Certified Automotive Grade Cells generally do not require balancing; however, you may choose

to balance your cells, we have a video explaining this process.

This process is explained in this tutorial video:

https://www.youtube.com/watch?v=JGbZozzCYvM

NOTE: if you are using an RTB (ready to build kit) the active balancer will assist in top balancing

your cells, simply assemble your pack, charge the battery at 5-20 amps and within 1-2 hours

your cells should be even balanced. Again, certified cells that are included with your RTB kit will

balance very quickly and the active balancer is included simply to assist balancing during high

amperage charging (over 80 amps).

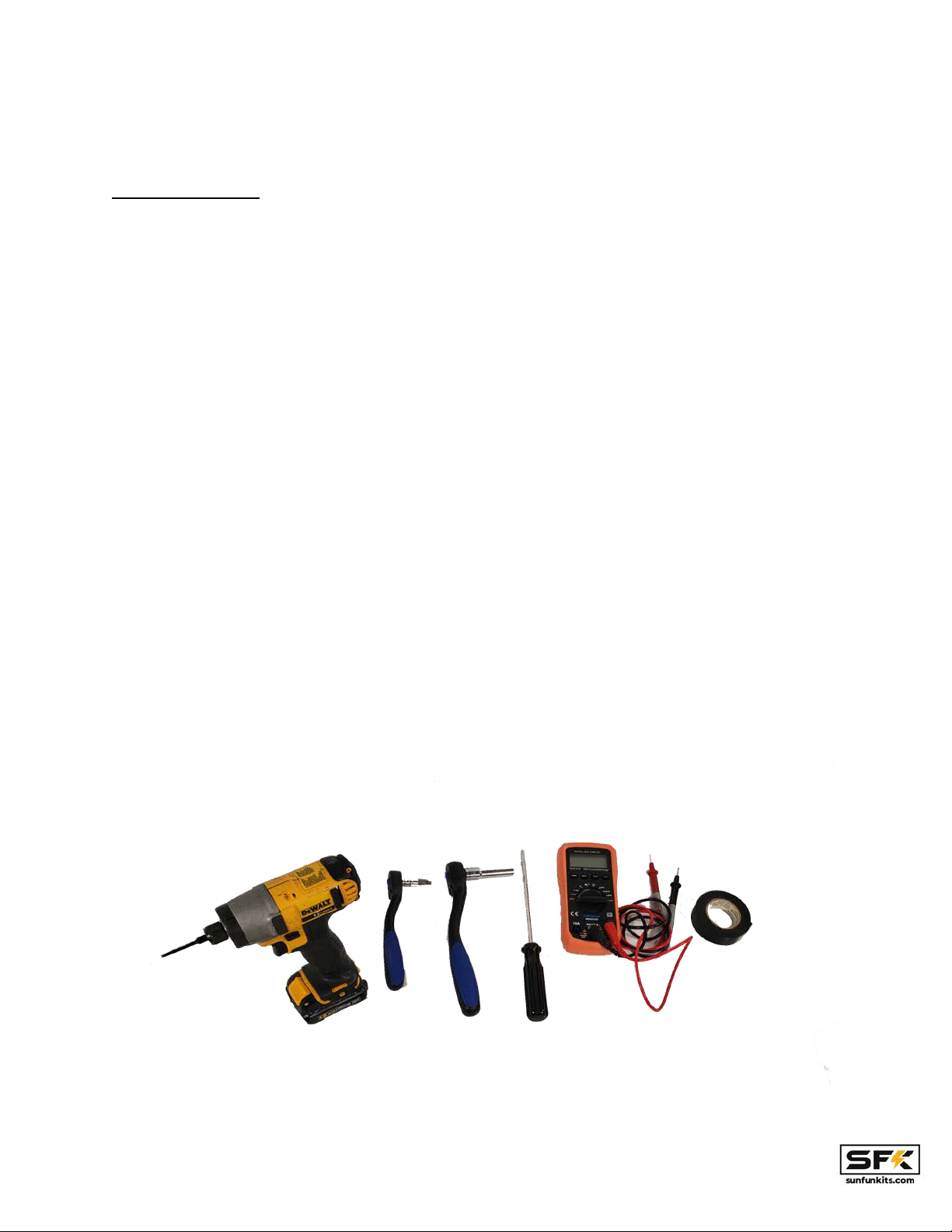

Assembling your battery cells:

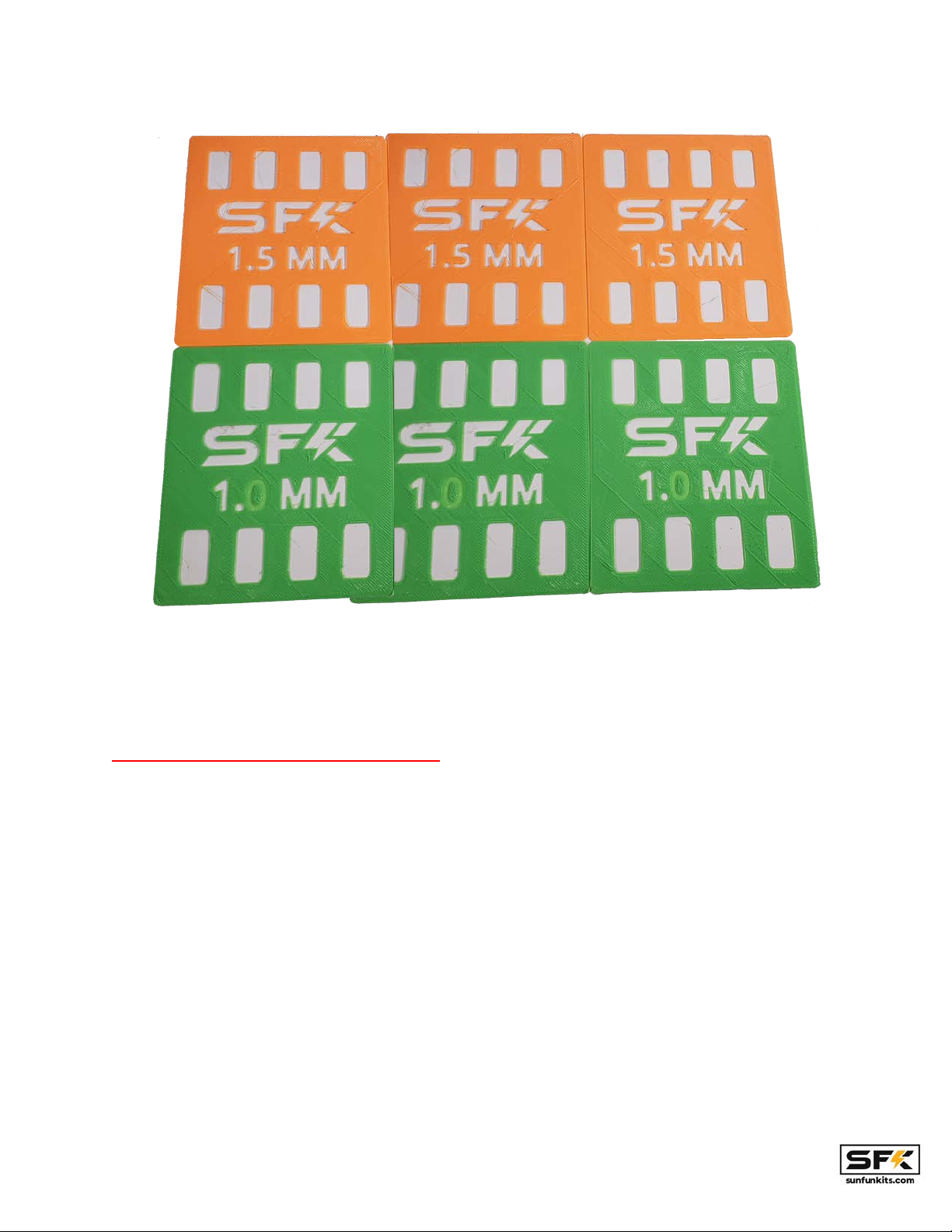

Starting with version 3.5 we are now including different cell shims or spacers, this allows users

to have a nice tight fit while also adding a third layer of insulation between cells. Version 3.5

includes 1 set of 1.5mm and 1.0mm shims (3 pieces each). The shims should be placed

between the inner cells and most installs will use about 3 shims. For Sun Fun Kits certified cells

(280K and LF304) you should be able to use 3 x 1.5mm shims to complete the install and have

a nice tight fit.

Page: 4 V3.5 Manual - Revision 1.3