Sumitomo CAK-0057-EX User manual

Technical Information

KOUTURIGISHI-1078H

Optical Connector Termination Tool

CAK-0057-EX

Instruction Manual

2011-03-16

SUMITOMO ELECTRIC INDUSTRIES, LTD.

★The information contained herein is presented only as a guide for the applications

of our products. No responsibility is assumed by SUMITOMO ELECTRIC for any

infringements of patents or other rights of the third parties which may result from

its use. No license is granted by implication or otherwise under any patent or patent

rights of SUMITOMO ELECTRIC or others

★The information contained here may be changed without prior notice. It is therefore

advisable to contact SUMITOMO ELECTRIC before proceeding with the design of

equipment incorporating this product.

© Sumitomo Electric Industries, Ltd.

CONTENTS

Page

1. Outline 3

1.1 Scope 3

1.2 Features 3

2. Composition of CAK-0057-EX 4

2.1 Composition diagram of CAK-0057-EX 4

2.2 Component parts of CAK-0057-EX 4

3. Component parts of optical connector 5

3.1 Parts list of optical connector 5

3.2 Conceptual diagram for assembly of optical connector 6

4. How to use a microscope 7

4.1 Inspection of a cut face of optical fiber 7

4.2 Batteries exchange 7

5. Assembling procedure for H-PCF cables / cords 8

5.1 Preparatory work for optical fiber cable 8

5.2 Preparatory work for the optical fiber cord 9

5.3 Preparatory works for the ferrule attaching process 9

5.4 Attaching the ferrule 13

5.5 Cleaving the optical fiber 15

5.6 Inspection of the end surface of the cleaved optical fiber 16

5.7 Assembly of the optical connector CF-2071 18

5.8 Assembly of the optical connector CF-1071,CF-1571 21

6. Cable end installation 22

7. Ordering information 23

8. Trouble shooting 24

1

2

Caution

,fingers or other parts of a body.

Be careful not to be stuck with tip of optical fiber in eyes,

It may cause lose sight or other serious injuries.

Handle the tools and connector component parts with care

Caution

not to get injured or damage them.

Don't put fingers or other parts of a body between the blades

of ferrule assembly tool JRFK-57 in use. It may cause injury.

Caution

Use tools according to this instruction manual.

Wrong usages may cause injury , damage of the tool or sub-

Attention

standard assembled connector.

Tool kit CAK-0057 is designed only for our applicable

connectors described on the page 3.

Don'tuseforanyotherproducts. It may damage the tool.

Attention

For the quality assurance of the applied fiber optic data-link

systems, please make sure to perform the optical loss tests

Attention

after assembling connectors.

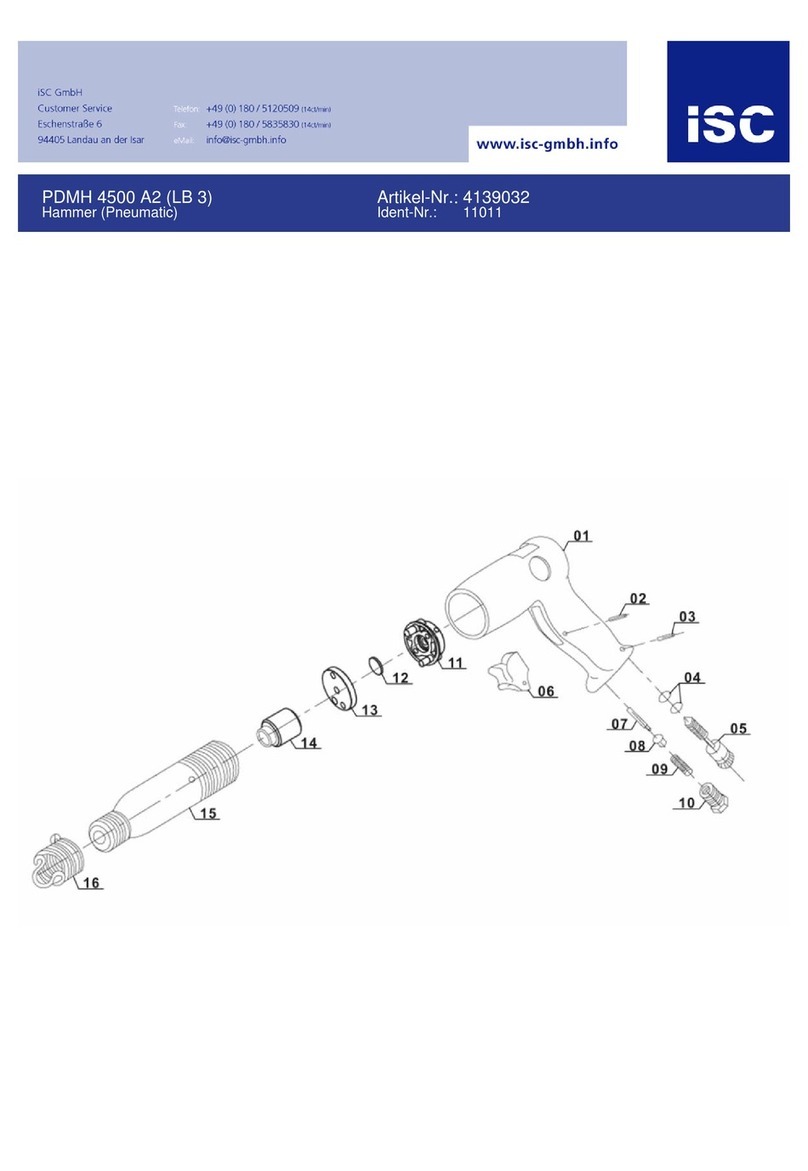

2. Composition of CAK-0057-EX

2.1 Composition diagram of CAK-0057-EX

6

5

4

3

2

1

2.2 Component parts of CAK-0057-EX

1 Optical fiber cleaver

2 Ferrule assembly tool

3 Microscope CAT-0057B 1

CR-CF2071

5 Scissors -1

6 -1

7 Instruction manuals (English) KOUTURIGISHI-1078 1

Carrying case

4 Cap remover

Product name of component

No.

1

1

JRF

K

-57

Quantity Sub code

FOCUS200-EX 1

4

3. Component parts of optical connector CF-1071,CF-1571,CF-2071

3.1 Parts list of optical connector

No. Product

name Item CF-1071 CF-1571 CF-2071

Figure

Code FL-CF1071

1 Ferrule

Quantity 1 2

5

Figure

Code Collar 4511

2 Collar

Quantity 1 2

Figure

Code VJA7084 CB-CF2071

3

Cord

Bush

Quantity 1 1

Figure

Code VJM7069 SP-CF1071

4 Coil

Spring

Quantity 1 2

Figure

Code VJA7218 CP-CF2071

5 Plug

Cap

Quantity 1 1

Figure

Code VJA7219-S1 VJA7217-S1 CS-CF2071

6 Plug

Case

Quantity 1 1 1

Figure

Code VJA7115 DC-CF2071

7 Dust

Cap

Quantity 1 1

Note (1) The quantity is the requirement for a piece of the fiber optic connector.

3.2 Conceptual diagram for assembly of optical connector

Plu

g

C

ase

Ferrule

Collar

Coil S

p

rin

g

Plug Cap

コードブッシ

光

フ

ァ

イバコー

Cord Bush

Plug Case

Ferrule

Collar

Coil Spring

Plug Cap

光

フ

ァ

イバコー

O

p

tical Fiber Cord

Optical Fiber Cord

Cord Bush

(1)CF-1071

(2)CF-1571

Optical Fiber Cord

6

Collar

Plu

g

Ca

p

Cord Bush

F

e

rr

u

l

e

Plug Case

(3)CF-2071

Coil Spring

4. How to use a microscope

4.1 Inspection of a cut face of optical fiber

Open the arms, then a lamp inside turns on.

Insert the ferrule into the hole of the ferrule

adaptor ,and then the face of the cut fiber and the

ferrule can be seen by adjusting focusing dial.

Attention: When the microscope is not in use, close its

arms to prevent batteries from exhausted.

Focusing dial

Ferrule adaptor

1. open

4.2 Batteries replacement

Open the arms and slide the cover in the direction

shown by “ “, then there appears the battery

container.

Attention: When the microscope is not in use, close

its arms to prevent batteries from exhausted.

2. slide

Cover 1. open OPEN

7

5. Assembling procedure for H-PCF cables/cords.

5.1 Preparatory work for optical fiber cables

(The work shown in this page is mentioned only for cables. In case of cords, please skip it and start

from the next page.)

8

Fig.3

(1) Remove the sheath by using your own

knife. (Fig.3)

Remove length ----- 200mm (Reference

value)

Fig.4

(2) Cut off the hold tape, the filler and the

filler cords at the end of the sheath with

the scissors to expose the optical fiber

cords and the central strength member .

(Fig. 4 to 5)

Strength member

O

p

tical fiber cord

Fig.5

Protective boot

Fig.6

(3) Insert the optical fiber cords and the

tension member into the protective boot

and cover the end of the sheath with the

protective boot. (Fig. 6)

5.2 Preparatory work for the optical fiber cord.

Fig.7

Fig.8

130±20mm

CF-2571

CF-2071

CF-1071・CF-1571

(1) Insert the optical fiber cord from the

bottom(smaller) mouth of the cord bush.

(Fig.7)

(2) Insert the gap at the end of the connection

part of the optical fiber cord, and then by

tearing the optical fiber cord, separate it into

simple cord each. ( Only for the duplex cord.)

Separation length ----- 130+

-20 mm (Fig.8)

5.3. Preparatory work for the ferrule attaching process

Fig.10

(1) Insert the cord into the outer

jacket remover of the ferrule

assembly tool from its front

face (label face) , and then

grasp the handle and pull

the cord back straight. In this

way, the outer jacket (black)

of the optical fiber is removed.

(Fig.9 ,10)

Remove length ----- 35 mm

Fig.9

Outer

j

acket remover

Max 1mm

Note:The difference in jacket lengths

should be no more than 1mm.

(Fig.11) Otherwise the optical

fiber may bend when the connector

is assembled.

(

Fi

g

. 11

)

Fig.12

Note:For remove length please refer to

the label that has 35mm width.

(Fig. 12)

9

10

補強材

最

大1mm

心

線

Protective coatin

g

Stren

g

th member

Collar

Max.1mm

撚り合わせる

Fold and strand the

strength member tightly

(Fig. 15)

(Fig. 13)

(Fig. 14)

(2) Fold bac

k the strength member yarn

at about two strands and then insert

the optical fiber into the collar . (Fig.

13)

(3) Insert the collar into the cord jacket.

Note: Please make the collar projected from

the cord jacket by no more than 1mm.

(Fig.14)

(4) Keep the strength member folded and

strand it tightly. (Fig.15)

(5) Put the optical fiber in protective coating

remover through guide hole from front

face (label face). (Fig.16 ,17)

(Fig. 17)

Protective coating remover

(guide hole)

Note: Be careful not to nip the strength

member between the blade of the

remover, or the blades will be

damaged.

(Fig. 16)

(6) Grasp the handle and pull the fiber back

straight. (Fig.18)

(Fig.18)

(Fig.19)

0

-

5mm

Note: The remaining length of the protective

coating should be less than 5mm. (Fig.19)

(7) Adjust the length of the strength member

to 5 to 6mm with scissors. (Fig.20)

5 to 6mm

(Fig.20)

Note: Make sure to leave the strength

member 5 to 6mm. This is necessary

to get the pullout strength between

the optical fiber cord and the ferrule.

(Fig.21)

(Fig.21)

11

Caution

12

When the blades of the protect coating remover are broken or the procedure is out

of accord with this manual, during the stripping of the protective coating, it may happen

that the plastic cladding of the optical fiber is damaged (surface of the cladding is whitened

or becomes glittering). In this case, the optical fiber may be broken at the point of the

damage in the succeeding assembling process or in the connector under use, because the

cladding of H-PCF is a vital part to insure its high-strength and high-reliability by

protecting the silica core. So please do not forget to perform the following proof test before

proceeding the next step in order to make sure that there are no damage on cladding

whether the the surface of the cladding is whitened or not.

Bend the o

p

tical fiber

(Important)

(8) Hold the optical fiber cord (black,

2.2mm dia.) by a hand and tip the

bare optical fiber (core & cladding) 3

to 4 times gently with a finger of

another hand so that the fiber bend

+-120 degrees. And squeeze the

surface of the whole length of the

bare optical fiber about ten times

from the protective coating end to the

fiber end.

(Fig.22)

Squeeze through the fingers

If the cladding is damaged, the fiber

is broken down through these

screening processes. (Fig.22 to 23)

Finally observe the bare optical fiber

against a black background so that

the damage of the cladding can be

seen white like. (Fig.24)

Note: Be careful not to damage the

cladding by scratching the fiber

surface with nails.

(Fig.23)

Note: Eye glasses or Protecting goggle is

recommended to save your eyes

from particles of the broken fiber.

Note: Particles of the broken fiber should

be collected by adhesive tape or

other method to avoid that they

harm human bodies.

Observe against

black background

(Fig.24)

5.4 Attaching the ferrule

(1) Fix the coil spring onto the optical fiber

cord. (Fig.25)

Coil spring

(Fig.25)

Note: When assembling duplex type

connectors, perform the operations from

this step to "5.5 cleaving of the optical

fiber" separately for each core of the

optical fiber.

(2) Insert the optical fiber into the ferrule.

(Fig.27)

(Fig.26)

Note: Make sure to insert the optical fiber

cord into the ferrule exactly until the

folded strength member projects no

more than 2mm from the bottom of

the ferrule.(Fig.27)

(Fig.27) The tip of the strength

member should be seen

Strength member should

Be folded back

Ferrule

(3) Set the flange of the ferrule inserted the

optical fiber on press-in blade.

Note the set direction. (Fiber cord

should be to ferrule guide.)

(Fig.28 ,29)

Flange

Ferrule guide

Ferrule

p

ress-in blade

Ferrulie guide

Optical fiber

Optical fiber cord

Ferrule

(Fig.29)

(Fig.28)

13

14

(4) Grasp the handle till it goes no more touching

on the limit screw. (Fig.30,31)

This makes the ferrule pressed axially and

shortened, and the optical fiber is held inside.

handle

limit screw

(Fig.30) (Fig.31)

(5) Set the ferrule onto ferrule guide putting the

flange of the ferrule on the ferrule guide from

inside. (Fig.32,33)

Flange

Ferrule guide

(Fig.33)

Ferrule guide

Flange

Ferrule

(Fig.32)

(Fig.34)

handle

(6) Grasp the handle till it goes no more touching

on the limit screw, with pushing the optical

fiber cord slightly toward the ferrule in order

not to get out the cord from the ferrule.

(Fig.34,35)

This makes the outer jacket of the cord and

the strength member grasped between the

collar and the ferrule.

limit screw

Lightly stretch

(Fig.36)

(Fig.35)

(7) Lightly stretch the ferrule from the optical

fiber cord by hands to confirm that the

optical fiber cord is tightly fixed onto the

ferrule. (Fig.36)

5.5 Cut the fibers (at the face of the ferrules)

Please see the instruction manual for respective connector and the tool kit except for the procedure

shown bellow.

15

(1) Hold the cleaver with your right hand as shown in the

left photo.

(2) Make sure that there are no fiber chips or other waste

remained on fiber chuck.

Don’t hold the cleaver covering

fiber chuck with the hand as

shown in the right photo.

Fiber chip at the fiber chuck may

hurt the hand.

(3) Let the optical fiber coming out of the ferrule through

the front slit, then insert the ferrule into the hole for

ferrule. Then make sure that the ferrule is put in

deep enough for the front face of it to be on the blade.

Note : Don’t let the optical fiber

through the hole for ferrule.

It may break the fiber.

(4) Direct the hole for ferrule upward, and slowly, press

up the lever to the end, then the optical fiber will be

cut properly.

*Don’t touch the ferrule when

pressing the lever. It can cause poor

cleave quality.

*Don’t press up the lever fast. It

can cause poor cleave quality.

*The lever should be pressed up to

the end. When the optical fiber is

cut, the fiber chuck is slide back.

*Hole for ferrule should face

upward when pressing the lever.

Otherwise, the optical fiber may be

cut at a little out of the face of

ferrule.

(5) Release the lever, and take out the chip of optical

fiber from fiber chuck with tweezers.

Chips or particles of optical fibers can hurt human body. Be careful

not to be stuck.

Hole for ferrule

Fiber chuck

lever No remained fiber

Bad example

! Attention

Front slit

(2)

(1)

! Attention Bad example

Hole for ferrule Upward

Slowly, press

up the lever

to the end. Bad

example

Close to

each other

Slide

back

Not finished Finished

Bad example

If the fiber chip is

short, insert tweezers

from this small slit to

pick it up

! Attention

(Important)

5.6 Inspection of the end surface of the cleaved optical fiber.

Inspect the finished end surface of the

optical fiber with using the microscope

CAT-0057B. (Fig.42)

(Pleas see page 7 for detail.)

* Make sure to perform also the optical

power test by using the optical power

tester.

* Inspect the face with revolving the

ferrule.

* Inspect the face with lighting the another

end of the optical fiber.

* The faces of the optical fibers, together

with those of the ferrules, will be seen

with a microscope. compare them with

examples shown next page. If they

correspond to any of sub-standard

samples, retry from the first stop.

(Fig.42)

Cladding

Face of the cleaved

optical fiber

ゴミ

(Fig.43)

Microscope

Face of the ferrule

(Satisfactory sample)

The face if the core is smooth and the

length of the crack is less than 1/10 of the

core diameter.

(Fig.44)

Crack

(Fig.44)

The faces of the optical fibers, together

with those of the ferrules, will be seen

with a microscope.

(Fig.43)

Core

16

(Sub-standard sample)

The length of cutting flaw is more

than 1/8 of the core diameter.

(Fig.45)

(Fig.45)

Cutting flaw

(Fig.46)

(Sub-standard sample)

Cutting face isn't right angled to the axis

of the fiber.

(Fig.48)

(Sub-standard sample)

The length of the crack is more than 1/10

of the core diameter.

(Fig.46)

(Sub-standard sample)

Hackle is observed on the face.

Crack

(Fig.47)

Hackle

17

Dark image

(Fig.47)

(Fig.48)

NOTE: When the quality of the faces of optical fiber get poor frequently, please move the blade

to shift the cutting potion reference in page 25.

5.7 Assembly of the optical connector CF-2071

(See 5.8 for CF-1071 and CF-1571)

(1) Insert the both ferrules into holes on the

plug case from inside, and fix the cord bush

onto the groove on the plug case. (Fig.49)

18

Plug cap

Cord bush stopper

Center guide pin

Side guide pin

Coil spring stopper

Cord bush

Coil spring

Guide groove taper

(2) Put the coil springs within the hollow inside the

plug case. (Fig.50)

Make sure that the each coil spring doesn't get on

the rim of the hollow.

(3) Put the plug cap into the plug case taking care

that the ferrules,the coil springs and the cord

bush don't get out of their places.(See below

and Fig51,52)

・This procedure will be easier when the plug case

is held slightly inclined as shown in Fig.51,52.

・Plug cap should be pushed in being kept parallel

to the plug case.(Fig.52)

・The spring stopper on the plug cap should go

along the taper part of the guide groove inside

the plug case, so that the stopper will hold the

end of the coil spring correctly.(Fig.52)

・The cord bush stopper on the plug cap should go

into the hole on the cord bush.(Fig.52)

・A center guide pin and two side guide pins on

the plug cap should go into respective holes on

the plug case.(Fig.52)

(Fi

g

.50)

(Fig.49)

Make sure that the each coil

spring doesn't get on the rim of

the hollow.

(Fig.51)

Ferrule

Plug case

(Fig.52)

(4) Push in the plug cap completely. (Fig.53)

Attention:

-Don't push on a latch arm especially a lock

release button. Stresses given on the latch arm

may break it and cause latch lock failure. (Fig.54)

(Fig.53)

Lock release button

Latch arm Attention:

-Incorrect placement of coil springs or ferrules

may cause interference against the plug cap.

When the plug cap isn't put in completely, remove

the plug cap and retry with new plug case and

plug cap.(They may be damaged with put-in and

remove procedure.)

(Fig.54)

Attention:

White marking arranged

symmetrical position

-Set the ferrules so that the white mark on the

optical fiber cord connected to one connector may

be symmetrical to that on the optical fiber cord

connected to another. (Fig.55)

(Pay attention to the positions of the

light-emission and light reception sides of the

two optical connectors.)

(Fig.55)

19

When pull the cord,

the ferrules are also

moved back .

When release,

ferrules return to

the original position. (5) To examine the connector assembled

correctly , pull the optical fiber cord lightly

(<20N) on and off holding the plug case ,

and see if the ferrules move to it. (Fig.56)

If not, there may be something wrong

inside.

Please disassemble and check up.

(Fig.56)

Table of contents