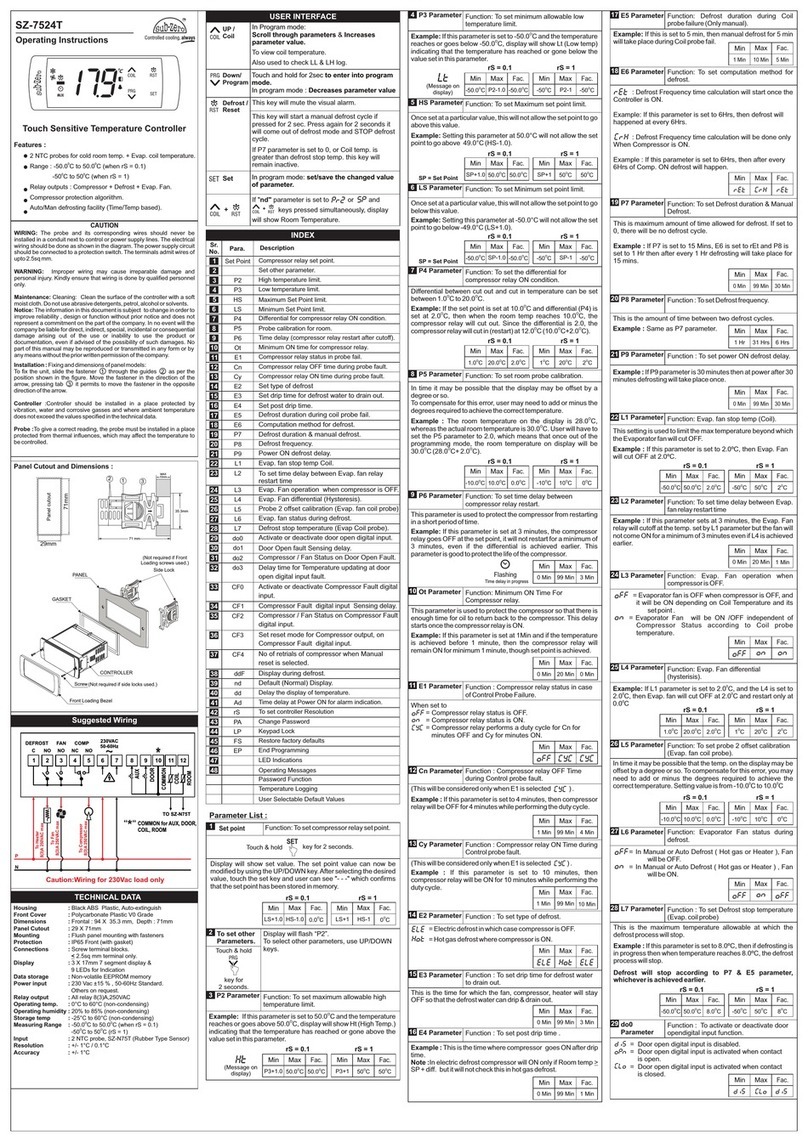

Description of parameters and functions.

Sr.No.

Parameter

Parameter setting

method.

Fact.

Set

Range

Min Max

Example (In cooling mode) :

O

If the set point is 40.0 C and

O

Hysterisis is set at 2.0 C then,

when the system reaches

O

40.0 C, the comp. Relay will

cut out. Since the Hysterisis is

O

2.0 C, the comp. Relay will cut

O

i n ( re s t a r t ) a t 4 2 . 0 C

O O

(40.0 C+2.0 C ).

(In Heating mode) : If the set

O

point is 40.0 C and Hysterisis

O

is set at 2.0 C then, when the

O

system reaches 40.0 C, the

Relay will cut out. Since the

O

Hysterisis is 2.0 C, the Relay

wi l l c u t i n ( r e s t a r t ) a t

O O O

38.0 C(40.0 C-2.0 C ).

Description of parameters and functions.

Sr.No.

Parameter

Parameter setting

method.

Fact.

Set

Range

Min Max

Example : If Cycle Time is

set to 10 sec, the duty cycle

of Relay/SSr ON-OFF in

proportional band will be

10 sec.

ON time +OFF time = 10 sec

Description of parameters and functions.

Sr.No.

Parameter

Parameter setting

method.

Fact.

Set

Range

Min Max

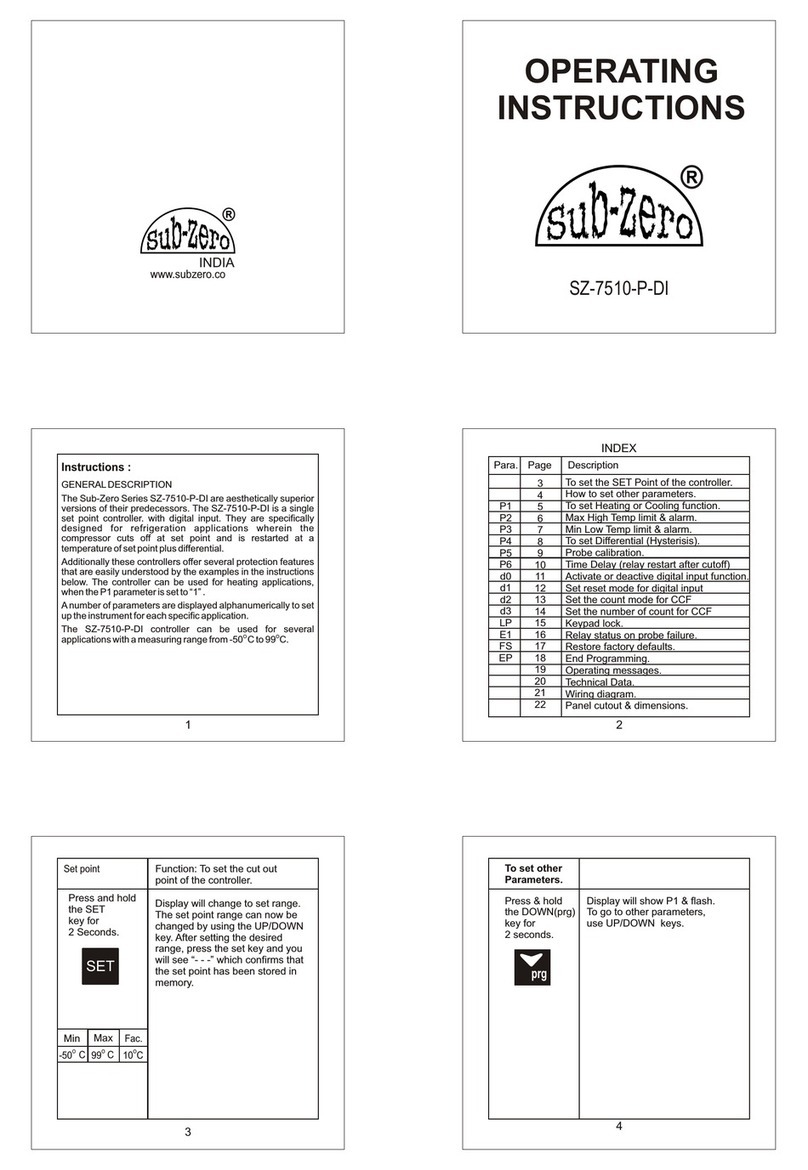

Function: To set Time Delay.

This parameter is activated in

On-Off Mode only.

Use UP/DOWN keys to get

desired value. After setting

desired value press SET key

& display will show “- - - -”

which confirms that value has

been stored in memory.

This parameter is used to

protect the compressor from

restarting in a short period of

time.

Time Delay

To change

the “ ”

Parameter,

press the

SET key.

0 Min 20 Min 0 Min

Description of parameters and functions.

Sr.No.

Parameter

Parameter setting

method.

Fact.

Set

Range

Min Max

Use UP/DOWN keys to get

desired value. After setting

desired value press SET key &

display will show “- - - -” which

confirms that value has been

stored in memory.

To change

the “ ”

Parameter

press the

SET Key

Function: To set minimum

limit for set point as per the

sensor selected.

Lower set

Limit

8

Function: To set maximum

limit for set point as per the

sensor selected

Higher set

Limit

Set

point

O

700 C

(J)

O

999 C

(K)

O

850 C

(Rtd2)

O

99.9 C

(rtd3)

O

700 C

9

Use UP/DOWN keys to get

desired value. After setting

desired value press SET key

& display will show “- - - -”

which confirms that value has

been stored in memory.

To change

the “ ”

Parameter

press the

SET key.

O

0 C (J)

O

0 C(K)

O

-99 C

(rtd2)

O

-99.9

C

(rtd3)

Set

point

O

0 C

10

Function: To set cycle Time in

seconds. Activated in

Proportional mode only.

Use UP/DOWN keys to get

desired value. After setting

desired value press SET key

& display will show “- - - -”

which confirms that value has

been stored in memory.

Cycle Time

To change

the “ ”

parameter

press the

SET key.

1 sec 99 sec 20 sec

6

Function: To set manual

offset for proportional band.

Activated in Proportional

mode only.

Manual

Offset

O

-99.9 C O

99.9 C O

0.0 C

Use UP/DOWN keys to get

desired value. After setting

desired value press SET key

& display will show “- - - -”

which confirms that value has

been stored in memory. This

parameter decides the

position of Proportional band.

To change

the “ ”

parameter

press the

SET key.

7

Example : If this parameter is set

to 3 minutes, the Relay will cut off

at the set temperature, but will not

restart for 3 minutes even if the

differential is achieved earlier.

This parameter is good to protect

the life of the compressor or even

in applications where the probe is

placed at places where there are

sudden & short changes in

temperature.

Example : Setting this parameter

O

at 60.0 C will not allow the set

O

point to go above 60.0 C. Also, if

O

the temperature reaches 60.0 C

or above, the display will show Ht

(High Temp) indicating that the

temperature has gone above the

range in this parameter.

5 6

78

Function: To set Hysterisis

(differential) Activated in On-

Off mode only.

Hysterisis O

0.1 C O

99.9 C O

2.0 C

5.1

Use UP/DOWN keys to get

desired value. After setting

desired value press SET key

& display will show “- - - -”

which confirms that value has

been stored in memory.

This parameter value is the

differential between cut out

and cut-in temperature.

To change

the“ ”

parameter,

press the

SET key.

O

Example : If “ ” is 0.0 C

O

,Set point is 60 C, Prbd =

O

10.0 C ,then proportional

O O

ba n d i s 5 0 C t o 60 C

(Proportional action will take

O O

place between 50 C to 60 C).

But for the same settings of

Set point and Prbd, if “ ” is

O

set to 5.0 C, then proportional

O O

band will be 55 C to 65 C.

Contd.

Contd.