R

Instructions for:

Hydrostatic Pump Models:SPAW

CHU LUN SING CO.,LTD Page:E1

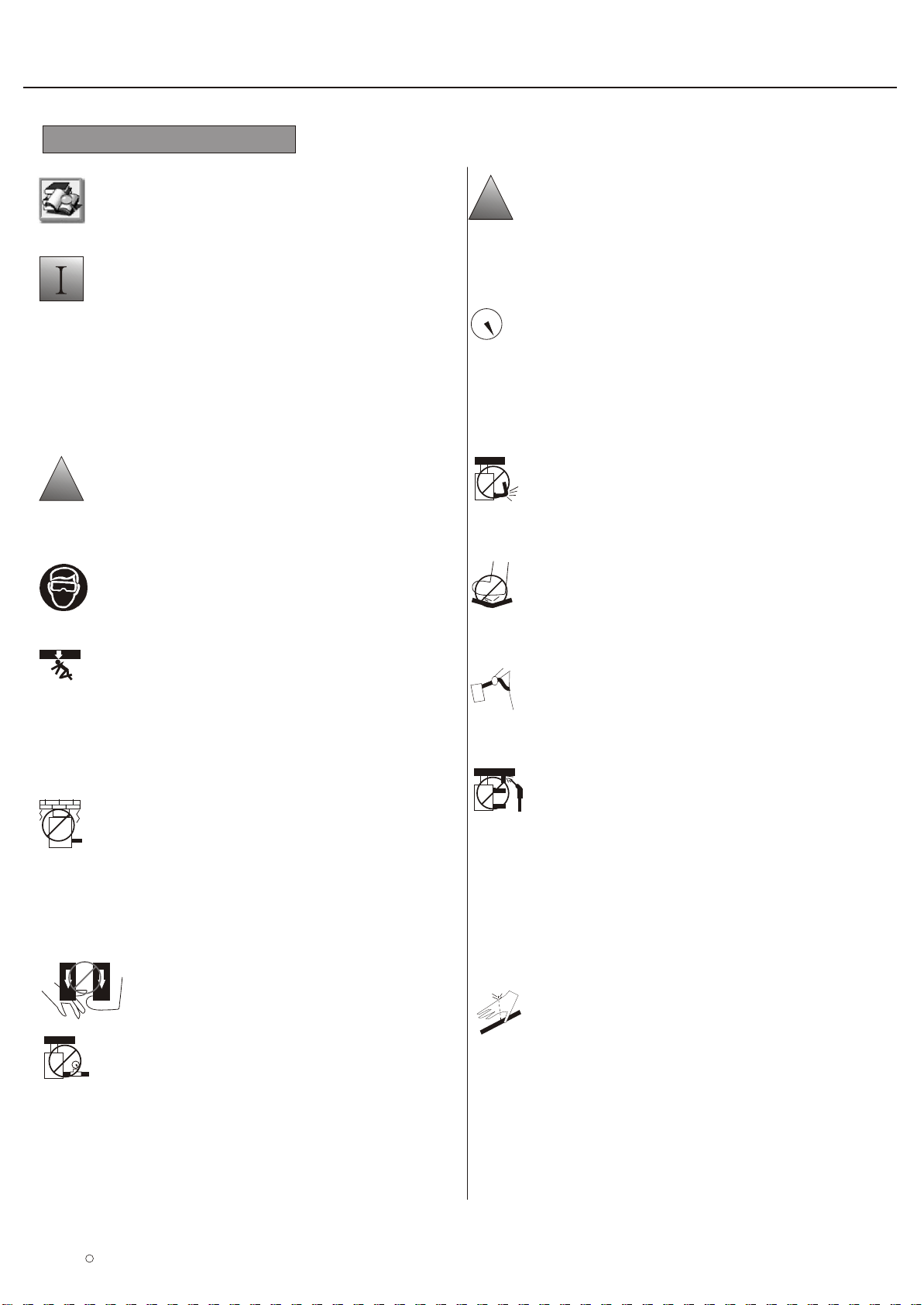

1. SAFETY PRECAUTIONS

Fail to comply with the following cautions

and warnings could cause equipment

damage and personal injury.

IMPORTANT :Minimum age of the

operator must be 18 years The operator

must have read and understood all

instructions, safety issues, cautions and

warnings before starting to operate the

SUN RUN equipment. The operator is

responsible for this activity towards other

persons.

WARNING : To avoid personal injury and

possible equipment damage, make sure all

hydraulic components withstand the

maximum pressure of 700 bar(10,000psi).

!

WARNING : Do not overload equipment.

Overloading cause equipment failure and

possible personal injury.The cylinders are

designed for a max. Pressure of 700 bar

(10,000psi).

WARNING: Always wear safety glasses.

The operator must take precaution against

injury due to failure the tool or workpiece.

!DANGER: NEVER set the relief valve to a

higher pressure than the maximum rated

pressure of the pump. Higher settings may

result in equipment damage and/ or personal

injury. Do not remove relief valve.

WARNING: Stay clear of loads supported

by hydraulics. Acylinder, when used as a

load lifting device, should never be used as

a load holding device. After the load has

been raised or lowered, it must always be

blocked mechanically.

WARNING: USE ONLYRIGID PIECES TO

HOLD LOAD. Carefully select steel or wood

blocks that are capable of supporting the

load. Never use a hydraulic cylinder as a

shim or spacer in any lifting or pressing

application.

DANGER: To avoid personal injury

keep hands and feet away from cylinder

and workpiece during operation.

WARNING : The system operating pressure

must not exceed the pressure rating of the

lowest rated component in the system. Install

pressure gauges in the system to monitor

operating pressure. It is your window to what

is happening in the system.

CAUTION: Avoid sharp bends and kinks

that will cause severe back-up pressure in

hoses. Bends and kinks lead to premature

hose failure.

DO NOT drop heavy objects on hose. A

sharp impact may cause internal damage to

hose wire strands. Applying pressure to a

damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or couplers. Use

the carrying handle or other means of safe

transport.

CAUTION : KEEP HYDRAULIC

EQUIPMENT AWAY FROM FLAMES AND

HEAT. Excessive heat will soften packings

and seals, resulting in fluid leaks. Heat also

weakens hose materials and packings. For

optimum performance do not expose

00

equipment to temperatures of 65 C(150 F)

or higher. Protect hoses and cylinders from

weld spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin causing serious injury. If

oil is injected under the skin, see a doctor

immediately.