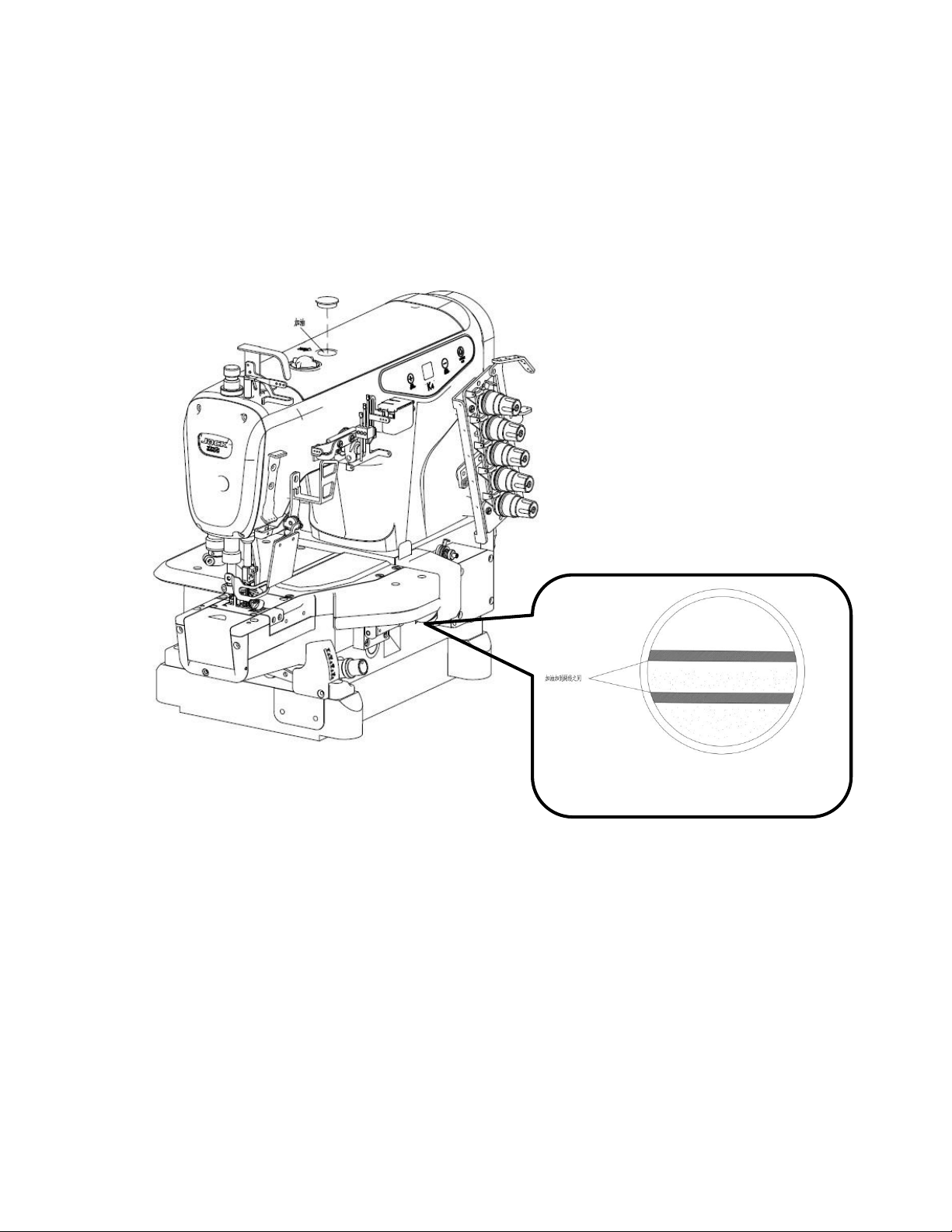

图3-2

脚踏板链条如上图所示安装

Pedal chain installed as shown above

四、关于加油、注油 Fourth, on the Lubrication, oiling

注意:为了防止机器突然启动造成人身事故,请关掉电源,确认电机确实停止转动

后再进行操作!

Note: In order to prevent personal accident caused by the sudden start of

the machine, please turn off the power, make sure the motor does stop

turning and then operate!

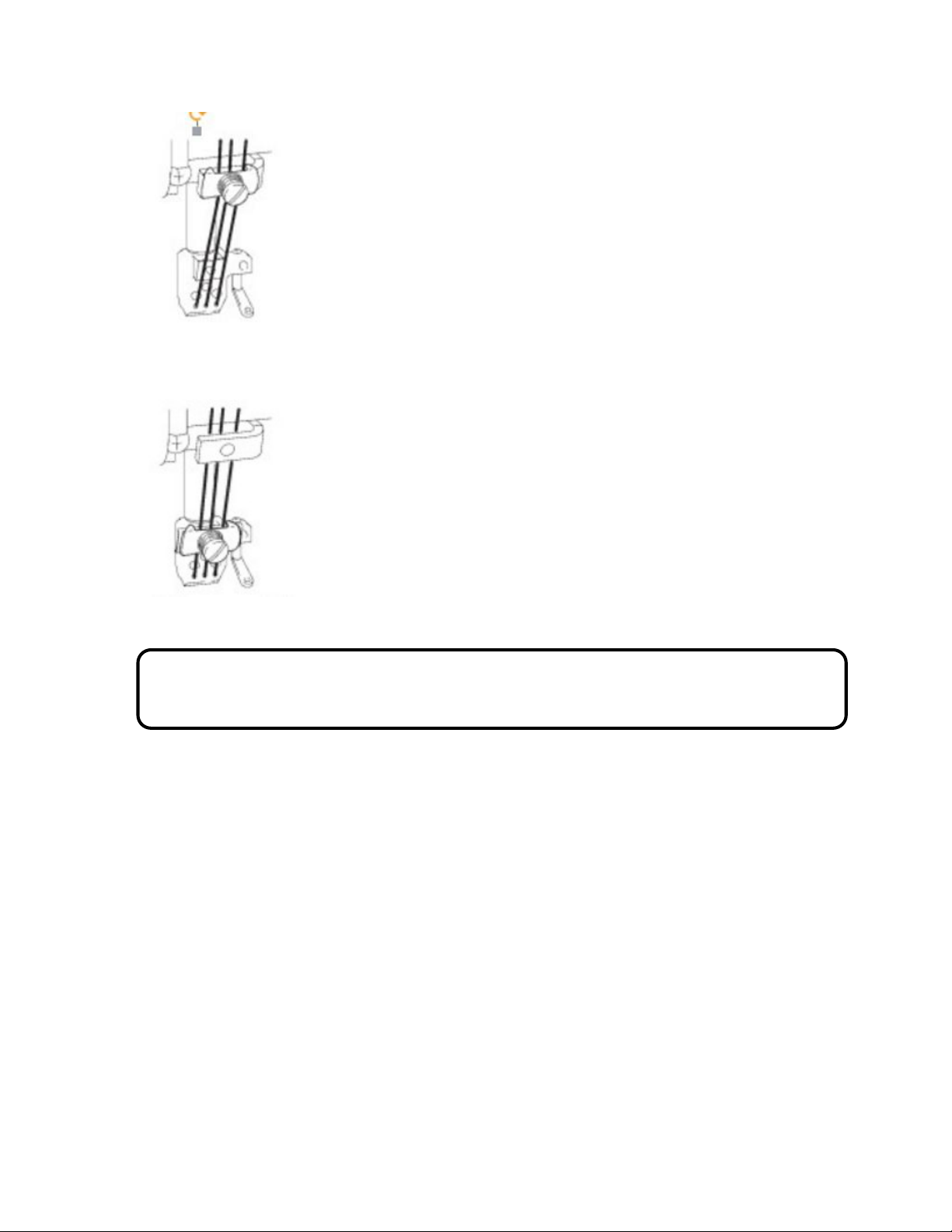

1、出厂加油

机器出厂时,机油均被排放,因初次使用缝纫机前,请一定要加入机油,推荐

使用机油:白油 22#,加油时请拿开标有 OIL 的加油口盖子,把机油加到油尺的上

下刻线之间,加油完成后转动缝纫机,看油窗是否有机油喷出,如果没有机油喷出,

请进行检修。

When the machine is shipped from the factory, the oil is discharged. Be

sure to add the oil before using the sewing machine for the first time. It is