Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

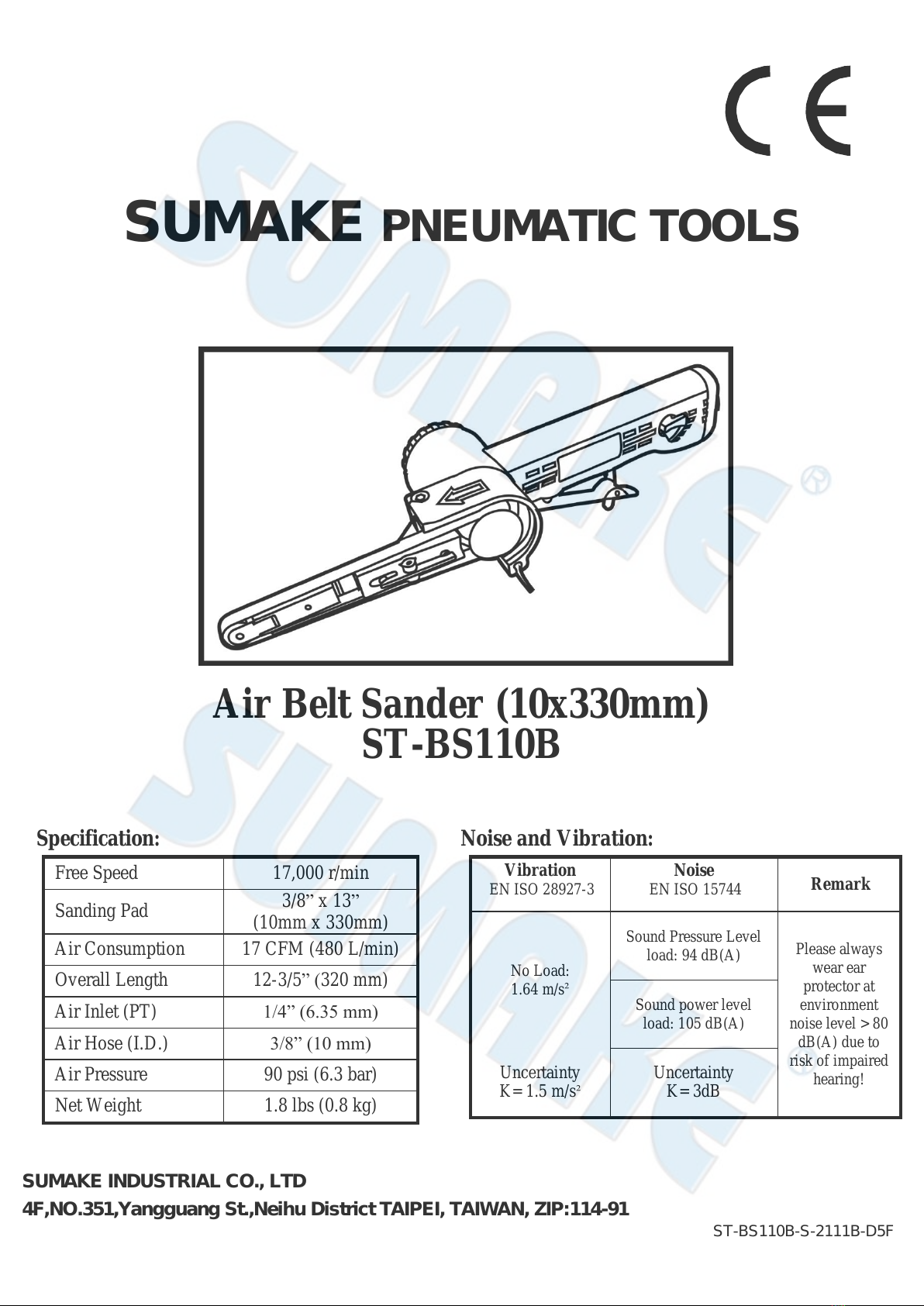

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

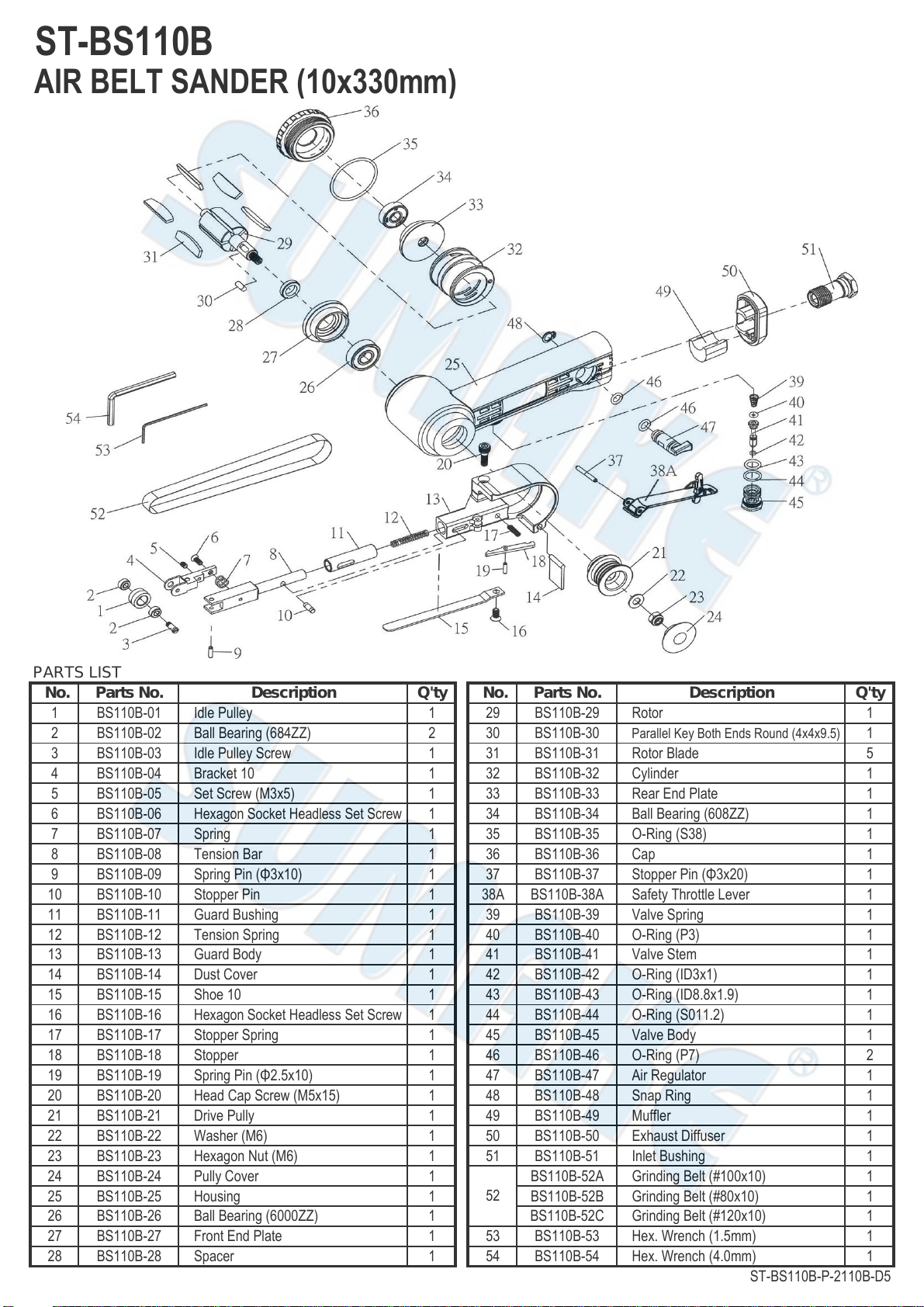

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

ST-BS110B-I-1810A-D5

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

-

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.

ST-BS110B-I-1810A-D5

Foreword

SUMAKE is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

1. Finishing of flat surfaces, curved surfaces, and

corner can be freely performed by changing the

shoe.

2. Since it is small, lightweight, and balanced so

that the grinding surface is stable, extremely fine

finishing is possible.

3. The grinding speed can be freely adjusted by

raising or lowing the lever according to the

application.

4. Rear exhaust eliminates flying dust and noise.

Operator‘s instruction

1. Main Applications

Finishing metal carts and products.

Finishing welded surface.

Trimming parts.

Filleting.

Finishing steel cabinets and furniture.

Foundation finishing prior to coating.

Finishing plastic products, glass, and

earthenware.

Finishing stone and decorative wood products.

Finishing sashes and other building material.

Light and medium duty auto, ship and aircraft

finishing.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from

5 to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/8“ air hose between the compressor an

the tool . Compressed air is cooled and its wate

content separated, as soon as the air leaves th

compressor. A portion of the water content

however, is condensed in the piping, and ca

enter the tool mechanism, and may cause trouble

So, install an air filter and on oiler between th

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Sandpaper

The specification of sandpaper ranges from # 4

to # 200. Also note that, the maximum operatin

speed which the sandpaper can afford shall b

higher than the rotation speed of this tool.

2-5 The approved eye protector,ear-muff

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacing

Method

3.1 On-off device

The on-off device is under the grip of this tool. It

is a “hold-to-run” type. You can also adjusting

the running speed by raising or lowering the lever.

This tool stops rotation within few sec, after

releasing the lever. For the sake of safety, put it

on a soft cloth or on hanger after it completely

stops.

3.2 Replace the sandbelt

Disengage and remove the sandbelt from the idle

ulley after pushing the idle pulley in the

direction shown below. Replace a new one and

keep your hand away from the idle pulley. Then

ush the tension bar indicated on the drawing and

the sandbelt will be propped into the ready

osition.

idle pulley tension bar

3.3 Adjusting tracking

If the sandbelt is not centered on the idle pulley,

adjust the hexagon socket head bolt on the idle

ulley bracket with accessory hexagon wrench

key until centering is correct. Turn the hexagon

socket counter clockwise, the belt is moved

toward the bracket, and vice versa.

clockwise

counterclockwise

bracket

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a

thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool a

the air inlet with spindle oil and run it for a short

4-3 Disposal

If the tool is too seriously damaged to be use

anymore, drop it in a resource recycling can.

Never drop it into fire.

4-4 Ordering service Parts

For further operational and handling informatio

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming into

contact with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it emit sparks

when grind with metal material.

3. Ensure that the sandbelt is on the central o

idle pulley and not to fix too tight/loose. Too

tight tends to break off and too loose tends to

break away.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whipping compressed air hose.

6. Rotating action can cause this tool to become

hot. Allow to cool and disconnect air hose before

any changing or adjusting.