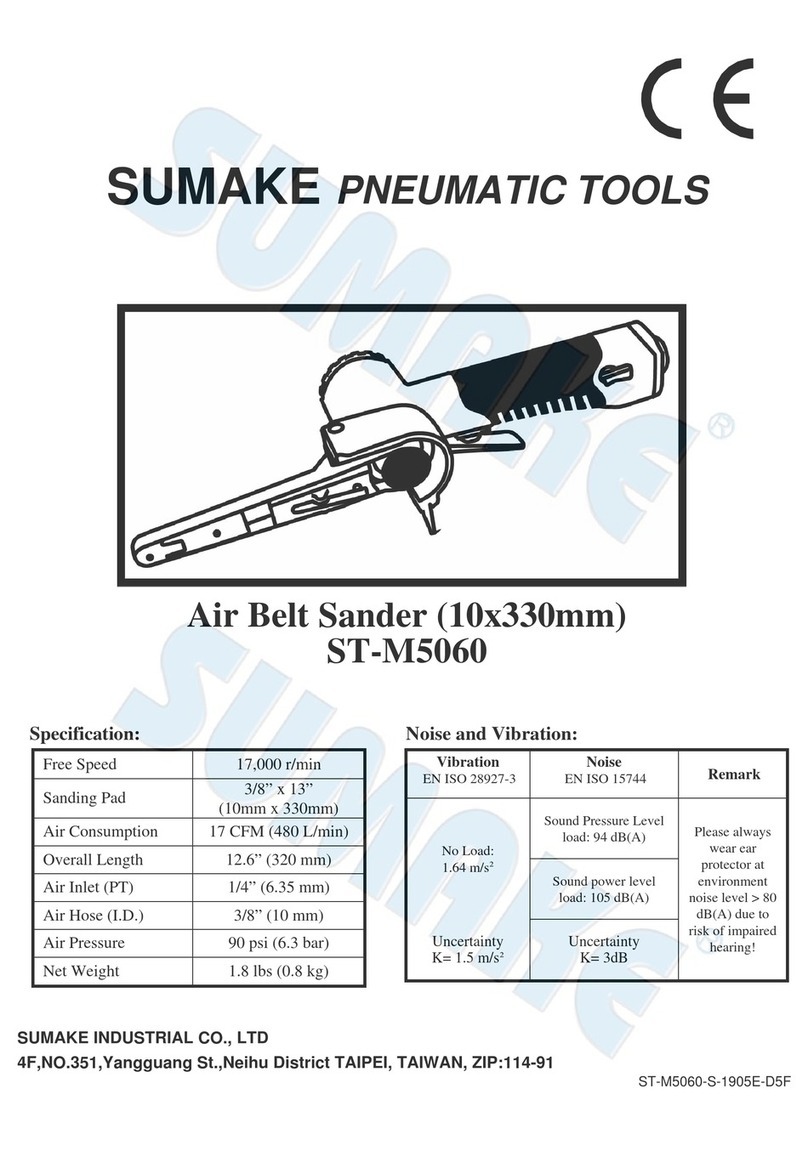

Application:

It is useful for various sanding work, to smooth wood and automotive or wood finishes by abrasion with sandpaper.

Belt-Sander applications: To grind plain surfaces

Safety instructions for belt-sanders

Belt mounting dangers:

Correct belt mounting is necessary to prevent injury from loosen belts.

Do not use chipped or cracked sanding belts

Use only belts fitting the machine easily. If you need more force than usual to install the belt the size could be differ from the requirement.

Before sanding, test belt by briefly running tool at full throttle. Be sure to use a barrier (such as under a heavy working table) to stop any possible loosen belts.

Acracked sanding belt will cause serious hurts !

Regularly check the speed of the device by a tachometer to make sure the speed has not been exceeded and is conform with the abrasive belts you use. The

approvable speed is mentioned down on the data sheet which comes with the belts.

Never use a belt marked with a speed lower than this tool !

Do not wear jeweled or loose clothing and avoid long hair.

Choking can happen if neckwear is not kept away from tool and accessories !

Avoid direct contact with accessories during and after use. Safety gloves will reduce the risk of cuts or burns.

Use only proper accessories retainers (refer to parts list).

Use only sanding belts with the correct diameter, dimension and approvable speed according to the technical data of this tool.

This unit has been developed as belt sander and must only used for this function.Any misuse could occur serious health damage.

Dangers in use:

Do not lay down the device before all the rotary parts stopped

Do not keep the air tool running while carrying it.

Maintain a firm grip on the power tool and position your body and arm to allow you to resist kickback forces.Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper precautions are taken

Never place your hand near the rotating accessory.Accessory may kickback over your hand.

Switch off the unit immediately in case of blocking or twist. Disconnect the air supply and do not switch on again until the problem is solved. Understand the reason why

the tool has been blocked and make sure that this situation will not occur once more by counteract.

Make sure that the accessory you intend to use has no damage. Exchange the part if you are not sure.

In case the air tool gives a strong vibration, replace the accessory / abrading medium, probably it’s damaged or worn out..

Remember that a cracked sanding belt will cause serious hurts.

Common Troubleshooting:

Event Appearance Possible Cause

Solution

Not operating

ir is coming from the exhaust valve Blades

broken or worn out

Replace blades

Ball bearing damaged

Replace ball bearing

Rusty motor

or clogged with objects

Disassemble and repair

No air coming from the exhaust valve Regulator is set at OFF

djust regulator

No air flow

Check air system and connections

Valve set damaged or broken

Disassemble and repair

Low efficiency

Low revolution rate Not enough air pressure

Check air pressure

Forwarder/reverse

valve is not set properly

djust forwarder/reverse

valve

Motor running abnormal or unusual noises

occur Not enough lubrication, ball bearing, upper/lower end

plate, cylinder, rotor, blade damaged Lubricate or replace parts

Motor keeps

running

Trigger does not bounce back or does not

bounce back correctly Trigger set has other objects stuck on it or the spring

is broken, deformed or rusty Disassemble and repair

Trigger function normally Trigger O-ring worn out or valve set damaged or

broken Disassemble, repair and replace parts

ST-7710-I-1904C-PZ