Super Flying Model EP-46K User manual

Other Super Flying Model Toy manuals

Super Flying Model

Super Flying Model Sbach 342 Thunderblot User manual

Super Flying Model

Super Flying Model 8709 User manual

Super Flying Model

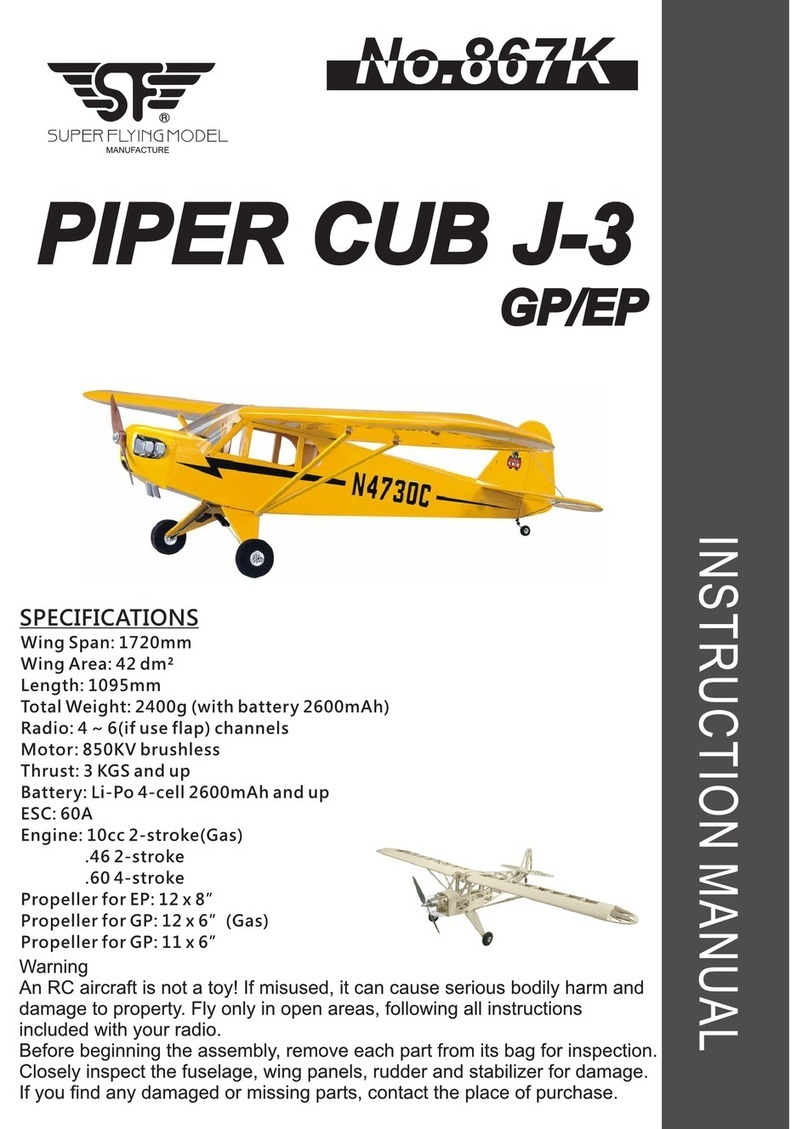

Super Flying Model PIPER CUB J-3 GP/EP User manual

Super Flying Model

Super Flying Model SE5a User manual

Super Flying Model

Super Flying Model P-51D Mustang User manual

Super Flying Model

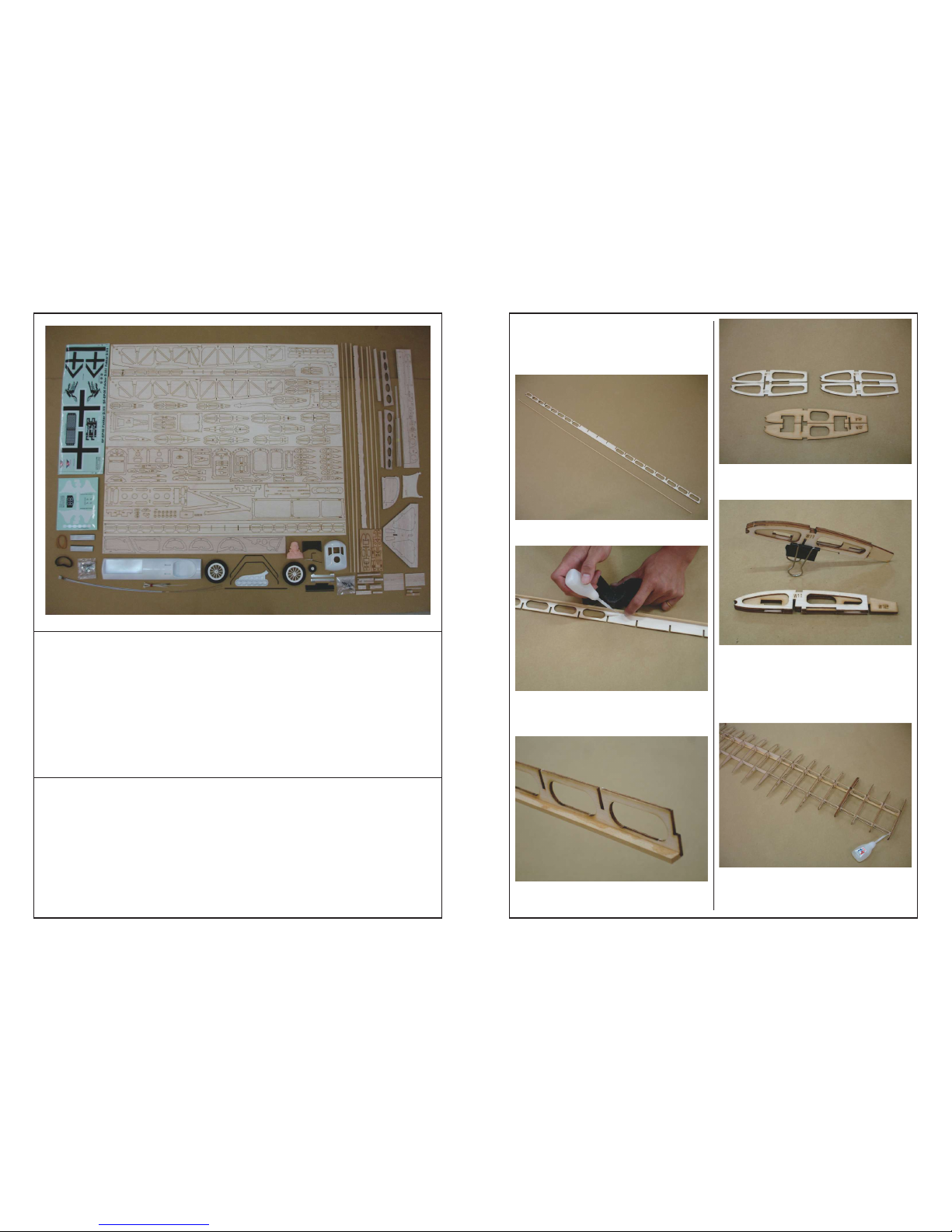

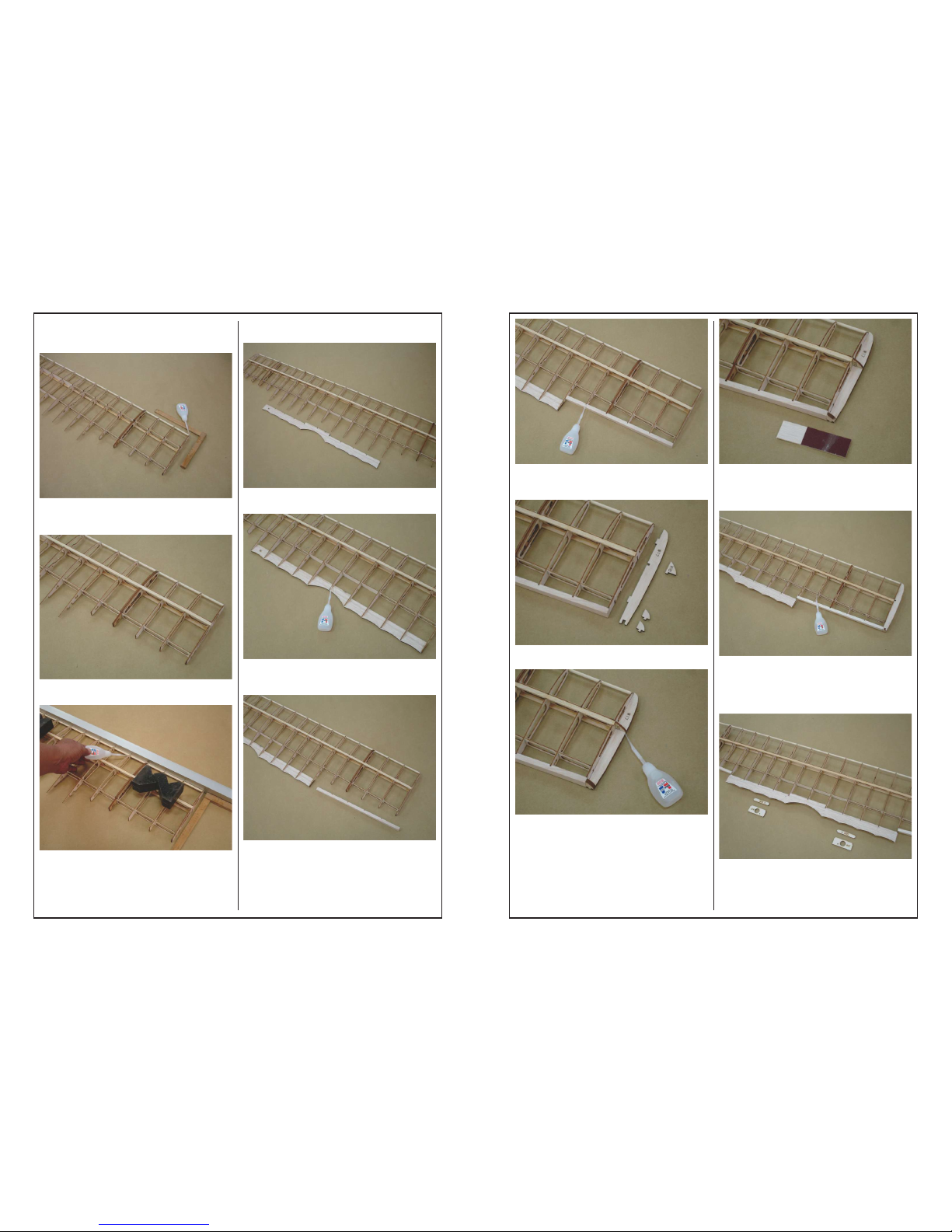

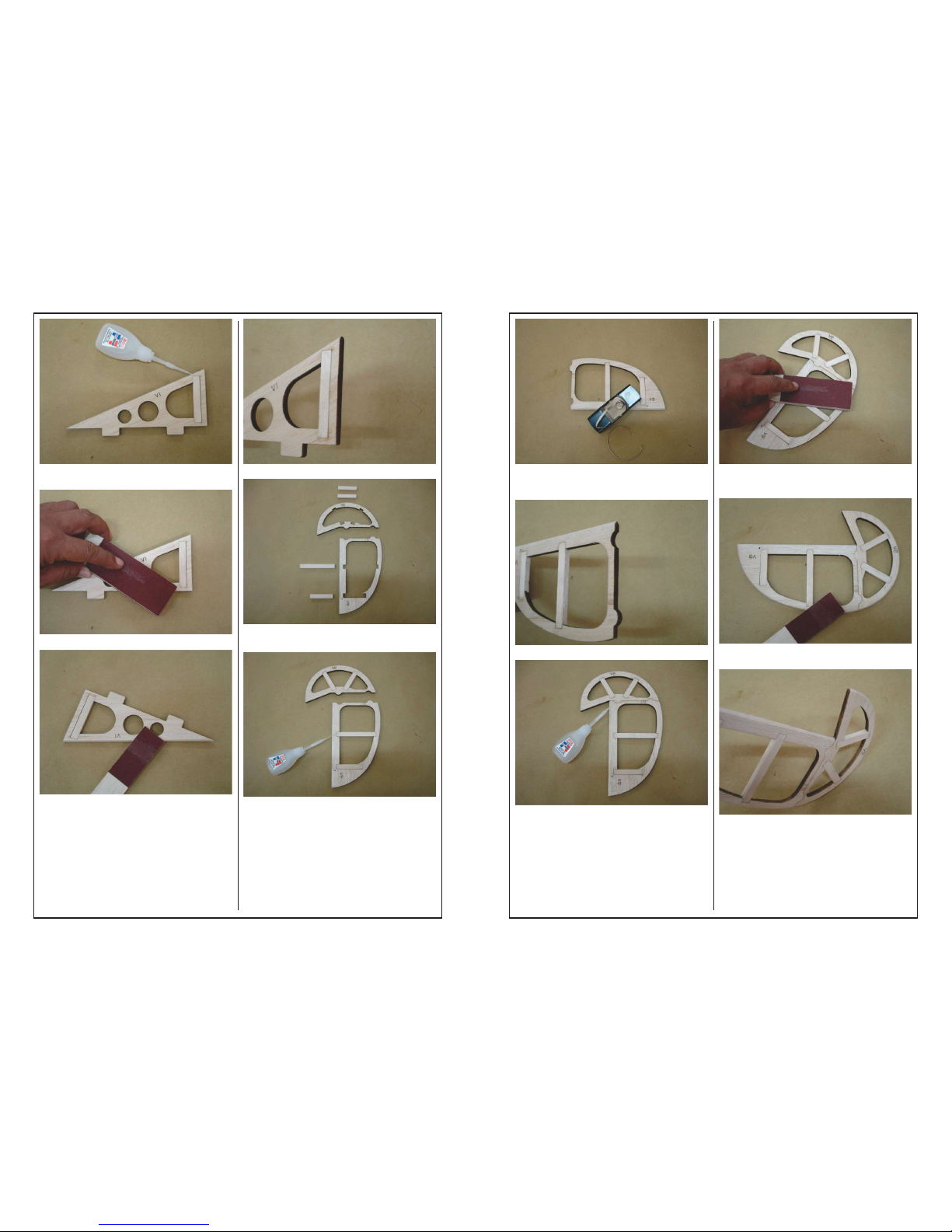

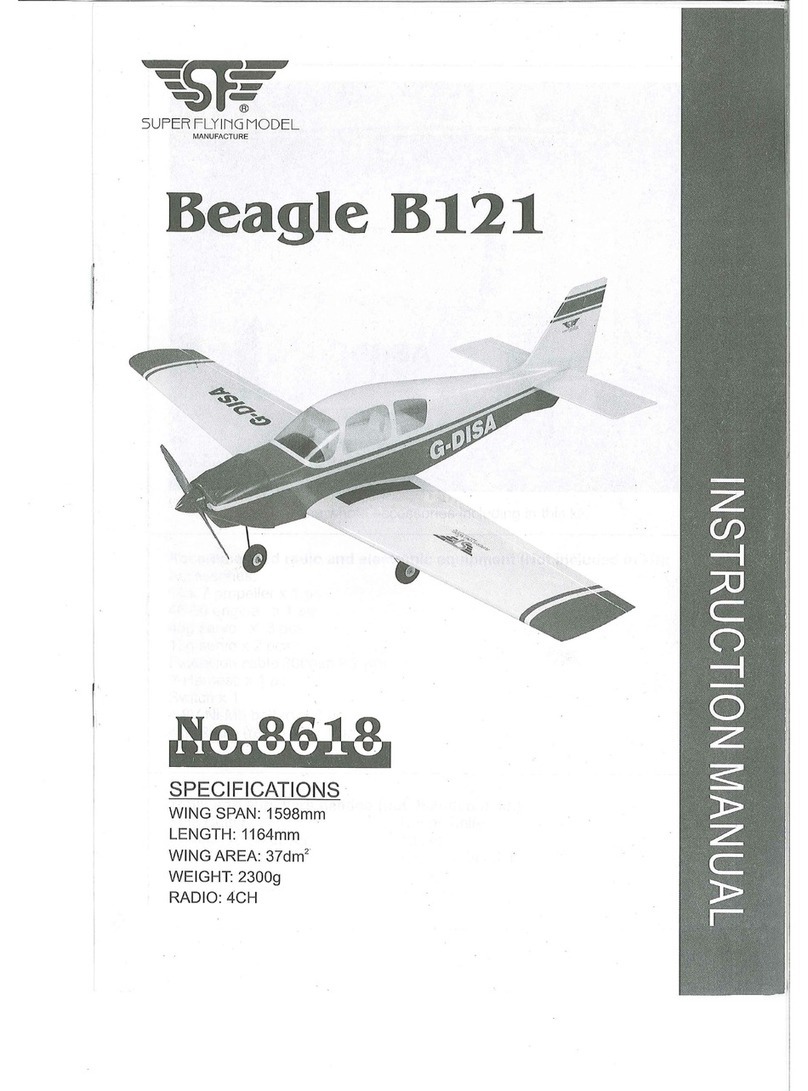

Super Flying Model Beagle B121 User manual

Super Flying Model

Super Flying Model Sbach 342 Thunderblot User manual

Super Flying Model

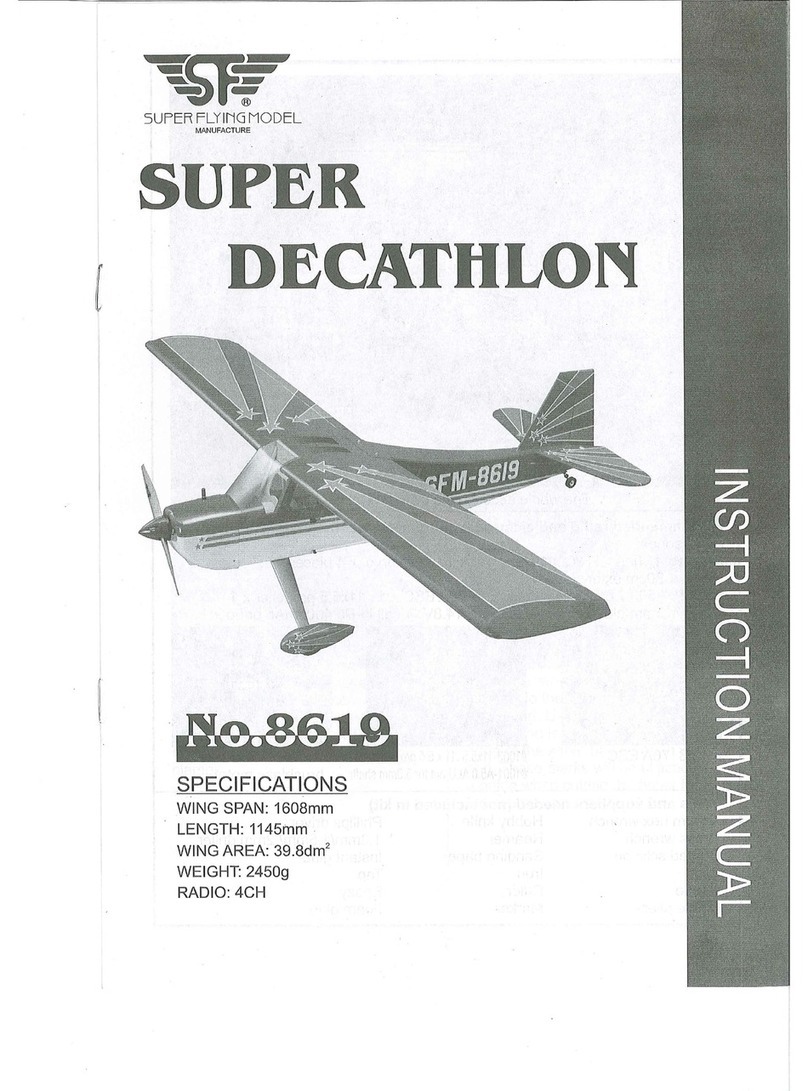

Super Flying Model Super Decathlon User manual

Super Flying Model

Super Flying Model Fournier RF-4D User manual

Super Flying Model

Super Flying Model PIPER CUB J-3 GP/EP User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions