Croplands Cropliner 1500XL User manual

1

WWW.CROPLANDS.COM.AU

HT-OMCROPLINE-E

1500XL | 2000XL | 3000XL | 4000XL | 5000XV

CROPLINER

OPERATORS MANUAL

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

HT-OMCROPLINE-E

2

INTRODUCTION | GENERAL MANAGER’S WELCOME

Dear Customer

Congratulations on the purchase of your new Croplands Sprayer.

Croplands have been in the business of building sprayer

equipment since 1972. For over 50 years we have been

supplying sprayers to farmers, contractors, growers and all

our customers involved in growing crops and in the control of

pests and diseases.

Croplands is a wholly owned subsidiary of Nufarm Ltd, the

largest supplier of crop protection chemicals for Australasia,

and one of the fastest growing global suppliers world-wide.

At Croplands, we pride ourselves on our commitment to

supplying machinery that is at the forefront of the industry’s

needs. We believe we can back up our products and through

constant research and development, bring to you the best

equipment you can find.

We welcome any feedback from you about our equipment.

On the back cover you will find our contact details, and locations

where our staff can be reached during business hours. After

hours, you can email us and expect a reply the following morning.

Please read this manual in its entirety before you operate your

sprayer. This will ensure you have a trouble free start up.

We trust you will get years of good use from your Croplands

Sprayer.

Yours Sincerely

Sean Mulvaney

General Manager

Sean Mulvaney

General Manager

Croplands has taken steps to ensure this operator’s manual is as current and as accurate as possible. Due to the ever-changing markets of cropping and farming, Croplands

is constantly striving to be at the forefront of innovation and technology. While the information in this manual is considered accurate at the time of writing, Croplands reserves

the right to change this information without notice. Croplands will not accept liability for any inaccuracy in this publication, or changes forthwith.

3

CONTENTS

SECTION 1

IMPORTANT INFORMATION

About this manual 4

Terminology 4

Before operating your sprayer 4

Warranty Policy 5

SECTION 2

SAFETY

Safety first 6

Safety signs and decals 7

SECTION 3

PRODUCT IDENTIFICATION,

SHIPPING & SPECIFICATION

Product identification 8

Shipping information 8

Weights 8

Dimensions 9

General Specification 12

SECTION 4

PRODUCT FEATURES /FAMILIARISATION

Fieni Fans 17

Fan pitch angle 18

Gearbox 20

Adjustable vanes 21

Nozzles 21

Fan safety 22

Chassis, axle, wheel & tyres 23

Tanks, lids etc 25

5000 XV Model 27

4000 XL Model 28

3000 XL Model 30

2000 XL Model 32

1500 XL Model 33

Pumps 34

Pto Shafts 34

Spray System Overview 35

Controls 38

SECTION 5

PREOPERATION

Safety first 42

Hook up 42

Hook-Up HV4000 Auto Rate Controller 46

Hook-Up Bravo 180S 48

Hook-Up HV2400 48

Hook Up Manual Controller 48

Hook-Up Braglia Electric Controller 49

Functionality checks 50

Set-up spray pressure 53

General notes on auto-rate controllers 54

Configure the fan 56

Pre-Operation Checklist 57

SECTION 6

SPRAY OPERATIONS

Safety first 60

Filters 60

Filling the sprayer 62

Agitation 63

Mixing basket 63

Chemical suction probe 64

Calculate water & chemical quantities 65

Proceed to spray 66

Drain & flushing 66

Tank cleaning 68

Unhitching the sprayer from the tractor 69

SECTION 7

SPRAYING INFORMATION

Spraywise 71

Calibration 71

Flowmeter calibration 72

Step 1 - ensure equipment is in good working order 72

Step 2 - determining the actual speed of travel 74

Step 3 - determine spraying volume required 74

Step 4 - determine sprayer configuration 74

Step 5 - determine the ideal spray pressure 75

Step 6 - determine & select correct nozzles 75

Step 7 - fit & test selected nozzles 78

Step 8 - calculate the actual application rate 78

Step 9 - if the tested rate is unsatisfactory 79

Step 10 - coverage assessment 79

Step 11 - add the correct amount of chemical to the tank 80

Step 12 - record all data for future reference 80

Discs & Cores 83

Calibration work sheets 85

SECTION 8

LUBRICATION & MAINTENANCE 93

SECTION 9

TROUBLESHOOTING 99

SECTION 10

ASSEMBLY DRAWINGS,

PARTS & SCHEMATICS 103

SECTION 11

INDEX 122

HT-OMCROPLINE-E

4

SECTION 1

IMPORTANT INFORMATION

ABOUT THIS MANUAL

This manual provides assembly, setting up, operating and

maintenance instructions for the Croplands Cropliner XL

series of sprayers.

In addition to this manual, the sprayer will be delivered

with the General Safety Manual (GP-SAFE-A) and

where applicable the Controller Manual. For details not

covered by the manuals, please contact Technical Support

on 1300 650 724.

Some features and options explained in this manual may

not be installed on your sprayer.

Please pass on this manual with the sprayer at the time of

resale for usage by the new owner.

This manual, HT-OMCROPLINE-E, was first published in

June 2022.

Check online as there may be more recent revisions of

this manual. www.croplands.com.au

TERMINOLOGY

These terms/symbols used throughout

this manual:

NOTE

This Note sign is in place to convey useful

information and will help you to identify

the best possible way to operate the

machine.

CAUTION

This Caution sign shows the potential for

incident. An incident may include damage

to the machine itself, or possible injury to

the operator.

WARNING

This Warning sign shows the potential for

risk or injury and highlights the need for

steps to be taken to protect ones safety.

DANGER

This Danger sign will be used in areas where

the highest risk is present. Always read the

information on these signs and ensure you

are taking steps to prevent risk or injury.

BEFORE OPERATING YOUR SPRAYER

Before attempting to use your sprayer, make sure you

read all Operator Manuals for this sprayer including but

not limited to:

This Operator’s Manual, and all other supplied

manuals for items such as Pumps and PTO etc.

And properly understand:

• All Safety Issues.

• Assembly & Installation instructions.

• Calibration of the sprayer.

• Sprayer Operation.

• Sprayer Maintenance.

DANGER

!

Probability of death or serious

injury if an accident occurs

WARNING

!

To stress potential dangers and the

importance of personal safety.

CAUTION

!

To highlight potential injury or

machinery damage.

NOTE

To convey useful operating information.

!

5

SECTION 1

IMPORTANT INFORMATION

WARRANTY POLICY

Each sprayer will be delivered with a

Specifications, Safety, Warranty & Delivery

Booklet which includes:

• the sprayer’s specification sheet including

the sprayers unique serial number,

•a safety induction checklist,

•a delivery checklist and customer

induction,

•the Croplands Warranty policy and

warranty registration form.

Always contact your Croplands Dealer

first and foremost for warranty matters.

NOTE

For full conditions of warranty and warranty

policy, please see the Specification,

Safety, Warranty & Delivery booklet

provided with this sprayer.

1GP-WARH-B

WWW.CROPLANDS.COM.AU

GP-WARH-B

HORTICULTURE

SPRAYER SPECIFICATIONS

SAFETY, WARRANTY & DELIVERY

INCLUDES SAFETY INDUCTION

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

HT-OMCROPLINE-E

6

SECTION 2

SAFETY

SAFETY FIRST

Please read and understand all supplied manuals,

guides and safety decals before operating this

sprayer. This includes the Croplands Operators

Safety Manual – as pictured here.

This manual is available on the Croplands Web site,

or for printed versions contact Croplands customer

support and ask for part number GP-SAFE-A (or later

version if available). WWW.CROPLANDS.COM.AU

SAFETY

MANUAL

OPERATORS

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

GP-SAFE-A | Update 2

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

7

SECTION 2

SAFETY

SAFETY SIGNS AND DECALS

All signs and decals for sprayer safety and operation must be maintained in good order and replaced if damaged or missing.

Most Croplands labels have a part number printed on the decal to aid identification and replacement.

Some examples are shown below.

Part No: XD -125V

Part No: XD -123

Part No: XD -126V

Part No: XD -176

Part No: XD -122V

Part No: XD -195

Part No: XD -175

Part No: XD -127V

Part No: XD -127V

Part No: XD-164

Part No: XD - 157

Part No: XD-115

Part No: XD -127V

HT-OMCROPLINE-E

8

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

PRODUCT IDENTIFICATION

Always use the serial number of the Sprayer when

requesting service information or when ordering parts.

Early or later models (identification made by serial number)

may use different parts, or it may be necessary to use a

different procedure for specific service operations.

The serial numbers of all controllers, pumps etc should also

be recorded for future reference.

SHIPPING INFORMATION

All provided tie down points (and more) should be used to

help secure the sprayer for transporting.

Note serial number plate in the attached image.

WEIGHTS

The below is a general guide to standard model empty

weights. For more detailed information consult the

Croplands Customer Service team.

Cropliner Model Weight

(single axle versions)

XL 1500Lt - 920DSV Fan

XL 2000Lt - 920DSV Fan 766kg

XL 3000Lt - 920DSV Fan

XL 3000Lt - 1060DSV Fan

XL 4000Lt - 920DSV Fan

XL 4000Lt - 1060DSV Fan 1160 kg

XV 5000Lt - 1060DSV Fan

Tandem axle, 2000XL - 920 Fan

Tandem axle, 3000XL - 920 Fan

Tandem axle, 4000XL - 1060 Fan

Tandem axle, 5000XL - 1060 Fan 2018 kg

9

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

DIMENSIONS CROPLINER 1500/920DSV

4078

2720

1425

3355

1448

1285

1507

DIMENSIONS CROPLINER 1500/920DSV

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP1500-920DSV STANDARD SPEC

HTP1500B-920DSV

17/02/2022

WEIGHT (Kg):

A3

SHEET 1 OF 1

SCALE: 1:20

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

MDK

PRELIMINARY

4078

2720

1425

3355

1448

1285

1507

DIMENSIONS CROPLINER 1500/920DSV

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP1500-920DSV STANDARD SPEC

HTP1500B-920DSV

17/02/2022

WEIGHT (Kg):

A3

SHEET 1 OF 1

SCALE: 1:20

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

MDK

PRELIMINARY

DIMENSIONS CROPLINER 2000/920DSV

1490

1744.57

1544.32

2744.50

4123.41

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP2000-920SV

WEIGHT:

A3

SHEET 2 OF 2

SCALE: 1:25

DWG NO.

TITLE:

ISSUE

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

A

MKULKARNI

25/06/2021

REVISION

E

2000LT CROPLINER

N/A

N/A

2000 LT CROPLINER WITH 920DSV

1490

1744.57

1544.32

2744.50

4123.41

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP2000-920SV

WEIGHT:

A3

SHEET 2 OF 2

SCALE: 1:25

DWG NO.

TITLE:

ISSUE

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

A

MKULKARNI

25/06/2021

REVISION

E

2000LT CROPLINER

N/A

N/A

2000 LT CROPLINER WITH 920DSV

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

10 HT-OMCROPLINE-E

DIMENSIONS CROPLINER 4000/1060DSVDIMENSIONS CROPLINER 3000/1060DSV

1930

1865

1439

2942

4475

1595

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP3000-920DSV DIM

WEIGHT (Kg):

N/A

A3

SHEET 1 OF 1

SCALE: 1:25

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

3000LT CROPLINER

3000LT CROPLINER WITH 920DSV FAN

A

RPJUCO

130521

(DSV update)

2075

1930

1626

5184

3250

4321

1865

1064

825

DIMENSIONS CROPLINER XL 4000/1060DSV

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP4000-1060DSV DIM STANDARD

SPEC

CROPLINER XL 4000LT

13/07/2022

WEIGHT (Kg):

A3

SHEET 1 OF 1

SCALE: 1:25

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

MDK

PRELIMINARY

HTP4000-1060DSV_DIM

1930

1865

1439

2942

4475

1595

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP3000-920DSV DIM

WEIGHT (Kg):

N/A

A3

SHEET 1 OF 1

SCALE: 1:25

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

3000LT CROPLINER

3000LT CROPLINER WITH 920DSV FAN

A

RPJUCO

130521

(DSV update)

2075

1930

1626

5184

3250

4321

1865

1064

825

DIMENSIONS CROPLINER XL 4000/1060DSV

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

HTP4000-1060DSV DIM STANDARD

SPEC

CROPLINER XL 4000LT

13/07/2022

WEIGHT (Kg):

A3

SHEET 1 OF 1

SCALE: 1:25

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

MDK

PRELIMINARY

HTP4000-1060DSV_DIM

11

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

DIMENSIONS CROPLINER 5000 / 1060 DSV SINGLE AXLE DIMENSIONS CROPLINER 5000/1060DSV; TANDEM AXLE

1665

2235

340

2290

735

650

5865

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

5000LT CROPLINER AIRBLAST 1060 FAN

HTP5000-1060

14/02/2022

WEIGHT (Kg): 7162.81

N/A

A3

SHEET 3 OF 3

SCALE: 1:40

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

CROPLINER

RPJ

N/A

PRELIMINARY

1665

1935

360

2315

2095

730

815

5865

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

5000LT CROPLINER AIRBLAST 1060

FAN

HTP5000-1060

14/02/2022

WEIGHT (Kg): 7162.81

N/A

A3

SHEET 4 OF 4

SCALE: 1:40

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

CROPLINER

RPJ

N/A

PRELIMINARY

1665

2235

340

2290

735

650

5865

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

5000LT CROPLINER AIRBLAST 1060 FAN

HTP5000-1060

14/02/2022

WEIGHT (Kg): 7162.81

N/A

A3

SHEET 3 OF 3

SCALE: 1:40

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

CROPLINER

RPJ

N/A

PRELIMINARY

1665

1935

360

2315

2095

730

815

5865

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

5000LT CROPLINER AIRBLAST 1060

FAN

HTP5000-1060

14/02/2022

WEIGHT (Kg): 7162.81

N/A

A3

SHEET 4 OF 4

SCALE: 1:40

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS EQUIPMENT PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS

EQUIPMENT PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

CROPLINER

RPJ

N/A

PRELIMINARY

HT-OMCROPLINE-E

1212

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

GENERAL SPECIFICATION

The Croplands range of Cropliner sprayers are built with

a respect for Australia and New Zealand’s tough and

varying terrain.

Engineered to endure, Croplands spraying equipment

gives growers the confidence to take on row after row.

The sprayers are available with a wide selection of tank

sizes, fan sizes and options.

For more detailed specification, see Section

4, Product Features / Familiarisation.

Please note this manual is applicable to the XL and XV

models from 1,500 Litres to 5,000 litres capacity.

The Slimline 2000 models use a different manual.

HIGH PERFORMANCE AIR BLAST FANS

All our air-blast fans are engineered by Fieni, a global

leader in agricultural fan design, manufacturing, and

innovation.

Croplands and Fieni have been collaborating since

1972, and together we set the standard for fan sprayer

performance, efficiency, penetration, and coverage.

For performance specification, see Page 17.

920MM DSV FAN

Stainless steel volute.

Variable pitch, high strength, glass-reinforced nylon

blades – shaped for maximum air delivery with lowest

possible power input.

2-speed heavy-duty gearbox and centrifugal clutch.

Stainless steel spray ring with 14 brass roll-over nozzle

bodies per side.

Fully guarded for safety.

83,798m3/hour max air output.

1060MM DSV FAN

Stainless steel volute.

Variable pitch, high strength, glass-reinforced nylon

blades – shaped for maximum air delivery with lowest

possible power input.

2-speed heavy-duty gearbox and centrifugal clutch.

Stainless steel spray ring with 15 brass roll-over nozzle

bodies per side.

Fully guarded for safety.

108,618m3/hour max air output.

13

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

FIKIT00000044 Upper deflector kit for 1060 DSV fan (L/R air deflectors) fitted

FIKIT00000045 Lower deflector kit for 1060 DSV fan (L/R air deflectors) fitted

HT-TOPACTUATORS Upper deflector, electric actuator kit for 1060DSV fan (shown above)

920MM LINEAR TOWER FAN

Stainless steel volute.

Variable pitch, high strength,

glass-reinforced nylon blades –

shaped for maximum air delivery

with lowest possible power input.

Stainless steel spray ring with

13 brass roll-over nozzle bodies

per side.

Fully guarded for safety.

83,7908m3/hour

Delivers even coverage in the

narrowed plantings

Upper and lower deflector kits for 1060 fan.

HT-OMCROPLINE-E

14

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

Tanks (sight gauges / sump / drain)

All tanks are constructed of impact-resistant polyethylene

and UV stabilized.

Main tank capacities range from 1,500 litres to 5,000

litres and feature

• Flip open filling lid with large basket strainer.

• Quick fill system (camlock direct fill).

• Calibrated sight tube for filling level indication.

• Drain completely via a large drain valve and sump.

All XL models are supplied with a Flushing tank.

No Flushing tank is fitted to the XV model.

All models are supplied with a Hand-wash /

freshwater tank with conveniently positioned tap.

Chassis & drawbar

Hot-dipped galvanised full-length, heavy-duty chassis

with adjustable draw bar. Slide-out step (not on 5000)

& jockey stand.

Axle

Cropliner 1500, 2000, 3000 & 4000 litre models are

fitted with a single fixed axle as standard. The 5000 litre

model is fitted with single suspension axle as standard.

• Optional Adjustable height and width axle for 2000

and 1500 litre models on single axle

• Optional suspension for 1500 and 2000 litre

Cropliner (non-adjustable axle)

• Optional suspension for 3000 and 4000 litre

Cropliner (non-adjustable axle)

• Optional Tandem walking beam axle available

for all models except the1500 litre.

Wheels & Tyres

11.5/80 x 15.3 wheels with tubeless tyres are fitted as

standard to the 1,500 and 2,000 Litre models.

400 x 15.5” flotation tyres are fitted as standard on

3,000 & 4000 Litre models.

400 x 22.5” wheel & tyres are fitted as standard to the

5,000 Litre model

Drive/PTO

A heavy-duty PTO shaft is supplied to drive the pump.

Wide angle PTO shafts are available as an option.

• Optional Wide angle PTO shaft

Pumps

All Cropliner Sprayers are fitted with an Annovi Reverberi

positive displacement diaphragm pumps with a capacity of

140 to 260 L/min - depending on the sprayer model.

• Optional ARBHS200 brass pump in lieu of the

“where normal” ARBHS170

Agitation

The agitation system is driven by the pump via twin

supa-flow venturis tank agitators & bypass agitation.

Single agitator for the 1,500 model.

Nozzles

Brass roll-over nozzle bodies fitted with 1 set stainless steel

disc and brass cores and 1 set ALBUZ ceramic hollow cone

nozzles to allow a greater choice of application rates.

Note the customer can specify the specific nozzle

requirements at the time of order.

Each sector of nozzle body(s) is fitted with a non drip

diaphragm.

15

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

Filtration

Lid-strainers & chemical mixing baskets are standard on

all models.

Large suction filter and optional high pressure brass

pressure filters.

Chemical Handling

Quick fill system and chemical suction probe standard on

all models.

Speed Sensors

Proximity sensors are used for Wheel (travel) speed.

Controls

Manual remote mounted ARBMH50 controller standard.

Functions include left/right, shut-off, simultaneous

shut-off, full bypass, pressurised bypass, manual pressure

adjustment with pressure gauge.

Options:

• Electric – high pressure solenoid valves, 2-section

in-cab control with electric pressure adjustment

• Croplands HV-2400, 2-section auto-rate controller

• HV-4000 auto-rate controller, 2-section

(left/right) with optional 4-section control

(left/right/upper/lower)

• Bravo 180S auto-rate controller, 2-section

(left/right) with optional 4-section control

(left/right/upper/lower)

Factory fitted options (other)

• NuPoint GPS tracking, mapping & data.

• In some models the Flushing tank is optional.

• Various fan options are available, such as …

o Linear tower (see buyers guide)

o Deflector kits (see buyers guide)

o Tall tree volute (see buyers guide)

Tractor requirements

Tractor size / power required is dependent upon a

combination of weight (sprayer tank capacity), fan

(size and pitch angle setting) and farm conditions

(soil and terrain).

Approximate engine HP requirements.

Models with:

920 DSV fan = 70 HP

1060 DSV fan = 105 HP

Also see Fan specification information for fan only

requirements (page 17).

Sprayer specifications are subject to change

without prior notification

HT-OMCROPLINE-E

16

FIENI FANS 17

FAN PITCH ANGLE 18

GEARBOX 20

ADJUSTABLE VANES 21

NOZZLES 21

FAN SAFETY 22

CHASSIS, AXLE, WHEEL & TYRES 23

TANKS, LIDS ETC 25

5000 XV MODEL 27

4000 XL MODEL 28

3000 XL MODEL 30

2000 XL MODEL 32

1500 XL MODEL 33

PUMPS 34

PTO SHAFTS 34

SPRAY SYSTEM OVERVIEW 35

CONTROLS 38

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

17

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

FIENI FANS

The attached table lists the performance details for each

Cropliner Fieni fan model.

The DSV fan was designed for low noise and lower power

absorption, while still guaranteeing a large air volume.

The 9 blades of the DSV fan are made of a composite

material and have been specifically designed to

guarantee high performance.

Rear intake fans run anticlockwise.

The fan blades can be set at three different pitch angles

to adapt the Fieni sprayer unit to the power of the tractor

available. All Cropliner sprayers are tested and supplied

with the fan set to the middle blade pitch setting.

The fans are equipped with a centrifugal clutch made of

metal with brake lining.

Each fan is PTO shaft driven via a 2 speed (plus neutral),

low maintenance, heavy duty gearbox.

Designed for maximum PTO speed = 540 rpm.

Each fan has a series of small independent moveable

flat blades fitted on the air outlet, to help direct the air to

where it is required.

Each side of the fan is a stainless steel “spray ring” with

13, 14 or 15 nozzles per side. Each nozzle is of the brass

“roll-over” type.

920 LINEAR

TOWER (LT) FAN 920 DSV FAN 1060 DSV FAN

ORDER CODE KH-5037 KH-5035 KH-5040

9-BLADE FAN

Fan blade diameter mm 913 913 1,060

Standard RPM (PTO 540)

(High) 1,780 1,780 1,780

OUTPUT AND POWER

Pitch 26° 26° 64°

M3/HR 73,682 73,682 84,696

HP 26.4 26.4 35.38

Pitch 34° 34° 72°

m3/hr 81,285 81,285 99,929

HP 36.9 36.9 50.08

Pitch 42° 42° 80°

M3/HR 83,798 83,798 108,618

HP 47.5 47.5 70.23

FAN GEARBOX MODEL CM-12VNS CM-12VNS CM-15

2-speed plus neutral 2 + N 2 + N 2 + N

Low box ratio 1:2:93 1:2.93 1:2.93

High box 1:3.29 1:3.29 1:3.3

PERFORMANCE*

(*in ideal conditions)

Y = metres 6 8 10

Z = metres 15 14 16

Suitable tank size 1500 - 4000 1500 - 4000 3000 - 5000

Recommended tractor HP ≥ 65 ≥70 ≥105

Nozzles per side 13 + 13 (26) 14 + 14 (28) 15 + 15 (30)

Noise rating (dB) @ 7.5m 92 92 96

Fan weight 178 130 188

The maximum canopy height and width figures are entirely subject to the canopy density, size, shape and weather conditions.

HT-OMCROPLINE-E

18

FAN UNITS

VPL

Fan VPL with clutch and nylon-glass blades, 550, 616, 712, 815, 913 mm diameter.

Overview Product image

Assembled Spin Blades Clutch

Specs Fan model VPL

Diameter ø 550 mm / 21 ″

ø 616 mm / 24 ″

ø 712 mm / 28 ″

ø 815 mm / 32 ″

ø 913 mm / 36 ″

Contacts Fieni Giovanni S.r.l.

Via Chiavicone 10

40051 Altedo - Bologna

Italy

Phone: +39 051 871004

Fax: +39 051 871865

Email: info@fieni.it

C.F. e R. I. Bologna 03052740374

P.IVA 00592031207 C.S.i.v 19.625,36 €

R.E.A. Bologna 0259358 del 12.09.1980

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

FAN PITCH ANGLE

All Cropliner fans have multiple pitch settings and are

normally supplied in the middle position.

To maximise performance, the blade pitch can be adjusted

to match the tractor’s capability / chosen operating

parameters such as PTO rpm.

To increase the blade angle will increase air (spray)

velocity and penetration, increase noise, and increase

tractor power requirements. Note the power increase on

a 1060 fan is very significant.

The reverse is true for reducing pitch angles.

Adjusting the pitch angles can be done on the sprayer

as follows.

a. Disconnect the PTO drive.

b. Remove the safety fan guard.

c. Remove the hub cover.

d. Loosen the fan hub bolts.

e. It’s now possible to move the blades. All blades need

to be set to the same pitch angle.

f. Re-tighten the fan hub bolts. Makes sure the hub is

snugly fitting back together – if not, it’s a sign that one

or more of the fan blade splines are not correctly fitted.

g. Re-attach the hub cover, and safety guards.

Fan Set-up

The fan has the following adjustments available.

• Fan pitch angle

• Gearbox ratio

• Adjustable vanes

• Adjustable nozzles

FAN UNITS

VPL

Fan VPL with clutch and nylon-glass blades, 550, 616, 712, 815, 913 mm diameter.

Overview Product image

Assembled Spin Blades Clutch

Specs Fan model VPL

Diameter ø 550 mm / 21 ″

ø 616 mm / 24 ″

ø 712 mm / 28 ″

ø 815 mm / 32 ″

ø 913 mm / 36 ″

Contacts Fieni Giovanni S.r.l.

Via Chiavicone 10

40051 Altedo - Bologna

Italy

Phone: +39 051 871004

Fax: +39 051 871865

Email: info@fieni.it

C.F. e R. I. Bologna 03052740374

P.IVA 00592031207 C.S.i.v 19.625,36 €

R.E.A. Bologna 0259358 del 12.09.1980

FAN UNITS

VPL

Fan VPL with clutch and nylon-glass blades, 550, 616, 712, 815, 913 mm diameter.

Overview Product image

Assembled Spin Blades Clutch

Specs Fan model VPL

Diameter ø 550 mm / 21 ″

ø 616 mm / 24 ″

ø 712 mm / 28 ″

ø 815 mm / 32 ″

ø 913 mm / 36 ″

Contacts Fieni Giovanni S.r.l.

Via Chiavicone 10

40051 Altedo - Bologna

Italy

Phone: +39 051 871004

Fax: +39 051 871865

Email: info@fieni.it

C.F. e R. I. Bologna 03052740374

P.IVA 00592031207 C.S.i.v 19.625,36 €

R.E.A. Bologna 0259358 del 12.09.1980

FAN UNITS

VPL

Fan VPL with clutch and nylon-glass blades, 550, 616, 712, 815, 913 mm diameter.

Overview Product image

Assembled Spin Blades Clutch

Specs Fan model VPL

Diameter ø 550 mm / 21 ″

ø 616 mm / 24 ″

ø 712 mm / 28 ″

ø 815 mm / 32 ″

ø 913 mm / 36 ″

Contacts Fieni Giovanni S.r.l.

Via Chiavicone 10

40051 Altedo - Bologna

Italy

Phone: +39 051 871004

Fax: +39 051 871865

Email: info@fieni.it

C.F. e R. I. Bologna 03052740374

P.IVA 00592031207 C.S.i.v 19.625,36 €

R.E.A. Bologna 0259358 del 12.09.1980

FAN UNITS

VPL

Fan VPL with clutch and nylon-glass blades, 550, 616, 712, 815, 913 mm diameter.

Overview Product image

Assembled Spin Blades Clutch

Specs Fan model VPL

Diameter ø 550 mm / 21 ″

ø 616 mm / 24 ″

ø 712 mm / 28 ″

ø 815 mm / 32 ″

ø 913 mm / 36 ″

Contacts Fieni Giovanni S.r.l.

Via Chiavicone 10

40051 Altedo - Bologna

Italy

Phone: +39 051 871004

Fax: +39 051 871865

Email: info@fieni.it

C.F. e R. I. Bologna 03052740374

P.IVA 00592031207 C.S.i.v 19.625,36 €

R.E.A. Bologna 0259358 del 12.09.1980

Assembled Spin Blades Clutch

19

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

The fan has been supplied “balanced”. Swapping blades

and hub components around risks upsetting the balance.

Do not operate with damaged fan blades.

If replacing a damaged blade, it’s necessary to balance

the fan.

VNS-A Fan

(rear air intake anti-clockwise)

VNS-O Fan

(front air intake, clockwise)

HT-OMCROPLINE-E

20

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

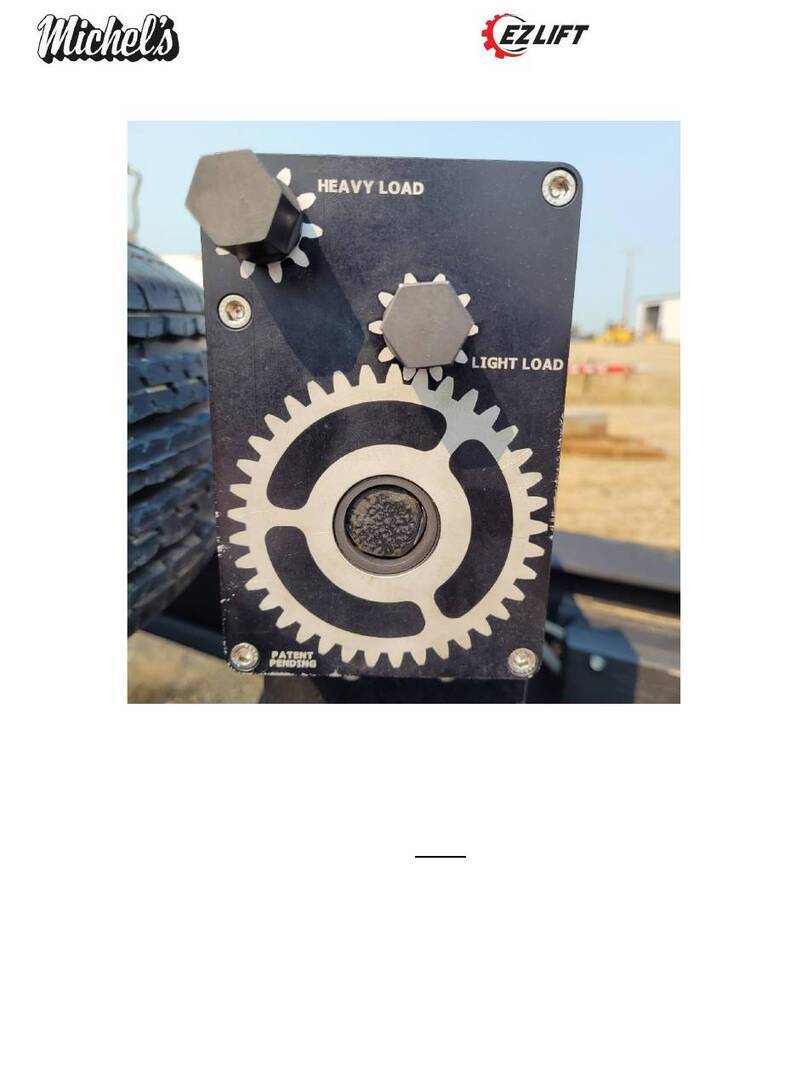

GEARBOX

There are 2 different gearboxes in the range (refer page

15) – both have a low ratio, neutral (as the middle setting)

and high ratio. Handle positions changes from fan to fan

as per below decals.

All units are supplied with a lever to engage and

disengage the fan.

To avoid damage to the gears of the gearbox and to

the sprayer unit, always disengage the PTO drive

before operating the gearbox lever / changing

gears etc.

Gearbox oil: Annually check the oil level of the gearbox

and if the level is low (below the middle of the sight gauge)

it’s necessary to add the oil (SAE 60:70) up to reach the

correct oil level. It is not necessary to change the oil once a

year, but only to add oil if the level is low.

The oil level sight gauge may be viewed via a hole in the

internal fairing (refer to image / yellow arrow).

If a low oil level is detected, an investigation as to why the

oil level has dropped should be undertaken.

To access the gearbox or the oil fill position will require the

partial disassembly of the fan.

Fieni gearboxes use Agip Blasia 68 oil.

Some common equivalents are;

• Castrol Alpha SP68

• Mobilgear 600 XP 68

• Shell Omala S2 G 68

Fan 920DSV 1060

G/box CM-12VNS CM-15

Oil (ml) 1900 2200

Maximum PTO Speed

Maximum PTO speed is 540 rpm.

Check the tractor PTO RPM before operating the sprayer.

More RPM at the PTO can give damage to the sprayer unit

and can be dangerous for the operator.

This manual suits for next models

4

Table of contents

Other Croplands Farm Equipment manuals

Croplands

Croplands PEGASUS 7000 Standard User manual

Croplands

Croplands PEGASUS 8000 Programming manual

Croplands

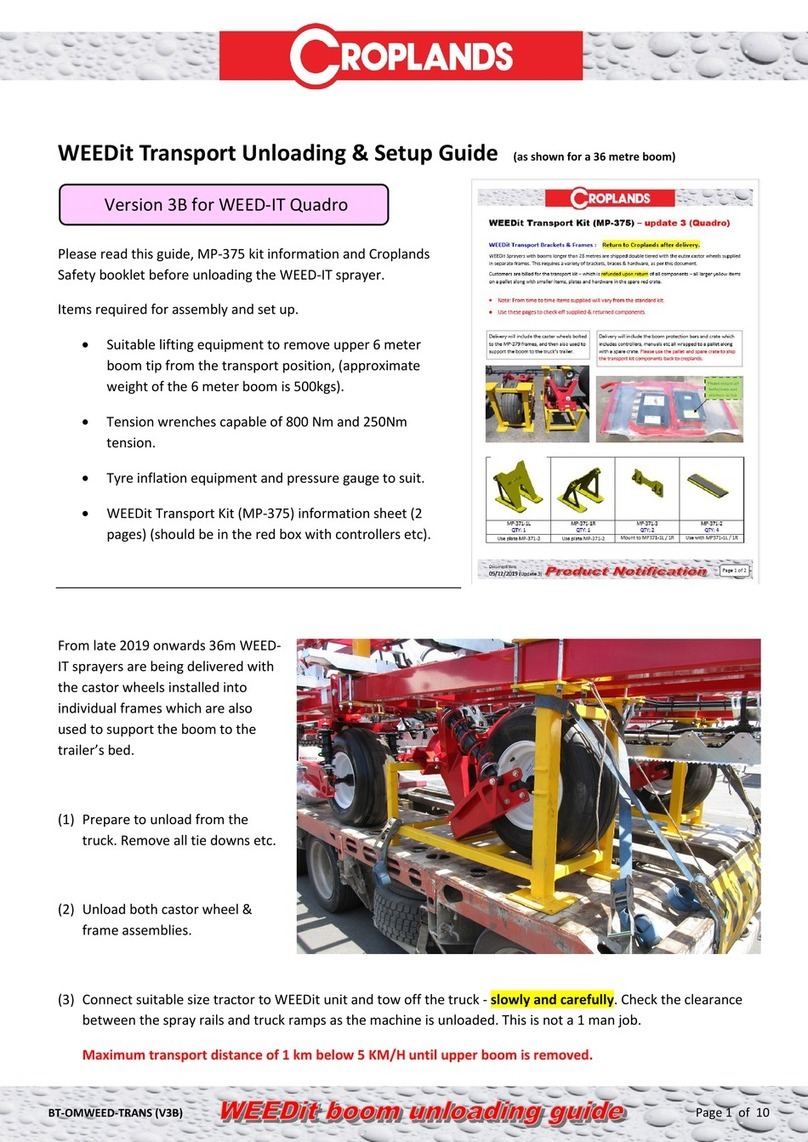

Croplands WEED-IT Quadro User manual

Croplands

Croplands CROPAIR 300 User manual

Croplands

Croplands WEED-IT Quadro User manual

Croplands

Croplands US20F/252/HR30 User manual

Croplands

Croplands PEGASUS 8000 User manual

Croplands

Croplands PEGASUS 4000 User manual

Croplands

Croplands QUANTUM FUSION User manual

Croplands

Croplands WEED-IT User manual