Contents v

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Quality and Regulatory Systems. . . . . . . . . . . . . . . iii

Health and Safety Information . . . . . . . . . . . . . . . . iii

Section 1. Introduction . . . . . . . . . . . . . . . . . . 1

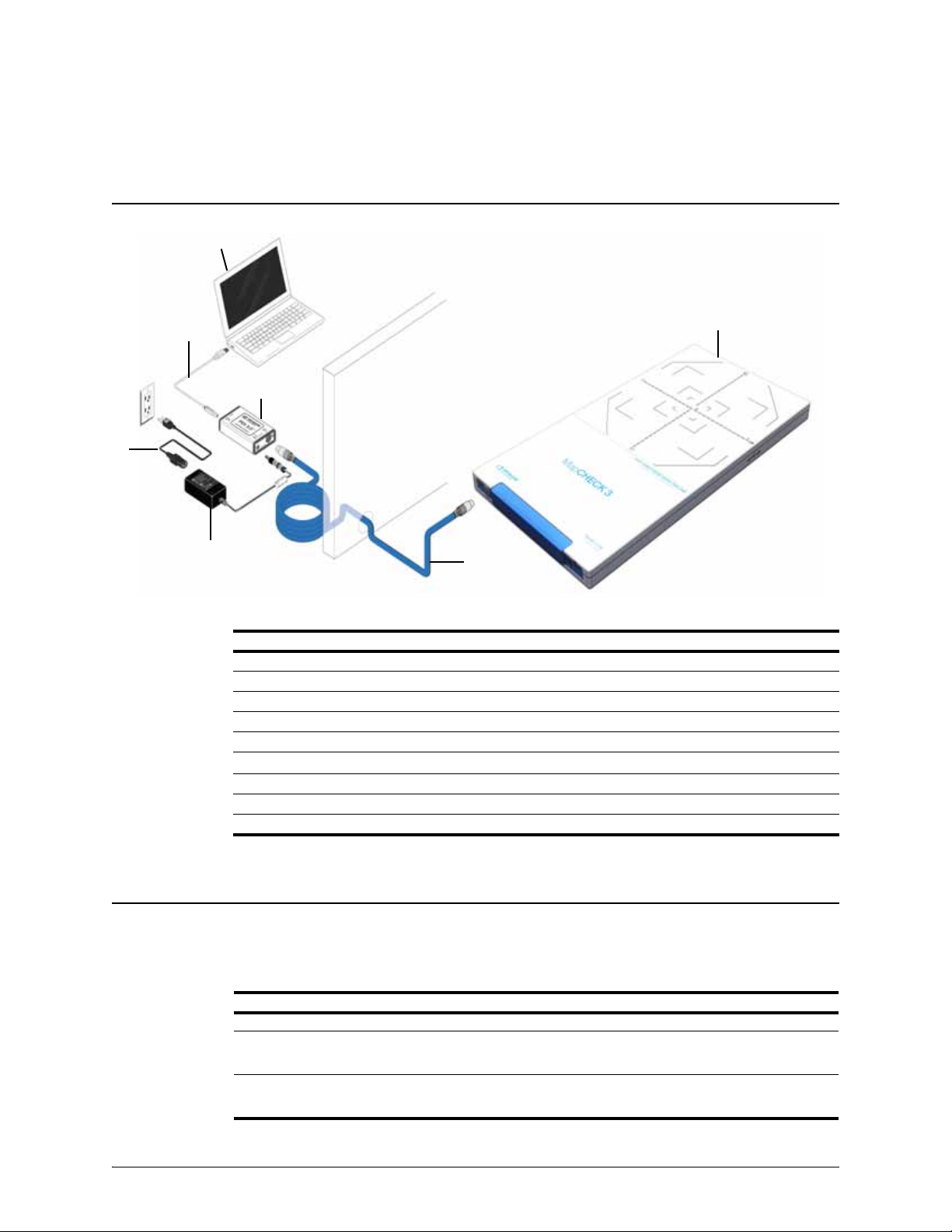

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Products, Options and Accessories . . . . . . . . . . . . 1

MapCHECK 3 Quick Start Procedure . . . . . . . . . . . 2

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Connect Hardware and Launch Software . . . . . 3

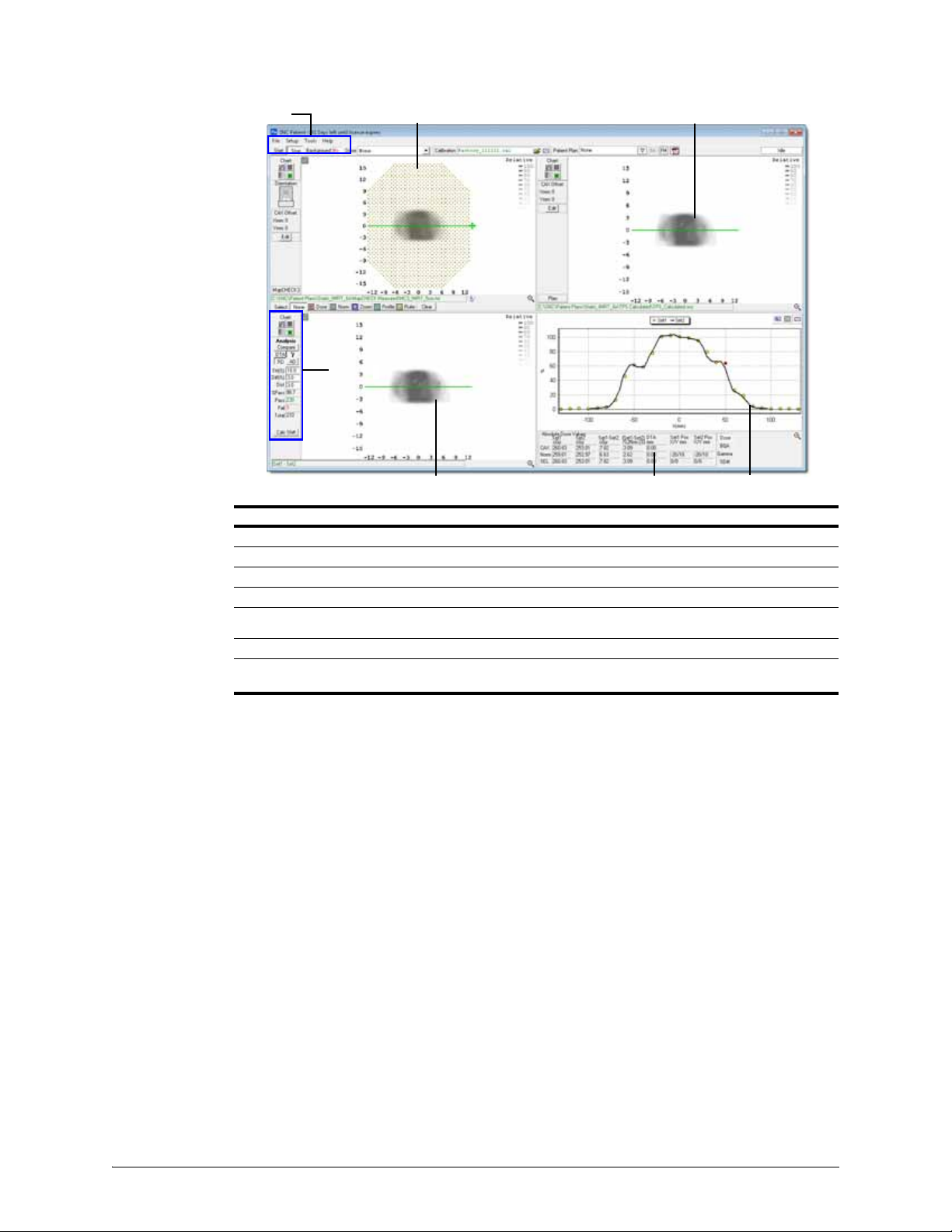

Overview of SNC Patient Software . . . . . . . . . . 4

Section 2. Operation . . . . . . . . . . . . . . . . . . . . 5

Temperature Equilibrium. . . . . . . . . . . . . . . . . . . . . 5

Background Measurement . . . . . . . . . . . . . . . . . . . 5

Array Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Array Calibration Conditions. . . . . . . . . . . . . . . . 5

Array Calibration Modes. . . . . . . . . . . . . . . . . . . 5

Flattening Filter Free (FFF) Beams . . . . . . . . . . . 6

Array Calibration Procedure . . . . . . . . . . . . . . . . 6

Recalibration Interval . . . . . . . . . . . . . . . . . . . . . 6

Absolute Dose Calibration. . . . . . . . . . . . . . . . . . . . 6

Dose Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Absolute Dose for Static Deliveries . . . . . . . . . . . . 6

Determine the Known Dose. . . . . . . . . . . . . . . . 6

Recommended Method . . . . . . . . . . . . . . . . 6

Alternate Methods. . . . . . . . . . . . . . . . . . . . . 7

Deliver Absolute Dose Calibration

Measurement . . . . . . . . . . . . . . . . . . . . . . . . 7

Absolute Dose for Rotational Deliveries . . . . . . . . . 8

Determine the Known Dose. . . . . . . . . . . . . . . . 8

Deliver Absolute Dose Calibration

Measurement . . . . . . . . . . . . . . . . . . . . . . . . 9

Set Up File Manager . . . . . . . . . . . . . . . . . . . . . . . . 9

Creating a New Patient Plan. . . . . . . . . . . . . . . . 9

Adding Files to Patient Plan . . . . . . . . . . . . . . . . 9

Position MapCHECK 3 for Measurement . . . . . . . . 9

Measurement Without MapPHAN Accessory . . 9

Measurement with MapPHAN Accessory . . . . 10

Acquire Measurement . . . . . . . . . . . . . . . . . . . . . . 10

MapCHECK 3 Measurement File Formats . . . . 11

Import Planned Dose. . . . . . . . . . . . . . . . . . . . . . . 11

Compare Device Measured to Planned Dose . . . . 12

Section 3. Support and Maintenance . . . . . . 13

Hardware Maintenance . . . . . . . . . . . . . . . . . . . . . 13

Minimizing Radiation Damage . . . . . . . . . . . . . 13

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Disposal and Recycling. . . . . . . . . . . . . . . . . . . 13

Maintaining Firmware . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Contacting Sun Nuclear Support . . . . . . . . . . . . . . 15

Support Website . . . . . . . . . . . . . . . . . . . . . . . . 15

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Section 4. Hardware Reference. . . . . . . . . . . 17

Top and Bottom Panels . . . . . . . . . . . . . . . . . . . . . 17

Detector Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Detector Plane Marking. . . . . . . . . . . . . . . . . . . . . 19

Section 5. Specifications . . . . . . . . . . . . . . . 21

System Requirements . . . . . . . . . . . . . . . . . . . . . . 21

MapCHECK 3 Specifications . . . . . . . . . . . . . . . . . 21

Appendix A: Regulatory Supplement . . . . . . 23

Sun Nuclear Corporation Symbols . . . . . . . . . . . . 23

Operator Responsibility . . . . . . . . . . . . . . . . . . . . . 24

Reporting Health or Safety Related Issues or

Concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Modifications to Equipment . . . . . . . . . . . . . . . . . 24

Interaction with Other Electrical Equipment . . . . . 24

Contents