Superabrasive UserManual OriginalLanguage Lavina®20N‐S‐E/Lavina®20N‐S‐OE 8/2014

2

1.GENERALINFORMATION..............................................................3

MACHINECHARACTERISTICS......................................................3

MAINDESIGN.............................................................................3

VACUUMCONNECTION...................................................................4

TECHNICALDATA........................................................................4

CE‐CERTIFICATION......................................................................4

VIBRATIONS................................................................................4

SONOROUSEMISSIONS..............................................................4

LABELDATA................................................................................4

2.SAFETYINSTRUCTIONS.................................................................4

RECOMMENDEDUSE..................................................................4

PROHIBITEDUSE.........................................................................4

PREPARATIONFORWORK..........................................................5

PROTECTIONDEVICES.................................................................5

ARRESTFUNCTIONS....................................................................5

SAFEUSE.....................................................................................5

RESIDUALRISKS..........................................................................5

BEFOREYOUBEGIN....................................................................5

PERSONALPROTECTIVEEQUIPMENT(PPE)................................5

3.HANDLINGANDTRANSPORTATION.............................................6

PREPARINGTHEMACHINEFORTRANSPORTATION....................6

STORAGE.....................................................................................6

4.OPERATION..................................................................................6

PRELIMINARYCONTROLS............................................................6

WATERFLOWCONTROLUNIT....................................................6

THECONTROLBOARD.................................................................7

STARTINGTHEMACHINE............................................................7

5.TOOLSANDACCESSORIES............................................................8

WEIGHTS.....................................................................................8

TOOLHOLDERKEY......................................................................8

FOAMPLATE...............................................................................8

SECURITYPLATEFORQUICKCHANGEPADS................................8

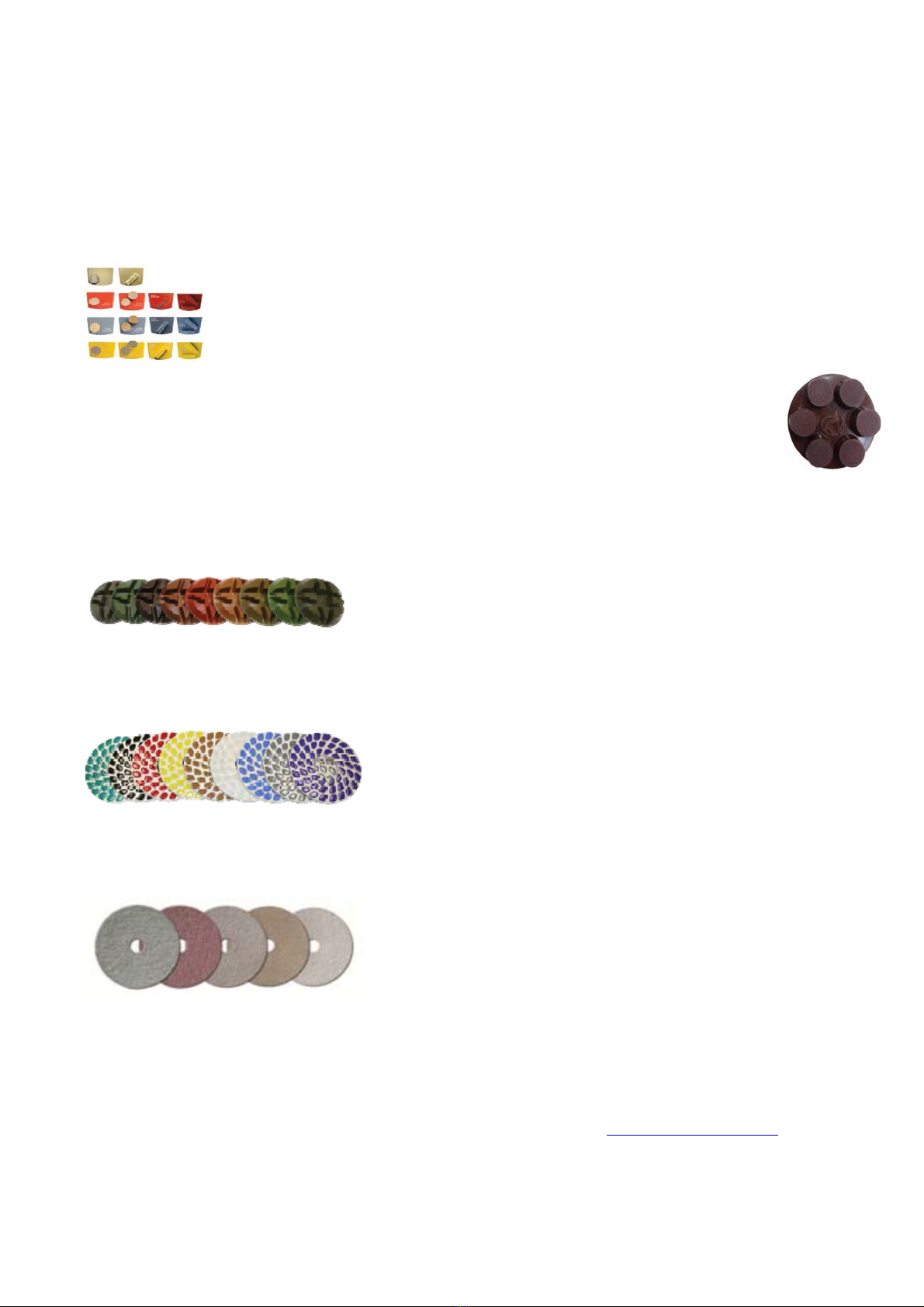

6.POPULARTOOLS..........................................................................9

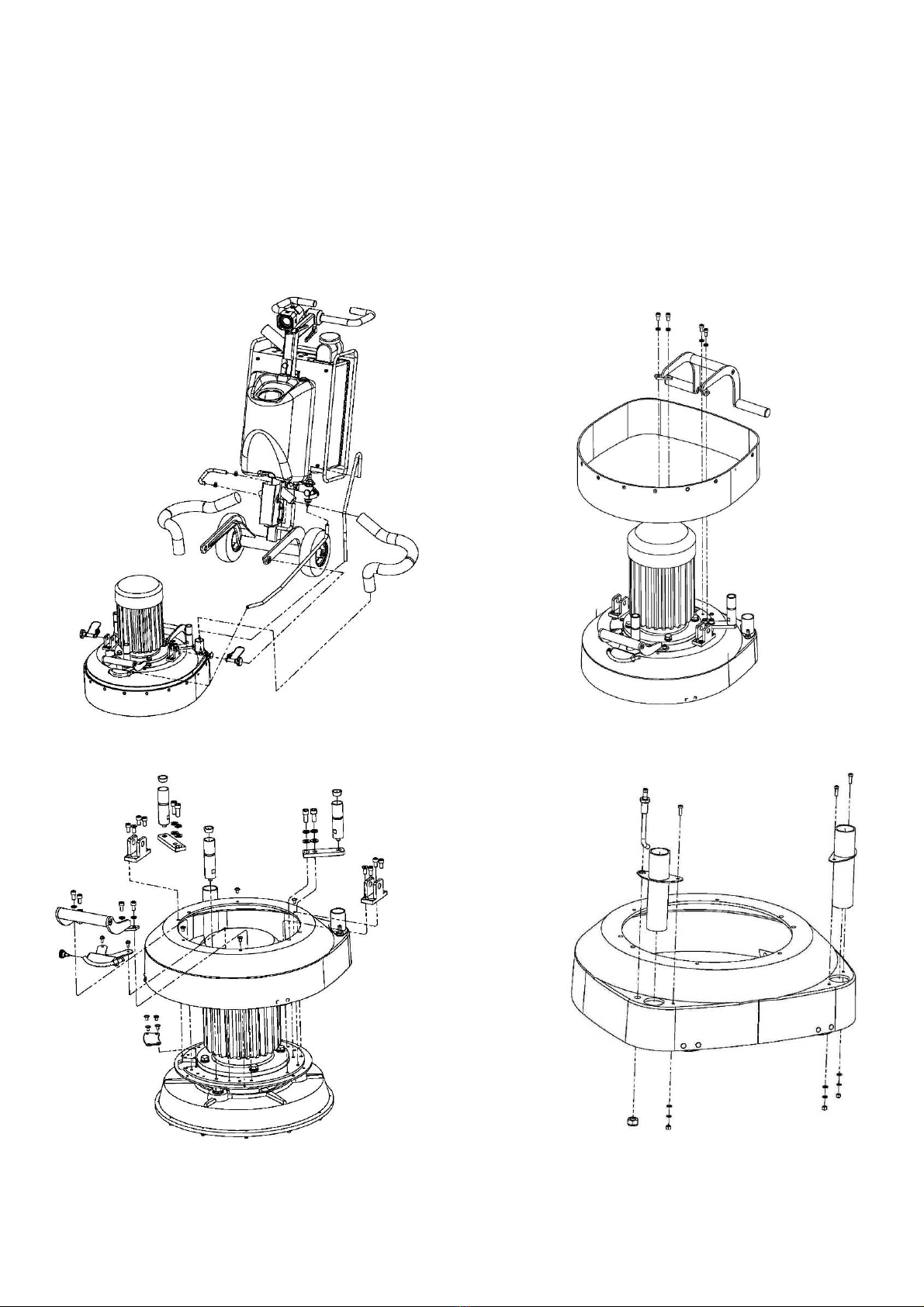

7.EXPLODEDVIEW.........................................................................10

GENERALEXPLODEDVIEW(FIG.7.1).........................................10

MAINHEADEXPLODEDVIEW(FIG.7.2).....................................10

TOPCOVEREXPLODEDVIEW1(FIG.7.3)...................................10

TOPCOVEREXPLODEDVIEW2(FIG.7.4)...................................10

BOTTOMCOVEREXPLODEDVIEW1(FIG.7.5)...........................11

PLANETARYDRIVEEXPLODEDVIEW(FIG.7.6)...........................11

BOTTOMCOVEREXPLODEDVIEW2(FIG.7.7)...........................11

PULLEYUNITSEXPLODEDVIEW(FIG.7.8).................................11

CARRIAGEEXPLODEDVIEW(FIG.7.9).......................................11

TOOLHOLDEREXPLODEDVIEW(FIG.7.10)...............................11

8.MAINTENANCEANDINSPECTION...............................................12

CLEANING.......................................................................................12

LAVINA®20N‐S‐OEELECTRICALSCHEMESWITHYASKAWA

INVERTER200‐240VOLT...........................................................11

LAVINA®20N‐S‐EELECTRICALSCHEMESWITHYASKAWA

INVERTER380VOLT..................................................................12

9.TROUBLESHOOTING...................................................................13

9.1REPLACINGPOWERCORDANDPLUGS...............................13

9.2DISMOUNTINGANDMOUNTINGTOOLHOLDERTOCHANGE

BUFFERSANDSPIDERS,CHANGINGV‐RINGSANDFELTRINGS..13

9.3TENSIONINGANDREPLACETHEPLANETARYBELT..............14

9.4TENSIONINGUSEDPLANETARYBELT..................................14

9.5MOUNTINGANDTENSIONINGANEWPLANETARYBELT....14

9.6REPLACINGPULLEYUNITS...................................................15

9.7MOUNTINGTHEBELT.........................................................17

9.8CHECKINGTHETENSIONOFTHEBELT................................18

9.9MOTORCONNECTION.........................................................18

9.10FAULTDIAGNOSISINVERTERYASKAWAV1000................19

10.WARRANTYANDRETURNS.......................................................22

WARRANTYPOLICYFORTHELAVINA®S‐EMACHINE...............22

RETURNPOLICYFORLAVINA®S‐EMACHINES..........................22

11.DISPOSAL..................................................................................22

12.MANUFACTURER’SCONTACTS.................................................22

13.SPAREPARTS............................................................................23

1.LAVINA®20N‐S‐EGENERALPARTS

FORMACHINESPRODUCEDBEFOREJAN.12014/....................23

1.LAVINA®20N‐S‐EGENERALPARTS

FORMACHINESPRODUCEDAFTERJAN.12014/......................23

2.LAVINA®20N‐S‐ETOPCOVERPARTS1................................24

3.LAVINA®20N‐S‐EGUARDPARTS.........................................24

4.LAVINA®20N‐S‐ETOPCOVERPARTS2................................24

5.LAVINA®20N‐S‐ETOPCOVERPARTS3................................25

6.LAVINA®20N‐S‐EBOTTOMCOVERPARTS1........................25

7.LAVINA®20N‐S‐EPLANETARYDRIVEPARTS........................25

8.LAVINA®20N‐S‐EBOTTOMCOVERPARTS2........................26

10LAVINA®20N‐S‐ETOOLHOLDERPARTS...............................27

11.LAVINA®20N‐S‐EWATERSUPPLYPARTS

FORMACHINESPRODUCEDBEFOREJAN.12014/...................27

11.LAVINA®20N‐S‐EWATERTANKPARTS

FORMACHINESPRODUCEDAFTERJAN.12014/....................27

12.LAVINA®20N‐S‐ECARRIAGEPARTS/FORMACHINES

PRODUCEDBEFOREJAN.12014/..............................................28

12.LAVINA®20N‐SCARRIAGEPARTS/FORMACHINES

PRODUCEDAFTERJAN.12014/................................................29

13.1LAVINA®20N‐S‐OECONTROLBOXPARTS200‐240VOLT.30

13.2LAVINA®20N‐S‐ECONTROLBOXPARTS380VOLT...........31