3. Remove the Retaining Ring from the Spindle Assembly. Use a (AVA0416) Bearing Separator to remove the Bearing, Shim,

Bearing, Shim, Dust Shield and the Washer from the Spindle Assembly. Discard Dust Shield.

4. The components are held in place by the light press fit of the retainer. These components can be damaged during removal and

may need to be replaced if removed. To remove the Retainer, use an O-ring pick or a #8 sheet metal screw to grip and pull out the

Retainer. Remove the Valve and Filter from the bore in the Shaft Balancer. If the Retainer and Valve were not damaged, they can

be reused. However, the filter should be replaced on re-assembly

Housing Disassembly:

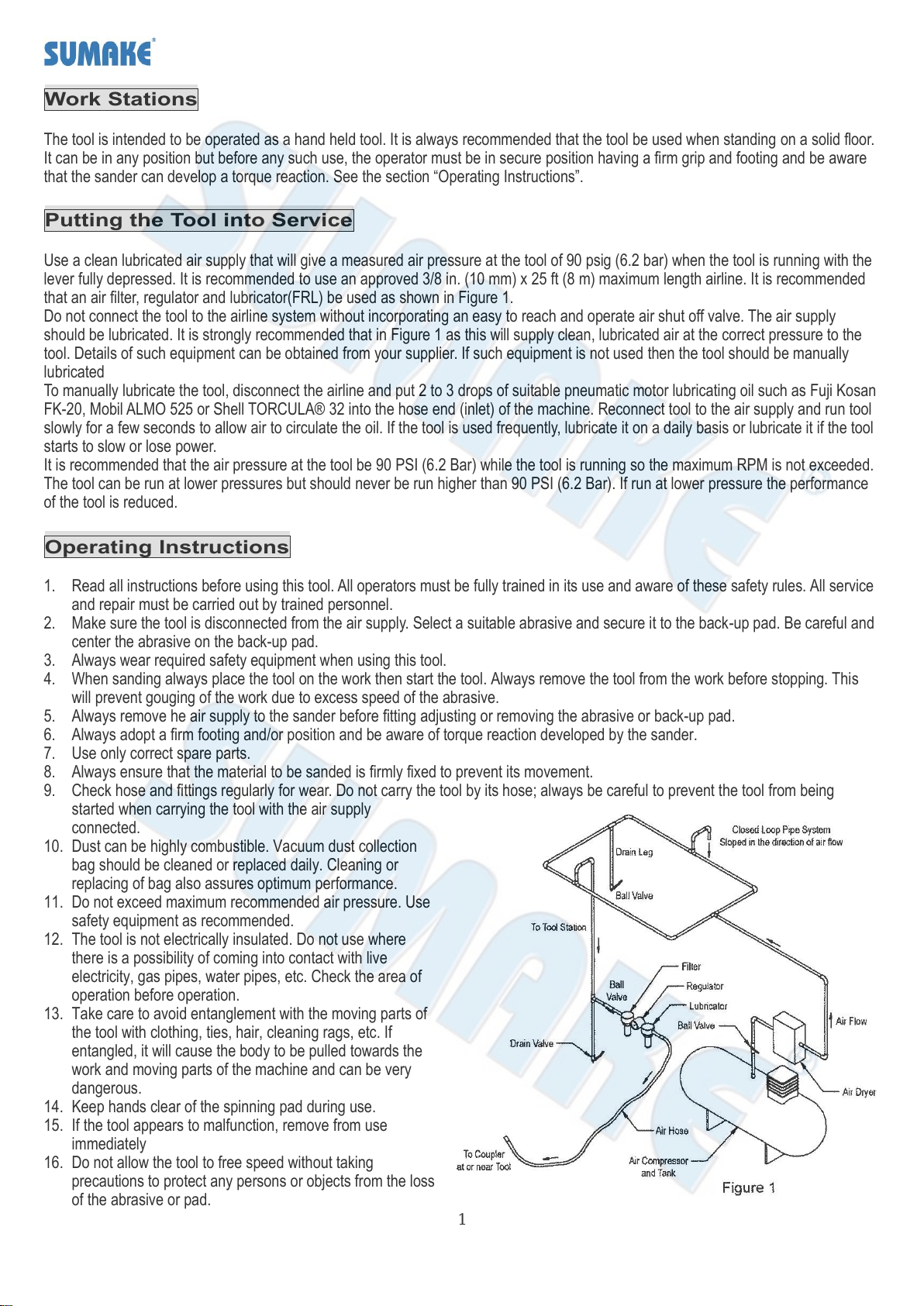

1. For Non-Vacuum (LMN-40H(V)/ LMN-W40H) and Central Vacuum (LMC-40H(HM)) machines follow steps A - C below (unless

otherwise noted). For Self Generated Vacuum (LMG-40H(HM)) machines disregard steps A - F and move onto Step G below.

A. Unscrew the muffler housing from the housing.

B. Remove the muffler from the cavity of the muffler housing

C. Remove the plate and second muffler from the exhaust port of the housing of the Housing.

For Central Vacuum (LMC-40H(HM)) Exhaust machines:

D. Remove the Screw, Washer and Nut.

E. Press downward on the swivel end of the Φ1in.(28 mm) CV Swivel Exhaust Assembly or the Φ3/4in.(19mm) CV Swivel Exhaust

Assembly releasing the tab on the end of the exhaust assembly from the Snap-In Exhaust Adapter.

F. Work off the Snap-In Exhaust Adapter. Move on to step 2.

For Self Generated Vacuum (LMG-40H(HM)) Exhaust machines:

G. Unscrew the SGV Retainer Assembly with an 8 mm hex key. Remove the two O-rings. Take off the Φ1in.(28 mm) SGV Swivel

Exhaust Assembly or the Φ3/4in.(19 mm) Hose SGV Swivel Exhaust Assembly.

H. Work off the Snap-In Exhaust Adapter.

2. Place the Speed Control to the midway position and remove the Retaining Ring. The Speed Control will now pull straight out.

Remove the O-Ring.

3. Unscrew the Inlet Bushing Assembly from the Housing. Remove the Valve Spring, Valve, Valve Seat, Valve Stem with the O-Ring.

Press out the Spring Pin from the Housing and remove the Lever.

ASSEMBLY INSTRUCTIONS

NOTE: All assembly must be done with clean dry parts and all bearings are to be pressed in place by the correct tools and procedures

as outlined by the bearing manufacturers.

Housing Assembly:

1. Install the Throttle Lever into Housing with the Pin.

2. Lightly grease O-Ring and place it on Speed Control. Install Valve Stem, O-Ring (cleaned and lightly greased) and insert the

Speed Control into Housing in the midway position. Install Retaining Ring.

CAUTION: Make sure the Retaining Ring is completely snapped into groove in the Housing.

3. Install the Valve Seat, the Valve and Valve Spring. Coat the threads of the Bushing Assembly with 1 or 2 drops of Loctite ™ 222 or

equivalent non-permanent pipe thread sealant. Screw the assembly into the Housing. See the “Parts Page” for torque settings.

Place a clean muffler and plate into the exhaust port of the Housing. Be careful not to lose the Plate and muffler out of the exhaust

before it is secured in one of the following steps.

NOTE: If the machine is a LMC-40H(V)/LMG-40H(V) model proceed with the appropriate vacuum exhaust assembly instructions,

otherwise move onto step 4.

For LMC-40H(HM) (Central Vacuum) Exhaust machines:

A. Attach the Snap-In Exhaust Adapter.

B. Take the Φ1in(28mm) CV Swivel Exhaust Assembly or the Φ3/4in.(19mm) CV Swivel Exhaust Assembly and put the “tongue” on

the male end of it into the female end of the Snap-In Exhaust Adapter. With the swivel end of the Exhaust angled towards the

ground work the “tongue” and male end into the female end of the Snap-In Exhaust Adapter by rotating the swivel end up and in at

the same time until it seats.

C. Thread the Screw into the mounting hole of the Φ1in.(28mm) CV Swivel Exhaust Assembly or the Φ3/4in.(19mm) CV Swivel

Exhaust Assembly and housing until the end of it is flush with the inside surface of the Housing. Place the washer and Nut into the

cavity of the Housing and thread the Screw into them until tight. Move onto step 4.

For LMG-40H(HM) (Self Generated Vacuum) Exhaust machines:

A. Attach the Snap-In Exhaust Adapter.

B. Lightly grease two O-rings and place them over the two grooves in the SGV Retainer Assembly. Slide the SGV Retainer Assembly

into the bore of the Φ1in.(28mm) SGV Swivel Exhaust Assembly or the Φ3/4in.(19mm) Hose SGV Swivel Exhaust Assembly.

C. Attach the SGV Swivel Exhaust Assembly to the exhaust port of the Housing by means of the SGV Retainer Assembly and by