INSTRUCTION MANUAL

Prior to operation read the operating instructions carefully.

LVLP(HLVP) [Lower (High) Volume Low Pressure] spraying equipment has been developed as an

introduction of the environmental protection action. HVLP equipment uses less air (less than 10 psi, 0.69

bar at the cap), but with a higher throughput resulting in more paint staying on the workpiece while less

released into the atmosphere. Most novices to the paint industry will be surprised to learn that HVLP guns

come in a variety of designs concepts.

HVLP showed that high pressure was not necessary to spray paint. Low pressure could work in exactly the

same way -with one major difference - the lower velocity of the air resulted in less overspray and wasted

paint.

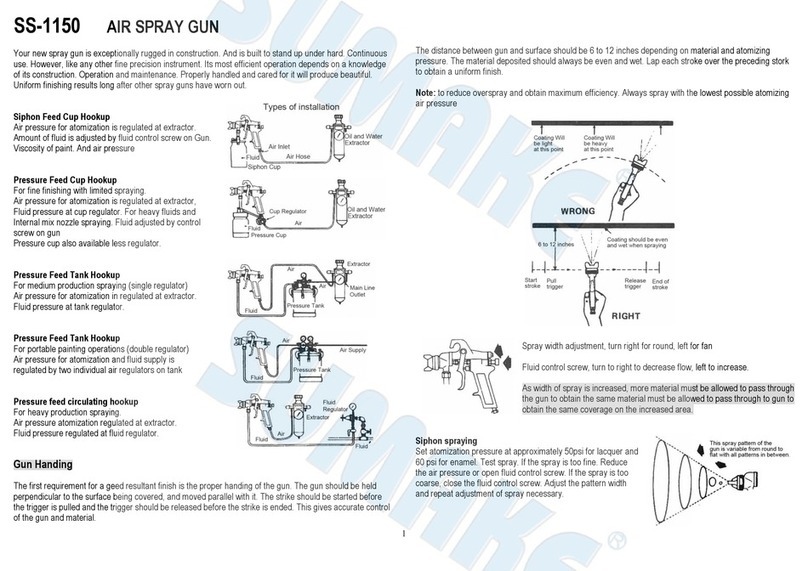

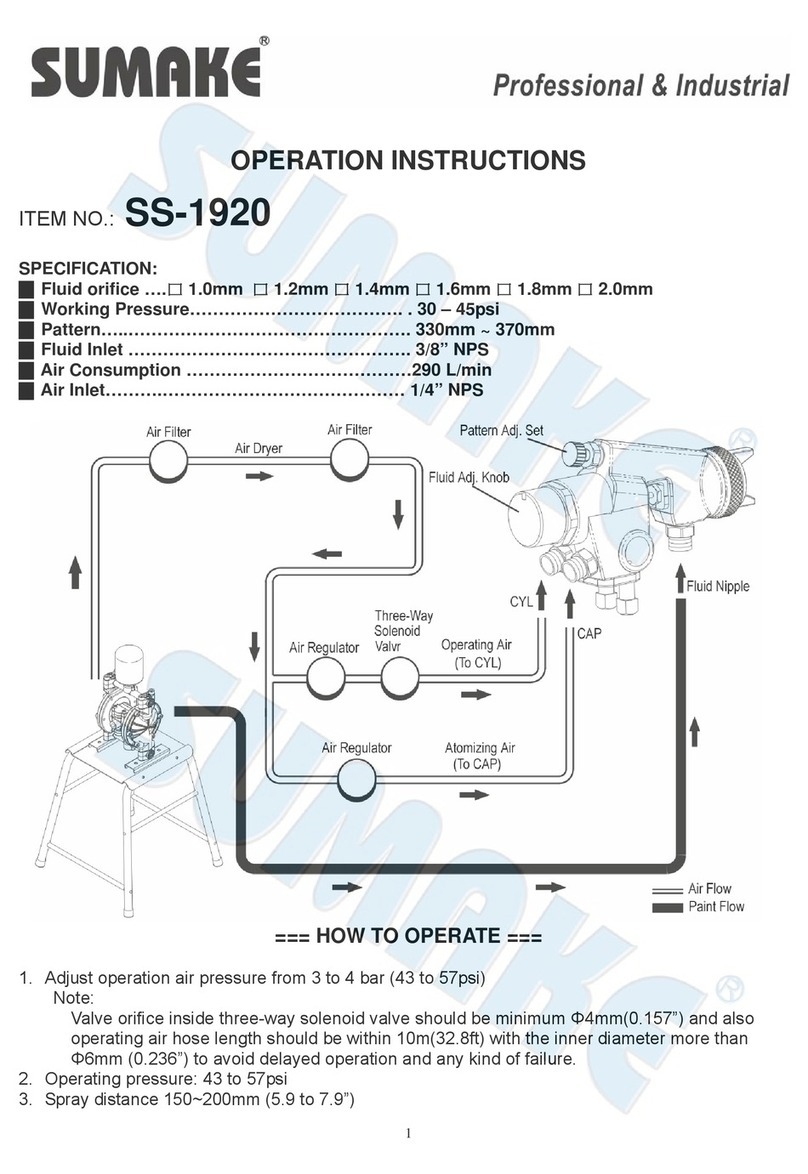

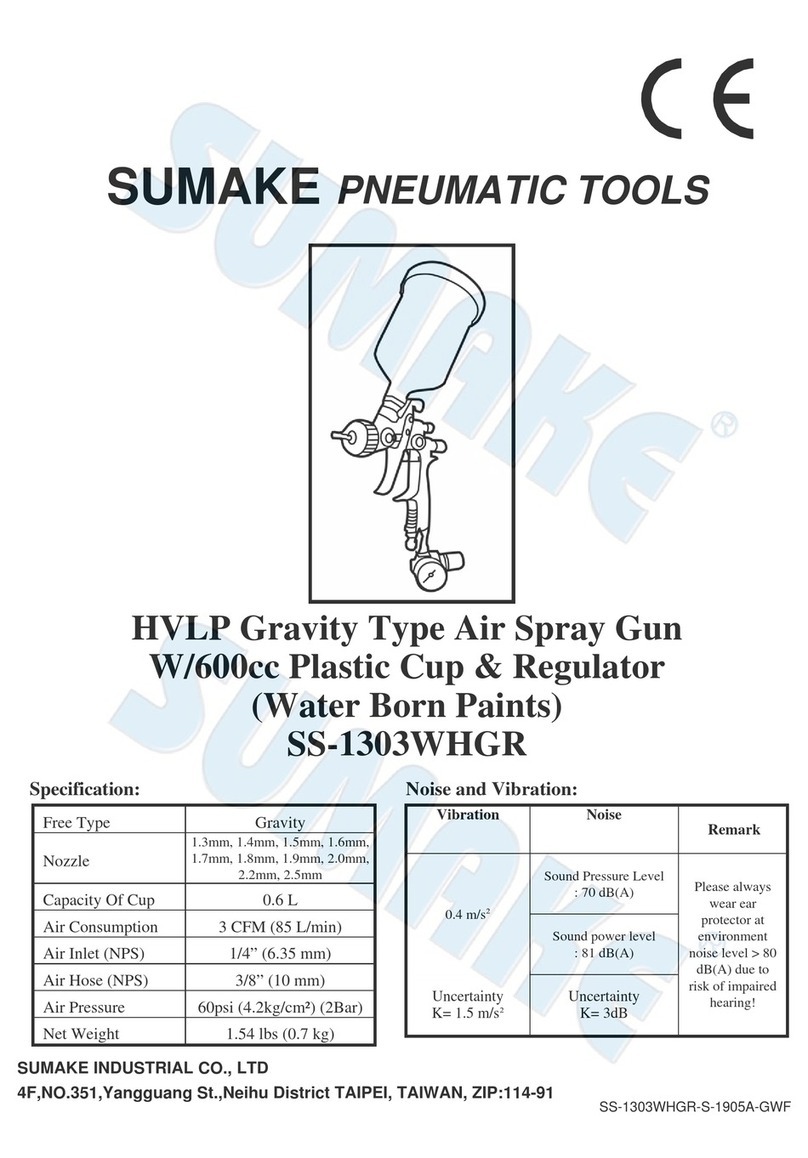

OPERATION

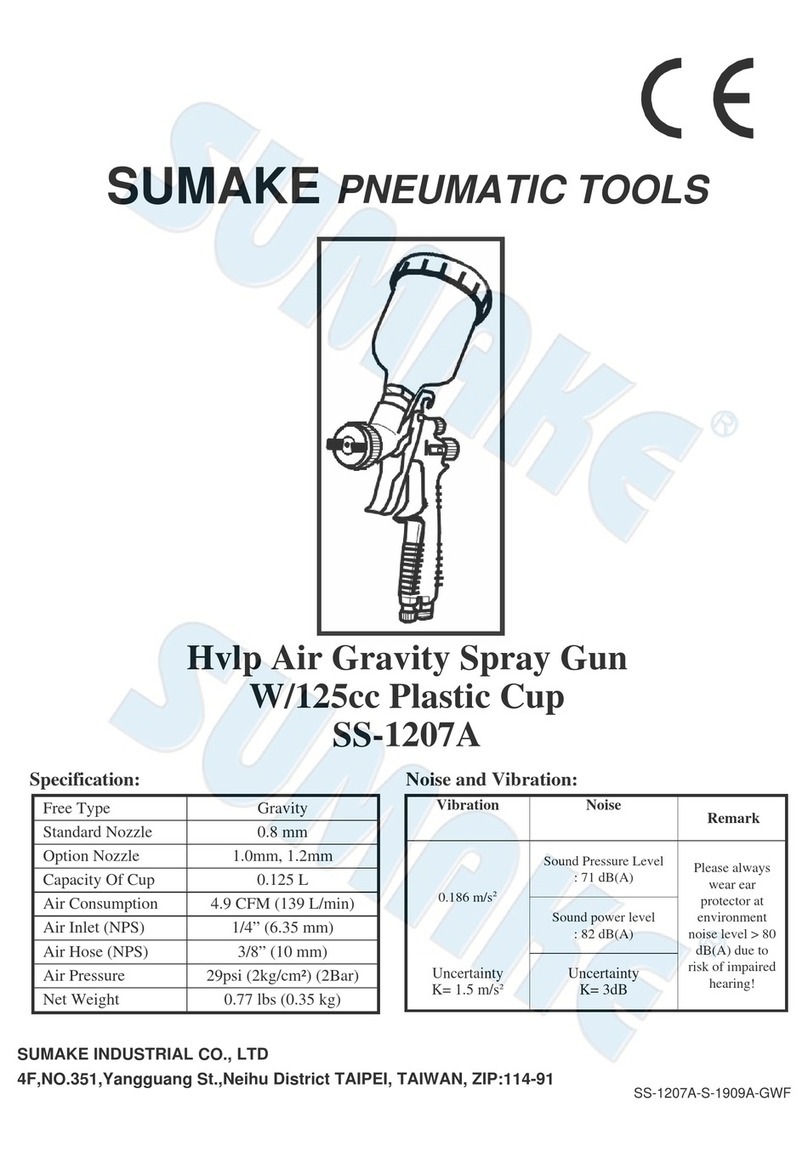

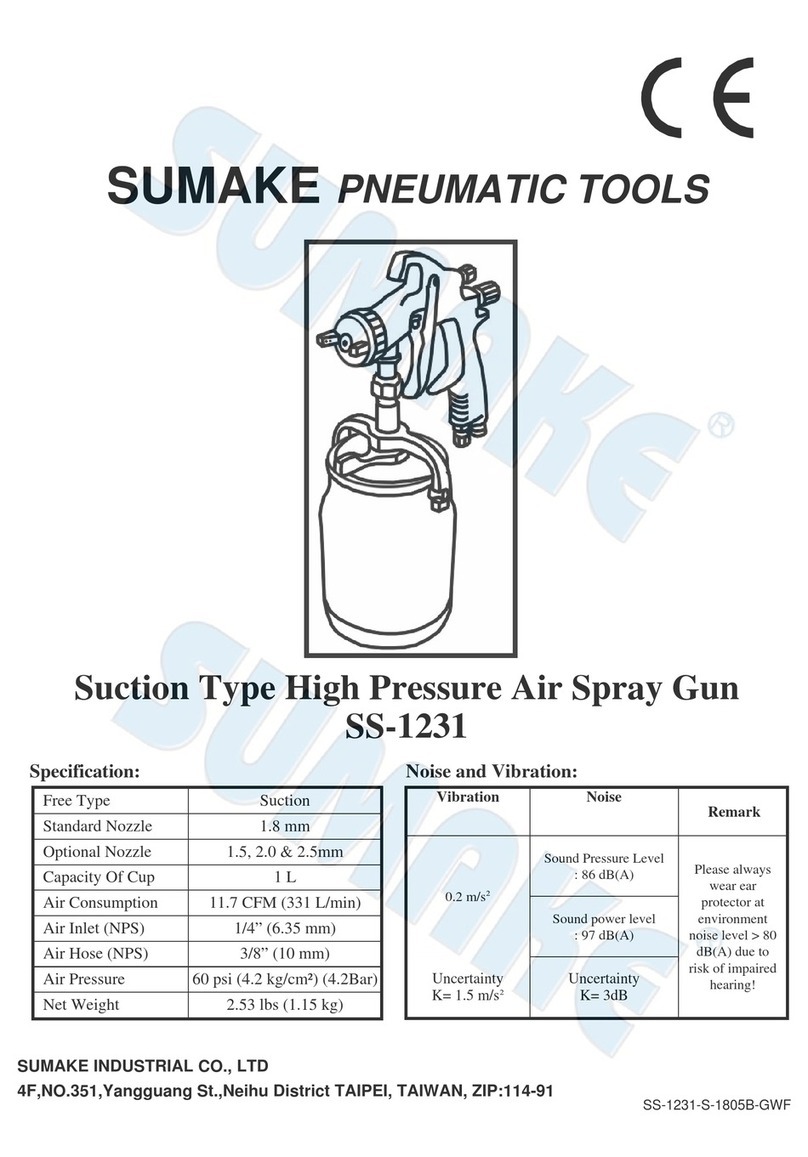

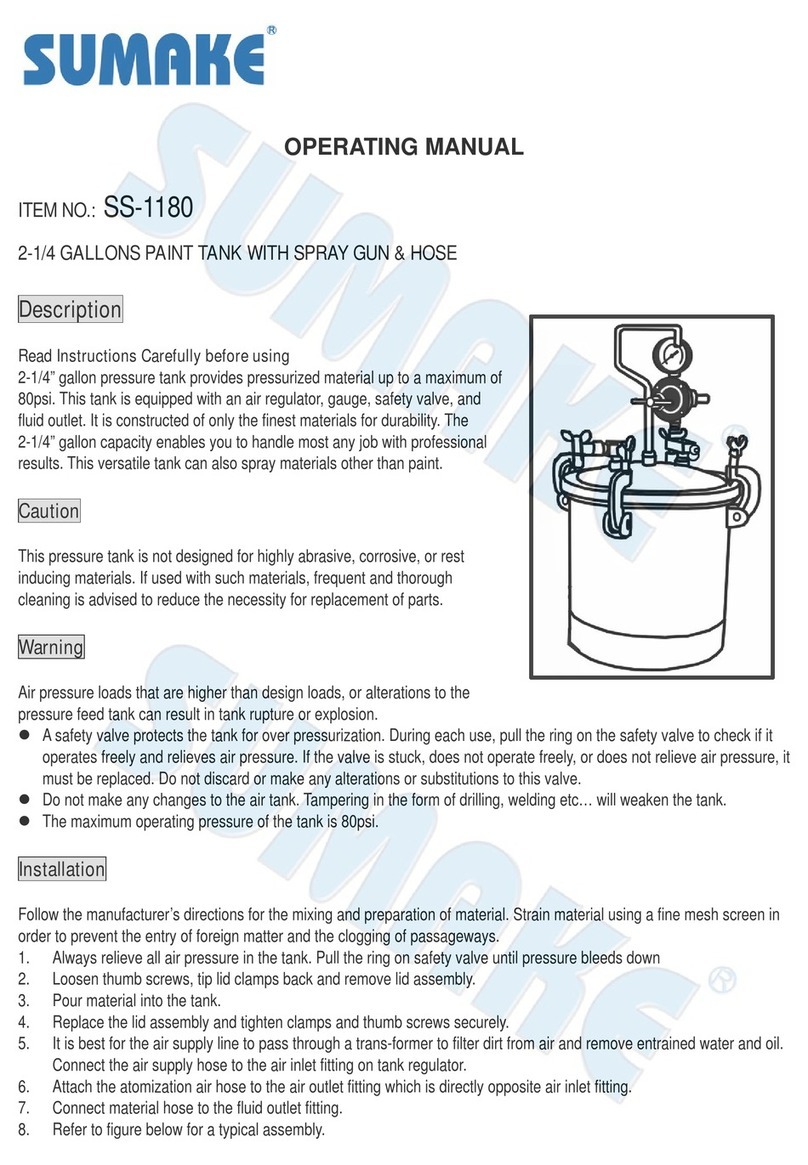

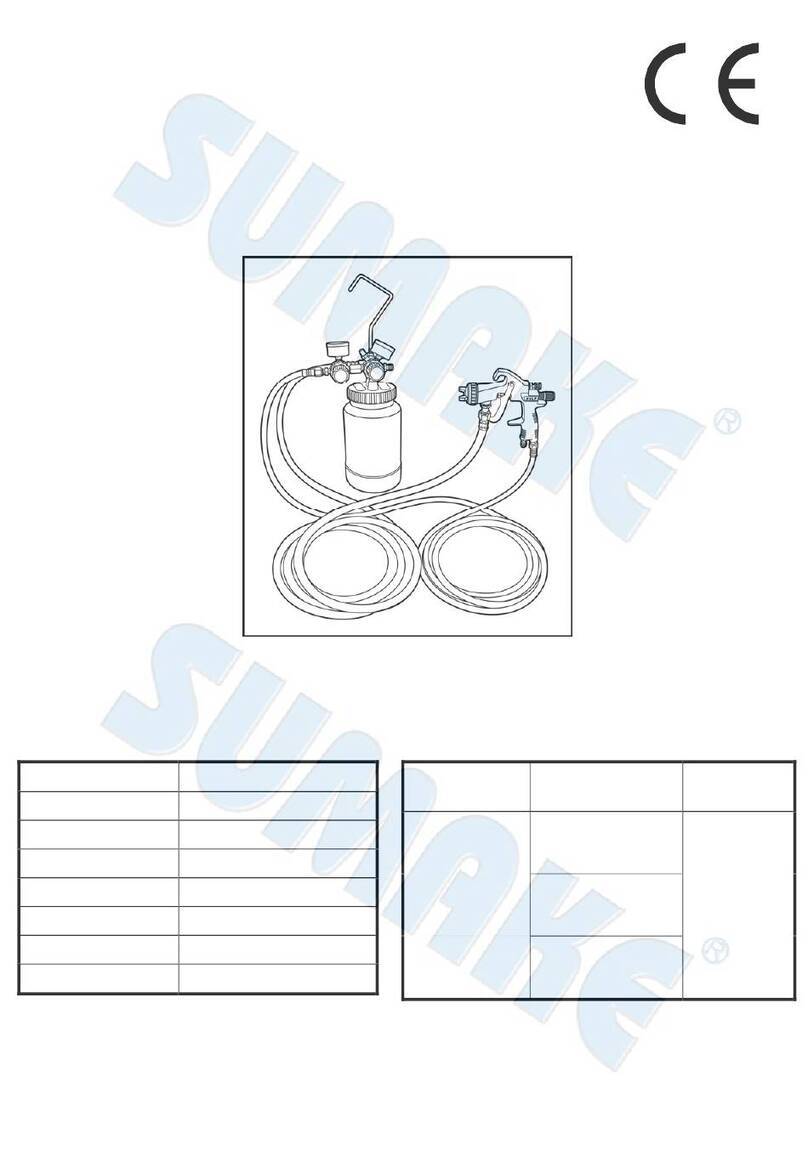

The Spray Gun should be connected to a clean air

supply using the recommended fittings and hose

size as specified in the diagram. Whenever possible

there should be an air filter & regulator in the system

as diagram. Check fittings and hoses regularly for

signs of fraying, or accidental damage. Replace any

worn

items before continuing to operate the Spray Gun.

Always connect the cup and the air hose tightly to

the Spray Gun before use. Ensure the material and

air supply are disconnected before effecting any

work on the Spray Gun.

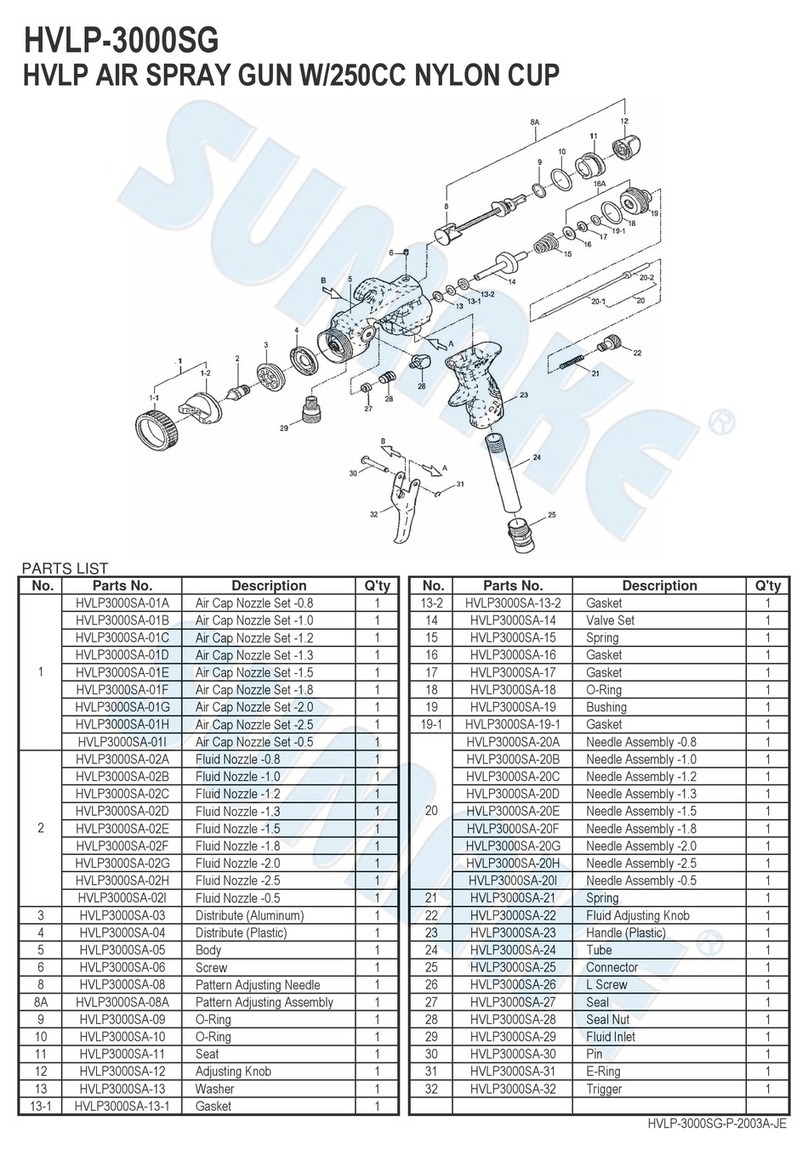

ADJUSTMENT

To obtain the required spraying pattern, volume of fluid and degree of atomisation, use the PatternAdjusting

Knob,AirAdjusting Knob and the FluidAdjusting Knob.

1. ToAdjust the Pattern-Turn the PatternAdjusting Knob to the Left to widen the spray pattern and to

the Right to narrow the spray pattern.

2. ToAdjust the Fluid Output-Turn the FluidAdjusting Knob to the Right to reduce the fluid output and to

the Left to increase the fluid output. Turning the FluidAdjusting Knob fully to the Right will slop the

fluid completely, the spray gun will then only emit air.

3. ToAdjust the AirVolume-Turn theAirAdjusting Knob to the Right to reduce the air volume and to the

Left to increase the air volume.

4. The recommended air pressure is 0.7-2.8 bar (15-43 psi). Therecommended spray distance toobject

is 15 - 20 cm (6-8 inches).

SERVICING

1. Clean air cap, fluid newly and fluid needle with brush after each operation.

2. Do not submerge complete spray gun in solvent.

3. Flush the gun material passage with a compatible solvent.

4. Fluid needle packing set should not be tighten completely, or the needle will be sluggish.

5. Turning the fluid adjusting knob too far to the left will weaken the fluid needle spring, this will make the

fluid nozzle to lea

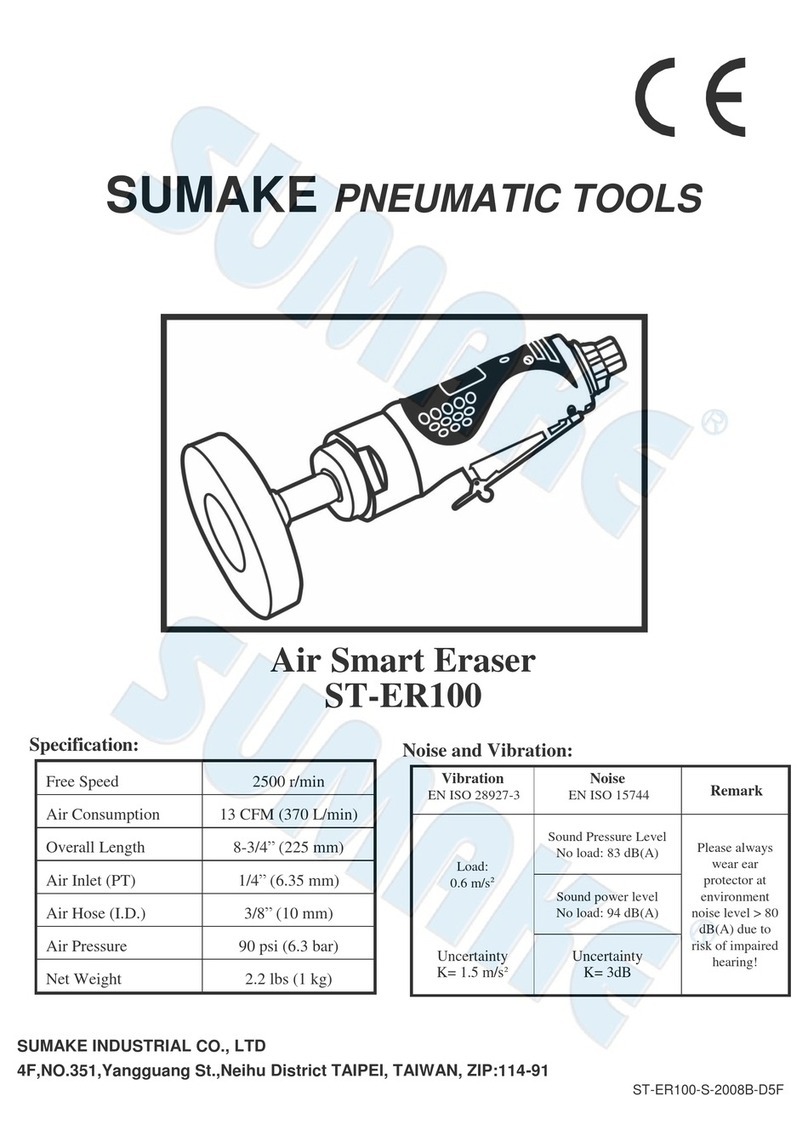

PERSONAL PROTECTIVE EQUIPMENT

The use of breathing mask is recommended at all times when spraying. The noise level may exceed

85 dB(A) when the spray gun is being used, a sound absorber protection is also recommended. Always

wear goggles and gloves when spraying or cleaning. There are no vibrations to be transmitted to the

operator when using the spray gun. lower back stroke.

SAFETY

1. Never allow untrained or unauthorized persons to operate this spray gun.

2. Never exceed the recommended air pressure.

3. Do not carry or pull the gun by the hose, this could cause failure of the hose/gun connection and

result in danger to the operator or other workers. 4.Use only original spare parts.

4. Never use matches, smoke or operate a spray gun in the vicinity of a naked flame.

5. Do not use the following solvents.1,1,1-Trichloroethane and Methylene Chloride.These solvents can

chemically react with aluminum used in spray guns and fluid cups possibly causing an explosion. Do

not use these solvents for equipment cleaning or flushing. Spray gun should never be stored in acid

laden

6. cleaners. If in doubt consult the material supplier.

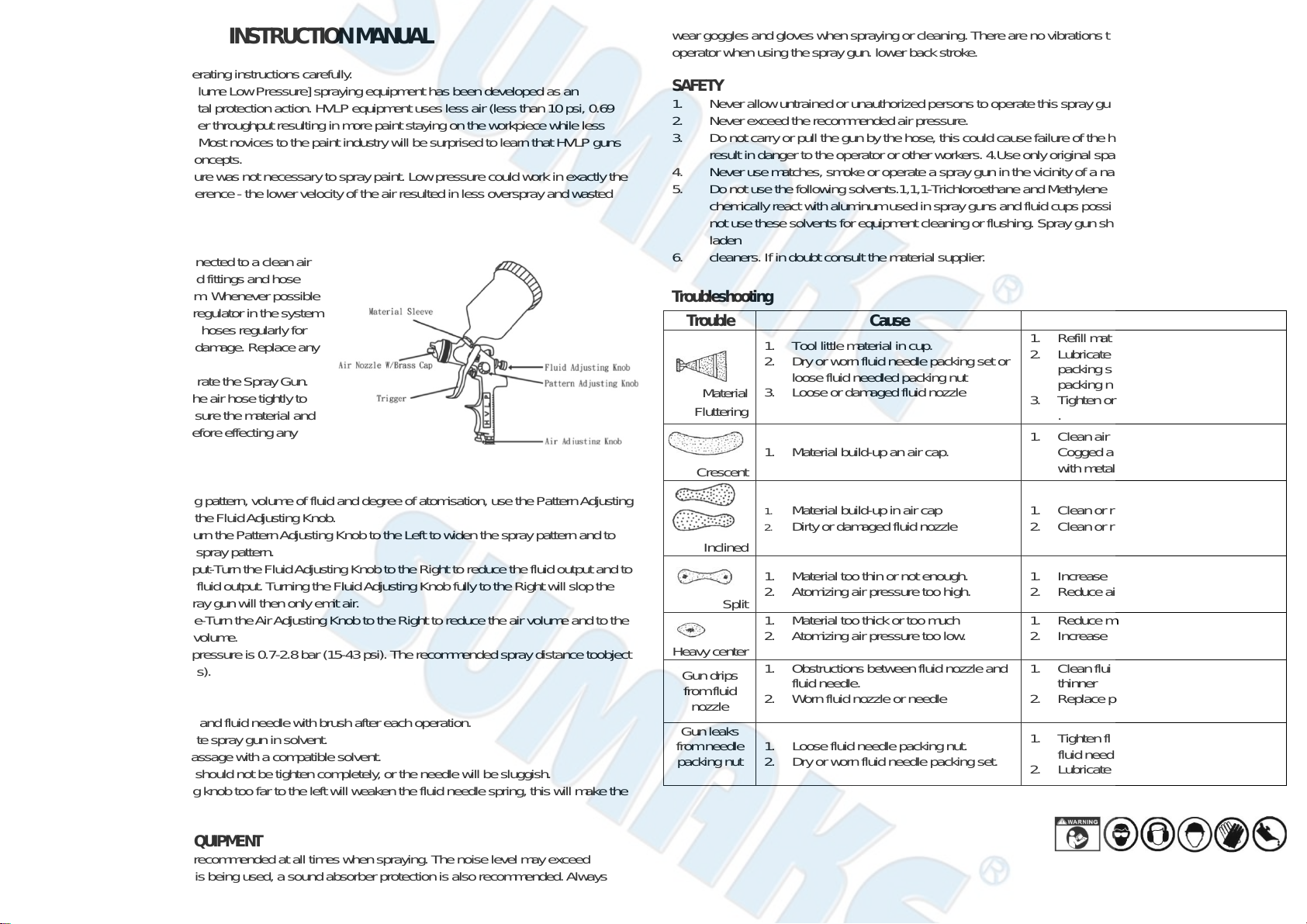

Troubleshooting

Trouble Cause Correction

Material

Fluttering

1. Tool little material in cup.

2. Dry or worn fluid needle packing set or

loose fluid needled packing nut

3. Loose or damaged fluid nozzle

1. Refill material.

2. Lubricate or replace fluid needle

packing set or tighten fluid needle

packing nut

3. Tighten or replace fluid nozzle

.

Crescent 1. Material build-up an air cap. 1. Clean air cap with proper objects.

Cogged air holes must not be cleaned

with metal objects

Inclined

1. Material build-up in air cap

2. Dirty or damaged fluid nozzle 1. Clean or replace air cap.

2. Clean or replace fluid nozzle.

Split

1. Material too thin or not enough.

2. Atomizing air pressure too high. 1. Increase material viscosity.

2. Reduce air pressure.

Heavy center

1. Material too thick or too much

2. Atomizing air pressure too low.

1. Reduce material viscosit

2. Increase air pressure.

Gun drips

from fluid

nozzle

1. Obstructions between fluid nozzle and

fluid needle.

2. Worn fluid nozzle or needle

1. Clean fluid needle and fluid nozzle in

thinner

2. Replace parts

Gun leaks

from needle

packing nut

1. Loose fluid needle packing nut.

2. Dry or worn fluid needle packing set. 1. Tighten fluid needle packing nut ,check

fluid needle for free movement.

2. Lubricate or replace.

SS-1303-I-1905B-GW