2-2

7040127 - Revision C - May, 2015

Installation Information Built-In (BI) Series

Built-In (BI) Series (SWS #4250000)

(SWS #4250000)

INSTALLATION CONSIDERATIONS

This section uses some of the information in the BI Series Installation Guide to address common installation issues

seen by Service Technicians. Improper installation, though not a valid service issue, has the potential to lead to a

call for service. Installation related complaints could include, but are not limited to: Unit leveling, unit movement,

door misalignment, improper door and drawer sealing, internal frost or condensation, exterior condensation, warm

compartment temperatures, etc.

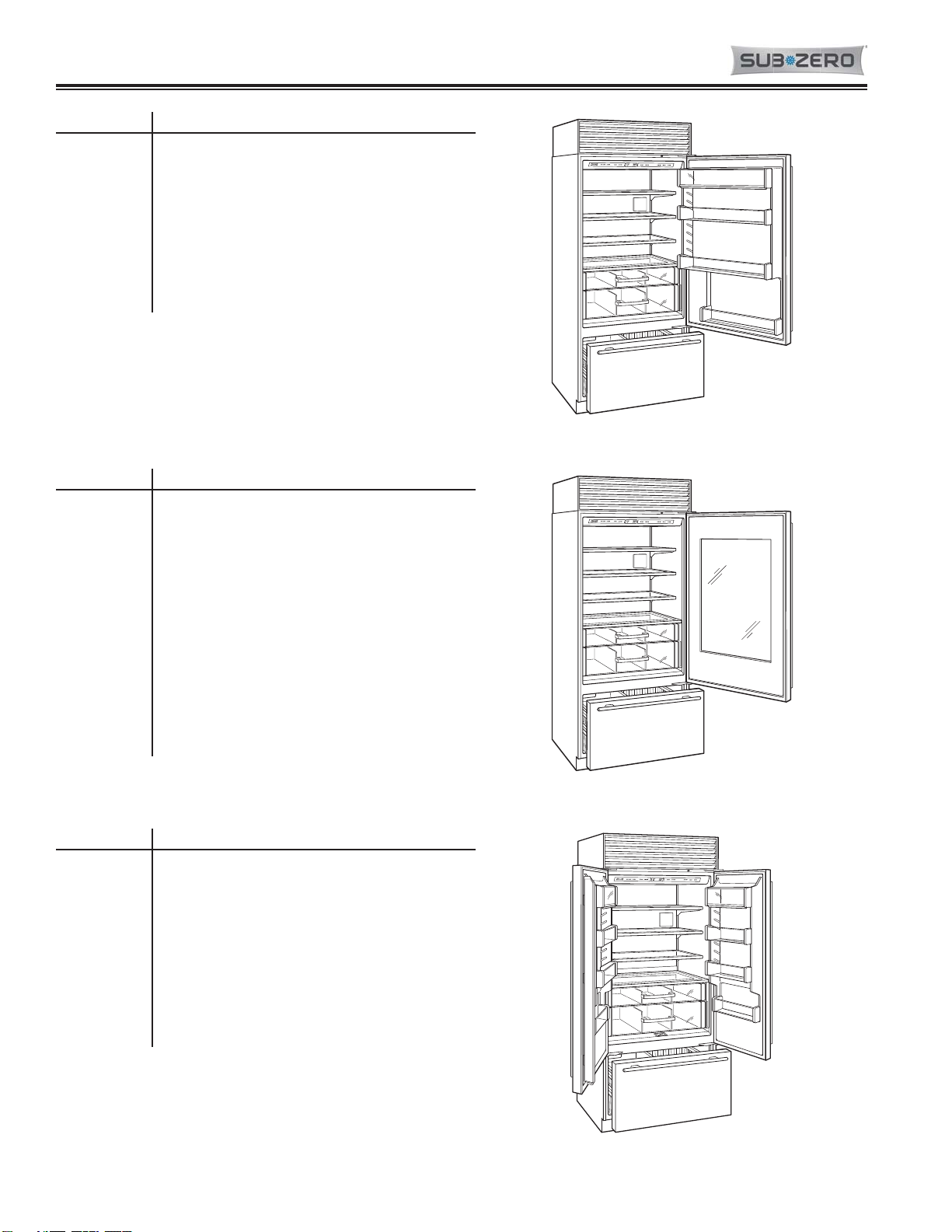

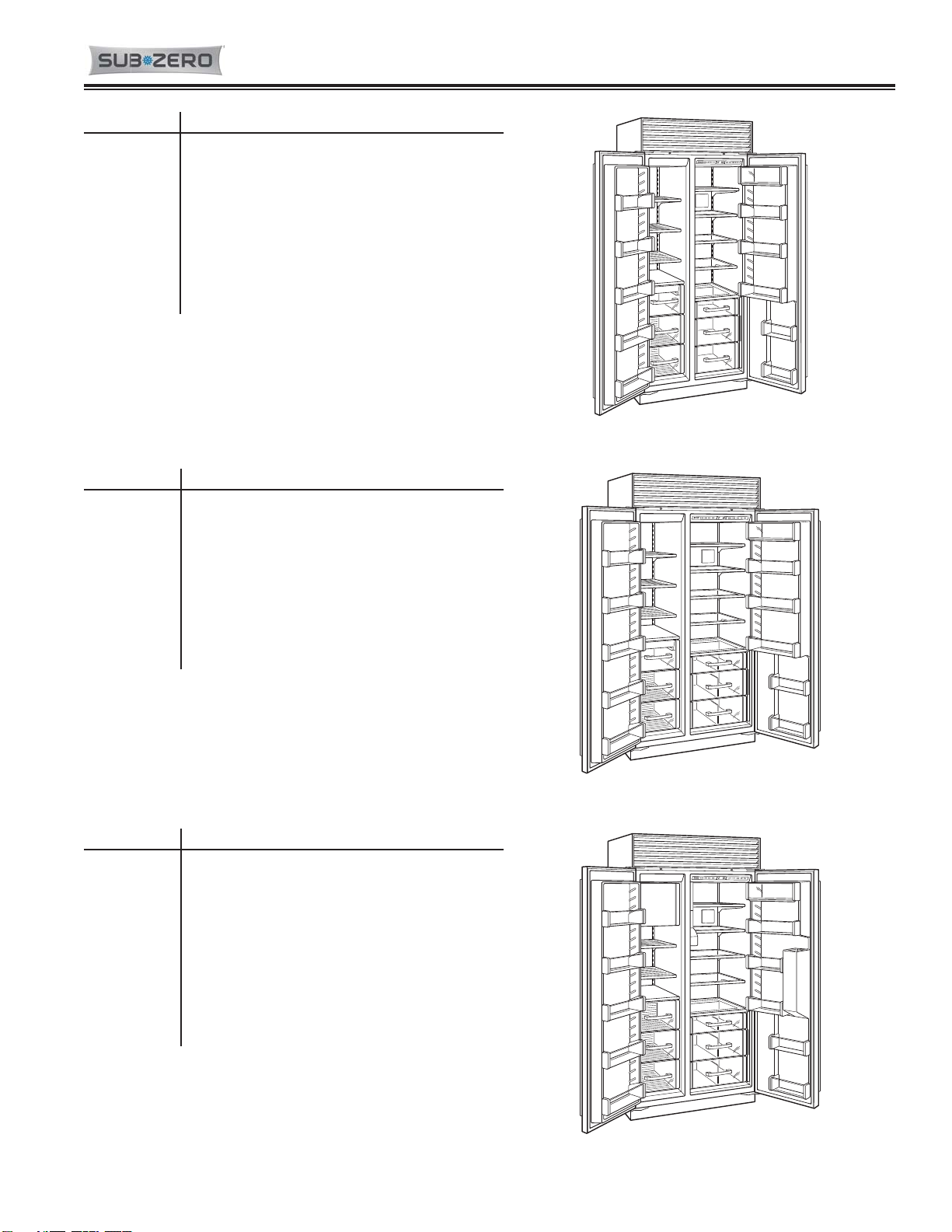

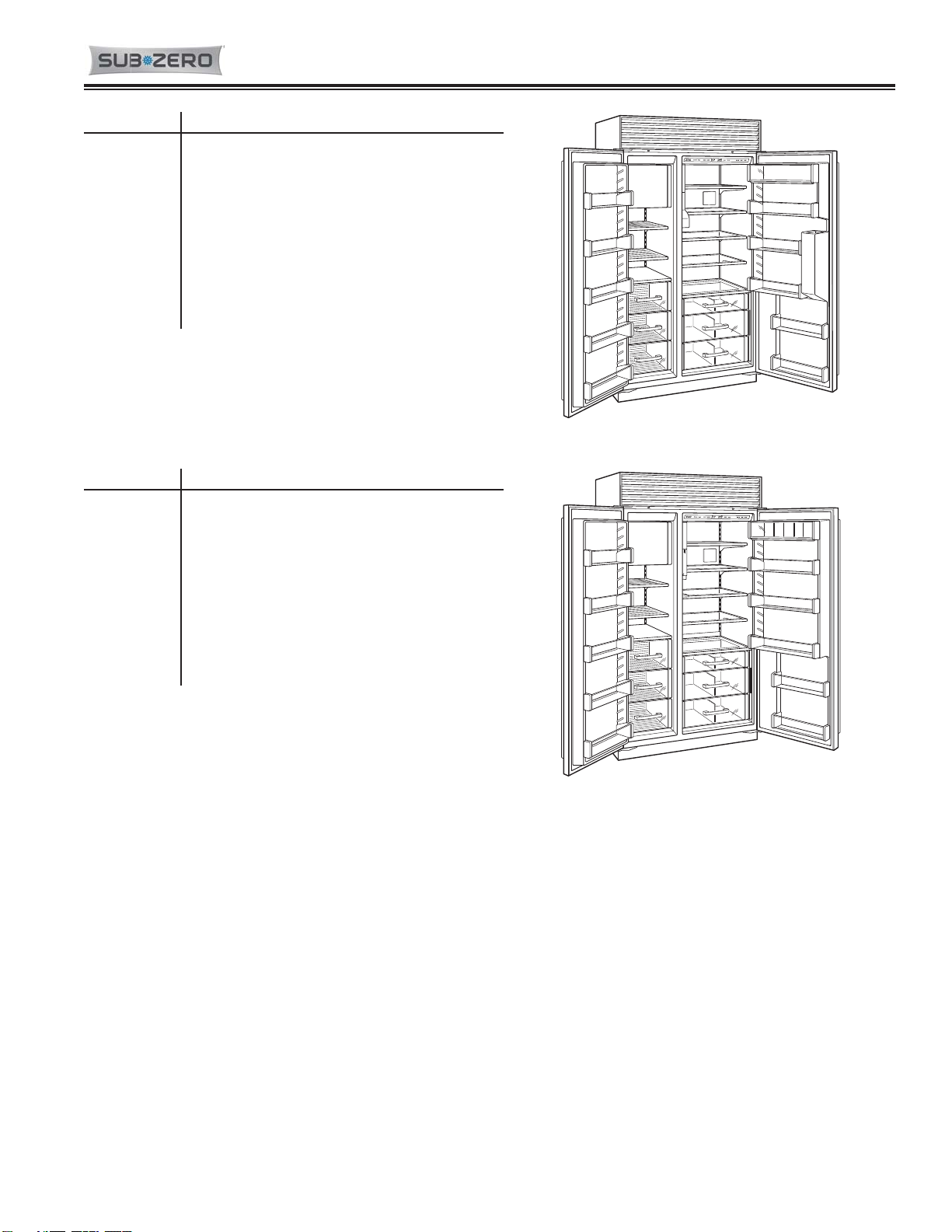

The Built-In line offers the following design alternatives - framed, overlay and stainless steel models. The overlay

design has two possible installation applications - standard overlay and flush inset. Each of these design options

has specific installation requirements, which means it is vital that the unit match the planning and space needs.

NOTE: If additional installation information is needed, refer to the complete Installation Guide, or contact Sub-Zero

Service Department.

Tools and Materials Required

The following is a list of tools and materials that will assist in a proper installation.

• Phillips screwdriver set

• Slotted screwdriver set

• 6-Lobe, Torx type drive screwdriver set (Specific sizes, T-10, T-20 and T-25)

• 4' (1.2 m) of 1/4" copper tubing and saddle

• valve for the water line—part #4200880

• (do not use self-piercing valves)

• Copper tubing cutter

• Level - 2' (.6 m) and 4' (1.2 m) recommended

• Appliance Dolly able to support 700 lbs (317 kg) and adequate manpower to handle the weight of the unit

• Various sized pliers

• Wrench set

• Allen wrench set

• 5/16" hex bolt nut driver

• Crescent wrenches

• Cordless drill and assorted drill bits

• Masonite, plywood, 1/8" pressed fiberboard, cardboard or other suitable material to protect finished flooring

• Appropriate materials to cover and protect the home and its furnishings during installation

Site Preparation

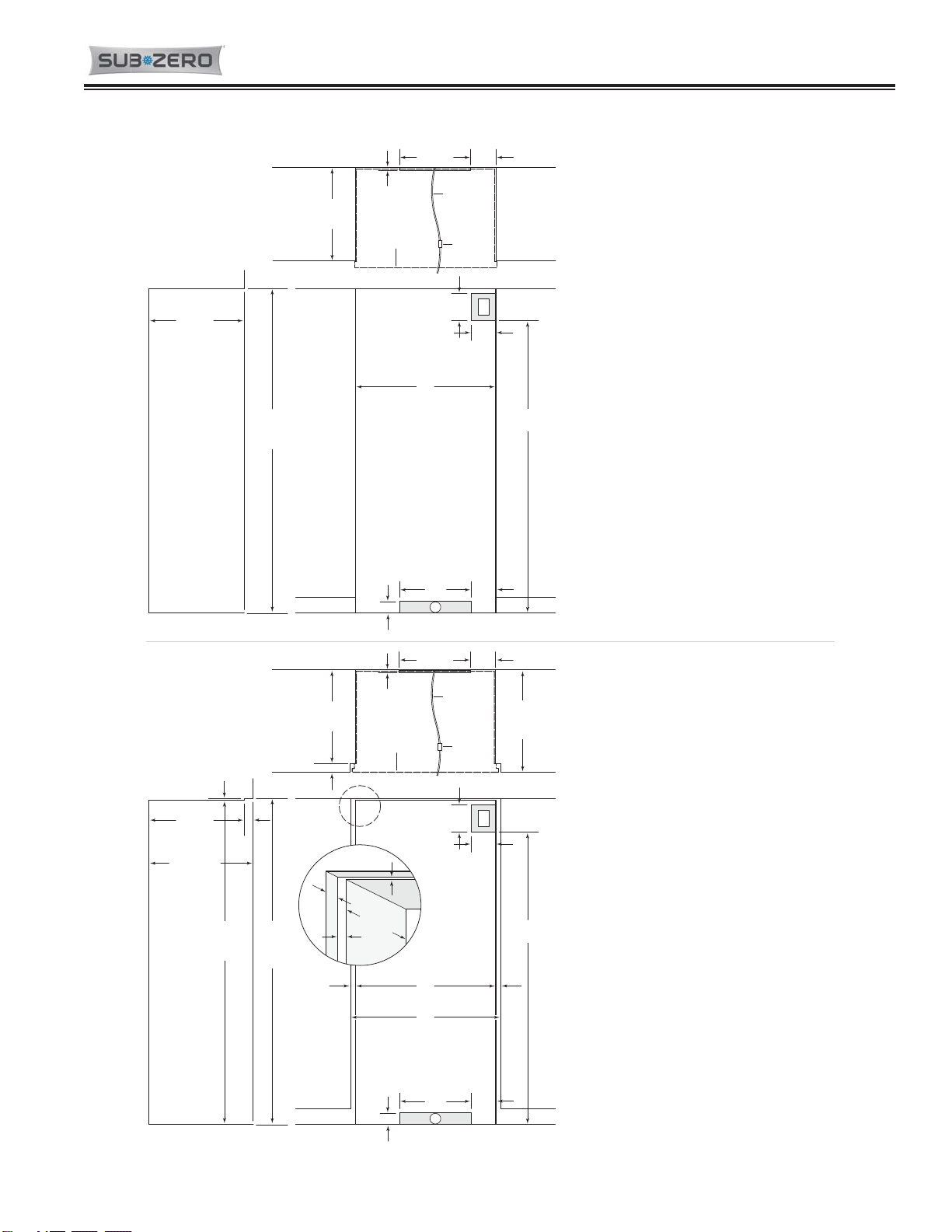

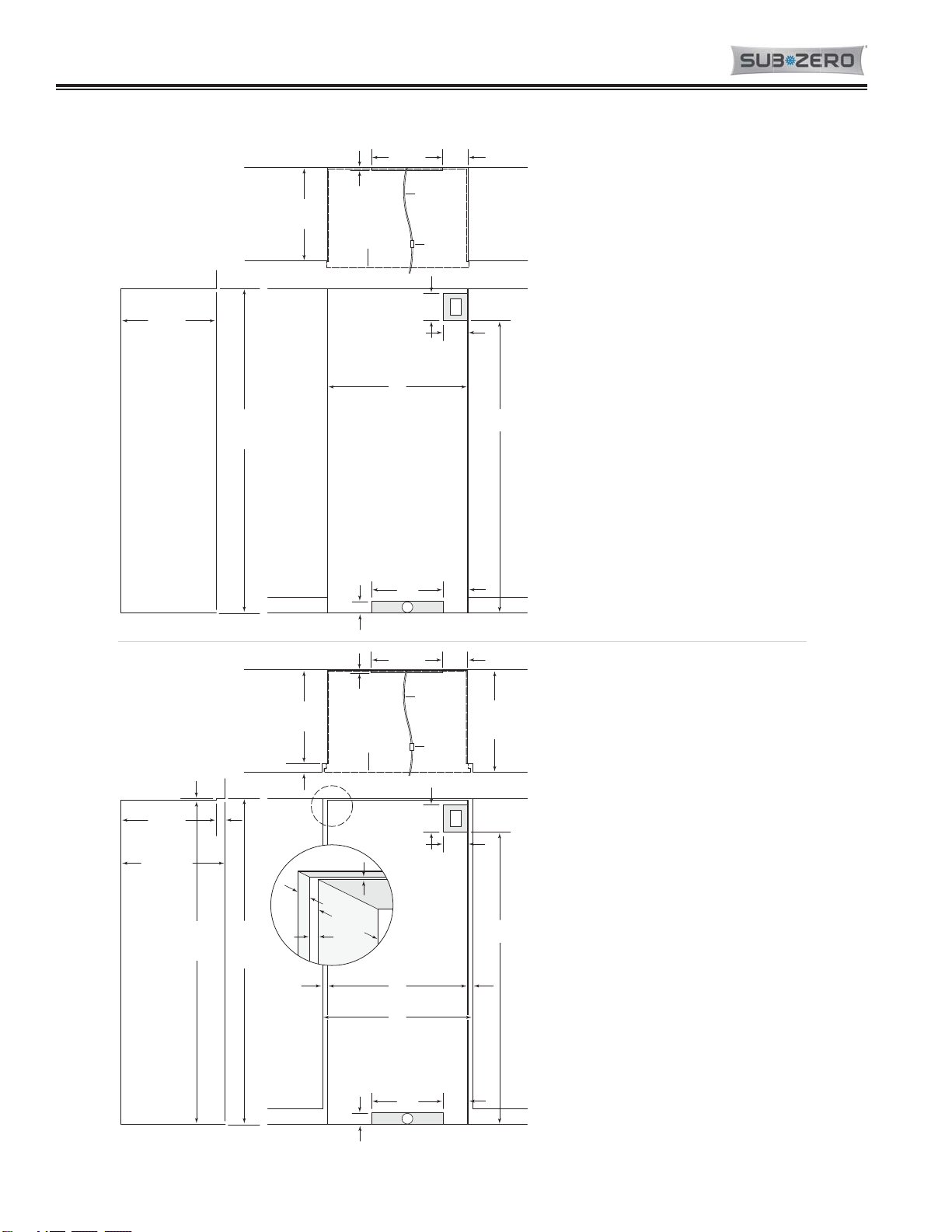

The finished rough opening where the Built-In unit is to be installed must be properly prepared. Refer to the Finished

Rough Opening Specifications for the specific model on the following pages. The specifications for the framed, over-

lay and stainless steel applications are identical. The Finished Rough Opening Specifications are different for the

flush inset application, whether using custom panels or Sub-Zero accessory stainless flush inset panels. Make sure

that the rough opening dimensions, door swing clearance, electrical service and plumbing are correct for the model

being installed.

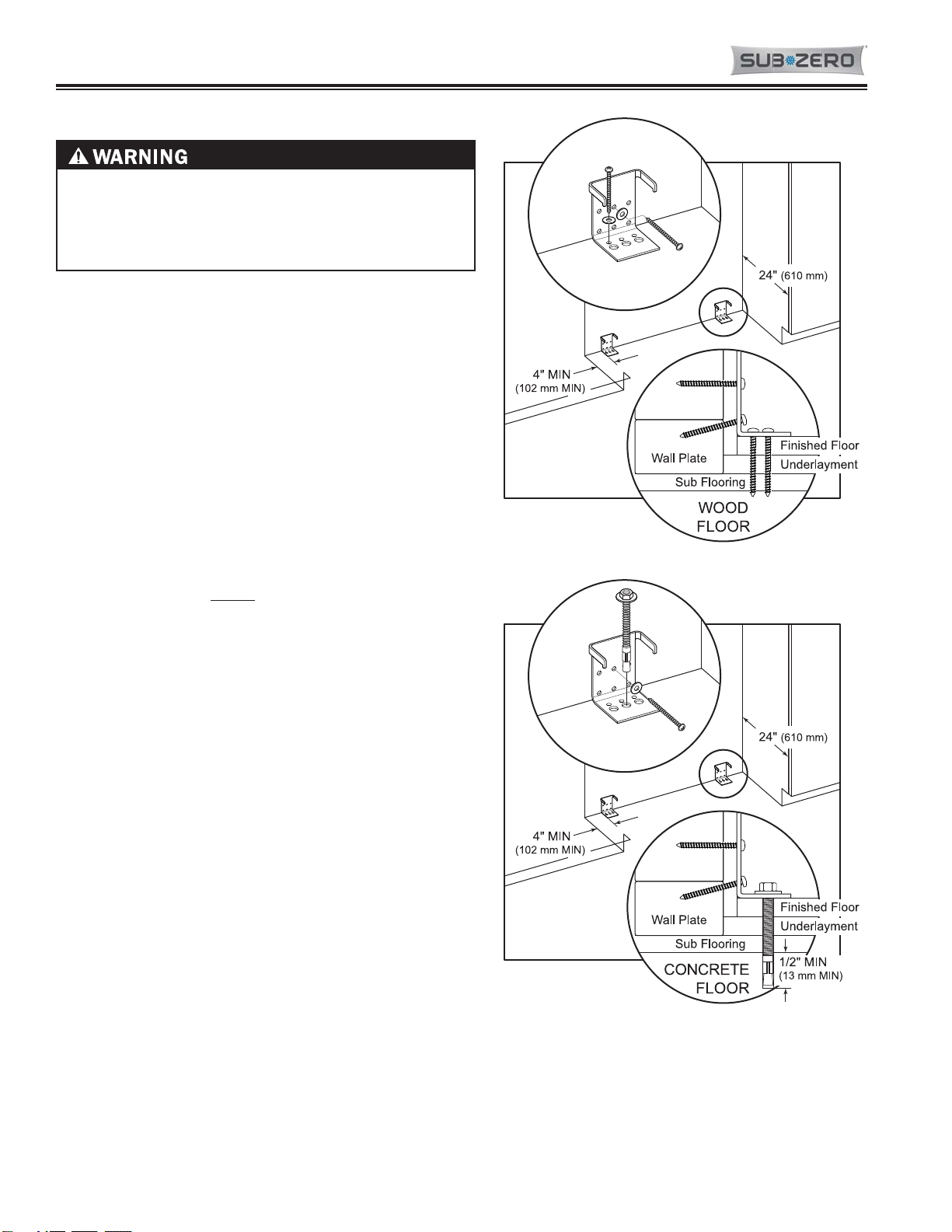

If installing two Built-In units side by side in the framed, overlay or stainless steel application, a separating filler strip

is recommended. Add the filler strip width to the finished rough opening dimension, and ALWAYS complete the

installation with the Anchoring Kit components.

For installation of two Built-In units side by side in the flush inset application, a dual installation kit will be necessary.

IMPORTANT NOTE: Built-in units installed side by side in the flush inset application cannot use the standard Sub-

Zero accessory overlay panels, and must have opposing hinges.

IMPORTANT NOTE: To operate properly, the door must open a minimum of ninety (90) degrees. Use a minimum 3"

(76) filler in corner installations to assure a ninety (90) degree door opening. Allow enough clearance in front of the

unit for full door swing.

IMPORTANT NOTE: Make sure the floor under the unit is level with the surrounding finished floor.