BUlL%_M iNSTALLATiON iNSTRUCTiONS

ELECTRICAL REQUIREMENTS PLUMBING REQUIREMENTS

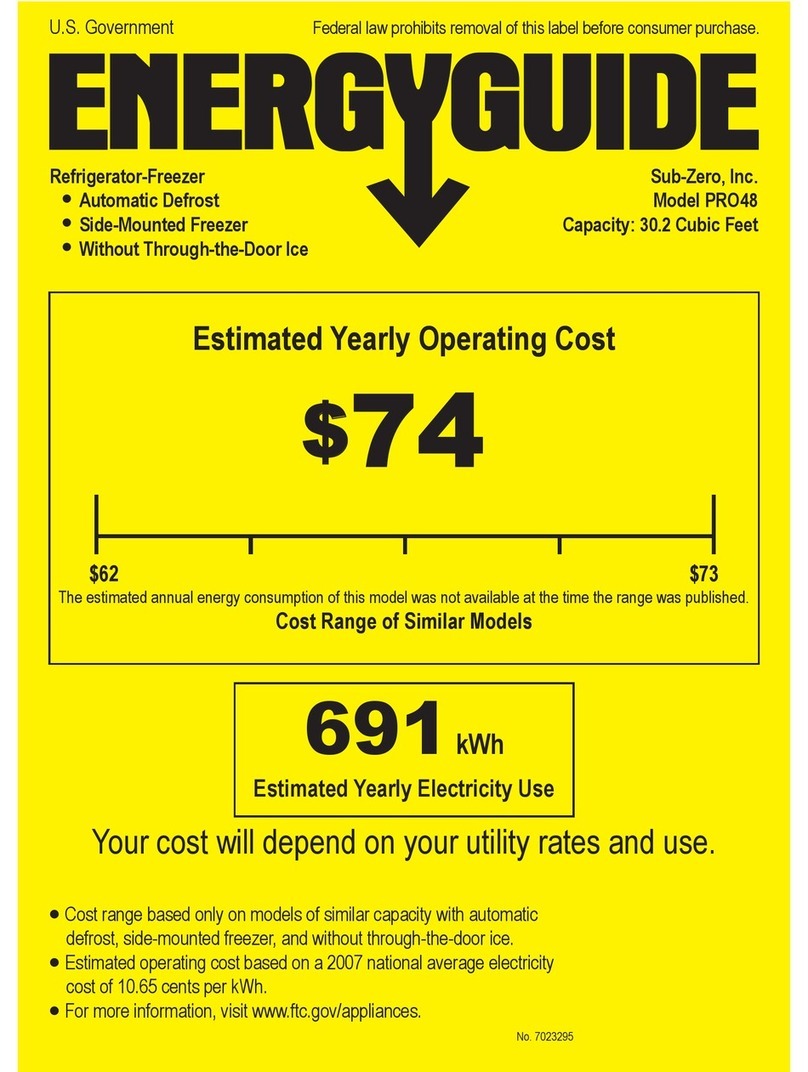

A 115VAC, 60 Hz, 15 amp circuit breaker and

ebctrbaJ sup@y are required. A separate

circuit, servicing onJy this ap@iance, is

required.

AU Sub-Zero B@tdn modeb are equipped with

a power sup@y cord with a 3-prong grounding

@ug, which must be @ugged into a mating

3-prong grounding4ype waU receptacb. FoUow

the National Electrical Code and local codes

and ordinances when installing the receptacb.

For location of the electrical supply, refer to the

Installation Specifications illustration for your

specific model on pages 5-X

IMPORTANT NOTE: A ground fault circuit

interrupter (GF@) is not recommended and

may cause interruption of operation.

The O_@÷t r_'_st be ¢he_l(ed by a qualified

deet_id_} to be s_e tha_ il ibm"wi_÷d with

For BuiMn models with an automatic ice

maker, rough in the water supply line. Connect

a %" OD copper line to the house supply. Use

an easily accessible shut-off valve between the

water supply and the unit. This valve is usually

placed about 6" (152) from the compression

fitting. Do not use self-piercing valves. A

saddle valve kit (part # 420088@ is available

from your Sub-Zero deabr.

The water line should be routed up through

the floor within 1/2" (13) from the back wall and

no higher than 3" (76) off the floor. If the water

supply is brought in from behind the unit,

route the water line through the back wail, no

more than 3" (7@ from the floor. Regardless of

the routing, allow 3' (1 m} of excess copper

tubing to remain outside the wall or floor for

easy connection to the unit. For location of the

water sup@y, refer to the Installation Specifica-

tions illustration for your specific model on

pages 5-7.

A line filter is required when water conditions

have a high sediment content. The ice maker

operates on water pressure of 20 psi (1.4 bart

to 100 psi (&9 barL

A reverse osmosis system can be used,

provided there is a consistent water pressure

of 20 psi (1.4 bart to 100 psi (6.9 bart supplied

to the water valve at aii times.

IMPORTANT NOTE: in some cases a reverse

osmosis water filter system may not be able to

maintain the minimum water pressure consis-

tently.

Good water is important for high quality ice.

it is not recommended that the ice maker be

connected to a softened water supply. Water

softener chemicals, such as salt from a

malfunctioning softener, can damage the ice

maker mold and lead to poor ice quality. If a

softened water supply cannot be avoided, it is

important that the water softener be weii main-

tained and operating properly.