4

OPERATOR SAFETY INSTRUCTIONS

IMPORTANT

Read and understand this instruction manual prior to

operating or performing maintenance on this tool.

3. Wear proper clothing. Hard hat, protective

eye covering, safety shoes and gloves should

be worn as a precaution while operating this

equipment.

4. Keep work areas clean. Always keep floor in

work area clear of clutter.

5. Keep alert. Avoid horseplay around equipment

and keep bystanders at a safe distance. Do not

allow children to operate this tool and always

keep them out of work areas.

6. Do not misuse tool. Perform only the function

for which the tool is designed. Never attempt to

operate the equipment for more than the recom-

mended function.

WARNING - Using the Clamp Champ as a

reforming tool on pipe unit greater than 1" or

25mm may result in operator injury or

damages to the tool.

7. Use only factory recommended

accessories.

CAUTION - Use of improper accessories

may be hazardous.

WARNING - The Clamp Champ is not to be

used in fitting applications.

To accomplish each of the functions safely requires

dexterity and mechanical skills, as well as sound

safety habits.

Although the Clamp Champ is manufactured for

safe, dependable operation, it is impossible to

anticipate those combinations of circumstances

which could result in an accident. The following

instructions are recommended for safe operation of

this tool.

1. Read and understand the Operator's

Manual. Before operating this tool, read the

Operator's Manual carefully. Become familiar

with the tool operation, applications and limita-

tions. Always contact the factory if in doubt. Be

particularly aware of its specific hazards. Store

the Operator's Manual in a clean area and

always at a readily available location. Additional

copies are available at no charge by request at

sumner.com.

2. Inspect the equipment. Prior to suing the

Clamp Champ, check all parts to ensure that

they are in proper operating condition.

IMPORTANT - Make any necessary repairs

before attempting to operate the unit.

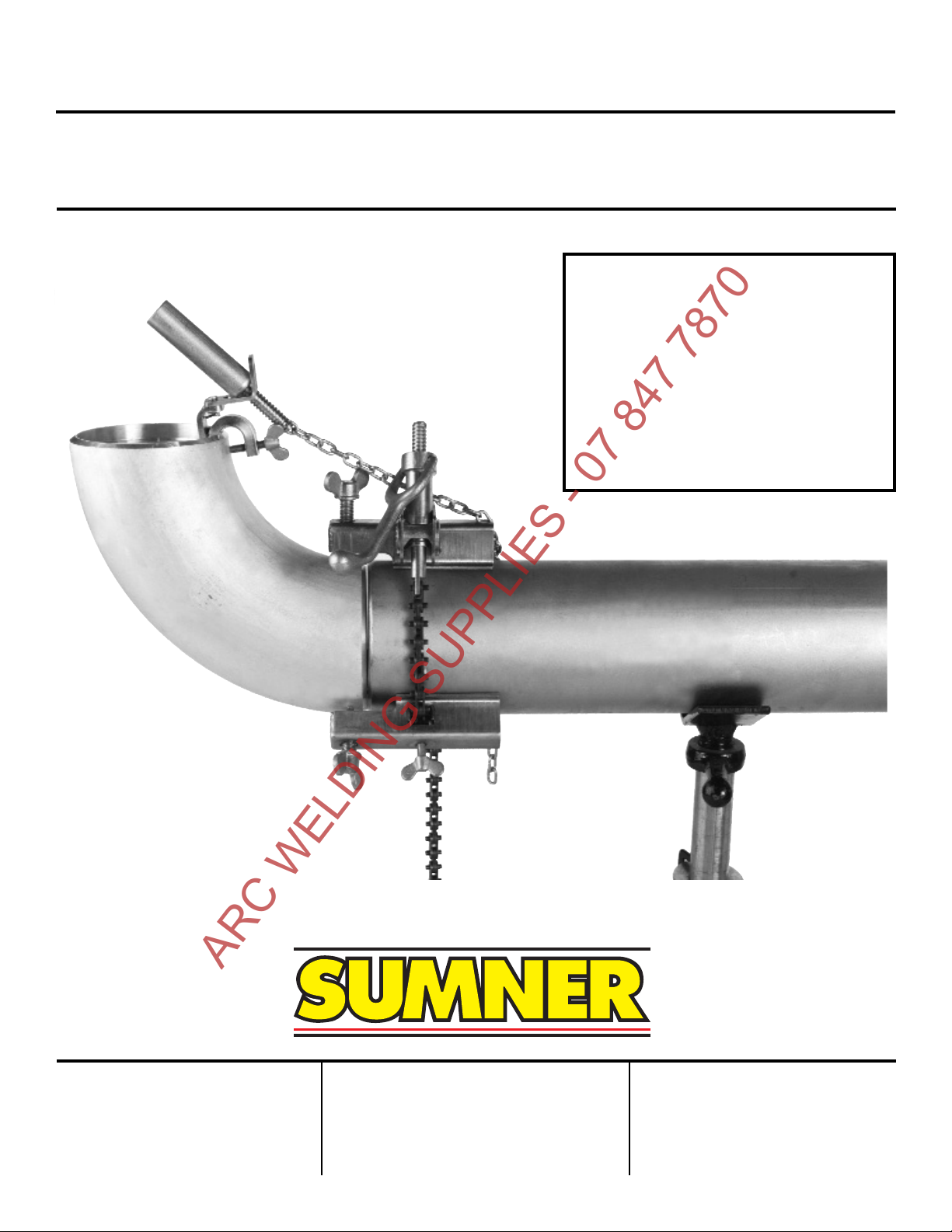

The Sumner Clamp Champ is designed for positioning and aligning pipe and fittings in the

range of 1-10", 1-16" and 10-36" Additional pipe sizes can be achieved using Clamp

Champ extension kits.

Sumner Clamp Champ, Operator’s Manual