NAME : TRAINING DEPARTMENT

RÉFÉRENCE : TECHNICIAN OPERATING MANUAL DX ISOBUS

The agitators improve the flow of the product through the shutters.

An incorrect adjustment of the agitators may cause a difference between the right-hand and the left-hand

application rate. This means that when working, the spreader is emptied faster on one side than on the other.

If this is the case, the following settings must be checked.

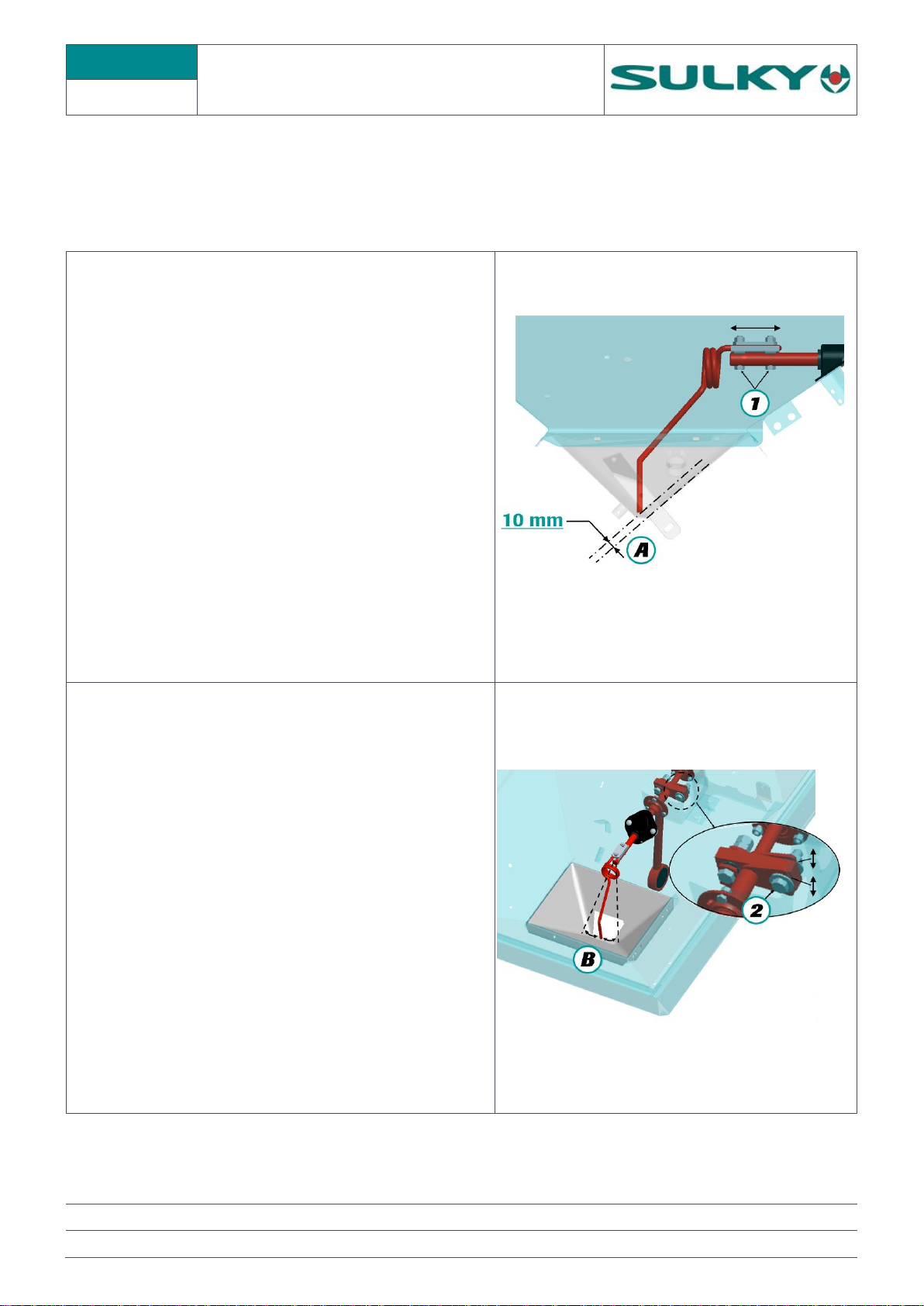

A) The space between the tip of the agitator (A) and the

shutter must be 10 mm.

This distance may not be exactly 10 mm; the most

important thing is that the two agitators have the same

dimension, for example: 12mm

To adjust the distance of an agitator tip, simply loosen

the screws ①, and move the tip on its support.

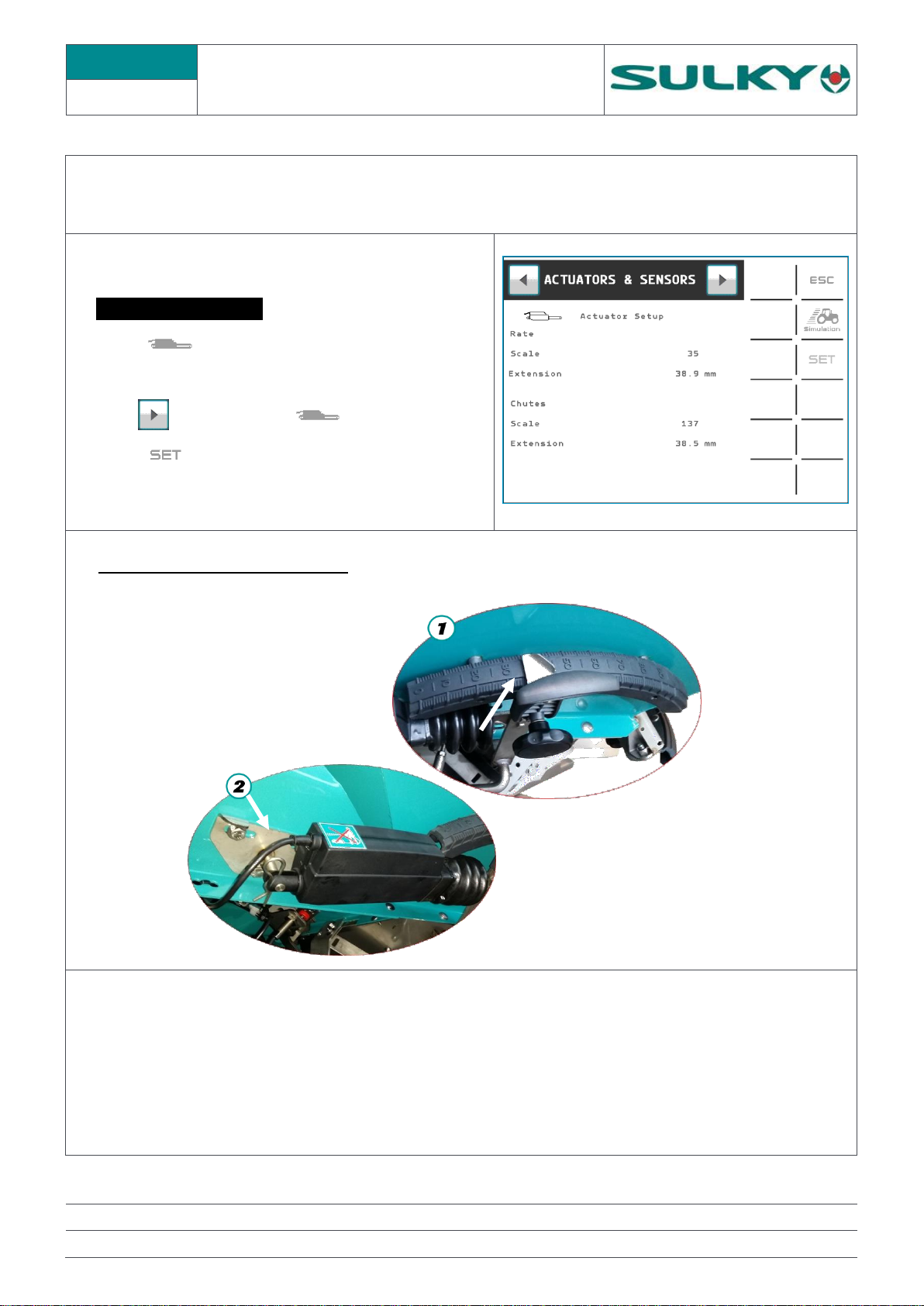

B) The agitator tip sweep must be symmetrical in relation

to the application rate openings.

The most important thing is that the two sides be set

identically.

To adjust the sweep, you must act on screw ②under

the hopper.

The two half shafts are fitted with a slot to allow their

adjustment.