Superabrasive UserManual OriginalLanguageLavina®20‐S‐E 9/2014

2

1.GENERALINFORMATION............................................................3

MANUFACTURER...........................................................................3

GENERALDESCRIPTION..................................................................3

MACHINECHARACTERISTICS..........................................................3

MAINDESIGN.................................................................................3

ENVIRONMENTALCONDITIONS.....................................................3

ELECTRICALCONNECTION..............................................................3

VACUUMCONNECTION.................................................................4

TECHNICALDATA...........................................................................4

CE‐CERTIFICATION..........................................................................4

VIBRATIONS...................................................................................4

SONOROUSEMISSIONS..................................................................4

LABELDATA...................................................................................4

CUSTOMERSERVICE.......................................................................4

2.SAFETYINSTRUCTIONS...............................................................4

RECOMMENDEDUSE.....................................................................4

PROHIBITEDUSE............................................................................4

FEATUREINCLEMENTCONDITIONS................................................4

POSSESSELECTROMAGNETICRADIATION......................................4

PREPARATIONFORWORK.............................................................4

ARRESTFUNCTIONS.......................................................................5

SAFEUSE........................................................................................5

RESIDUALRISKS.............................................................................5

BEFOREYOUBEGIN........................................................................5

OPERATINGMACHINE..................................................................5

AFTERWORKISCOMPLETED...........................................5

THEWORKAREA..........................................................5

PERSONALPROTECTIVE.................................................5

EQUIPMENT(PPE)..........................................................................5

OPERATOR................................................................................5

3.HANDLINGANDTRANSPORTATION...........................................6

PREPARINGTHEMACHINEFORTRANSPORTATION.......................6

STORAGE........................................................................................6

4.OPERATION................................................................................6

PRELIMINARYCONTROLS...............................................................6

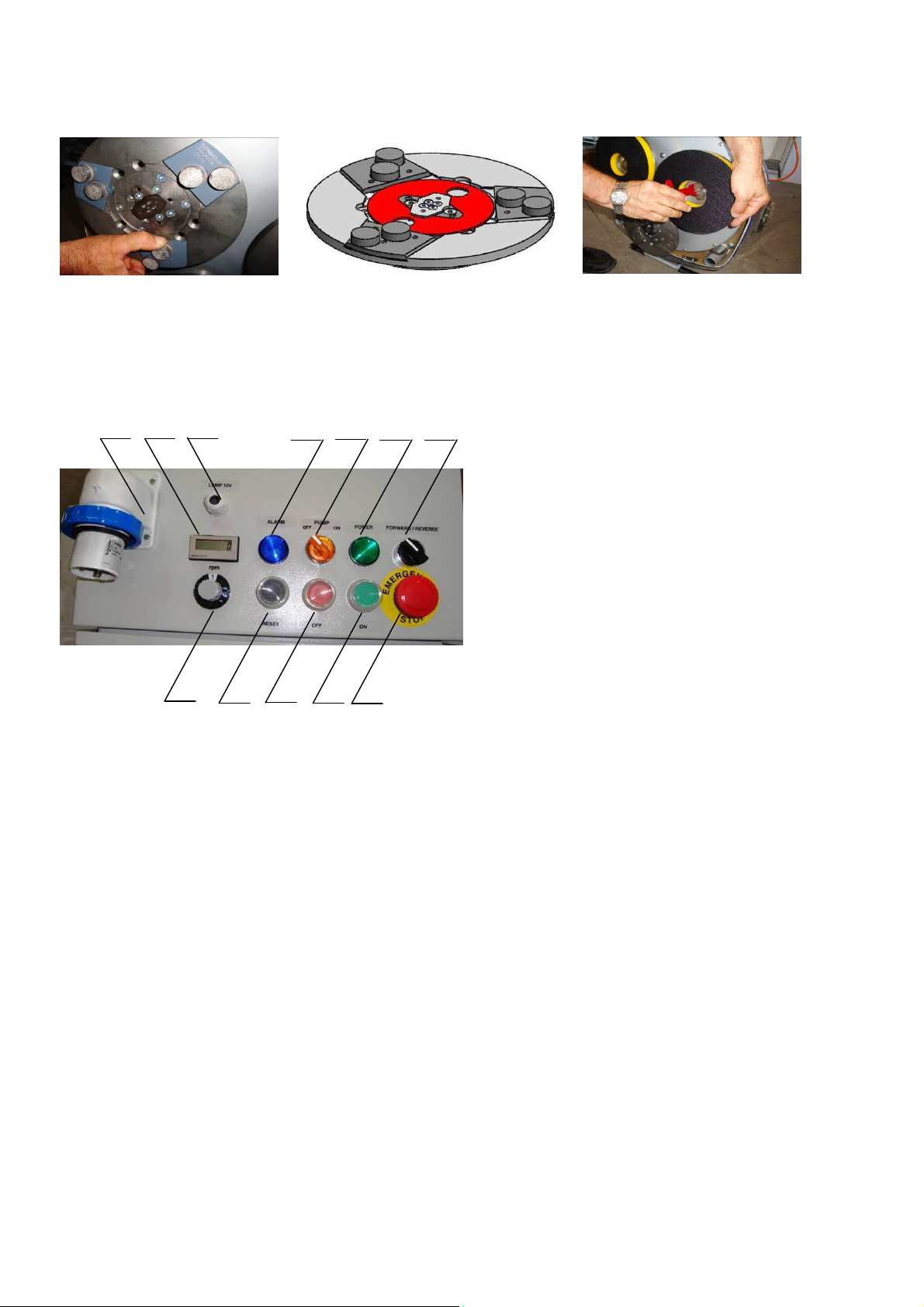

THECONTROLBOARD....................................................................7

STARTINGTHEMACHINE...............................................................7

5.TOOLSANDACCESSORIES..........................................................8

WEIGHTS........................................................................................8

TOOLHOLDERKEY.........................................................................8

FOAMPLATE..................................................................................8

6.POPULARTOOLS........................................................................9

RECOMMENDEDTOOLS.................................................................9

7.EXPLODEDVIEW......................................................................10

GENERALEXPLODEDVIEW(FIG.7.1)............................................10

MAINHEADEXPLODEDVIEW(FIG.7.2)........................................10

TOPCOVEREXPLODEDVIEW1(FIG.7.3)......................................10

TOPCOVEREXPLODEDVIEW2(FIG.7.4)......................................10

BOTTOMCOVEREXPLODEDVIEW1(FIG.7.5)..............................11

PLANETARYDRIVEEXPLODEDVIEW(FIG.7.6)..............................11

BOTTOMCOVEREXPLODEDVIEW2(FIG.7.7)..............................11

PULLEYUNITSEXPLODEDVIEW(FIG.7.8).....................................11

CARRIAGEEXPLODEDVIEW(FIG.7.9)...........................................11

TOOLHOLDEREXPLODEDVIEW(FIG.7.10)...................................11

8.MAINTENANCEANDINSPECTION............................................12

CLEANING....................................................................................12

ELECTRICALSYSTEM.....................................................................12

LAVINA®20‐S‐EELECTRICALSCHEMESWITHYASKAWA

INVERTER...................................................................................13

INDEXOFPROBLEMSANDSOLUTIONS........................................14

9.2DISMOUNTINGANDMOUNTINGTOOLHOLDERTOCHANGE

BUFFERSANDSPIDERS,CHANGINGV‐RINGSANDFELT‐RINGS....14

9.3TENSIONINGANDREPLACETHEPLANETARYBELT.................15

9.4TENSIONINGUSEDPLANETARYBELT.....................................15

9.5MOUNTINGANDTENSIONINGANEWPLANETARYBELT.......15

9.6REPLACINGPULLEYUNITS......................................................16

9.7MOUNTINGTHEBELT.............................................................18

9.8CHECKINGTHETENSIONOFTHEBELT....................................19

9.9MOTORCONNECTION............................................................19

9.10FAULTDIAGNOSISINVERTERYASKAWAV1000...................20

WARRANTYPOLICYFORTHELAVINA®S‐EMACHINE..................23

RETURNPOLICYFORLAVINA®S‐EMACHINES.............................23

ASSEMBLYANDPARTSSPECIFICATIONS......................................24

1.LAVINA®20‐S‐EGENERALPARTS

FORMACHINESPRODUCEDBEFOREJAN.12014........................24

1.LAVINA®20‐S‐EGENERALPARTS/FORMACHINESPRODUCED

AFRTERJAN.12014/..................................................................24

2.LAVINA®20‐S‐ETOPCOVERPARTS1.......................................25

3.LAVINA®20‐S‐EGUARDPARTS................................................25

4.LAVINA®20‐S‐ETOPCOVERPARTS2.......................................25

5.LAVINA®20‐S‐ETOPCOVERPARTS3.......................................26

6.LAVINA®20‐S‐EBOTTOMCOVERPARTS1...............................26

7.LAVINA®20‐S‐EPLANETARYDRIVEPARTS...............................26

8.LAVINA®20‐S‐EBOTTOMCOVERPARTS2...............................27

10.LAVINA®20‐S‐ETOOLHOLDERPARTS....................................28

11.LAVINA®20‐S‐EWATERSUPPLYPARTS

FORMACHINESPRODUCEDBEFOREJAN.12014........................28

11.LAVINA®20‐S‐EWATERTANKPARTS

FORMACHINESPRODUCEDAFTERJAN.12014..........................28

13.LAVINA®20‐S‐ECONTROLBOXPARTS200‐240VOLT...........31