Summer Ar-Gone Weld Gas Analyzer User manual

OPERATOR’S MANUAL

Ar-Gone Weld GAs AnAlyzer

July 2011

WARNING!

Before operating this product,

read and understand this

Operator’s Manual.

Become familiar with the

potential hazards of this unit.

Contact SUMNER

if you have any questions.

www.sumner.com

2

OWNER’S RESPONSIBILITIES

Throughout this publication, the words WARNING, CAUTION

and IMPORTANT will be used to alert the user to special

instructions concerning a particular operation that may be

hazardous if performed incorrectly or carelessly.

OBSERVE THEM CAREFULLY !!

WARNING Hazards or unsafe practices which could

result in severe personal injury or death.

CAUTION Hazards or unsafe practices which could

result in minor personal injury, product

or property damage.

IMPORTANT Indicates information or instructions that

are necessary for proper operation and/

or maintenance.

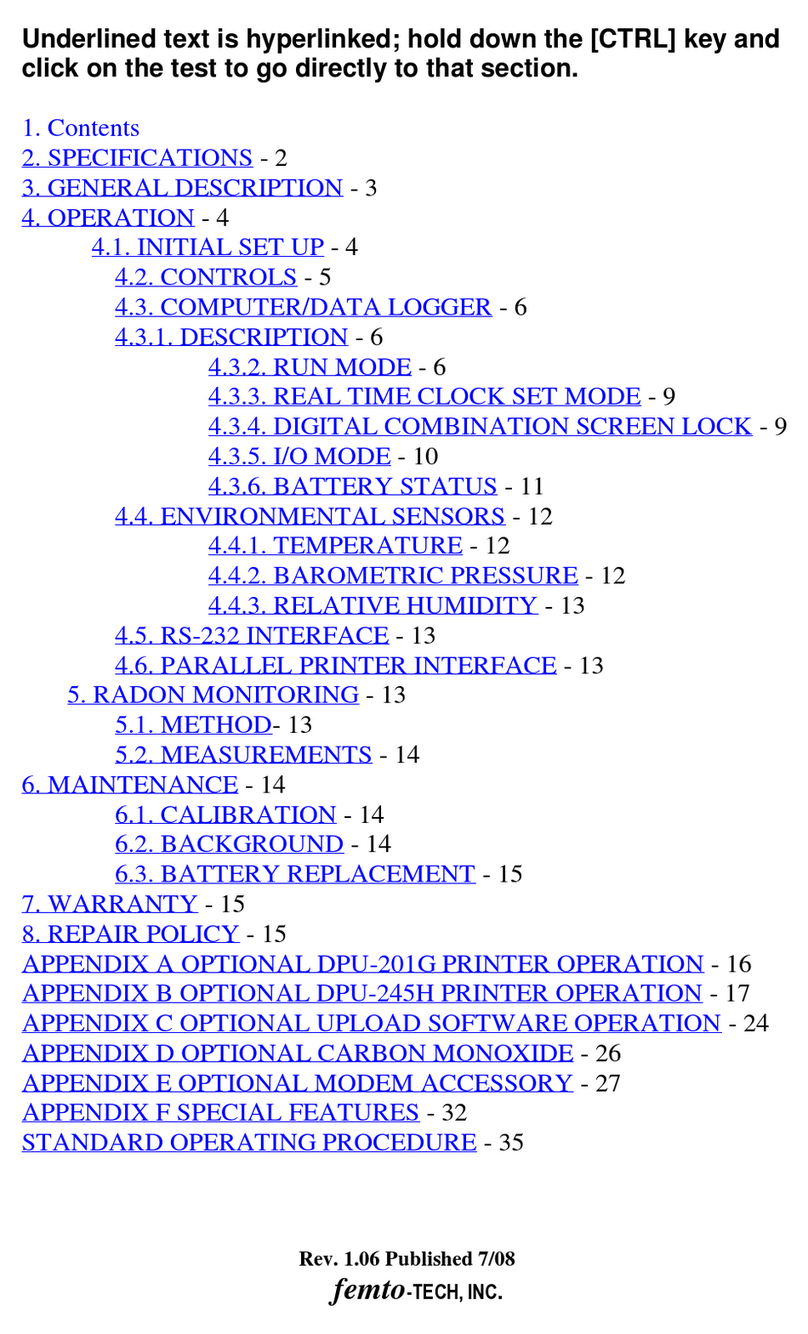

Index

General............................................................................................. 3

Before Use................................................................................. 3

Unpacking......................................................................................... 3

The Complete Kit.............................................................................. 3

Assembling Your Weld Gas Analyzer............................................... 4

Instructions For Use ......................................................................... 5

Instrument Care................................................................................ 5

Sensor Care ..................................................................................... 6

Sensor Replacement........................................................................ 6

Troubleshooting................................................................................ 7

Oxygen Calibration Table ................................................................. 8

3

General

The Ar-Gone Weld GasAnalyzer reliably and

accurately measures the oxygen content in the

welding environment, enabling you to closely monitor

the quality of your purge. It will tell you as soon as a

low enough oxygen content has been reached to start

welding which will save time and argon gas and can

also monitor the purge atmosphere during welding to

warn you if any oxygen penetration occurs.

Before Use

• Carefullyreadtheseinstructionsbeforeusingyour

weld gas analyzer.

• Donotputpressureonthemeasuringsensorin

the Weld GasAnalyzer.

• AlwaysconnecttheWeldGasAnalyzertoa

volume that has an exhaust to avoid pressurizing

the sensor.

• DonotusetheWeldGasAnalyzerdirectly

connected to a gas bottle.

• Alwaysconnectaregulatorandowmetertothe

gas bottle.

Unpacking

The Ar-Gone Weld GasAnalyzer is supplied in a

lightweight storage case that is easily portable and will

assist in assuring your instrument’s safety and

longevity.

Your Weld Gas Analyzer was thoroughly tested and

calibrated before dispatch and is ready for you to use

immediately. However, we recommend checking the

instrument for shipment damage before use. If

damaged please do not use and notify Sumner

Manufacturing or your distributor.

The Complete Kit

Your Weld Gas Analyzer kit contains the following:

• Ar-GoneWeldGasAnalyzer

• Oxygensensor(alreadytted)

• Flowadapter

• Metalsamplingprobe

• 6-1/2’(2m)rubberhoseforconnectiontothe

sampling probe

• Rubberaspiratorbulb(ttedwith250mm

connectionhose)

• Carryingstrap

• Operatinginstructions

• Calibrationandtestcerticate

4

6.Connectthehosettedtotheaspiratorbulb(E)to

oneportoftheowadapter.Theaspiratorbulbis

used to draw a gas sample to the sensor for

measurement.

7.Connectthesteelsamplingprobe(F)tooneendof

therubberhose(G)andconnecttheotherendof

thehosetoremainingportoftheowadapter.

8.Clipthecarryingstrap(H)intotheloopsoneach

side of the Weld GasAnalyzer.

YourAr-Gone Weld Gas Analyzer is now ready for use.

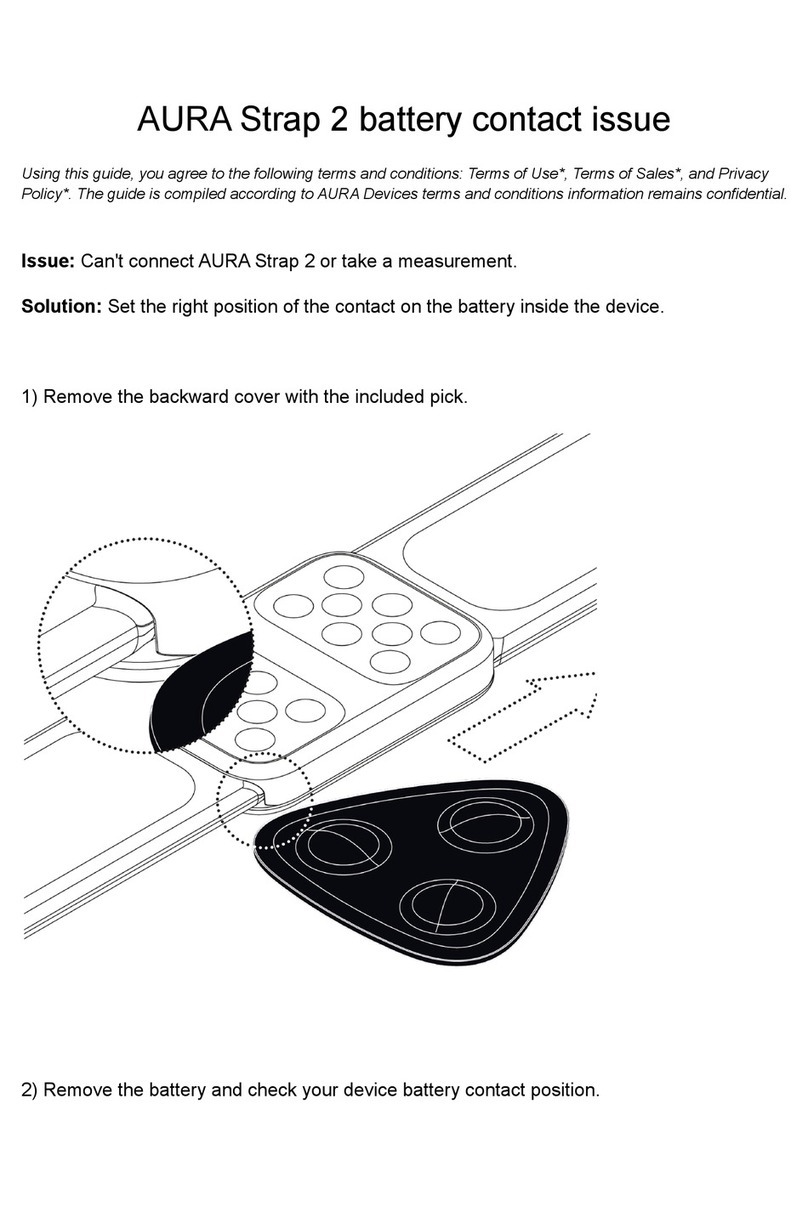

Assembling Your Weld Gas

Analyzer

1. The sensor of your Weld Gas Analyzer is covered

byanadhesivefoamseal(A)whichprotectsit

duringshipment.Removethissealbeforetherst

use since it will hinder the gas reaching the sensor.

2. Switch on your Weld Gas Analyzer using the on/off

switch(B).

3. Adjust the oxygen content displayed to the air oxy-

gen content of 20.90 % using the adjustment wheel

(C).

4. Wait 5 minutes to allow display to stabilize.

Re-adjust if necessary.

5.Connecttheowadapter(D)tothesensoroutletof

the Weld GasAnalyzer.

A

B

C

D

E

F

G

H

5

Instructions For Use

The Ar-Gone Weld GasAnalyzer can be used for all

purge applications where the oxygen content has to be

monitored. This includes purging with purge bladders,

purgedams,siliconediscsystems,solublepurgelms

and papers as well as foam dams and welding

enclosures and chambers.

For the best welding results, Sumner Manufacturing

recommendstheuseofinatablepurgedamsystems

together with your Ar-Gone Weld GasAnalyzer when

welding pipe work and tubular vessels.

1. Your Weld GasAnalyzer can be secured on the

pipe using the carrying strap.

2a.WhenusingaSumnerinatablepurgesystem

together with the Weld GasAnalyzer, the metal

sampling probe may be removed from the

connection hose. The connection hose can then

be directly connected to the exhaust outlet of the

purge system. This guarantees reliable continuous

measurements of the oxygen content in the purge

environment.

2b. Whenusingotherpurgebladders,papers,lms

etc., the metal sampling probe can be inserted

through the weld gap between the two pipes that

arebeingjoined(ifopenrootgapweldingis

applied).

3. Once the Weld Gas Analyzer is connected to the

purge volume, a sample of the gas can be drawn

by squeezing the aspirator bulb.

4. Once the appropriate oxygen level has been

reached(usuallyaround0.1%)andappears

stable, welding can begin.

5. Weld gas samples should be drawn regularly

throughout welding since oxygen penetration can

damage the weld at any stage of the welding

process.

IMPORTANT

Sampling with the aspirator bulb will

pressurize the sensor and can cause

a slight distortion of readings for a

few seconds. This does not reect the

actual oxygen level in the purge and

will return to normal within seconds.

IfconnecteddirectlytoaSumnerinatablepurgedam

system,gaswillowoverthesensorcontinuously.

This allows a constant and close monitoring of the

oxygen level throughout the duration of the weld

without having to draw samples.

Instrument Care

The Ar-Gone Weld GasAnalyzer is a very

accurate instrument and if looked after properly will

give many years of accurate oxygen measurement.

There are very few parts that wear out except sensors

and batteries. The instrument is robust and designed

to be used in the welding environment.

Although it is protected against water it should not be

submerged, left in standing water or left outside

unprotected against weather.

The instrument should be cleaned with warm soapy

water(notimmersed).Nodetergentsorsolvents

should be used on the case or sensor.

Never use the Ar-Gone Weld GasAnalyzer once the

low battery indicator is visible, from this point the

electronics quickly become unstable and will produce

false readings.

DonotsubjecttheAr-GoneWeldGasAnalyzertome-

chanicalshocks.Althoughrobust,theLCDdisplayisa

glass component and can be broken. This is

usually apparent by black areas spreading across the

LCDscreen.

The Ar-Gone Weld GasAnalyzer should be kept in

its case when not in use and should be shielded from

high and low temperatures and long exposure to

sunlight.

Regular Calibration

For greatest accuracy the Ar-Gone Weld GasAnalyzer

should be re-calibrated in normal air every 8 hours.

1. Switch on instrument

2.Removeowadapter

3. Move instrument through air slowly

4. Use calibration knob to set to appropriate reading

forcurrentaltitude(seeOxygenCalibrationTable)

Replacement of Instrument Parts

The case of the Ar-Gone Weld GasAnalyzer is

hermetically sealed to prevent water damage and

contamination. The only parts that can be replaced by

the user are the batteries and sensor.

6

Contact your distributor or Sumner Manufacturing

directly for return instructions. When doing so please

have serial number and purchasing information handy.

Sensor Care

CAUTION

The sensor may be cleaned with warm

water but should never be submerged

in water.

CAUTION

Do not use excessive force to rotate

the sensor into the inner compart-

ment as this can damage the threads.

Sensors prefer a cool and damp environment when

stored.

Never:

• Storesensorsforlongperiodsbeforeuse.

• Subjectsensorstohightemperatures.

• Freezesensors(e.g.leaveon-siteovernight).

• Storeinasealedcontainerwithlimitedorno

oxygen. When this occurs it can take several

hours for the analyzer to stabilize when put back

into use.

• Subjectsensorstophysicalshocks.

• Subjectsensorstoavacuum.

• Submergesensorsinliquids.

• Attempttoopenasensor.

IMPORTANT

Sensors deteriorate very slowly

and near the end of their useful life

may show a drift up or down soon

after calibration. Sensors should be

checked periodically in 100% oxygen

or pure argon.

Sensor Life Expectancy

Sensor life expectancy depends on the amount of

oxygenitisexposedtoandisnotinuencedby

whethertheinstrumentisswitchedonoroff(this

howeverwillaffectbatterylifeexpectancy).Inambient

air sensors will usually work for 24 to 48 months. In an

oxygendeprivedenvironment(i.e.whenusedregularly

duringpurging)thesensorlifewillnormallyincrease.

Correct Sensor Disposal

The sensor contains an electrolyte which is caustic.

Leaking or exhausted sensors should be disposed of

in accordance to local regulations which are usually

similar to the disposal of batteries.

Sensor Replacement

Replacement sensors are supplied by Sumner

Manufacturing.

It is not recommended to stock replacement sensors

since the shelf life and performance will decrease

when they are not in use.

1. Switch off your Weld GasAnalyzer and remove the

owadapter.

2. Remove the battery compartment cover by sliding it

off and disconnect the battery.

3. PlacetheWeldGasAnalyzerface-downonaat

and stable surface and remove the four screws in

thecornersoftherearofthecase.Disconnectthe

back casing from the front casing.

I

7

4. Thesensor(I)iswiredtothecircuitboard.Wires

are connected to the sensor by a pin connector

which can be disconnected by lifting the locking

latch on the connector outwards. The connector

can be lifted off the connector housing which is

located on the circuit board.

5. Unscrew the sensor and remove it.

6. Screw the new sensor in place and re-connect the

pin connector to the connector housing by pushing

it in.

7. Re-attach the back casing to the front casing using

the 4 screws. Take care to feed the battery wires

into their slots in the case.

8. Reconnect the battery and put the battery cover

back in place.

9. SwitchonWeldGasAnalyzertoconrmthatitis

working properly.

First Aid Procedures:

CAUTION

The electrolyte in the sensor is

caustic, very similar to the

electrolyte in batteries.

If it gets in contact with eyes or skin

it can cause irritation and burning or

stinging.

Wash and rinse affected area with

plenty of water and seek medical

attention if burning persists.

In case of ingestion drink plenty of

cold water, do not induce vomiting

and seek medical attention

immediately.

Troubleshooting

Problem Possible reason Solution

No display Not switched on Switch on

Batteries dead Replace batteries

Batteries inserted incorrectly

Lo symbol appears Low battery Replace batteries

Turns off during welding Turns off automatically after 5

minutes of stable readings Switch on

Zero reading Sensor disconnected, deposit in jack

plug or sensor jack socket Rotate sensor whilst in instrument

Not calibrating to 20.9 Sensor exhausted Replace sensor

Zero reading

Reading drifts

Sensor nearly exhausted Replace sensor

Sensorinowinggastoolong Removesensorfromgasow

Ambient temperature changes Check ambient temperature

Strong winds Shield against winds

Inaccurate reading

Old sensor Replace sensor

Toohighowpressurizessensor Reducegasowifpossible

RF interference Move away frmo RF source

(e.g.radio)

Condensation on sensor face Remove condensate

0.1% oxygen levels cannot be

reached

Sensor not calibrated in air Move calibration wheel in air to

display 20.9

Purge gas is not pure enough Measure purge gas sample directly

Leak in gas hose Check gas hose

Pipe is contaminated Clean pipe from dirt, oil or moisture

Porous purge materials used Usehigherowrateifpurgingwith

foam,paperorsolublelms,use

pure system

8

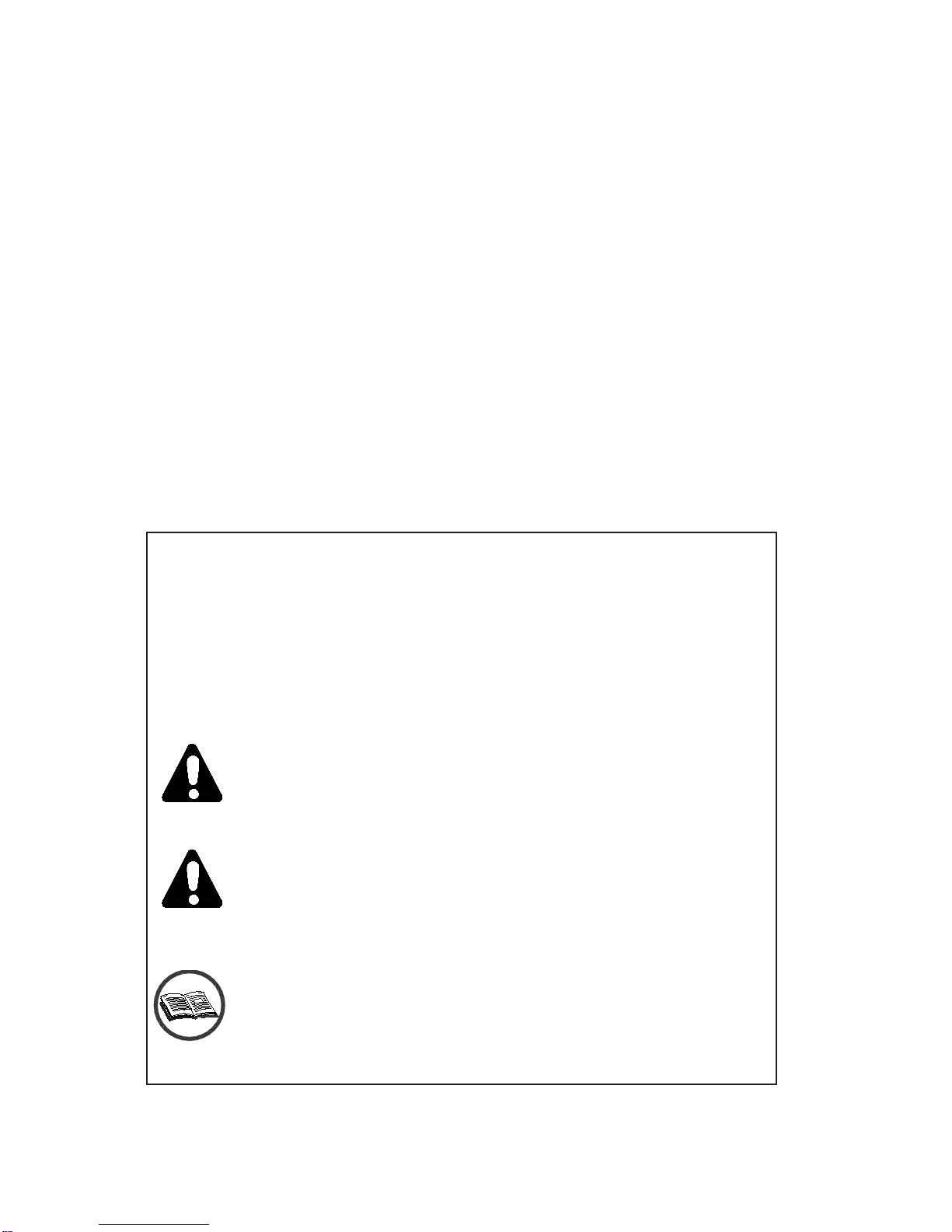

Oxygen Calibration Table

The Effects of Pressurizing the Sensor

Oxygen sensors usually do not measure the

percentage of oxygen in a mixture of gas but they

measure the partial pressure of oxygen. This is why

Weld GasAnalyzers can sometimes give erratic

readingswhenexposedtotoohighgasoworstrong

winds which cause the sensor to be pressurized.

Feet

(above sea level) Meters

(above sea level) Calibrate Sensor To

0 0 20.90

1,000 305 20.20

2,000 610 19.40

3,000 915 18.70

4,000 1,220 18.10

5,000 1,525 17.40

6,000 1,830 16.80

8,000 2,440 15.50

10,000 3,050 14.40

12,000 3,660 13.30

The Effects of Altitude on the Sensor

Thepartialpressureofoxygeninairis0.209bar(20.9

%)atsealevel.Inhigheraltitudestheairbecomes

thinner and the partial pressure of oxygen in the air

changes.Thecalibrationgureof20.90inaircanbe

adapted to the altitude to ensure optimum accuracy.

Please see table below for more information.

Table of contents

Popular Measuring Instrument manuals by other brands

Topcon

Topcon RL-H3C instruction manual

Graco

Graco IM5 Instructions and parts list

FujiFilm

FujiFilm FUJI DRI-CHEM IMMUNO AU CARTRIDGE vf-SAA Instructions for use

Stahl

Stahl 8485/111-42 operating instructions

Industrial Test Systems

Industrial Test Systems eXact iDip quick start guide

Niigata seiki

Niigata seiki SCDI S Series instruction manual