NAME: TRAINING DEPARTMENT DATE : 2017 PAGE : 3 / 59

REFERENCE: TECHNICIAN’SOPERATING MANUAL X40+-X50+ ISOBUS IND 03

++

5

-

I - SPECIFICATION SHEETS

SHEET NO.SPECIFICATION SHEETS PAGE NO.

A1 Global view 4 - 5

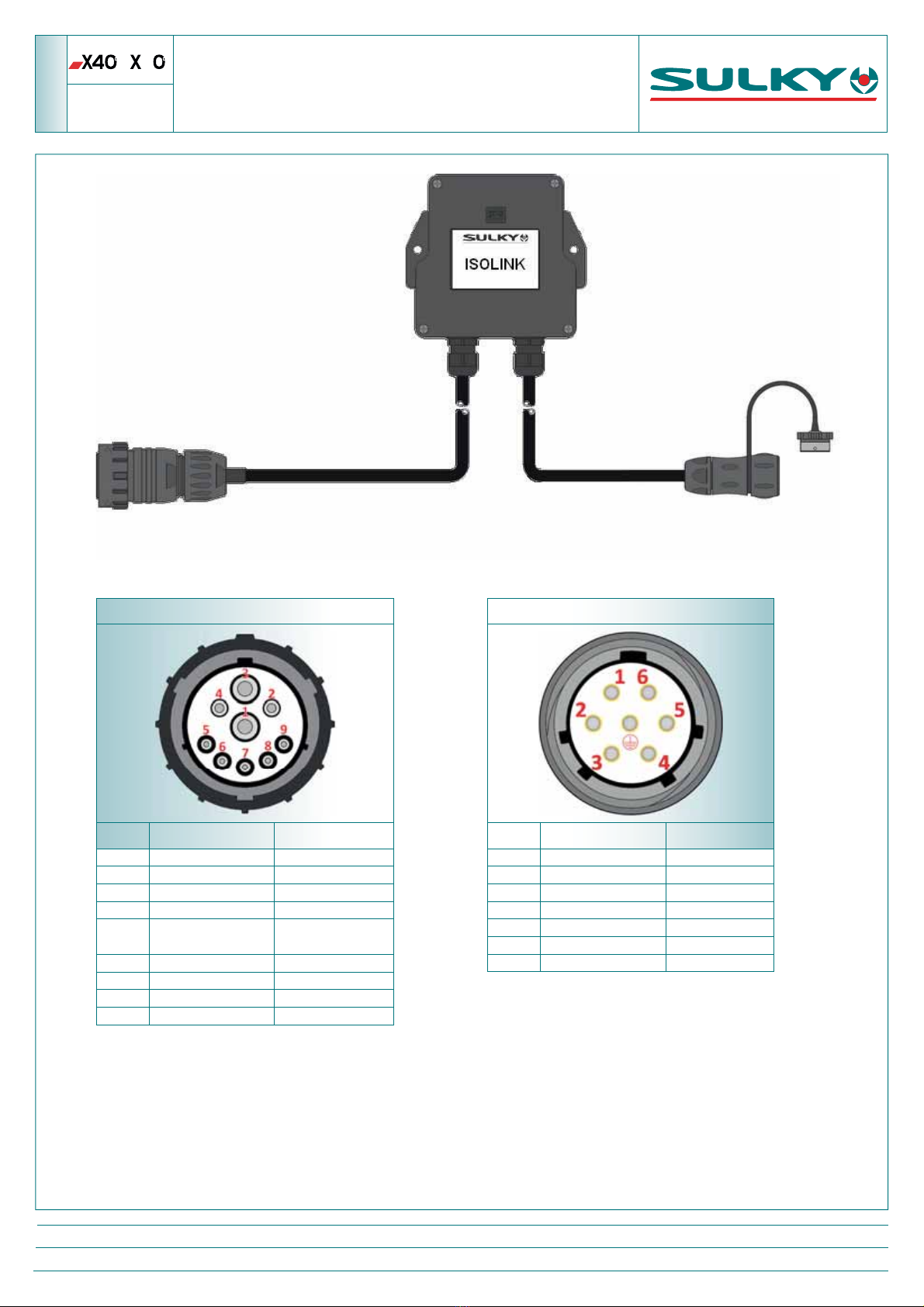

A2 ISOLINK wiring bundle 6

A3 ECU - CAN connection box 7

B1 Regulator settings check 8

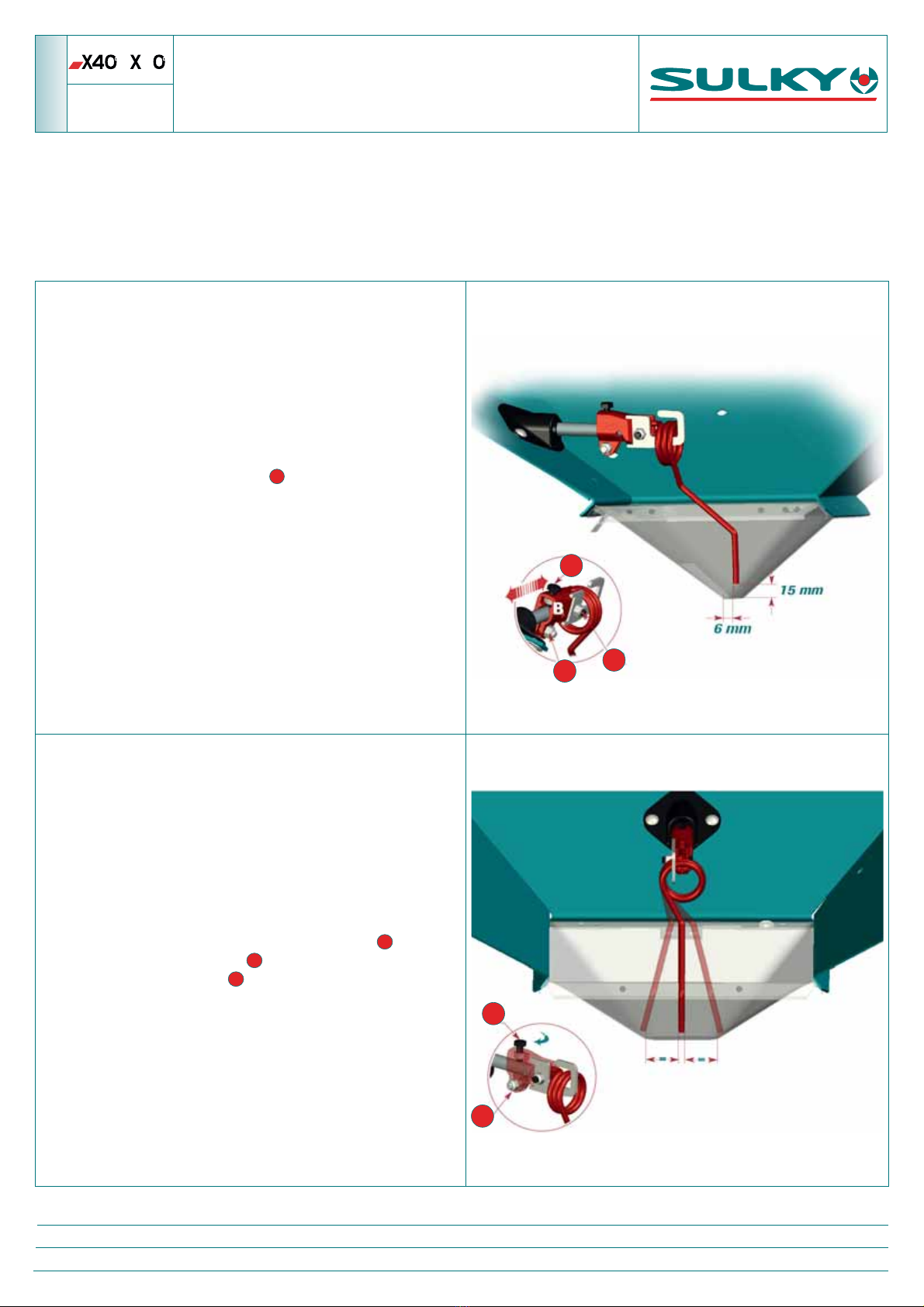

B2 Mechanical calibration of the shutters 9

B3 Mechanical calibration of the chutes 10

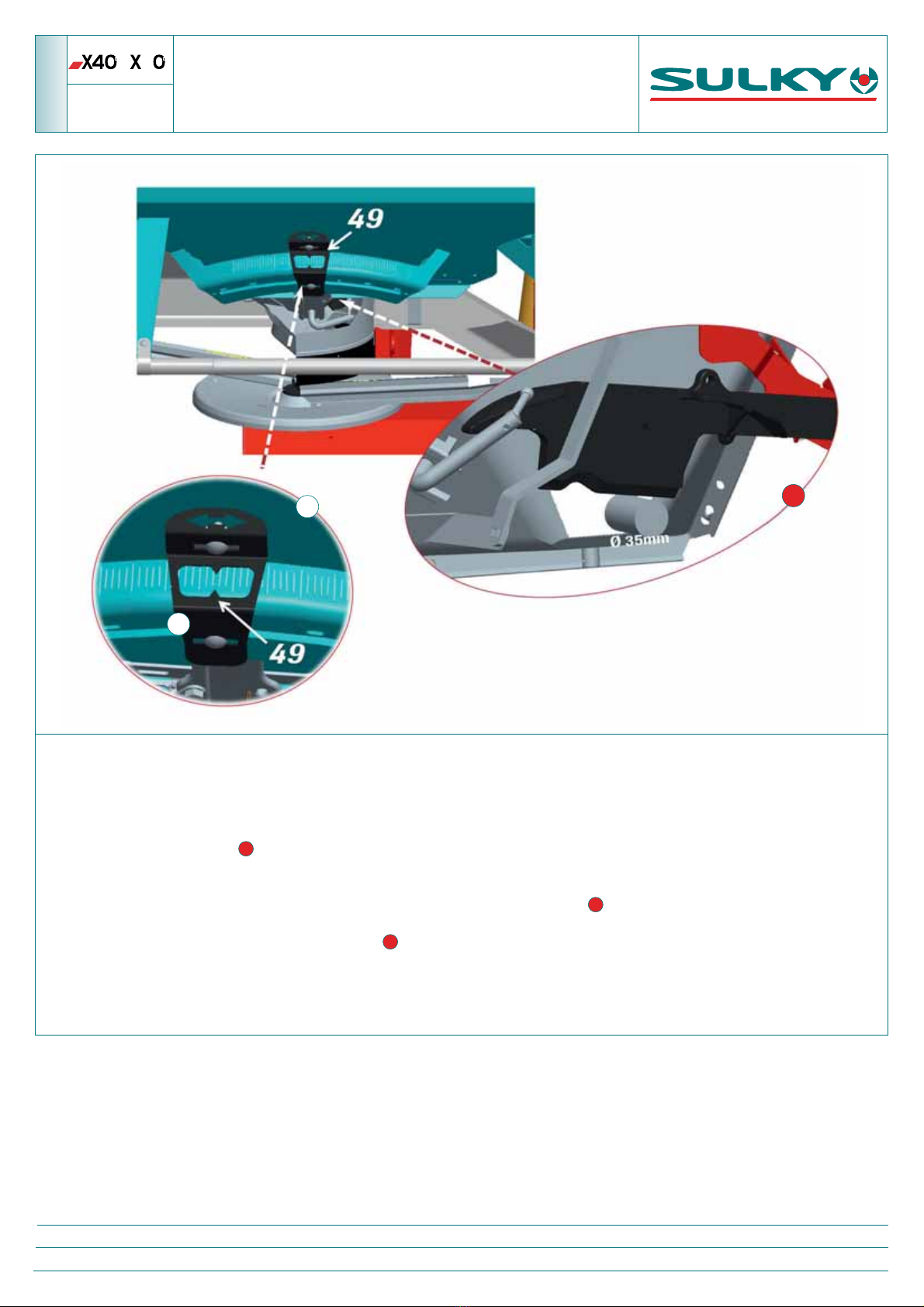

B4 Calibration of application rate and width actuators 11

B5 Shutter guides settings 12

C1 Calibration of the weighing device 13

C2 Angle sensor of the weighing device 14

C3 Weighing blades check 15

C4 Replacement of weighing blades 16 -17

C5 Pre-tensioning spring dimension inspection 18

C6 Weighing sensor 19 - 20

D1 Electrical application rate actuators 21 - 23

D2 Tribord actuators 24 - 26

D3 Chute actuators (Width) 27 - 29

D4 Stop & Go actuators 30 - 31

D5 Shutter sensors 32

D6 End of hopper sensors 33

D7 ECU (Electronic Control Unit) 34 - 35

E1 Diagnostics Menu 36

E2 Machine History 37

F1 Retrieve the data from an ISOLINK 38 - 40

F2 Perform an ISOLINK RESET 41

F3 Set up the ISOLINK 42 - 46

F4 Updating the ISOLINK software 47 - 48

H1 FERTITEST import 49 - 50