor)

• Working Width Horizontal - Fully Extended to

Left : 55cm / 21.6 in (center of Column to center of Cam-

era plate)

• Working Width Horizontal - Fully Extended to Right :

55cm / 21.6 in (center of Column to center of Camera

plate)

• Overall Working Width Horizontal - Fully Extended from

Left to Fully Extended Right : 110 cm / 3.2 in (center of

Camera plate to center of Camera plate)

• Width : 85cm / 33. 6 in

• Weight : 0kg / 88lbs

• uggested Wheels : 01-350-20-02

• Base Diameter :100cm / 39.3 in

• Recommended General load capacity : 10kg (22lbs)

• Camera Plate Hardware: 3/8th inch - 16 thread

• Includes two Camera Head Mount Plates and Basket as

shown

Options:

-Large accessory shelf STA-01-395 for notebook comput-

er

-Small accessory shelf STA-01-397A for notebook com-

puter

-STA-01-390 3-way head

Studio Titan reserves the right to make product

changes and improvements as required. As a re-

sult, the product supplied may not be delivered

exactly as advertised or indicated on the website

or manual.

• The column box blue outer

plastic material is olypropyl-

ene, abbreviated as , is a re-

cyclable thermoplastic polymer

widely used in many different

products. is rugged. 's

resin identification code is 5,

and it is recyclable.

• lastic bags are made of LD E

(Low-Density olyethylene) –

Recyclable plastic (check Local

Authority) LD E can be recy-

cled. However, check with your

Local Authority to ensure it is

recycled in your area. This is

described as a hard flexible

plastic.

• The Corrugated cardboard

box can be recycled at depots,

in municipal curbside collection

programs and through private

recyclers.

Other Studio Titan Camera Accessories manuals

Studio Titan

Studio Titan STA-01-398 User manual

Studio Titan

Studio Titan STA 01-350R-MK2 User manual

Studio Titan

Studio Titan STA 01-360MK2 Series User manual

Studio Titan

Studio Titan STA 01-380 Series User manual

Studio Titan

Studio Titan STA 01-397 U User manual

Studio Titan

Studio Titan STA 01-360 User manual

Studio Titan

Studio Titan STA 01-350MK2 User manual

Studio Titan

Studio Titan STA 06-105 User manual