PS-2078 Page 4 of 4

Limited Warranty

ESD Systems.com expressly warrants

that for a period of one (1) year from the

date of purchase, our Mini Megs will be

free of defects in material (parts) and

workmanship (labor). Within the

warranty period, the unit will be tested

repaired or replaced at our option, free of

charge. Call Customer Service at 508-

485-7390 for a Return Material

Authorization (RMA) and proper

shipping instructions and address. You

should include a copy of your original

packing slip, invoice, or other proof of

purchase date. Any unit under warranty

should be shipped prepaid to the ESD

Systems.com factory. Warranty repairs

will take approximately two weeks.

If your unit is out of warranty, ESD

Systems.com will quote repair charges

necessary to bring your unit to factory

standards. Call Customer Service at

508-485-7390 for a Return Material

Authorization (RMA) and proper

shipping instructions and address.

Warranty Exclusions

THE FOREGOING EXPRESS

WARRANTY IS MADE IN LIEU OF

ALL OTHER PRODUCT

WARRANTIES, EXPRESSED AND

IMPLIED, INCLUDING

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE

WHICH ARE SPECIFICALLY

DISCLAIMED. The express warranty

will not apply to defects or damage due

to accidents, neglect, misuse, alterations,

operator error, or failure to properly

maintain, clean or repair products.

Limit of Liability

In no event will ESD Systems.com or

any seller be responsible or liable for any

injury, loss or damage, direct or

consequential, arising out of the use of or

the inability to use the product. Before

using, users shall determine the

suitability of the product for their

intended use, and users assume all risk

and liability whatsoever in connection

therewith.

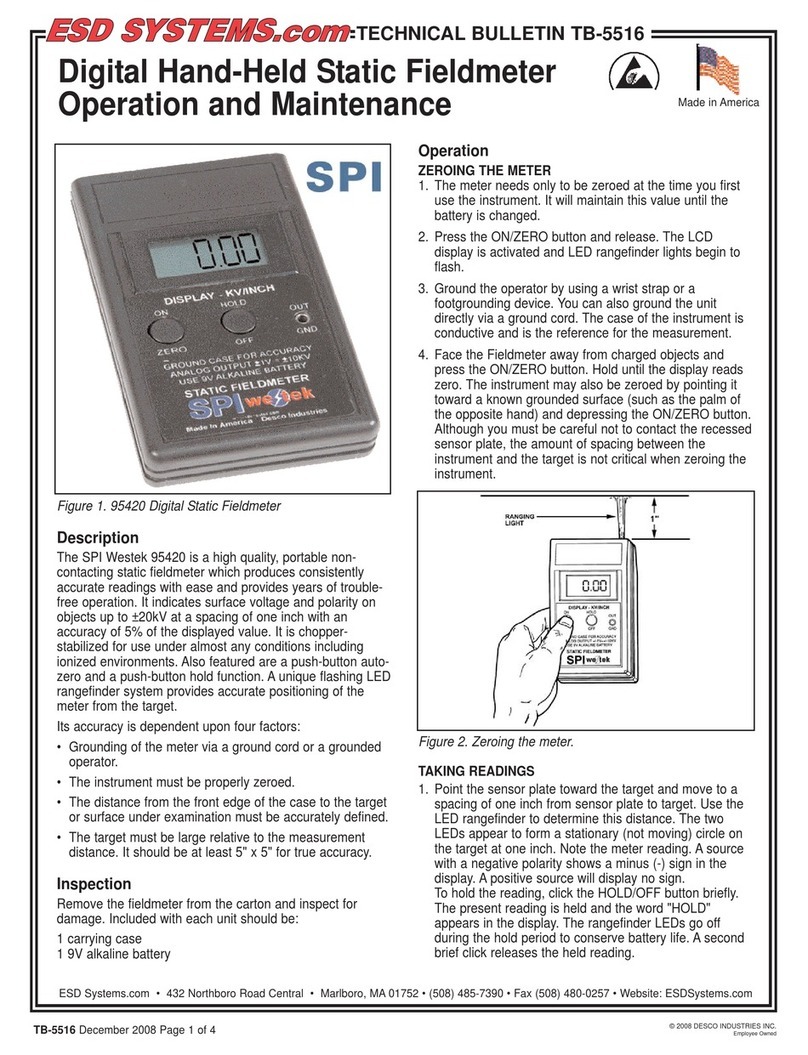

Relative Humidity 0% to 99% (non

condensing)

Operation Resistance bridge

Readout Seven LEDs

Resolution One order of

magnitude

Accuracy ±10% all, except

±20% 109, 1010

Repeatability ±3%

Weight 6 ounces

Dimensions 4" x 2.5" x 1.75"

Calibration

The 41256 is calibrated to NIST

traceable standards. Any MiniMeg

may be returned to the factory for

calibration. Contact our Customer

Service Department at (508) 485-7390

for a Return Material Authorization.

Written Purchase Orders are required

for calibration services.

A check on the function of the

MiniMeg can be performed with the

following procedure. You will need

1% resistors of the following values:

100K, 1M, 10M, 100M, 1G and 10G

ohms. These precision resistors will be

placed across the two electrodes on

the bottom of the meter (see Figure 8).

A. Place the MiniMeg on an insulator

(e.g. Teflon or glass) and press the

white test button. Only the first red

LED on the right, marked “On”

should be illuminated. If this LED

fails to light, the battery should be

replaced before proceeding.

B. Place the 10G ohm resistor across

the middle electrode and the side

electrode as illustrated in Figure 8.

Press the test button. The second LED

should light. Be sure not to contact the

leads or the buttons as your body’s

resistance will affect the readings.

Figure 8. Calibration of the MiniMeg

C. Continue this process with each

consecutive resistor, checking to make

sure the appropriate LEDs are

illuminated. If all resistors check

properly, the unit’s calibration is

verified.

Adjustment

Unauthorized servicing or

modifications to the MiniMeg will

void the product warranty. Servicing

should only be performed by the

factory. See warranty section for repair

charges.

RESISTOR

ELECTRODE

Visit our online

library of Tech Briefs:

http://www.esdsystems.com/

432 NORTHBORO ROAD CENTRAL

MARLBORO, MA 01752-3170

PHONE (508) 485-7390

FAX (508) 480-0257

© 2005 DESCO INDUSTRIES INC.

Employee Owned