Sumake SS-1170T User manual

Other Sumake Paint Sprayer manuals

Sumake

Sumake SS-1111 User manual

Sumake

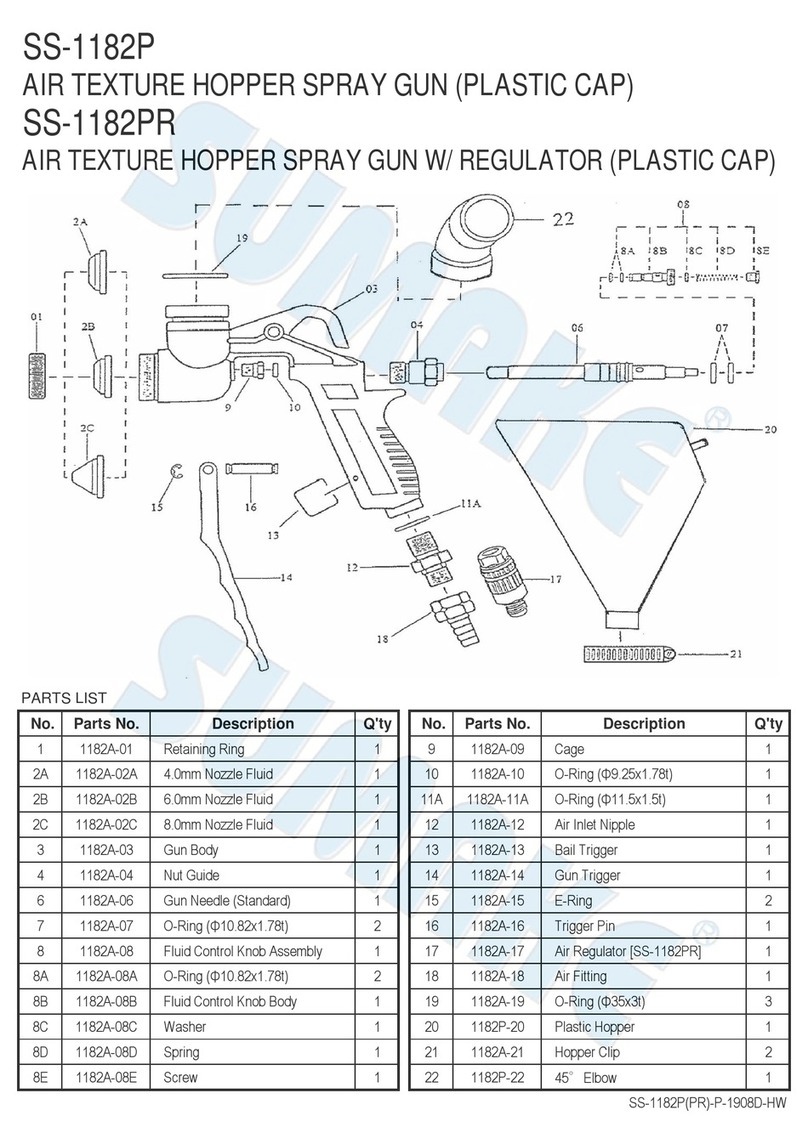

Sumake SS-1182P User manual

Sumake

Sumake HVLP-3000SA User manual

Sumake

Sumake SS-1303WHG User manual

Sumake

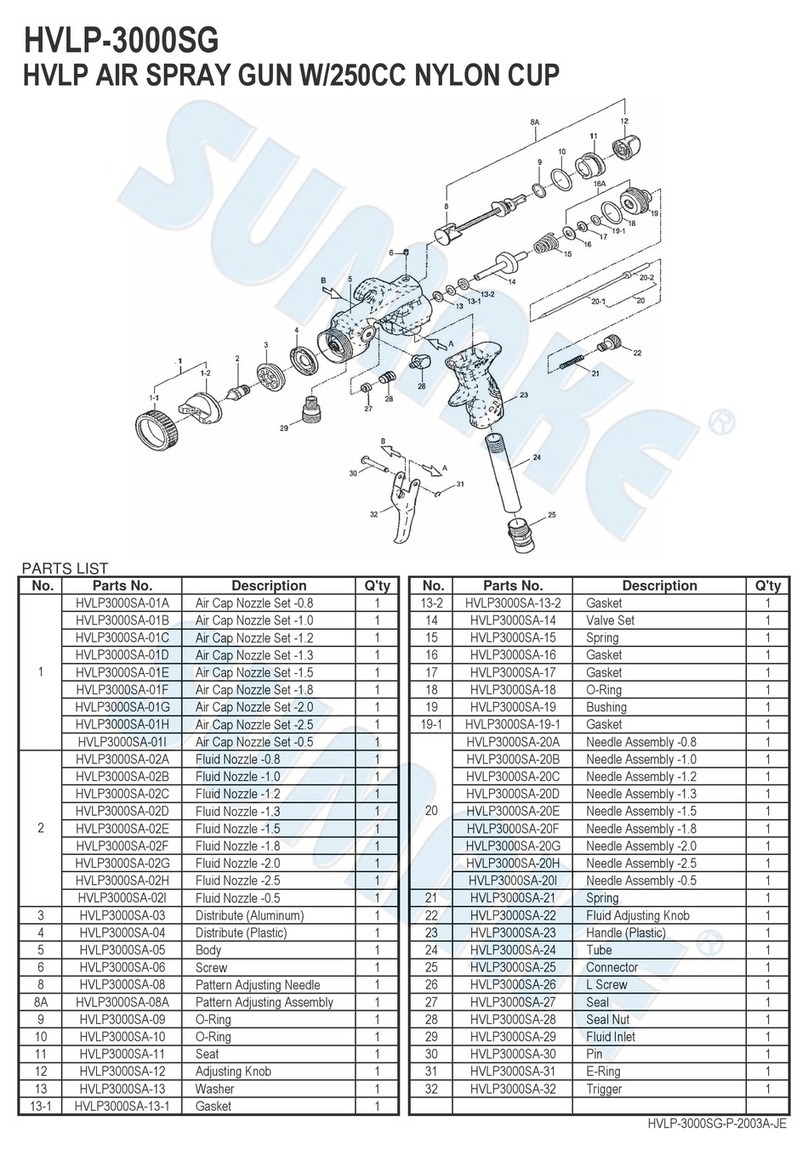

Sumake HVLP-3000SG User manual

Sumake

Sumake SS-1203 User manual

Sumake

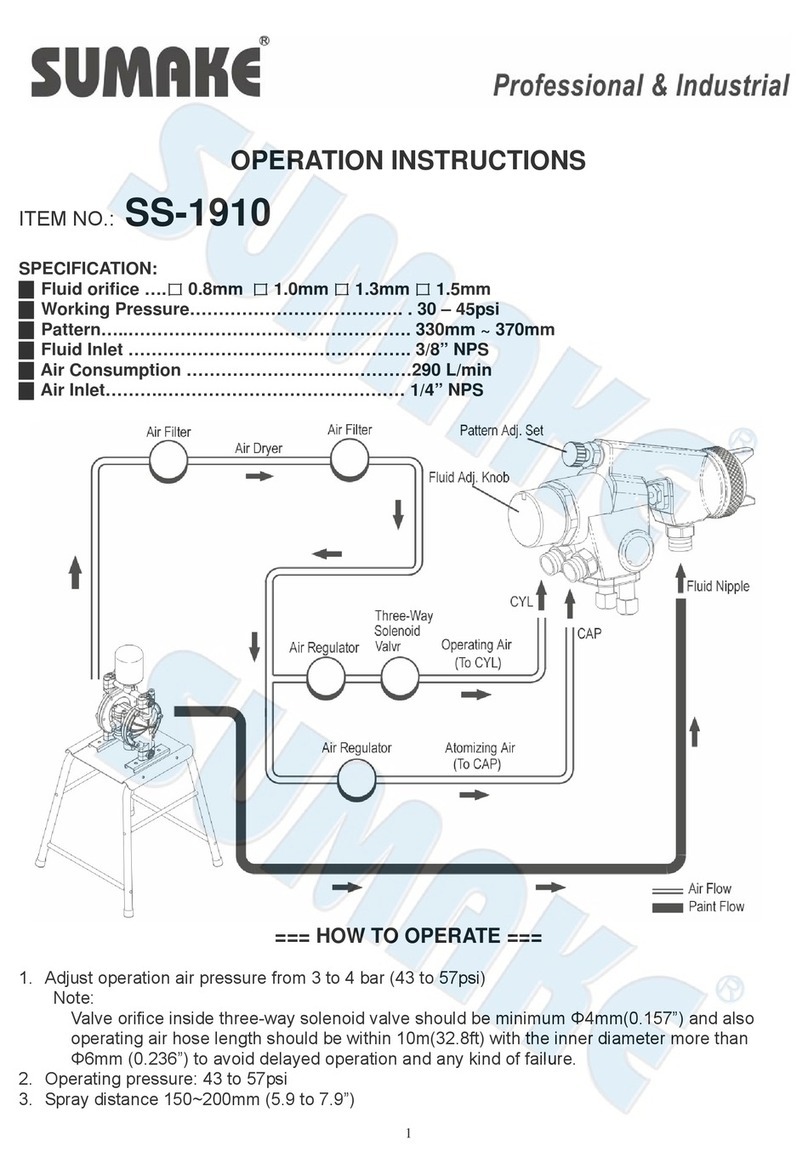

Sumake SS-1910 User manual

Sumake

Sumake SS-400G User manual

Sumake

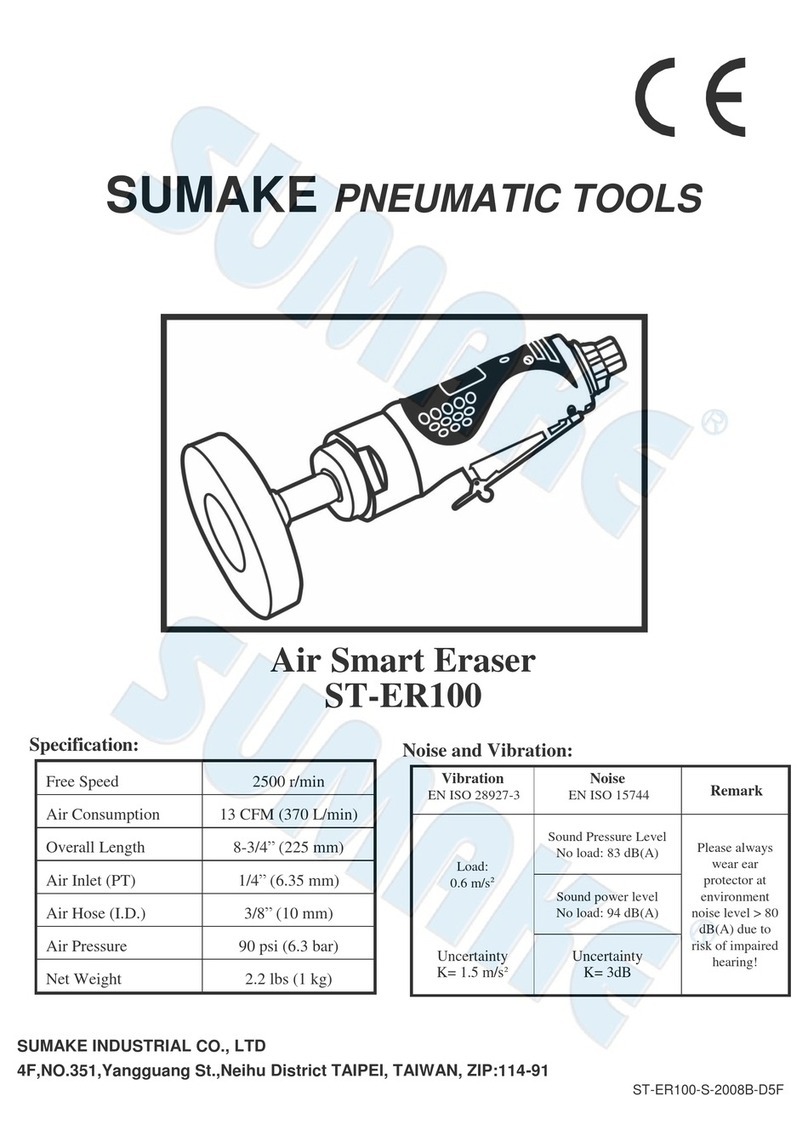

Sumake ST-ER100 User manual

Sumake

Sumake SS-1140SS/G User manual

Sumake

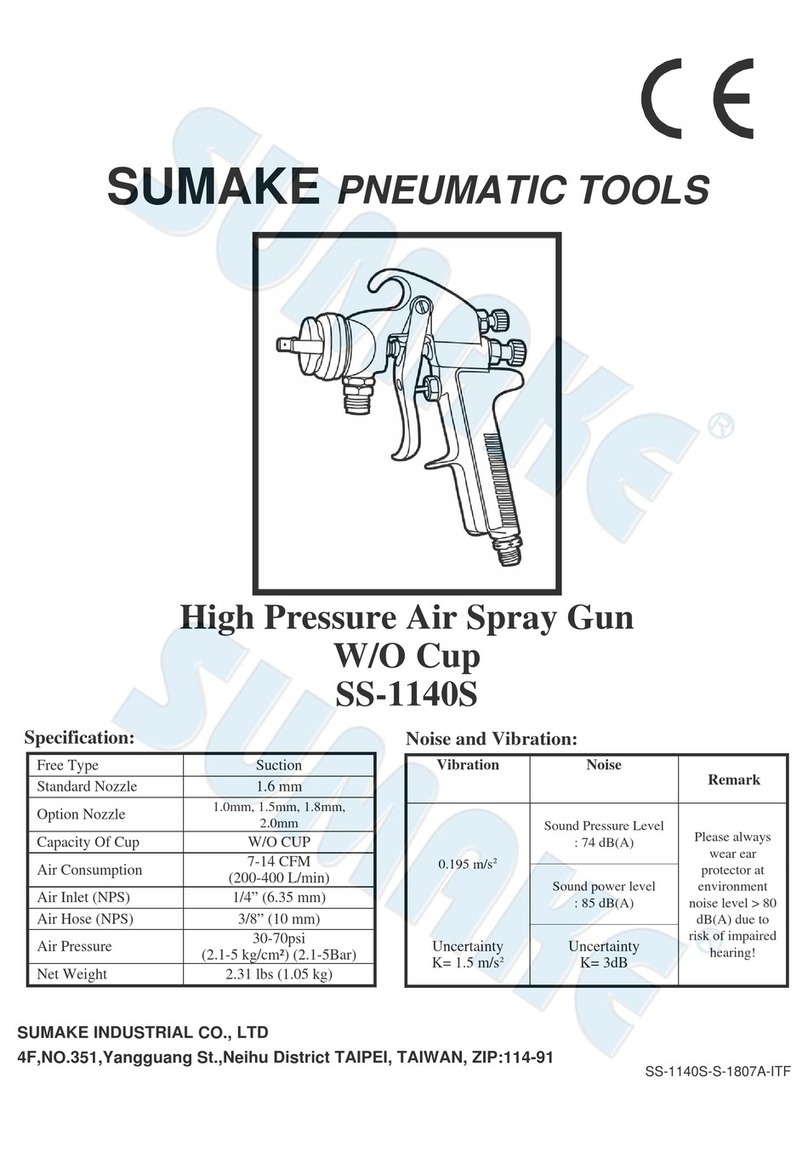

Sumake SS-1140S User manual

Sumake

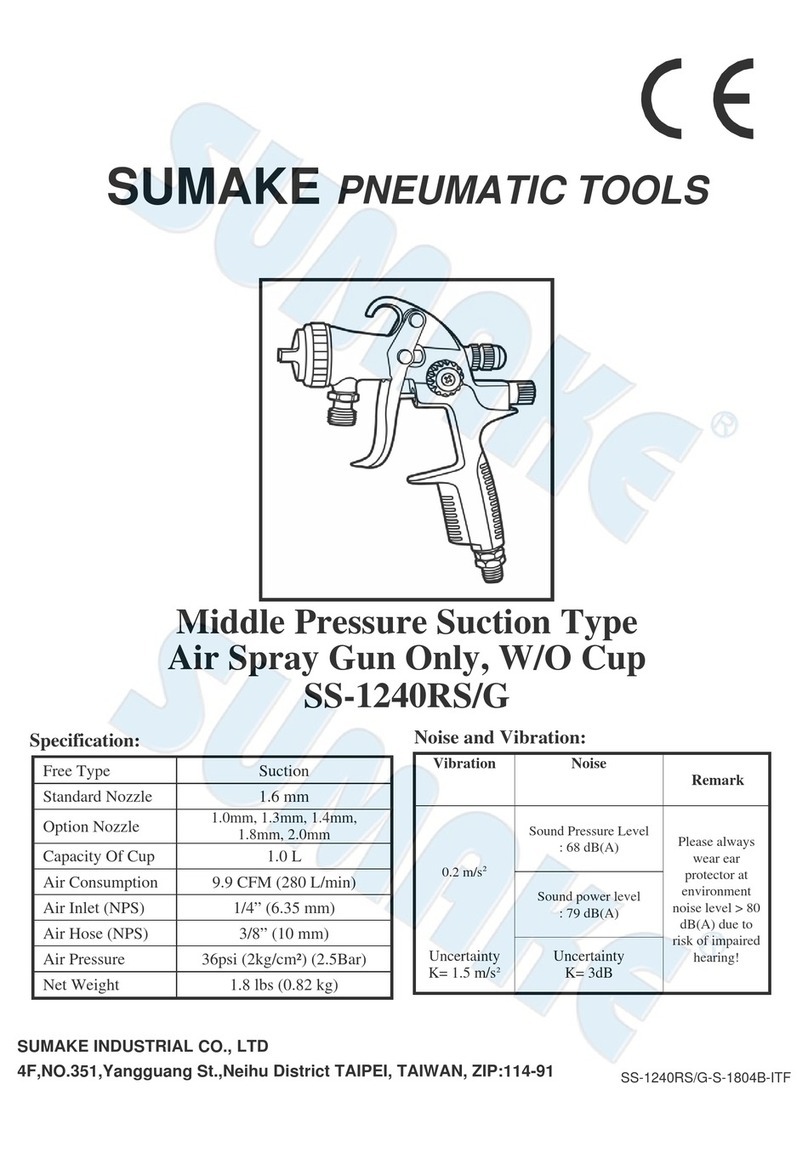

Sumake SS-1240RS/G User manual

Sumake

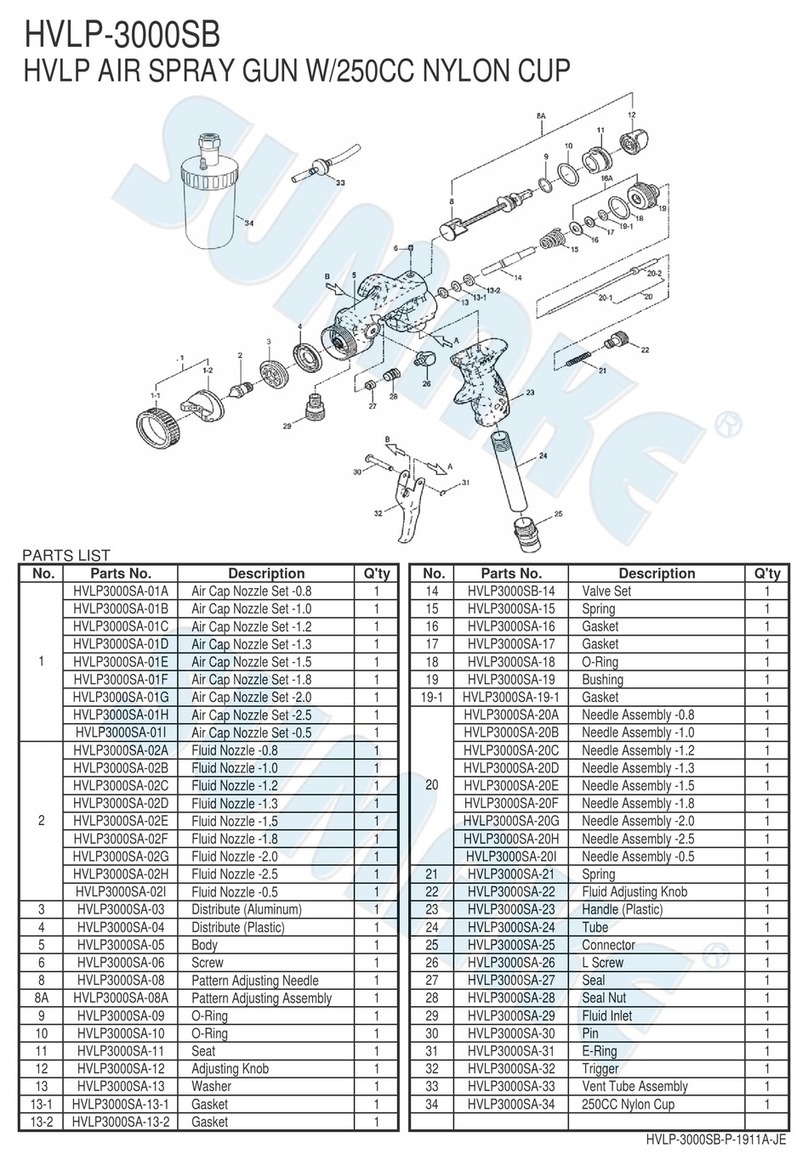

Sumake HVLP-3000SB User manual

Sumake

Sumake SS-1305HSPA-R User manual

Sumake

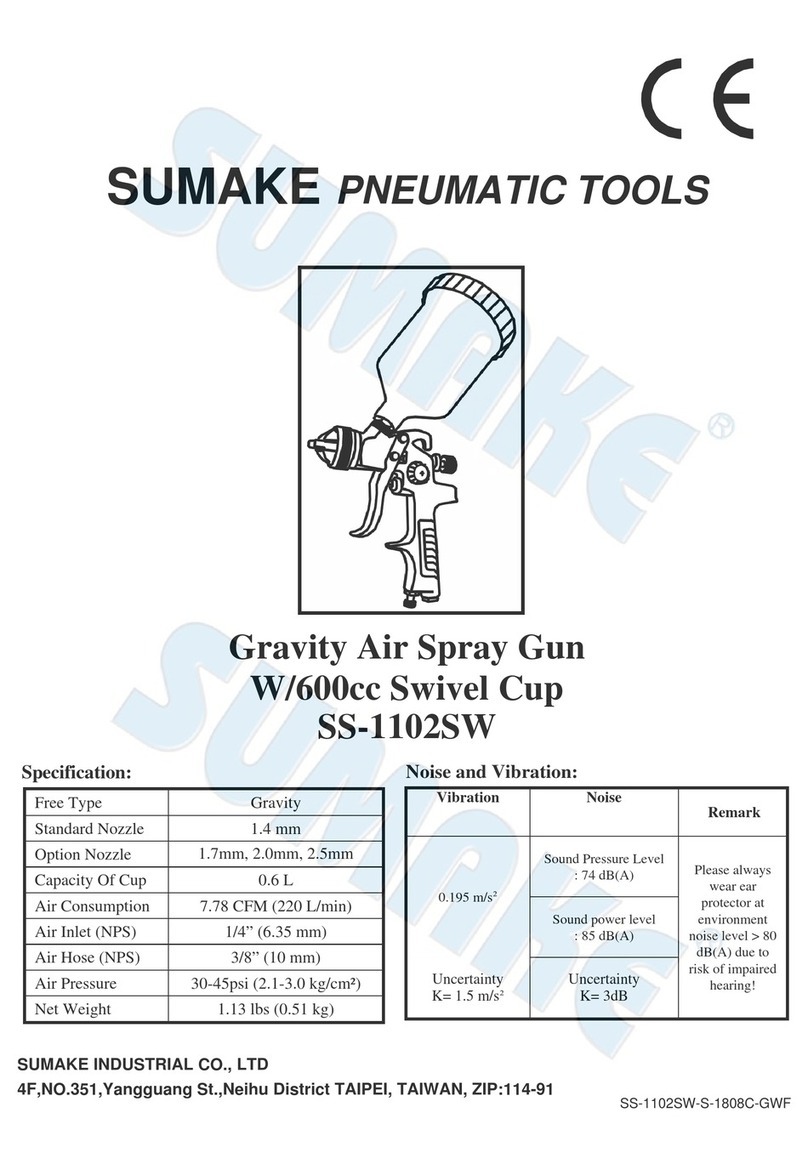

Sumake SS-1102SW User manual

Sumake

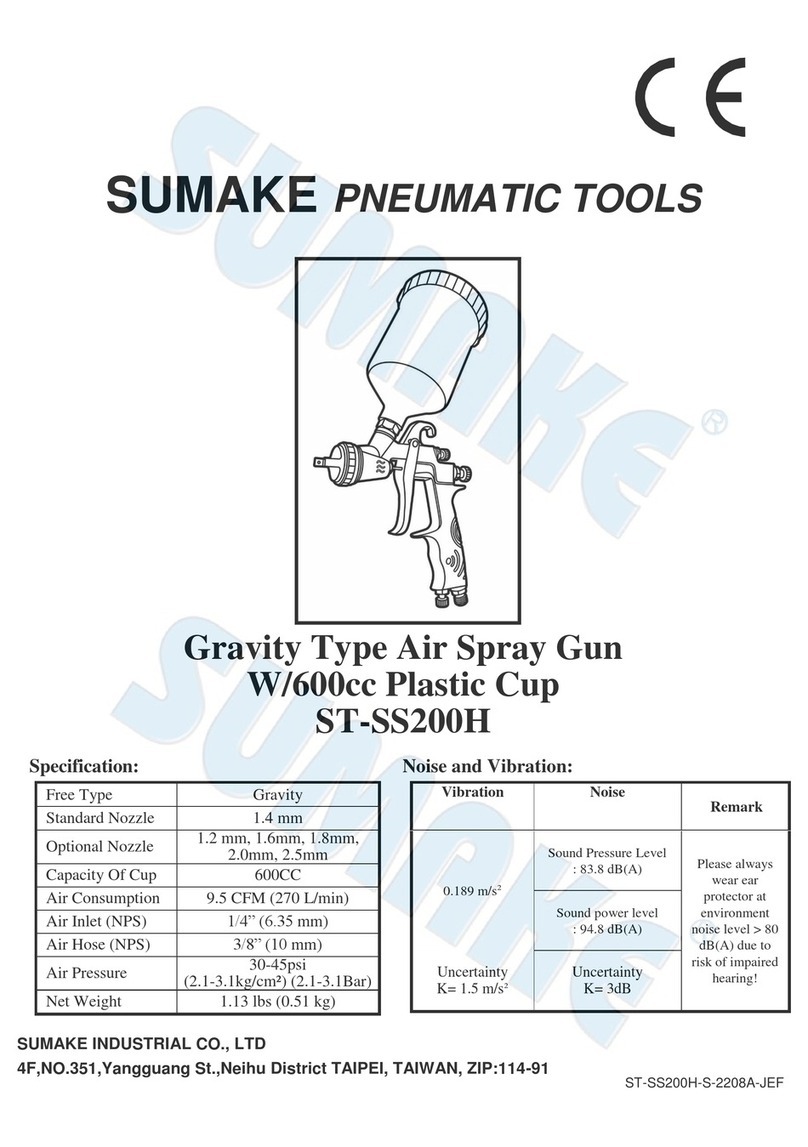

Sumake ST-SS200H User manual

Sumake

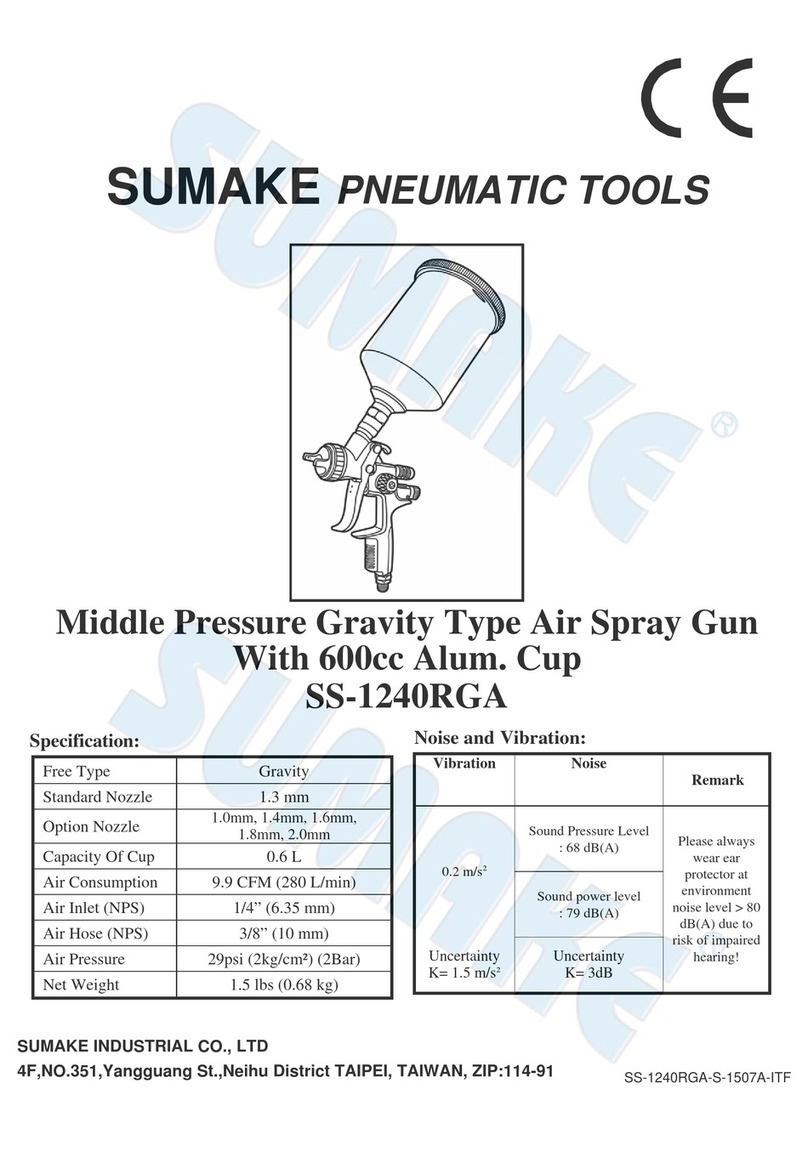

Sumake SS-1240RGA User manual

Sumake

Sumake SS-400S User manual

Sumake

Sumake SS-1203A User manual

Sumake

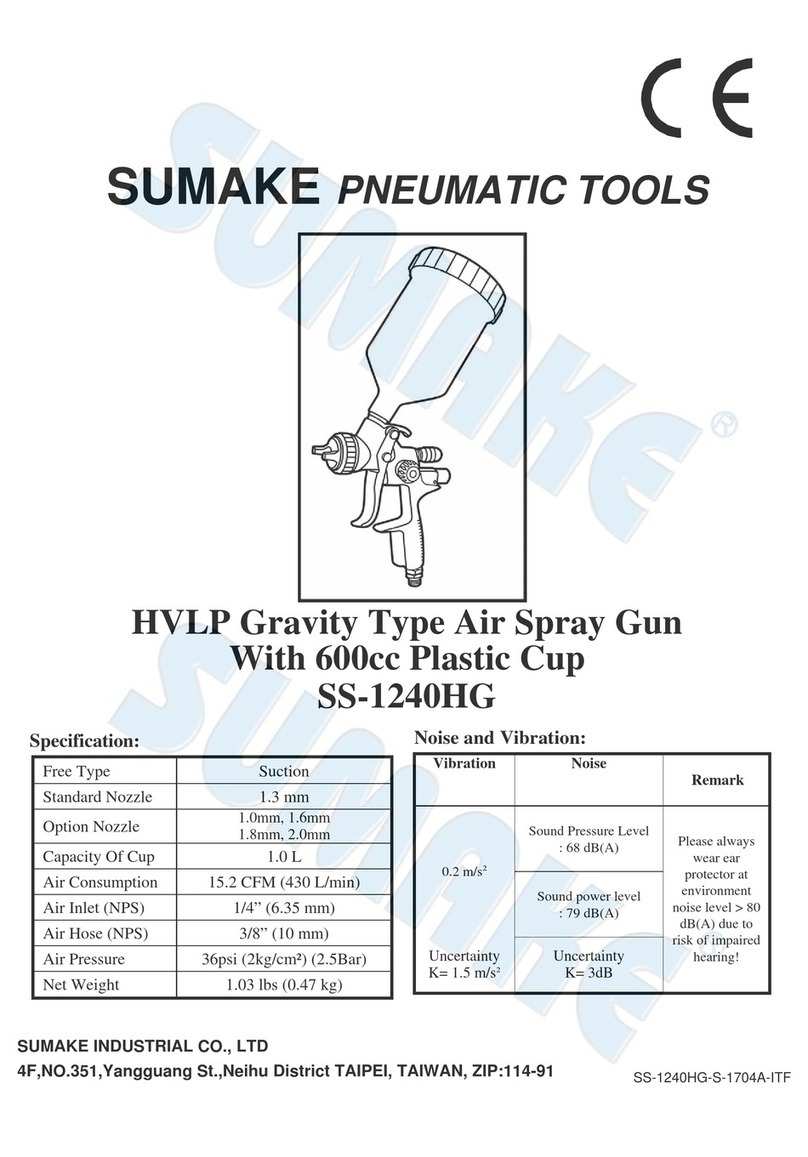

Sumake SS-1240HG User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual