Safety precautions for repetitive motions hazards

1. When using the tool, the operator may experience discomfort in the hands, arms, shoulders, neck, or other parts of the body.

2. While using the tool, the operator should adopt a comfortable posture. Maintain secure footing and avoid awkward or off-balanced

postures. The operator should change the posture during extended tasks which may help avoid discomfort and fatigue.

3. If the operator experience symptoms such as persistent or recurring discomfort, pain, throbbing, aching, tingling, numbness, burning

sensation or stiffness, these warning signs should not be ignored. The operator should tell the employer and consult a qualified health

professional.

Safety precautions for accessory hazards

1. Disconnect power tool from energy supply before changing the accessory.

2. Only use sizes and types of accessories and consumables that are recommended by the tool manufacturer.

Safety precautions for workplace hazards

1. Slips, trips and falls are major causes of workplace injury. Be aware of slippery surfaces caused by use of the tool and also of trip hazards

caused by the air line.

2. Proceed with care in unfamiliar surroundings. Hidden hazards may exist, such as electricity or other utility lines.

3. The tool is not intended for use in potentially explosive atmospheres and is not insulated from coming into contact with electric power.

4. Make sure there are no electrical cables, gas pipes etc. that could cause a hazard if damaged by use of the tool.

Safety precautions for dust and fume hazards

1. Dusts and fumes generated when using the tool can cause ill health (for example: cancer, birth defects, asthma and/or dermatitis); risk

assessment of these hazards and implementation of appropriate controls of is essential.

2. Risk assessment should include dust created by the use of the tool and the potential for disturbing existing dust.

3. Operate and maintain the power tool as recommended in these instructions, to minimise dust or fume emissions.

4. Direct the exhaust so as to minimise disturbance of dust in a dust filled environment

5. Where dusts or fumes are created, the priority shall be to control them at the point of emission.

6. All integral features or accessories for the collection, extraction or suppression of airborne dust or fumes should be correctly used and

maintained in accordance with the manufacturer’s instructions.

7. Use respiratory protection as instructed by your employer or as required by occupational health and safety regulations.

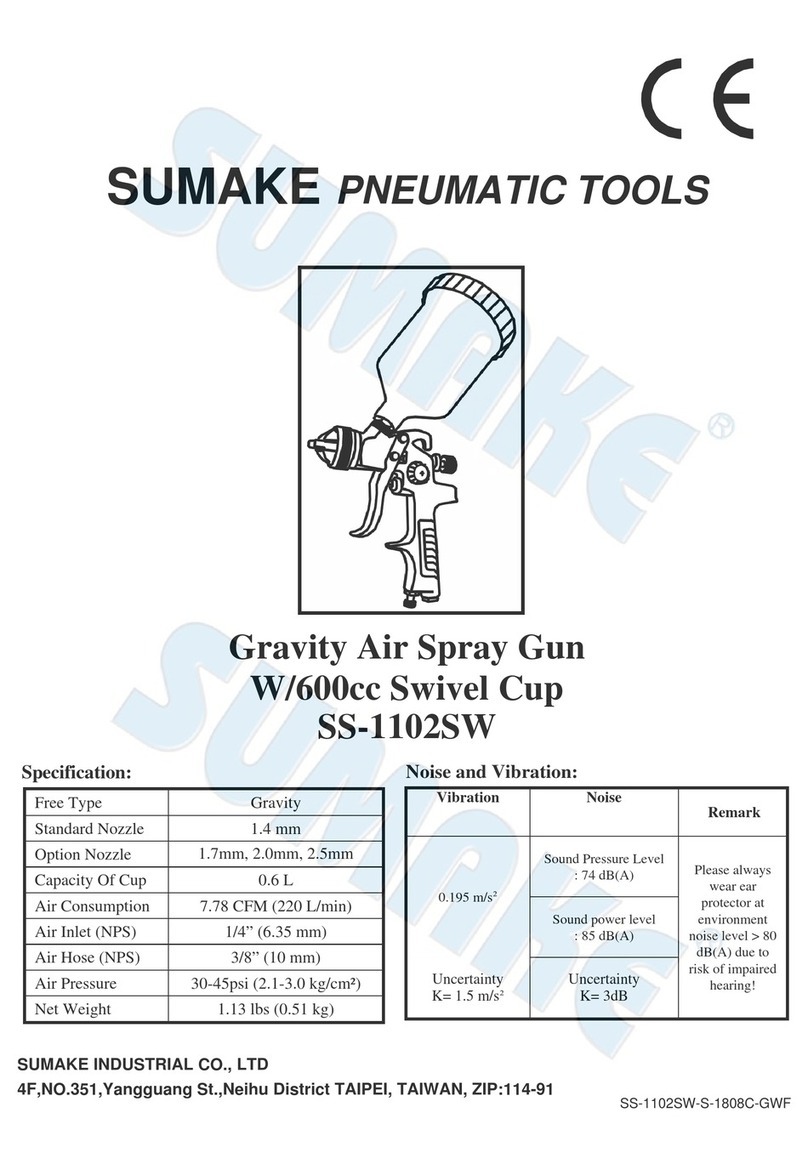

Safety precautions for noise hazards

1. Unprotected exposure to high noise levels can cause permanent, disabling, hearing loss and other problems such as tinnitus (ringing,

buzzing, whistling or humming in the ears).

2. Risk assessment of these hazards and implementation of appropriate controls of is essential.

3. Appropriate controls to reduce the risk may include actions such as damping materials to prevent work pieces from ‘ringing’.

4. Use hearing protection as instructed by your employer or as required by occupational health and safety regulations.

5. Operate and maintain the power tool as recommended in these instructions, to prevent an unnecessary increase in noise.

6. If the tool has a silencer, always ensure it is in place and in good working order when the tool is operating.

7. Select, maintain and replace the consumable/inserted tool as recommended in these instructions, to prevent an unnecessary increase in

noise.

Safety precautions for vibration hazards

1. Exposure to vibration can cause disabling damage to the nerves and blood supply of the hands and arms.

2. Wear warm clothing when working in cold conditions and keep your hands warm and dry.

3. If you experience numbness, tingling, pain or whitening of the skin in your fingers or hands, stop using the assembly power tool for

non-threaded mechanical fasteners, tell your employer and consult a physician.

4. Support the weight of the tool in a stand, tensioner or balancer, because the operator can then use a lighter grip to support the tool.

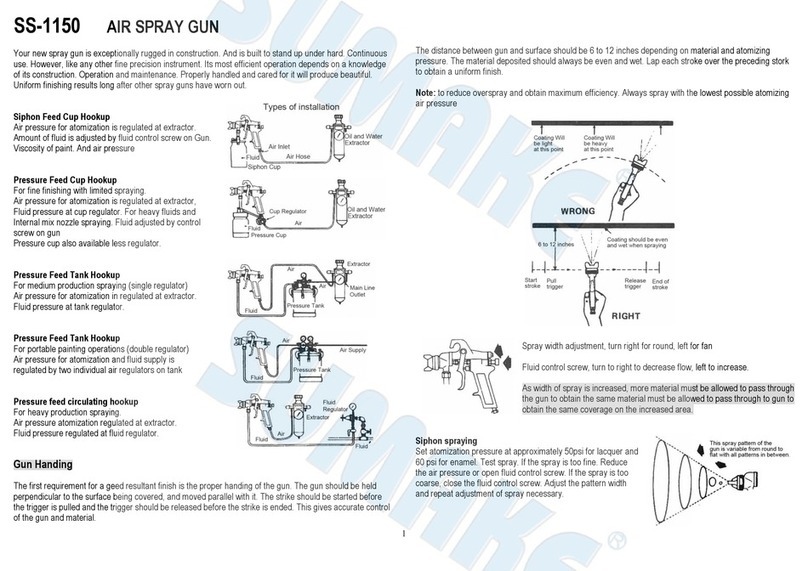

Additional safety instructions for pneumatic power tools

1. Always shut off air supply, drain hose of air pressure and disconnect tool from air supply when not in use, before changing accessories or

when making repairs.

2. Never direct spraying air or liquid at yourself or anyone else.

3. Whipping hoses can cause severe injury. Always check for damaged or loose hoses and fittings.

4. Cold air shall be directed away from the hands.

5. Whenever universal twist couplings (claw couplings) are used, lock pins shall be installed and whipcheck safety cables shall be used to

safeguard against possible hose-to-tool and hose-and-hose connection failure.

6. Do not exceed the maximum air pressure stated on the tool.

7. Never carry an air tool by the hose.

Specific safety instructions

Warnings shall be given about any specific or unusual hazards associated with the use of the power tool. Such warnings shall indicate the

nature of the hazard, the risk of injury and the avoidance action to take.