10

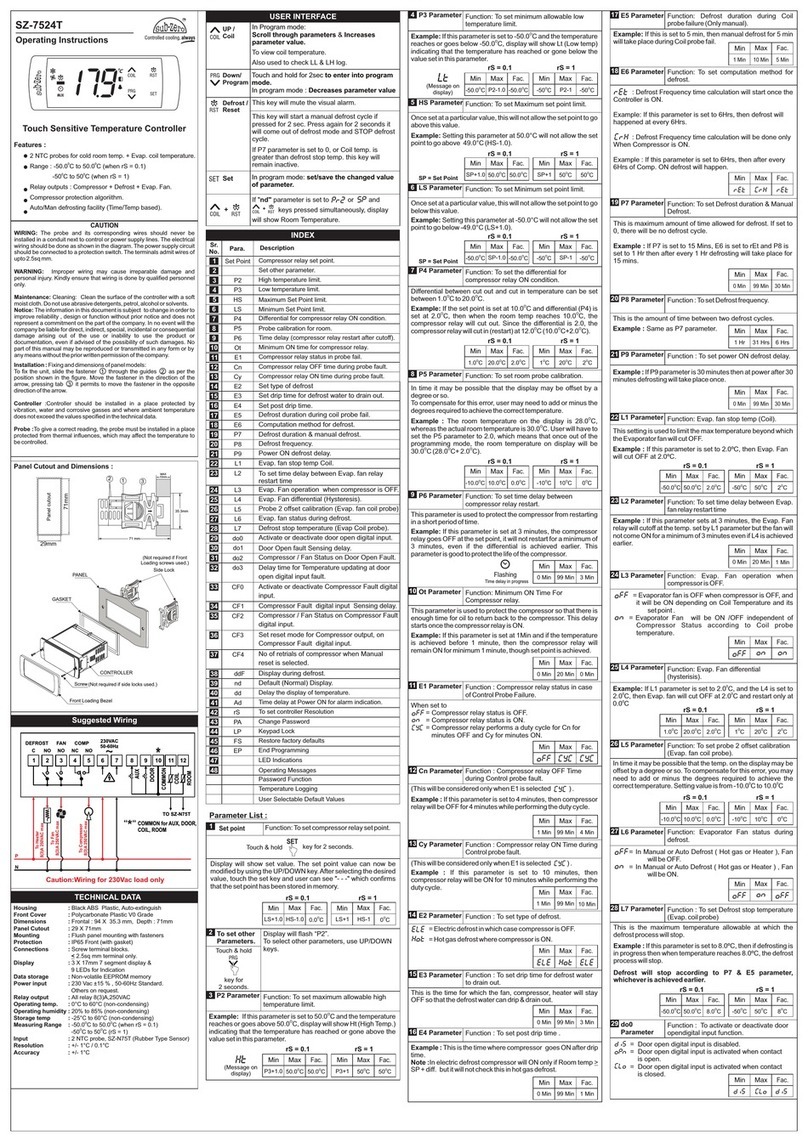

R1 & time delay of setpoint 1

will flash. Use UP/DOWN keys to set

desired value. Once desired value is

achieved, press set key and you will

see “- - -” which confirms time delay for

set point 1 has been stored in memory.

After pressing UP key R2 flashes

alongwith the time delay for setpoint 2.

Use UP/DOWN keys to set desired,

value.Once desired value is

achieved, press set key and you will

see “- - -” which confirms time delay for

set point 2 has been stored in memory.

To prevent both compressors from

switching on together, there is an

internal 10 second time delay

between simultaneous startups

to prevent an electrical surge.

Function : Set time delay between relay

restart time for comp1 and comp2.

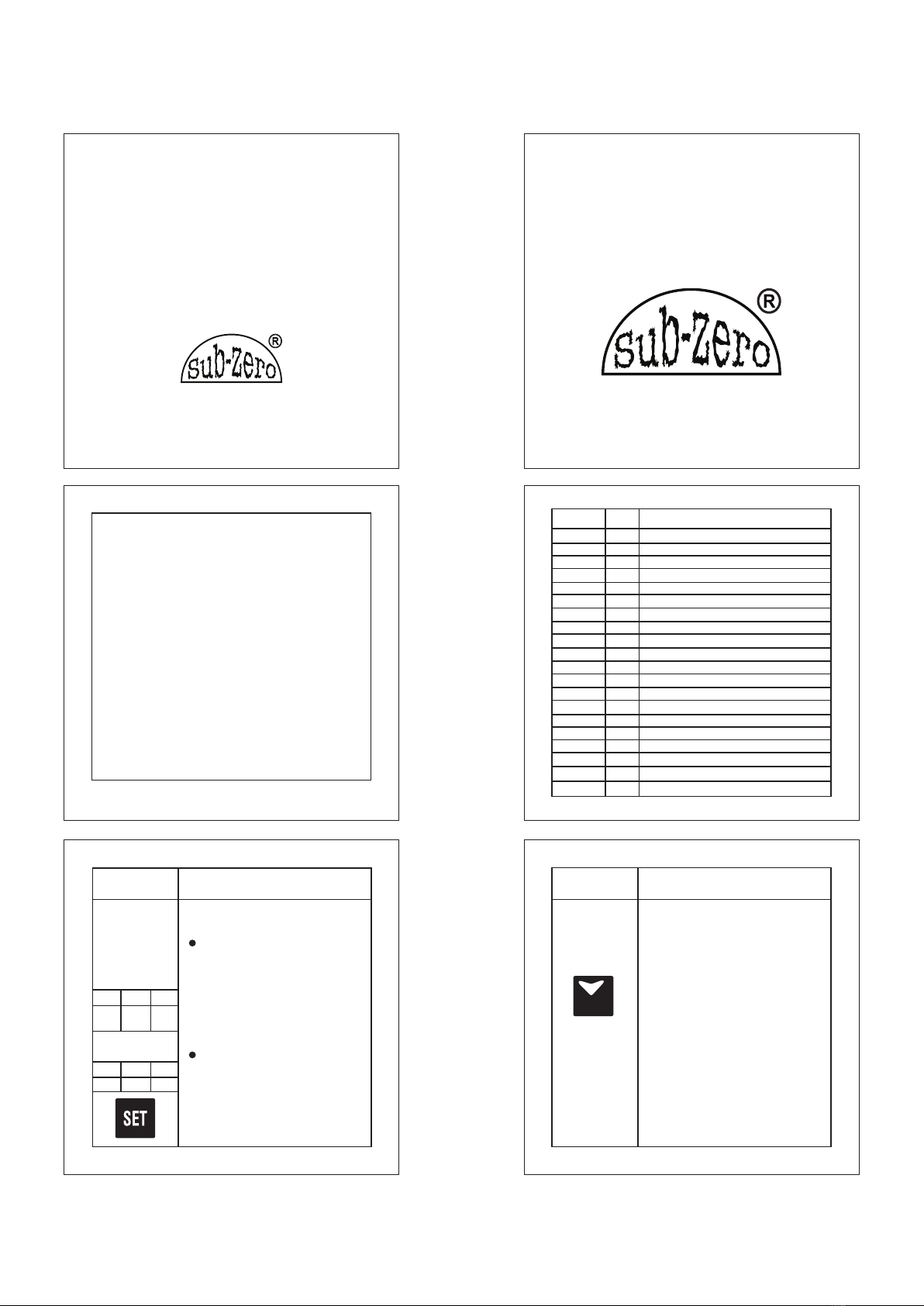

To change

P6 parameter,

press the

SET key.

Time delay R1

Time delay R2

P6

Parameter

Fac.

3 Min

Max

20 Min

Min

0 Min

Fac.

3 Min

Max

20 Min

Min

0 Min

R1

R2

8

P4

Parameter

Once in this mode, R1 and

differential of setpoint 1 will flash.

use UP/DOWN keys to set desired

value. Once desired value is achieved,

press set key and you will see “- - -” this

confirms differential for set point 1 has

been stored.

After up key is pressed

R2 flashes alongwith the differential

for set point 2. Use UP/DOWN keys to

set desired value. Once value is

achieved, press set key. This confirms

differential for setpoint 2.

0

Example : If setpoint 1 is set at 10.0 C.

and differential for setpoint 1 is set

0

at 2.0 C, then when the system

0

reaches 10.0 C, the relay for

compressor 1 will cutout and since

O

the differential is 2.0 C the relay will

O

cutin(restart) at 12.0 C (10.0+2.0).

Function: To set the differential of

set point 1 and set point 2

To change

P4 parameter,

press the

SET key.

Differential 1 & 2

Differential 1 & 2

Max Fac.

0

20.0 C

0

0.5 C

Min

0

2.0 C

Max Fac.

0

20 C

0

1 C

Min

0

2 C

rS = 0

rS = 1

rS = Resolution

Set Parameter

9

Use UP/DOWN keys to set

desired value. In time it may be

possible that the display may be

offset by a degree or so.

To compensate for this error. you

may need to add or minus the degree

required to achieve the correct

temperature. Setting value is from

O O

-10.0 C to + 10.0 C.

Example : The temperature on the

O

display is 28.0 C, whereas the actual

O

temperature is 30.0 C. You will need

to set the P5 mode to 2.0, which

mean that once out of the

programming mode, the display

O

will show temperature 30.0 C

O O

(28.0 C + 2.0 C).

To change

P5 parameter

press the

SET key.

Function : To set probe calibration.P5

Parameter

Max Fac.

0

10.0 C

0

-9.0 C

Min

0

0.0 C

rS = 0

Max Fac.

0

10 C

0

-9 C

Min

0

0 C

rS = 1

rS = Resolution

Set Parameter

6

Function : To set maximum

allowable high temperature limit.

To change

P2 parameter,

Press the

SET key.

Use UP/DOWN key to set

desired value. Once set at a

particular value, this will not

allow both set points to go above

this value.

Example : Setting this parameter

0

at 30.0 C will not allow both set

0

points to go above 30.0 C. Also if

0

the temperature reaches 30.0 C, the

display will show Ht (High

Temperature), indicating that the

temperature has reached or gone

above the value in this

parameter.

XX = Highest Set Point

(Message on Display)

P2

Parameter

Max

Max

Fac.

Fac.

0

50.0 C

0

50 C

Min

Min

0

XX+1 C

0

50.0 C

0

50 C

rS = 0

rS = 1

rS = Resolution

Set Parameter

XX

0

+1.0 C

7

To change

P3 parameter,

press the

SET key.

Use UP/DOWN key to set

desired value. Once set at a

particular value, this will not

allow both set points to go below

this value.

Example : Setting this parameter

0

at 10.0 C will not allow both set

0

points to go below 10.0 C. Also if

0

the temperature reaches 10.0 C, the

display will show Lt (Low

Temperature), indicating that the

temperature has reached or gone

below the value in this

parameter.

Function : To set minimum

allowable low temperature limit.

(Message on Display)

P3

Parameter

XX = Lowest Set Point

0

0.0 C

0

0.0 C

Max Fac.Min

rS = 0

0

XX-1 C

Max Fac.

0

0 C

0

0 C

Min

rS = 1

rS = Resolution

Set Parameter

XX

0

-1.0 C

5

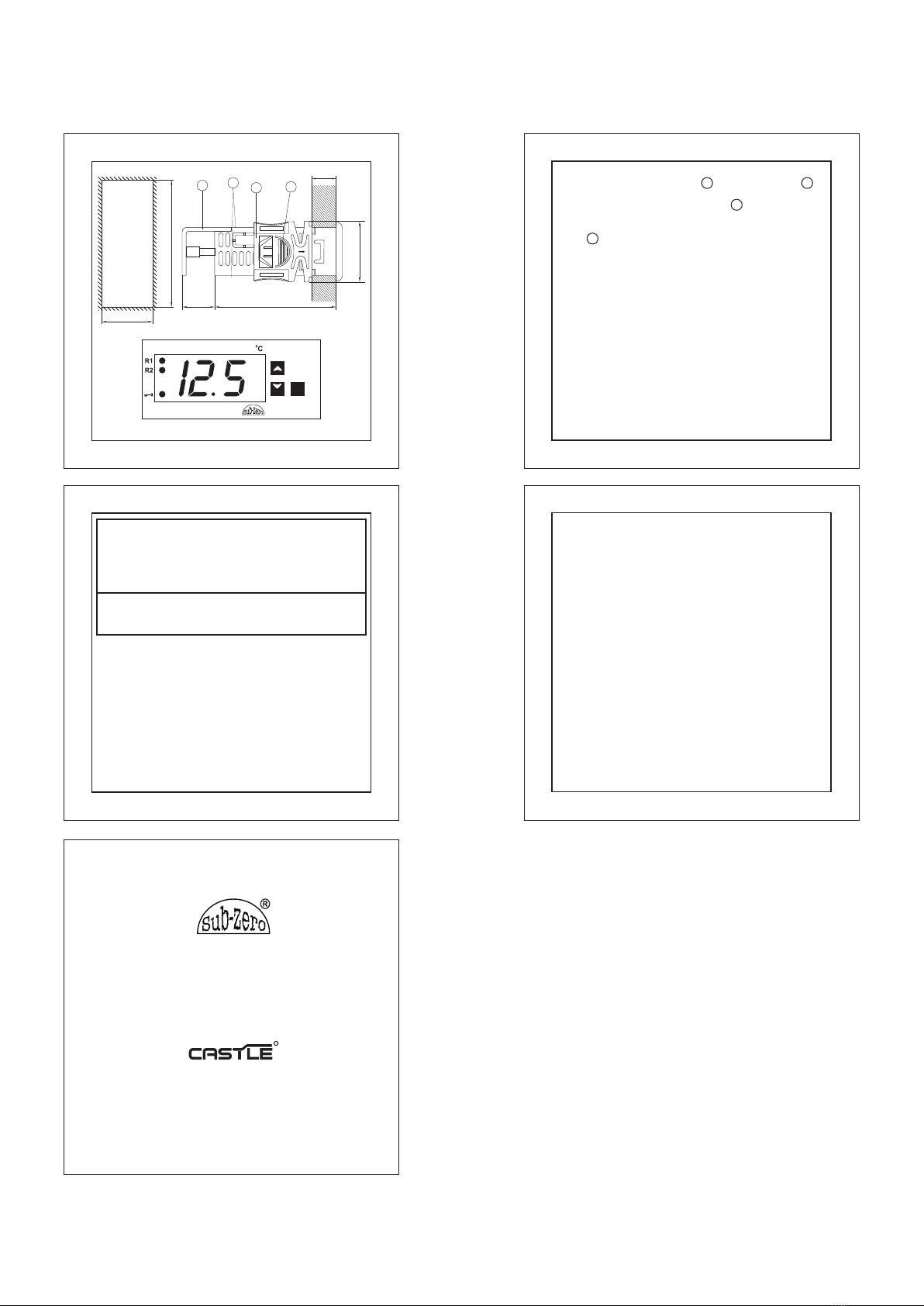

P1 Parameter

Function: To set controller for heating

or cooling.

0 1 0

To change

the P1

parameter,

press the

SET key.

Use UP/DOWN keys to get

desired value & press set

to confirm.

0: Cooling mode and

1: Heating mode.

Min Max

Fac.

NOTE : T2 parameter is activated

only when P1=0 (cooling).