7.2 Connecting with SOPAS ET....................................................................... 49

7.3 Changing the IP address on the BCU...................................................... 50

7.4 Adjusting.................................................................................................... 50

7.4.1 Setting the test gas.................................................................. 50

7.4.2 Setting the test gas with SOPAS ET........................................ 50

7.4.3 Determining adjustment gas purging times........................... 51

7.4.4 Determining calibration gas purging times with SOPAS ET... 51

7.4.5 Selecting the gas sampling unit for validation and calibra‐

tion............................................................................................ 51

7.4.6 Performing zero point validation and adjustment................. 52

7.4.7 Performing zero point validation and adjustment with

SOPAS ET.................................................................................. 52

7.4.8 Performing sensitivity validation or adjustment.................... 53

7.4.9 Performing sensitivity validation or adjustment with SOPAS

ET.............................................................................................. 53

7.4.10 Programming automatic adjustment and validation............. 53

7.4.11 Setting automatic validation and adjustment with SOPAS

ET.............................................................................................. 54

7.5 Parameterization....................................................................................... 54

7.5.1 Setting the time....................................................................... 54

7.5.2 Setting the heating controller................................................. 55

7.5.3 Setting the cooler temperature............................................... 55

7.5.4 Checking the condensate pump cooler.................................. 56

7.5.5 Setting the instrument air flow............................................... 56

7.5.6 Adjusting the flow sensor with SOPAS ET............................... 56

7.5.7 Setting the measuring and purging times.............................. 57

7.5.8 Setting the measuring and purge times with SOPAS ET....... 57

7.5.9 Activating and deactivating measuring points....................... 58

7.5.10 Activating and deactivating measuring points with SOPAS

ET.............................................................................................. 58

7.5.11 Setting analog outputs with SOPAS ET................................... 59

7.5.12 Testing analog outputs with SOPAS ET................................... 59

7.6 Performing the leak tightness check....................................................... 59

7.7 Recognizing the safe operating state...................................................... 61

7.7.1 Recognizing the safe operating state..................................... 61

8 Operation............................................................................................ 62

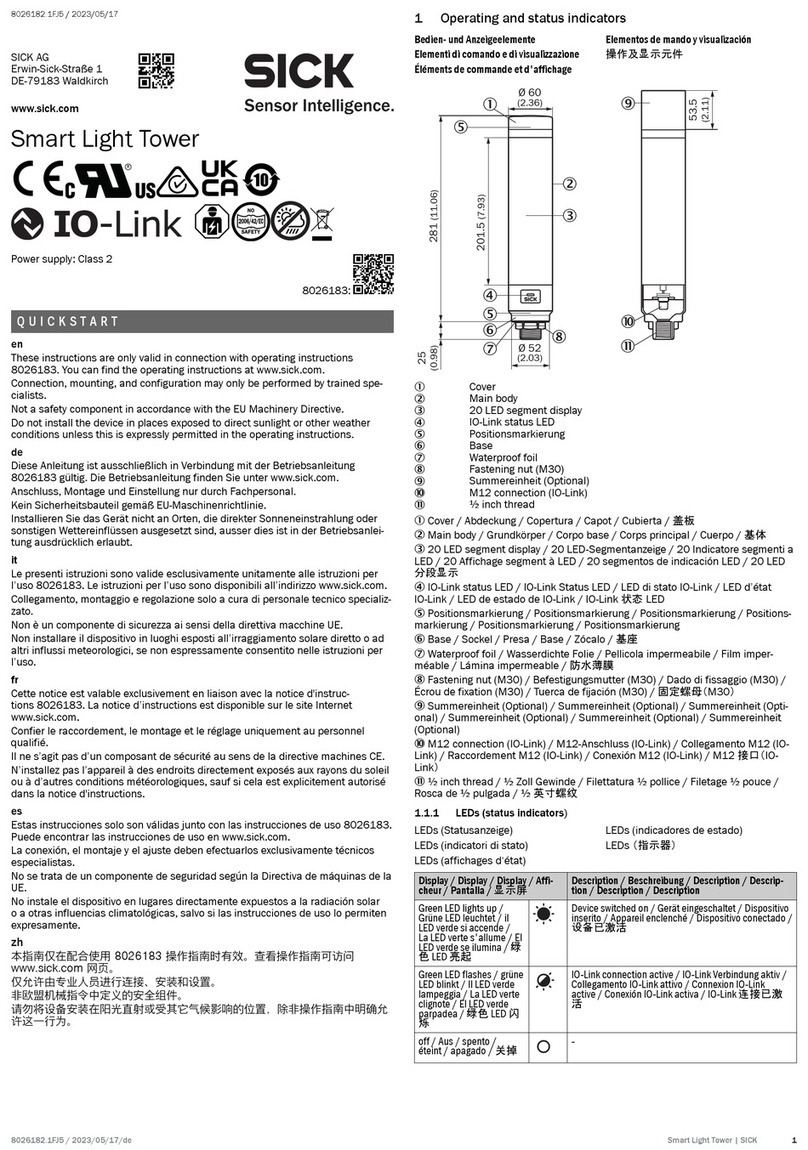

8.1 Operating and display elements.............................................................. 62

8.1.1 LED........................................................................................... 62

8.1.2 Function buttons ..................................................................... 62

8.2 Status messages...................................................................................... 63

8.2.1 Opening the logbook................................................................ 63

8.2.2 Checking the DEFOR hours of operation................................ 63

8.3 Activating Standby mode.......................................................................... 64

8.4 Switching the device off........................................................................... 64

8.5 Modbus functions..................................................................................... 64

8.5.1 Activating Modbus functions................................................... 64

CONTENTS

8021339/1CHC/V1-1/2021-07 | SICK O P E R A T I N G I N S T R U C T I O N S | MARSIC280 5

Subject to change without notice