Page 3 of 27

•Read Operation Manual before operating.

•At least every 20 minutes, check patient’s temperature and skin condition of areas in contact with

blanket; also, check blanket water temperature. Pediatric, temperature-sensitive patients with

vascular disease, and operating room patients should be checked more frequently. Notify physician

promptly of any change, or if the patient’s temperature is not responding properly, or does not

reach the prescribed temperature in the prescribed time, or there is a change in the prescribed

temperature range. Failure to inform physician of the deviation may result in injury to the

patient.

•Observe patient’s skin condition frequently due to individual differences in sensitivity and

susceptibility to injury from cold and/or externally applied chemicals or pressure. Patients

at greatest risk are those unconscious, on prolonged therapy, diabetics, children, and

persons incapacitated or with insensitive skin areas or poor circulation.

•Prevent excessive and/or prolonged tissue pressure and shearing forces, especially over bony

prominences to prevent skin damage that mayresult.

•Do not place additional cold sources between the patient and blanket. Skin damage may result.

•The area between the patient and the blanket should be kept dryto avoid injury to patient.

•Do not wrap pad so tightly as to constrict blood flow. Do not use pins to secure pad or

hoses. Do not allow pad or hoses to come in contact with any sharp object.

•Do not use the Electri-Cool

®

II system in the presence of flammable anesthetics. Risk of explosion

can result.

•The Electri-Cool

®

II system has been designed and tested according to UL-60601-1 and has passed

testing regarding the reception and emission of electromagnetic interference. However, operation of

the Electri-Cool

®

II system near sources of electromagnetic interference or near sources that may

receive electromagnetic interference may cause abnormal operation of this unit or other devices. If

interference of this type is observed, re-locate the unit away from such devices.

•Power interruption will cause the Electri-Cool

®

II to revert to the default range of 40°F-45°F (5°C-7 °C).

Follow instructions for First Time Set-Up/System Test Routine to resume operation. Failure to

resume the desired therapy could result in injury.

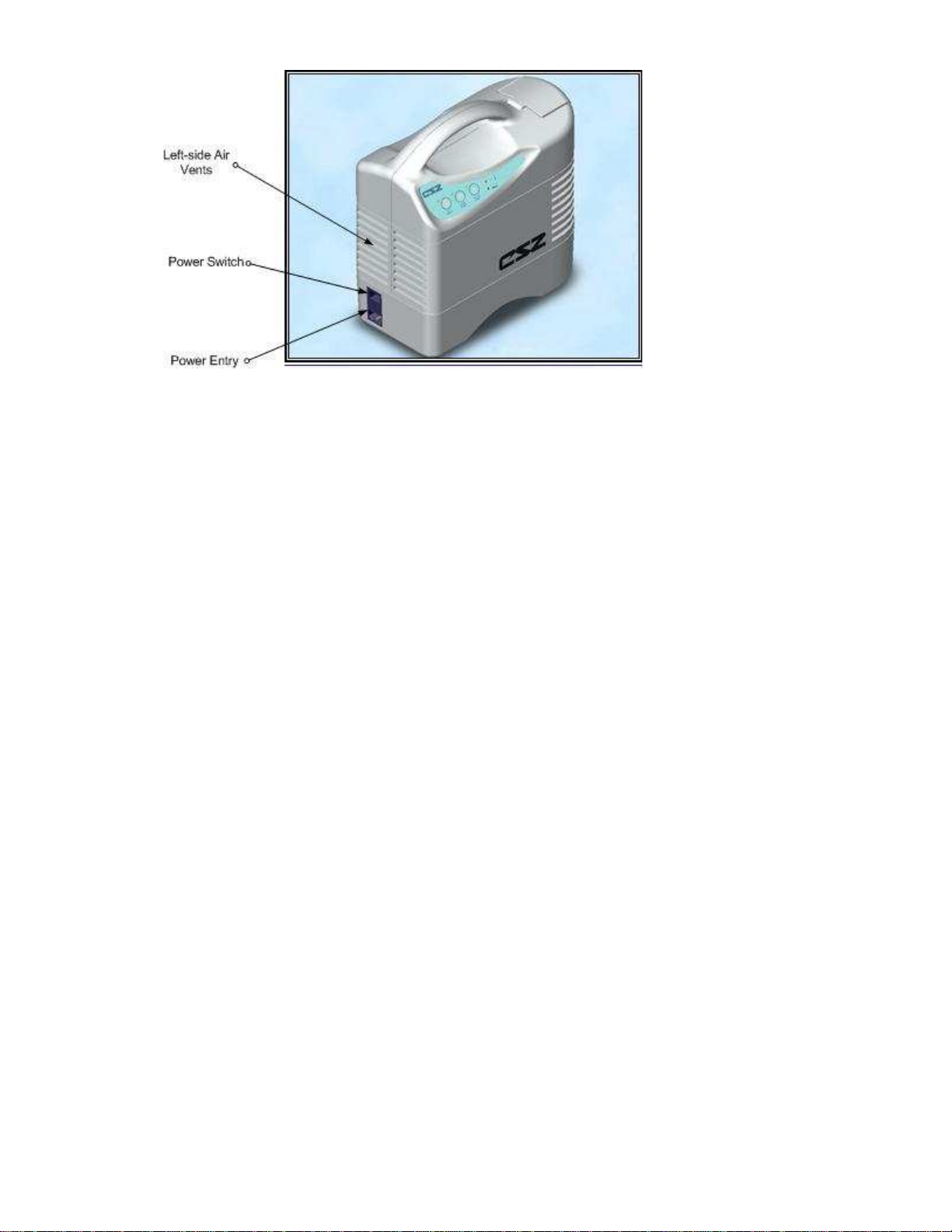

•This device is still energized when the inlet switch is in the off position. To completely

disconnect the device from the power source, remove the appliance plug from the back of the

unit.

•Electric shock hazard. Do not remove cover. Service to be performed by qualified

personnel only.

•For continued protection against risk of fire, replace only with same type and rating of fuse.

WARNING