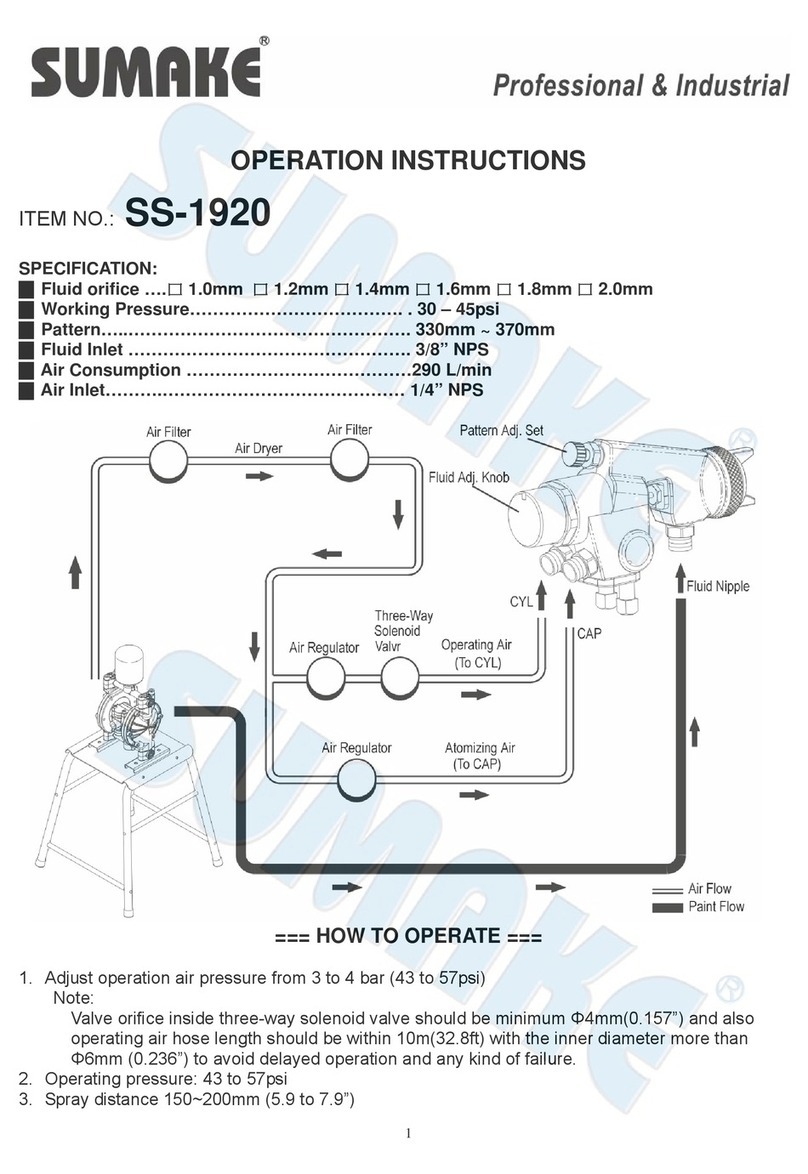

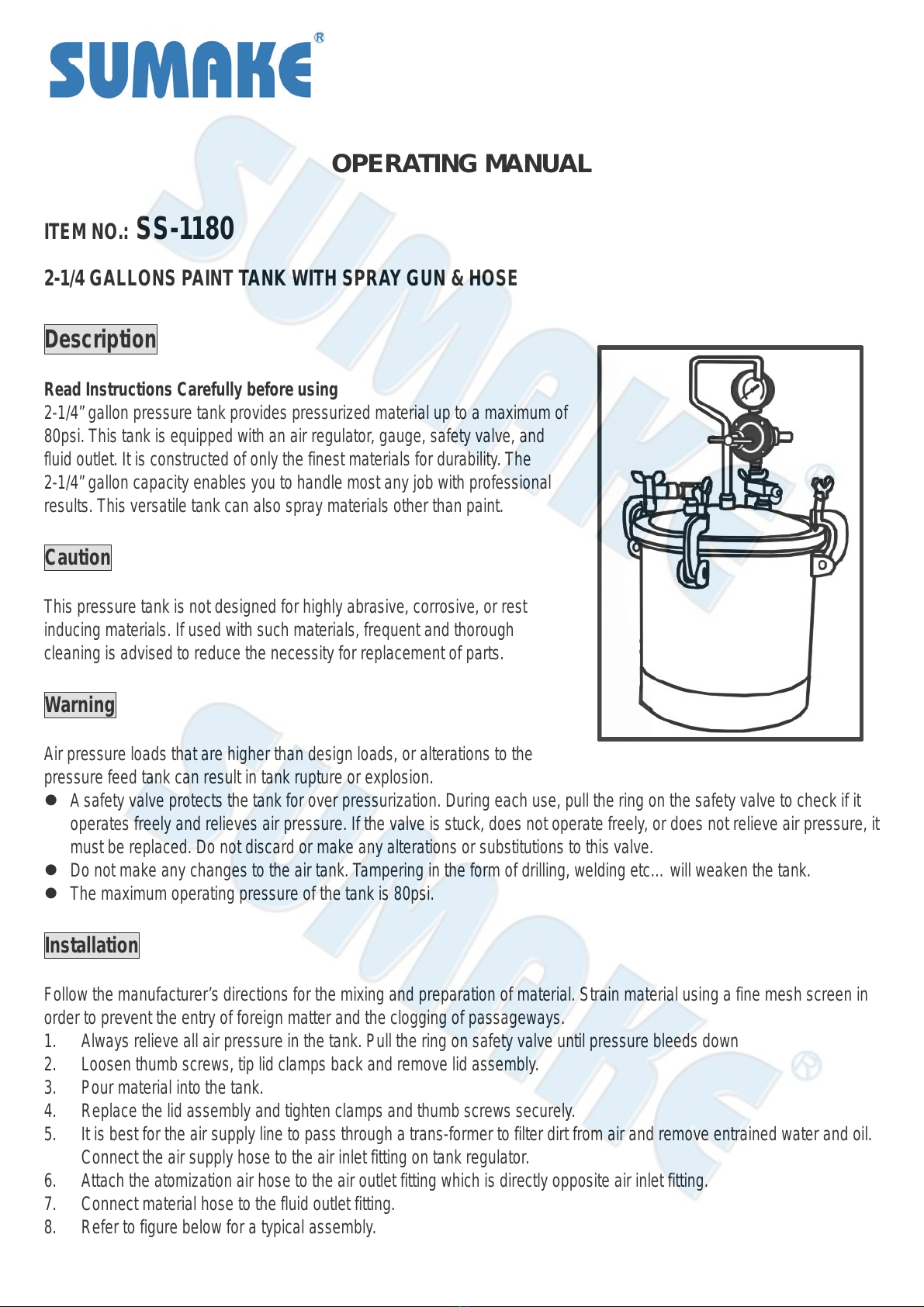

Sumake SS-1180 User manual

Other Sumake Paint Sprayer manuals

Sumake

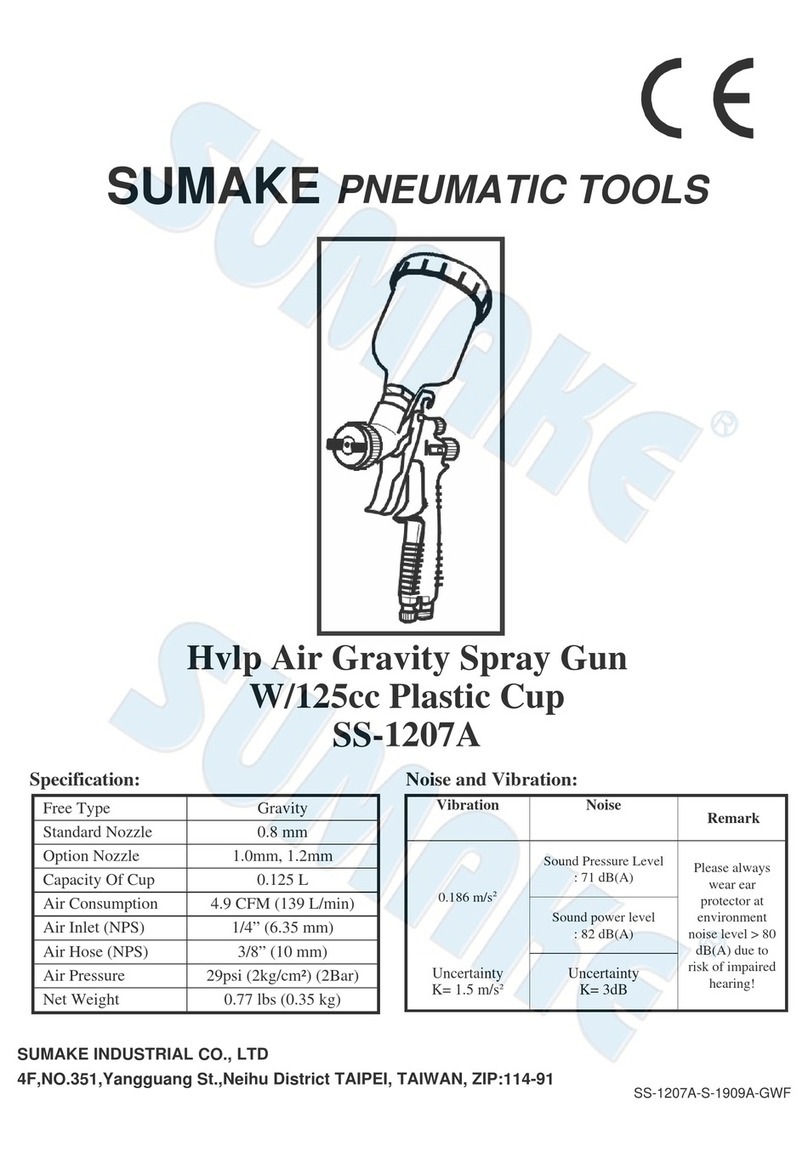

Sumake SS-1207 User manual

Sumake

Sumake HVLP-3000SA User manual

Sumake

Sumake SS-1303WHG User manual

Sumake

Sumake SS-1208B User manual

Sumake

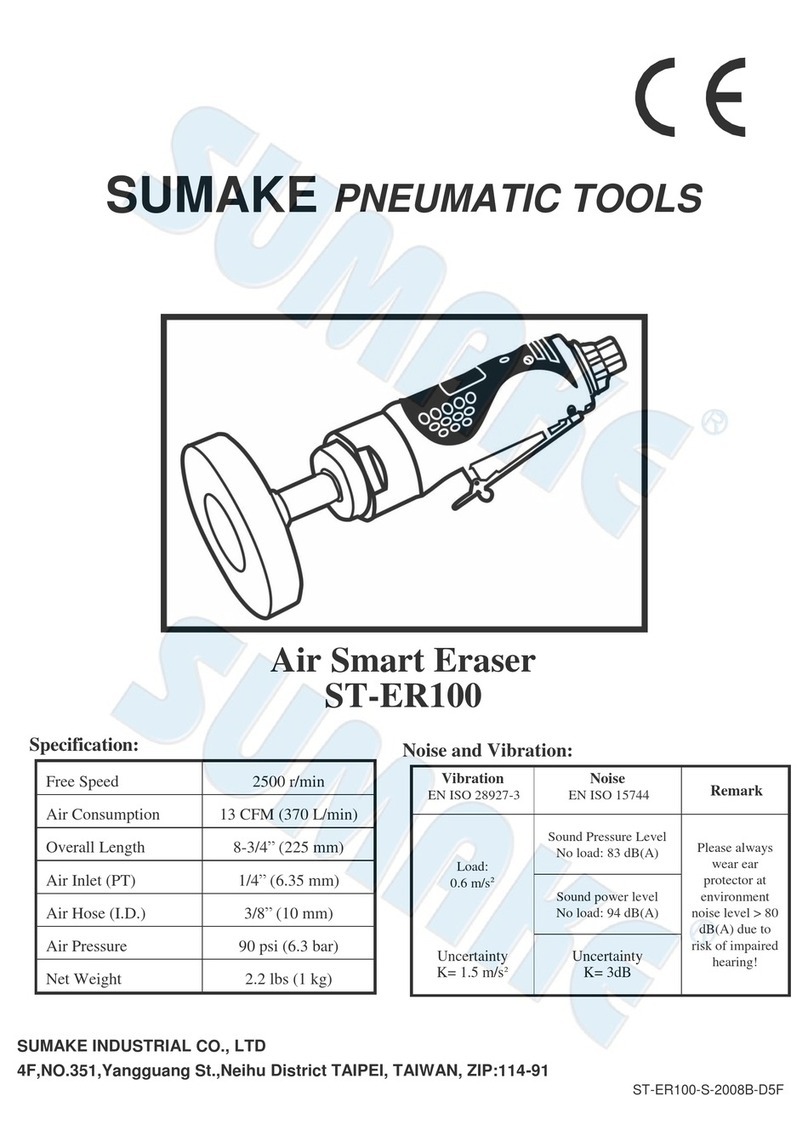

Sumake ST-ER100 User manual

Sumake

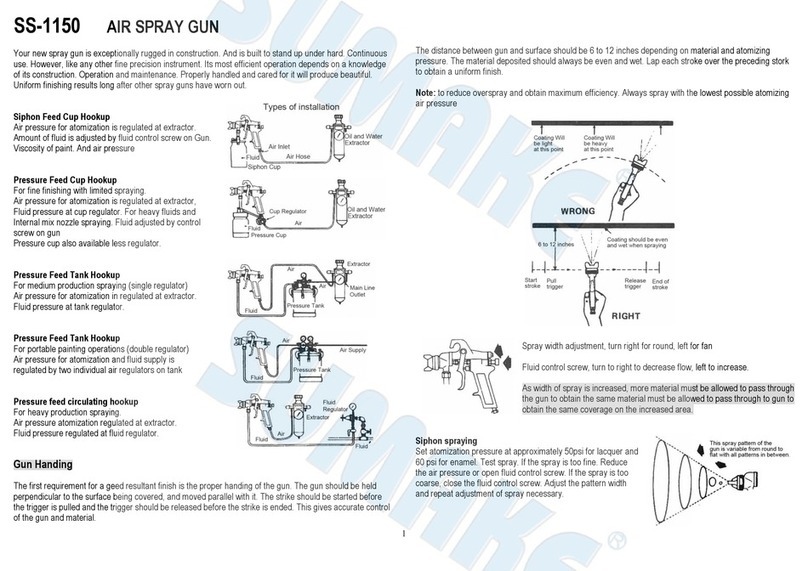

Sumake SS-1150 User manual

Sumake

Sumake SS-1303LG User manual

Sumake

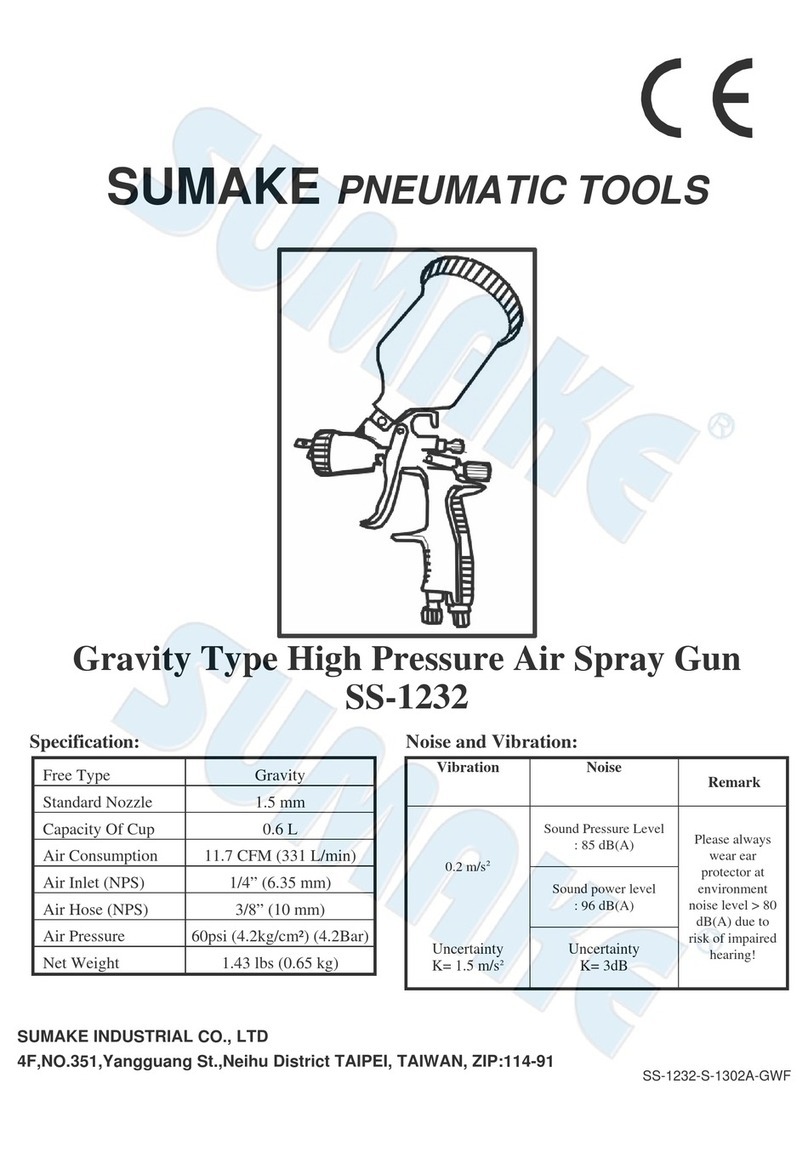

Sumake SS-1232 User manual

Sumake

Sumake SS-1111 User manual

Sumake

Sumake SS-1108R User manual

Sumake

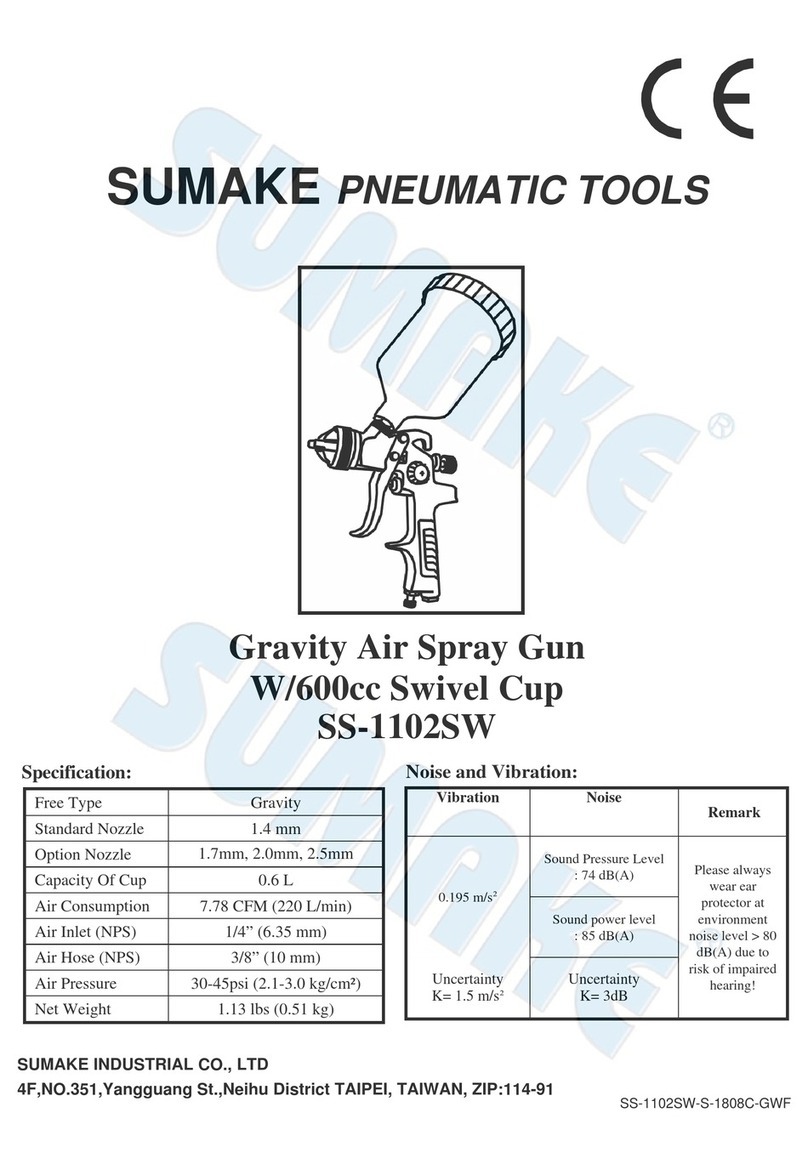

Sumake SS-1102SW User manual

Sumake

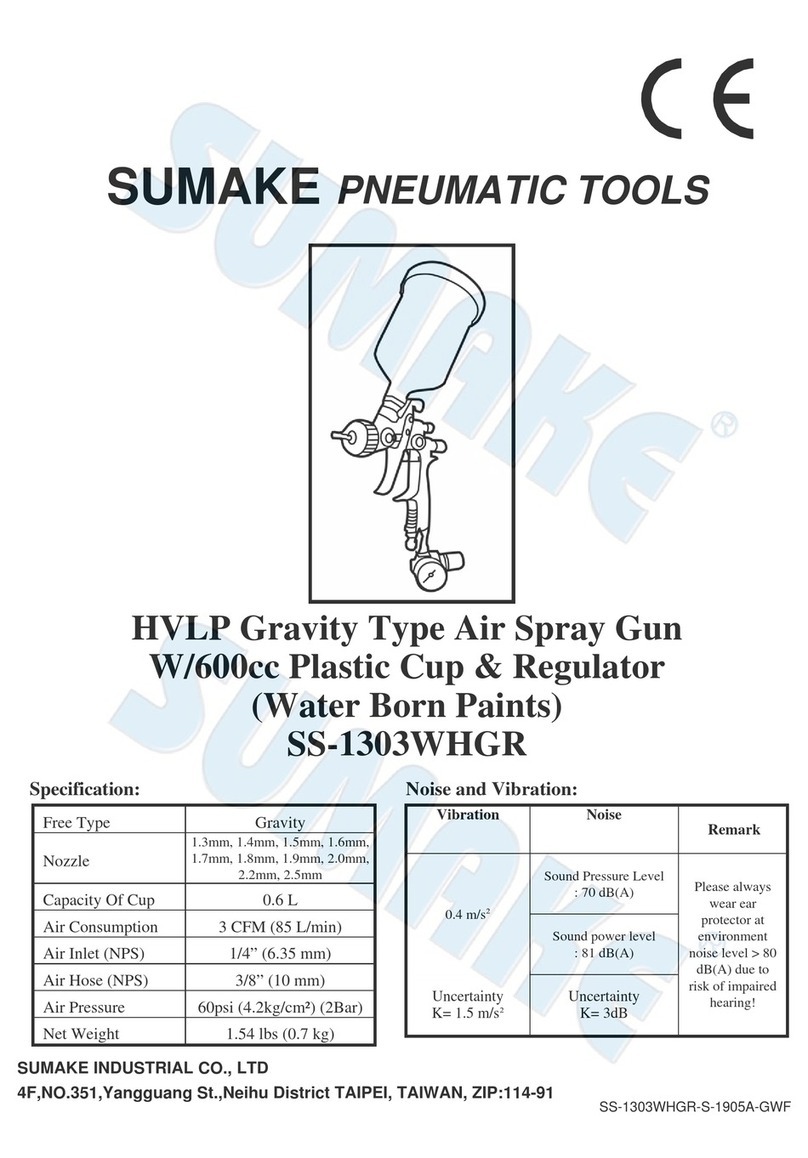

Sumake SS-1303WHGR User manual

Sumake

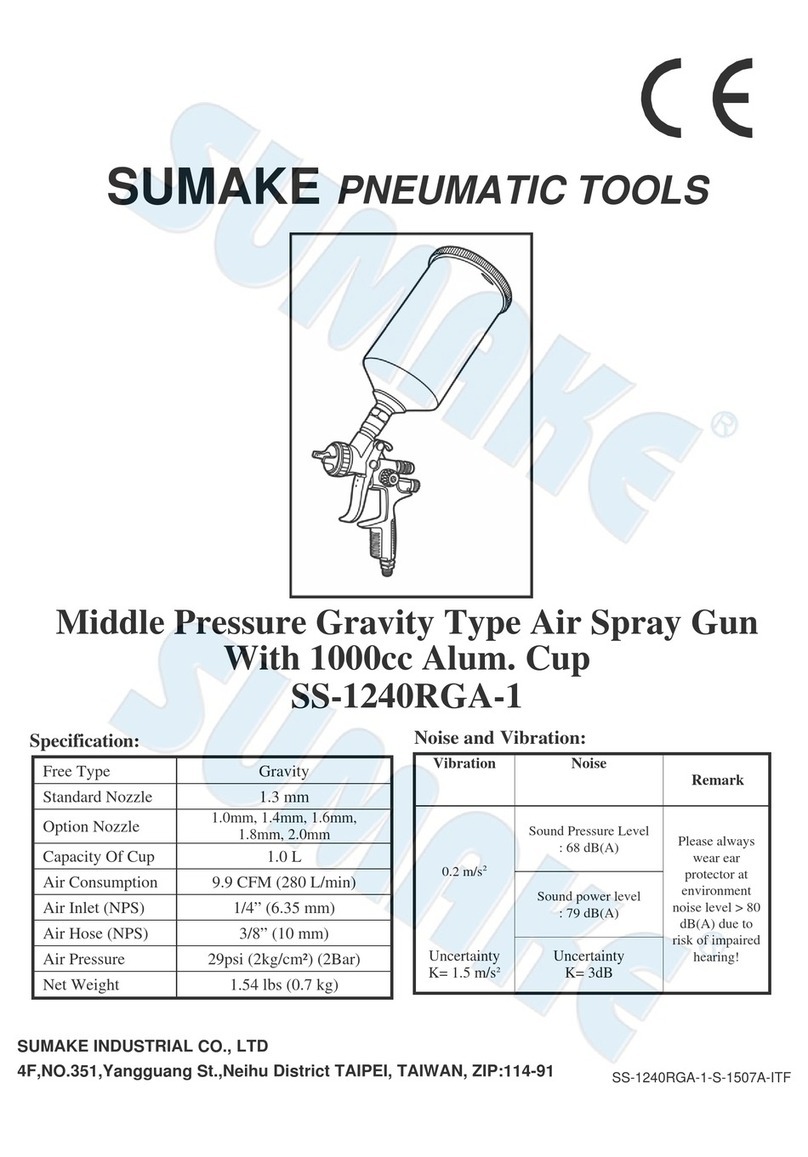

Sumake SS-1240RGA-1 User manual

Sumake

Sumake SS-1305HS User manual

Sumake

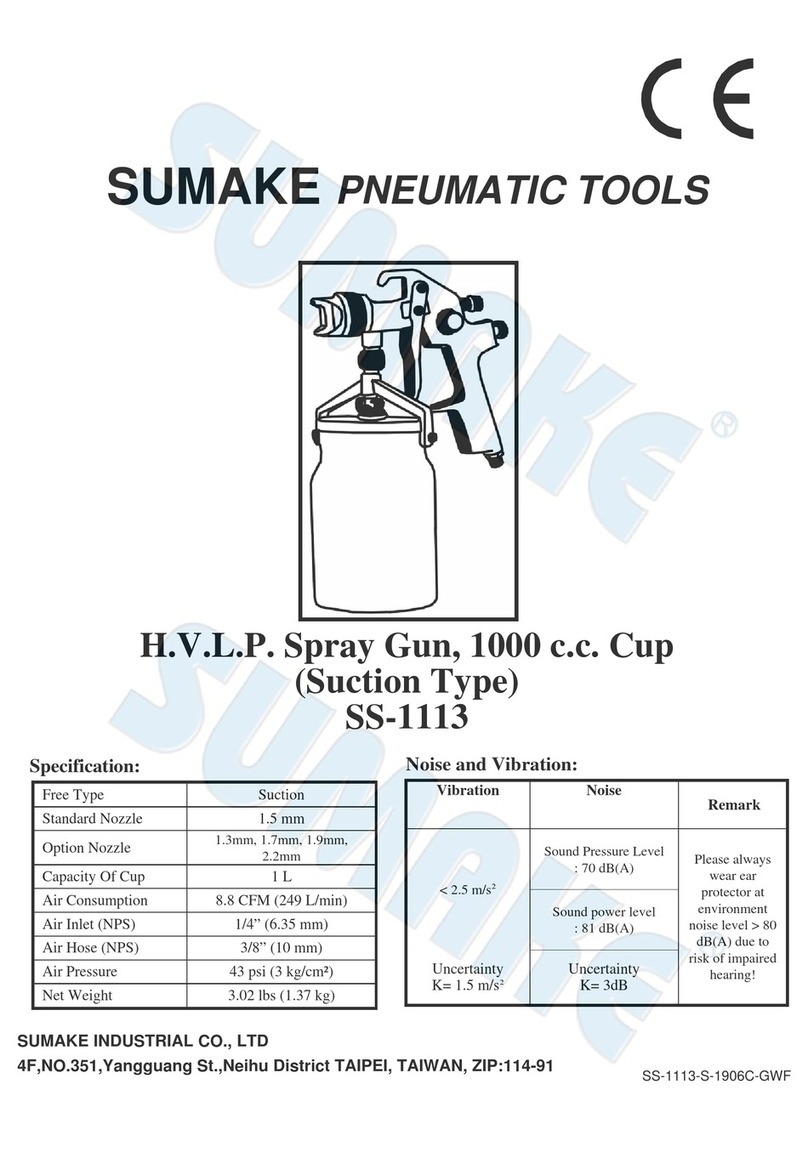

Sumake SS-1113 User manual

Sumake

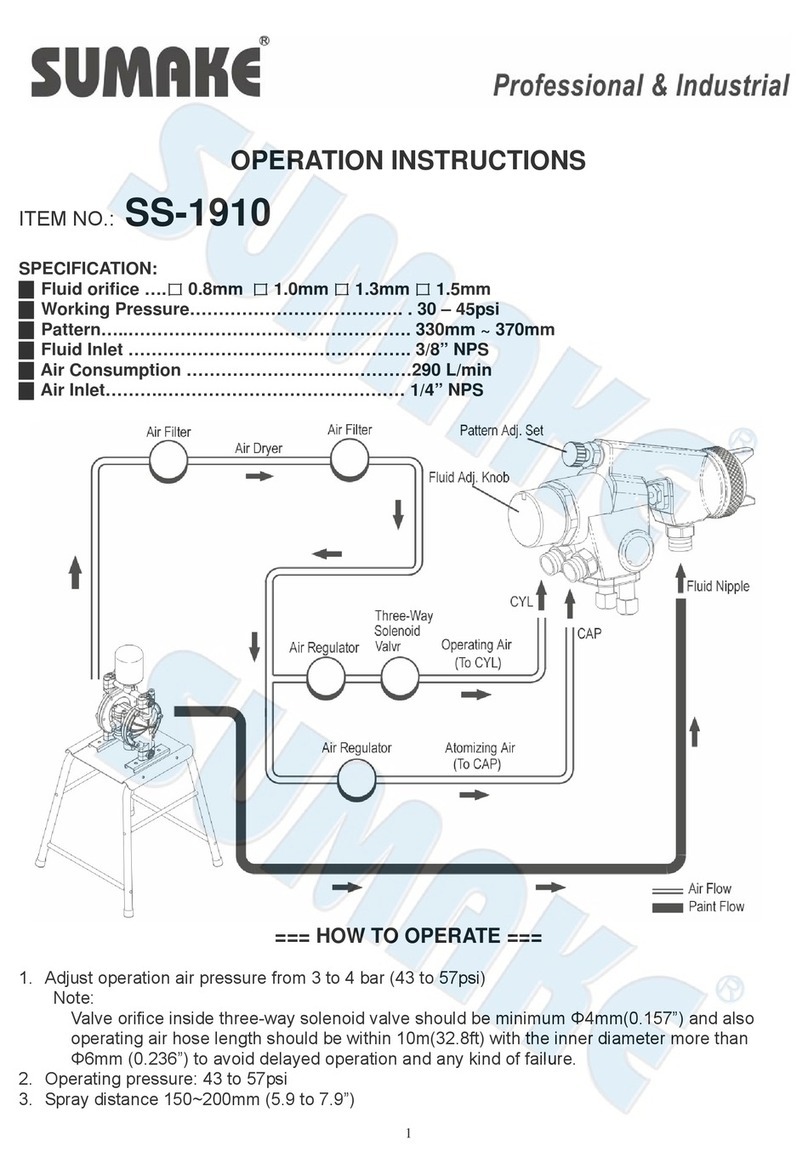

Sumake SS-1910 User manual

Sumake

Sumake SS-1180S User manual

Sumake

Sumake SS-1305HSPS User manual

Sumake

Sumake SS-1305HSPA-R User manual

Sumake

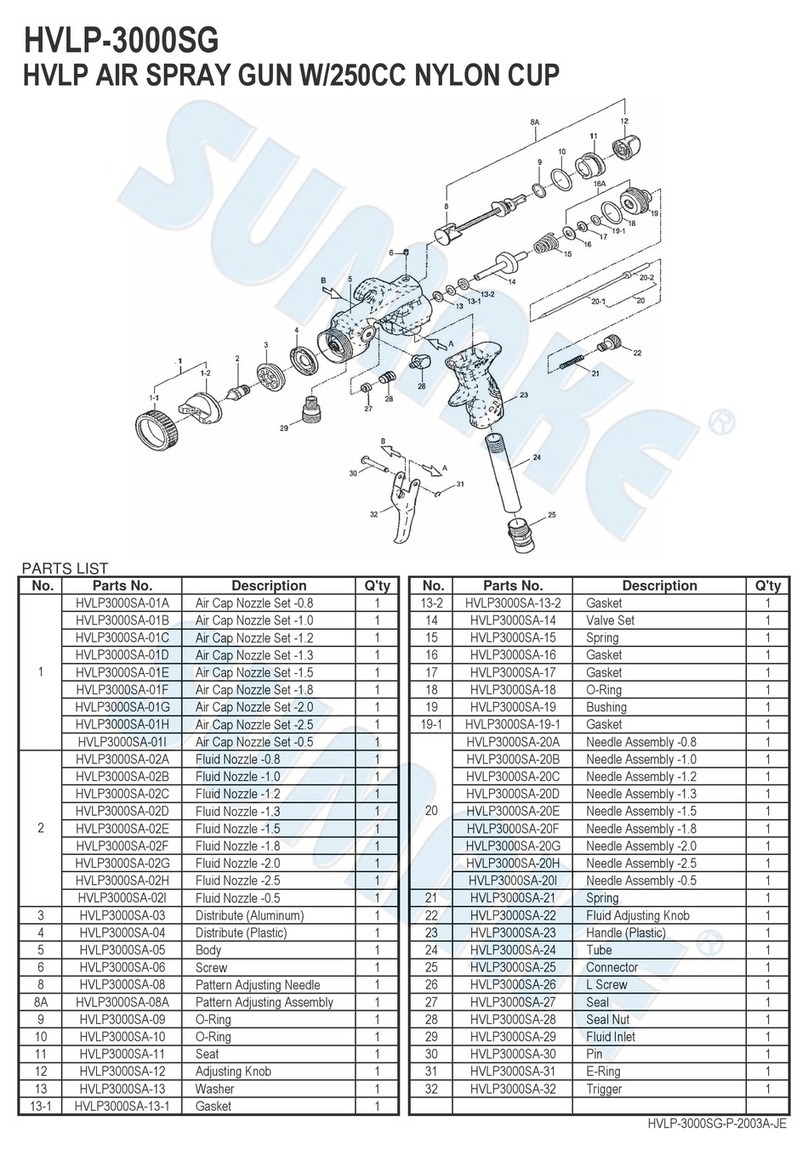

Sumake HVLP-3000SG User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual