1-5 #7013423 - Revision A - April, 2009

General Information

W

Wine S

ine Storage (WS) Series

torage (WS) Series

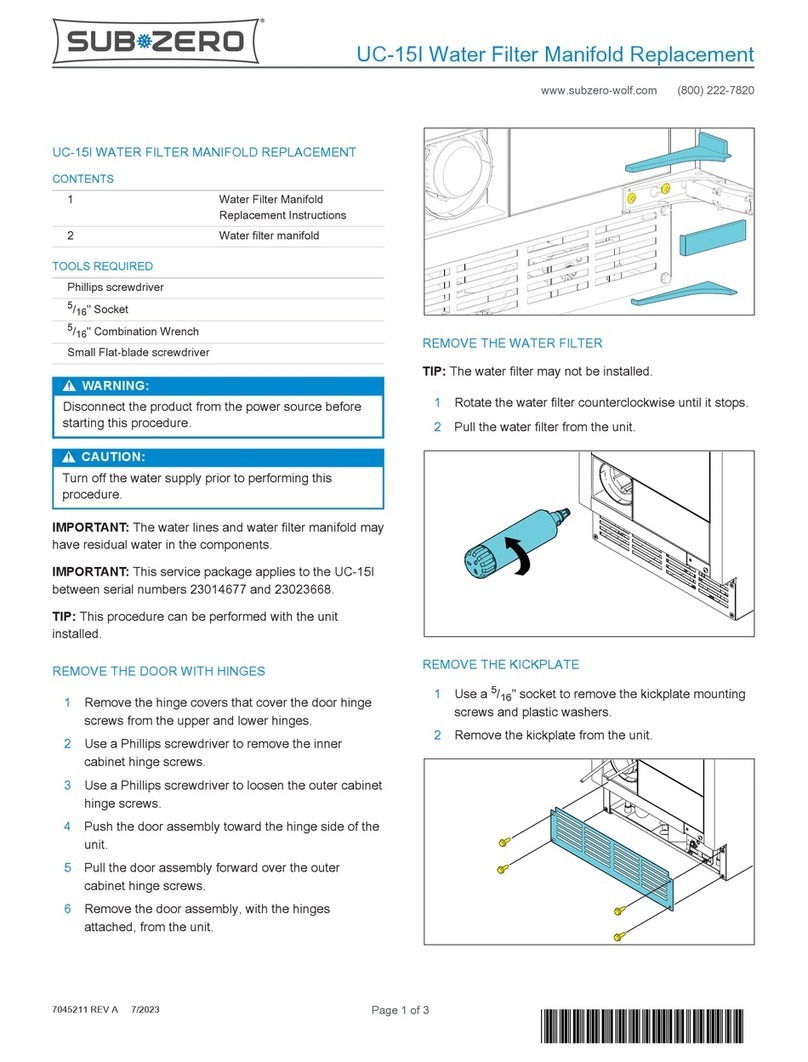

Serial Tag Location Control Panel

Figure 1-1. Serial Tag Location

WARRANTY INFORMATION

This page summarizes the 2, 5 & 12 Year Warranty pro-

vided with every Sub-Zero appliance, as well as the two

special warranties:

•Non-Residential Warranty - Applies to units

installed in non-residential applications.

•Display/Model Home Warranty - Applies to distrib-

utor and dealer display units, and units in model

homes, sold three years after date of manufacture.

Following the warranty summaries are details and notes

about the warranties.

TWO, FIVE & TWELVE YEAR Warranty

• 2 year TOTAL PRODUCT, *parts and labor.

NOTE: Stainless Steel doors, panels, grilles & prod-

uct frames are covered by a 60 day parts & labor

warranty for cosmetic defects.

• 5 Year SEALED SYSTEM, **parts and labor.

• 6th - 12th year LIMITED SEALED SYSTEM, **parts

only.

ONE & FIVE YEAR Non-Residential Warranty

(Example: Office, Yacht, etc.)

• 1 Year TOTAL PRODUCT, *parts and labor.

NOTE: Stainless Steel doors, panels, grilles & prod-

uct frames are covered by a 60 day parts & labor

warranty for cosmetic defects.

• 5 Year SEALED SYSTEM, **parts and labor.

ONE & FIVE YEAR Display/Model Home Warranty

(Display units sold three years after date of manu-

facture)

• 1 Year TOTAL PRODUCT, *parts and labor.

NOTE: Stainless Steel doors, panels, grilles & prod-

uct frames are covered by a 60 day parts & labor

warranty for cosmetic defects.

• 5 Year SEALED SYSTEM, **parts and labor.

Figure 1-2. Serial Tag Layout (Layout Reference Only)

Warranty Details:

* Includes, but is not limited to the following:

Electronic Control System Components, Fan & Light

Switches, Fan Motors & Blades, Drain Pan, Drain

Tubes, Wiring, Light sockets & bulbs, Door Hinge

Assemblies, Door closers, Compressor Electricals,

etc. . .

NOTE: Stainless Steel doors, panels, grilles & prod-

uct frames are covered by a 60 day parts & labor

warranty for cosmetic defects.

** Includes the following:

Compressors, Condenser, Evaporators, Filter-Driers,

Heat-exchangers, All Tubing that Carries the Freon.

NOTE: Condenser Fan Motors, Freon, Solder and

compressor electricals are NOT considered sealed

system parts.

Warranty Notes:

• All warranties begin at unit's initial installation date.

• All Warranty and Service information collected by

Sub-Zero is arranged and stored under the unit serial

number, and the customer's last name.

Sub-Zero requests that you have the model and serial

numbers available whenever contacting the factory or

parts distributor.

• The serial number tag for models WS-30 is located on

the bottom side of the compartment divider, directly

behind the control panel. (See Figures 1-1 and 1-2)