Sullair SM160 User manual

SM-160 to SM-800

MAINTENANCE MANUAL

DATE : 22Sep2004 REVISION : 1

domnick hunter limited, Dukesway, Team Valley trading Estate, Gateshead, England, NE11 0PZ. Tel: +44 (0) 191 4029000 Fax:+44 (0) 1914826296

Page 2 of 36

FOREWORD

The compressed air dryer systems have been designed and manufactured to ensure that

maximum safety and performance is achieved. It is expected that users of these systems

will employ safe working practices and ensure that when installing, commissioning,

operating or maintaining the equipment, any legal requirements are fulfilled. For example,

in the UK, users should refer to the Health and Safety Act, 1974.

All ancillary equipment such as pipework, valves, fittings etc., must be suitable for the

pressures and capacities involved.

Replacement parts are available from your distributor or the manufacturers ( see front page

for information). The adoption of a regular servicing policy is strongly recommended and

will result in ensuring that a high performance is achieved. Serial numbers and customer

order numbers should be referred to in any communication. (Serial numbers can be found

on the identification plate on the left hand side of the instrumentation shroud). The figure

number and the appropriate diagram in this manual and the item number (shown in circle,)

will also assist in part identification.

Any warranty will be invalidated if the dryer is not commissioned in accordance with the

manufacturers recomendations or non-approved parts substituted. Substitute parts could

reduce the performance or service life in addition to creating potential hazards.

The manufacturers reserve the right to modify the contents of this manual without notice.

The data given is a guideline to users and in no way binding on the manufacturers.

BEFORE SERVICING OR DISMANTLING ALL PRESSURE MUST BE RELEASED FROM

THE SYSTEM AND ITS ASSOCIATED PIPEWORK AND ANY ELECTRICAL SUPPLY

ISOLATED.

Page 3 of 36

RECOMMENDED ROUTINE MAINTENANCE

Daily

1. Open kaddis drains on lower manifold and valve housings to discharge any entrained

condensate.

2. Ensure ’power on’ light is illuminated .

Monthly

As above and include:

1. Ensure all manifold, valve housing and end plate gaskets do not leak.

2. Check all control valves, pipe and fittings (within instrumentation shroud) for air leaks.

Page 4 of 36

MAXI MAINTENANCE

CONTENTS

Section

A1

A2

A3

A4

A5

A6

A7

A8

Description

Inlet Valve Assembly

Manifolds

Exhaust Valve Assembly

Column Assemblies

Outlet Valve Assembly

Control & Instrumentation

Piping & Wiring Diagrams

Fault Finding Guide

Page

5

8

14

16

19

21

26

32

Page 5 of 36

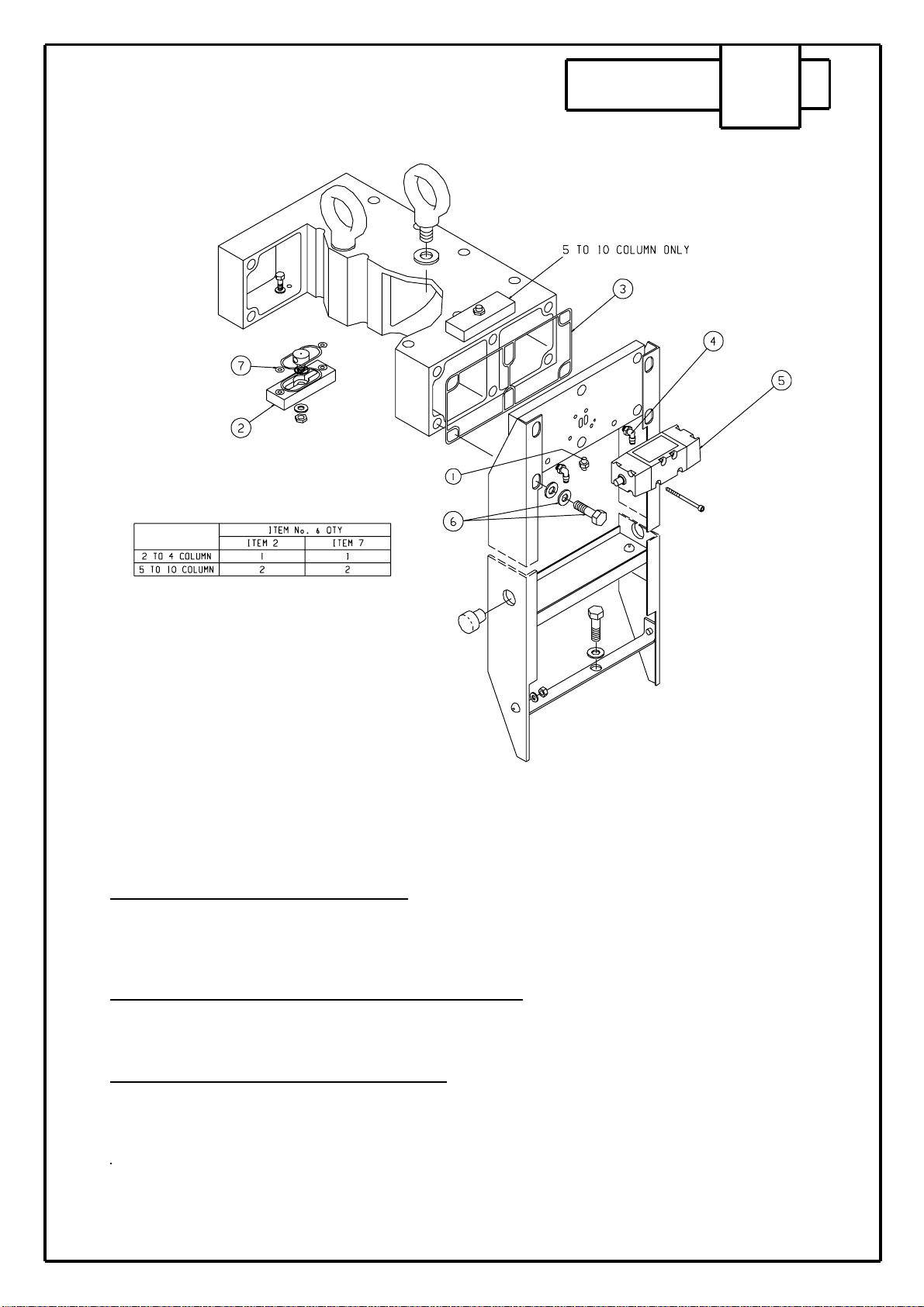

SECTION A1

INLET VALVE ASSEMBLY

A1.1

A1.2

A1.3

Inlet Head Removal

Inlet Valve Disc Removal

Cylinder Piston Seal Renewal

INLET VALVE ASSEMBLY SECTION A1

A1.1 Inlet Head Removal

Remove inlet flange nuts and nylon pipes. Remove Allen screws from cylinders and pull back

cylinders. The bolts from the head assembly can now be removed.Take care when removing the valve

strike plate.

A1.2 Inlet Valve Disc Removal

Secure valve stem and unscrew retaining nut. Inspect strike plate before re-fitting.

A1.3 Cylinder Piston Seal Renewal.

Remove 4 allen screws from cylinder body, secure piston across flats and unscrew valve stem.

Remove circlip from cylinder body and pull out piston. New seals should be fitted using silicon free

grease, press out retaining cover nose seal and renew.

For re-assembly, follow reverse procedure always fitting new moulded gaskets, and ’O’ ring on center

head bolt.. Ensure that the strike plate is located with it’s recessed side towards the valve disks.

TORQUE HEAD BOLTS TO 34Nm (25lbs.ft).

Page 6 of 36

Page 7 of 36

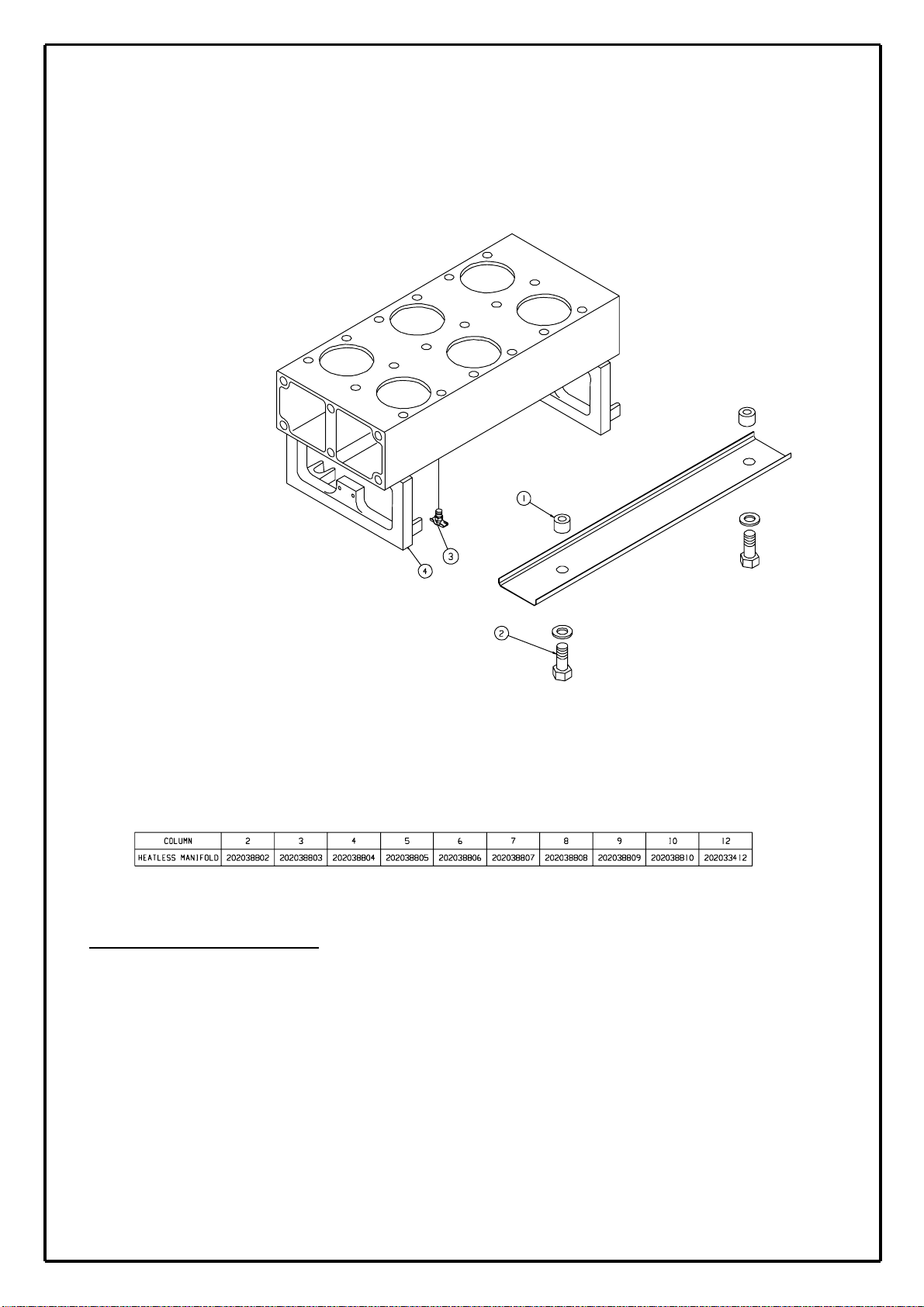

SECTION A2

UPPER & LOWER MANIFOLDS

A2.1

A2.2

A2.3

A2.4

A2.5

A2.6

A2.7

Upper Manifold Removal (Heatless)

Quick Re-Pressurisation Valve Removal (H/L)

Purge Plate Removal

Purge Adjustment

Lower Manifold Removal

Bolt Torque Sequence HEATLESS.

Bolt Torque Sequences - Inlet, Outlet & Exhaust

Valve Assemblies

UPPER & LOWER MANIFOLDS SECTION A2

A2.1 Upper Manifold Removal (Heatless)

Remove nylon pipes from end plate,remove bolts from end plate connected to side plates, disconnect

QRV solenoid coil, remove shroud as detailed in section A6, remove outlet housing as detailed in

section A5. Slacken and remove bolts in the reverse order of torque sequences shown. Screw in M12

location studs. Lift manifold off using eye bolts provided.

A2.2 Quick Re-pressurisation Valve Removal (Heatless)

The QRV can be removed without removing the end plate, by removing the four retaining bolts.

Disconect QRV soleniod coil.To service the valve, remove the end cap and withdraw the piston, clean

piston and refit. (Lubrication is not recomended).

A2.3 Purge Plate Removal (Where Applicable)

Remove outlet housing as shown in Section A5. This will give access to 2 Hex. head screws securing

the purge plate, slacken and remove. The purge plug ‘O‘ ring can be changed by pressing the brass

purge plug clear from the purge plate.

Page 8 of 36

Page 9 of 36

A 2.4 PURGE ADJUSTMENT

A2.4 Purge Adjustment

Before attempting any adjustments to the purge on the

Maxi Smart Dryers ensure that the dryer is in

re-pressurisation.

At this point switch off the electrical supply to the dryer.

Find and locate the solenoid control valves for INLET

VALVE A and EXHAUST VALVE B.

Manually turn the over-ride on Inlet valve A to the

open position.

Manually turn the over-ride on the Exhaust valve B to

the open position. Column B will now de-pressurise.

Unscrew the two exhaust silencers located in the control shroud at the front. Using a 1" BSP plug, blank off one

of the exhaust ports so that all the purge air escapes through one port. Ensure that the flow meter to be used

has a full scale deflection larger than the required purge flow.

Using 1" BSP flexible hose, connect from the exhaust port to the inlet of the flow meter NB. never allow the

float of the flow meter to go off the top of the scale, and never pressurise the flow meter.

Using the brass purge plug, adjust the purge flow to the correct flow rate for the dryer, this must be carried out

with the dryer at its MINIMUM operating pressure. On certain dryers there will be two purge plugs, on these

dryers it is recommended that the plug nearest the inlet and outlet be fully open and the plug nearest the control

shroud be used for fine adjustment.

Page 10 of 36

A 2.4 PURGE ADJUSTMENT

Once the purge flow is set, remove the flow meter and the 1" BSP plug and replace the silencers. Return the

over-ride switches to the correct position. Re-install the electric supply to the dryers and ensure the dryer

cycles correctly.

Purge Settings

Specific purge setting may vary from site to site according to operational/enviromental conditions. In general for

up to 35˚C inlet temperatures the table below gives recommended flow settings for both -40˚C and -70˚C PDP.

Purge flow rates are factory set to 6 barg. This may need to be re-set by a domnick hunter trained installation

engineer at other operatiing pressures during commissioning

MAXI HEATLESS

CODES

SM160

SM240

SM320

SM400

SM480

SM560

SM640

SM800

PURGE FLOW RATE

L/M

714

1070

1427

1784

2141

2498

2855

3568

Page 11 of 36

A 2.5 LOWER MANIFOLD REMOVAL

A2.5 Lower Manifold Removal

Remove inlet and outlet pipes as detailed in section A1 and A5 respectively, remove exhaust silencers as

shown in section A3. Remove shroud as detailed in A6. Remove the two eye bolts on the top manifold and

invert the dryer completely. Remove the nylon pipes from the changeover valve and slacken bolts in the

reverse order of torque sequence shown and lift manifold clear.

Page 12 of 36

MANIFOLDS - Bolt Torque Sequence

Note:

Tighten the bolts in the numerical order shown, always starting with the middle

column working outwards.

TORQUE to 35N.m (25lbs.ft)

A2.6 -HEATLESS

Page 13 of 36

A 2.7 INLET, OUTLET & EXHAUST VALVE

Bolt Torque Sequence

When removing or assembling the INLET VALVE,

OUTLET VALVE or EXHAUST VALVE housings always

loosen and tighten in the sequence shown above

TORQUE TO 34Nm (25lbs.ft)

Page 14 of 36

SECTION A3

EXHAUST VALVE ASSEMBLY

A3.1

A3.2

A3.3

Exhaust Valve Removal.

Exhaust Valve Disc Removal.

Cylinder Piston Seal Renewal.

EXHAUST VALVE ASSEMBLY SECTION A3

A3.1 Exhaust Valve Assembly Removal.

Unscrew exhaust elements. Remove assembly bolts and nylon pipes. Take care when removing the

valve strike plate.

A3.2 Exhaust Valve Disc Removal.

Secure valve stem and unscrew retaining nut. Inspect strike plate before re-fitting.

A3.3 Cylinder Piston Seal Renewal.

Remove 4 cap screws from cylinder body, secure piston across flats and unscrew valve stem. Remove

circlip from cylinder body and pull out piston. New seals should be fitted using silicon grease, press out

retaining cover nose seal and renew.

A3.4 Exhaust Element Replacement

Unscrew element and replace, ELEMENTS ARE NOT REUSABLE.

For re-assembly, follow reverse procedure always fitting new graphite gaskets and ’O’ rings on

retaining bolts.

Page 15 of 36

Page 16 of 36

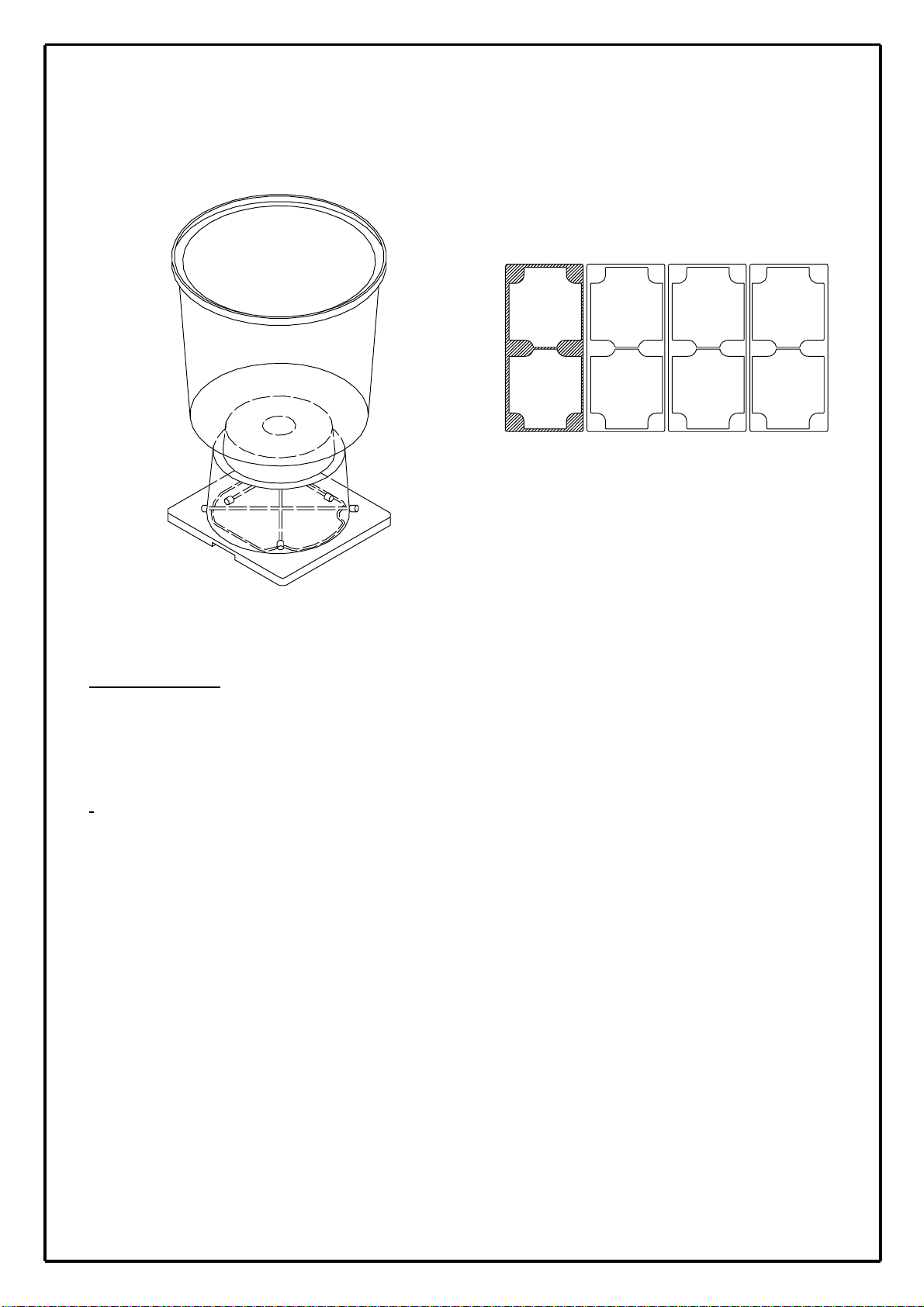

SECTION A4

COLUMN ASSEMBLY

A4.1

A4.2

Column/Desiccant Removal

Desiccant Replacement

COLUMN ASSEMBLY SECTION A4

A4.1 Column/Desiccant Removal

Remove upper manifold as described in manifold section remove gasket retaining screws and remove

gaskets. The desiccant can now be extracted from the column using a vacuum cleaner. Bottom column

bolts can then be removed and the column lifted clear

A4.2 Desiccant Replacement

Ensure columns are free from dust and that the lower manifold gasket is in good condition. Refilling can

now take place. In order to maintain dryer performance, the columns must be refilled using a snow storm

filling device which will achieve maximum packing density. The best results are obtained by using a

smooth and continuous operation.

HEATLESS

Page 17 of 36

Page 18 of 36

Desiccant Replacement

A4.2.1 GENERAL

Each extrusion consists of 2 E-shaped chambers containing a total of 15kg of desiccant material. Sullair

suggests a performance life of 10,000 - 30,000 hours, however, many factors can influence this nominal

figure which should only be used as a guide. Accurate dewpoint monitoring with a hygrometer is the only true

indication of the desiccant condition ( consultSullair ).

HEATLESS COLUMN ARRANGEMENT

Page 19 of 36

SECTION A5

OUTLET VALVE ASSEMBLY

A5.1

A5.2

Outlet Housing Removal

Outlet Valve Disc Removal

OUTLET VALVE ASSEMBLY SECTION A5

A5.1 Outlet Housing Removal.

Remove outlet flange nuts, head bolts and nylon pipes. Take care when removing the valve strike plate

A5.2 Outlet valve disc removal

Remove valve and spring from guide, secure valve stem and unscrew retaining nut. Inspect strike plate

before re-fitting.

For re-assembly follow reverse procedure. Always fitting new graphite gaskets, seals and o-ring on

centre retaining bolt.

Page 20 of 36

This manual suits for next models

7

Table of contents

Other Sullair Industrial Equipment manuals