8

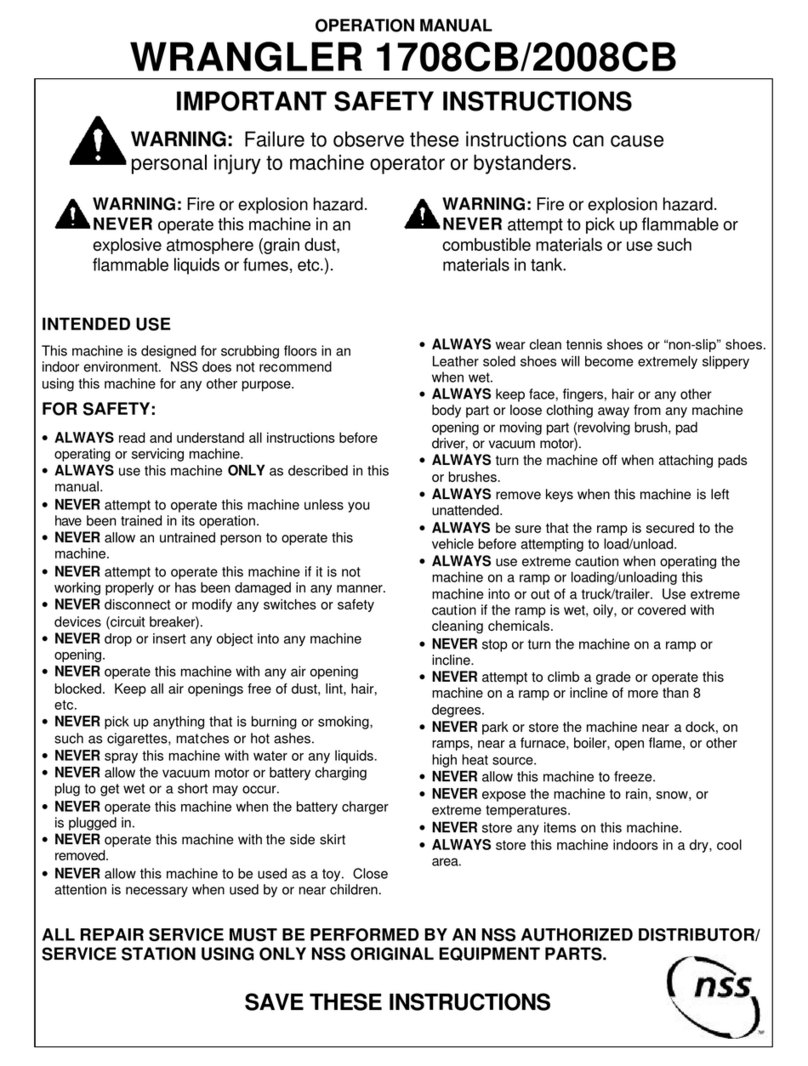

!ATTENTION!

• Remove the ignition key to prevent unauthorised use of the machine.

• Do not leave the machine unattended without ensuring that the machine cannot move independently.

• Always protect the machine from the sun, rain and other weather both during operation and downtime.

Store the machine indoors and in a dry environment: this machine is only for dry use and should not be

used or kept outdoors in humid conditions.

• Close all doors and/or covers before using the machine, as indicated in the Use and Maintenance Man-

ual.

• Do not let the machine be used as a toy. Pay careful attention when using it near children.

• Do not use the machine for purposes other than those indicated in this manual. Only use accessories

recommended by the manufacturer (NSS).

• Take the appropriate precautions so that hair, jewellery, and loose clothing are not caught by the mov-

ing parts of the machine.

• Do not use the machine on sloping surfaces with an angle greater than the one stated on the identica-

tion plate, to avoid jeopardising stability and safe operation.

• Do not use the machine in especially dusty environments.

• Only use the machine in suciently-lit areas.

• If the machine is used in the presence of people other than the operator, the rotating light and reverse

drive buzzer (optional) should be used.

• Make sure people and objects are safely protected when operating the machine.

• Do not hit shelving or scaolding, especially if there is danger of falling objects.

• Do not place containers of liquid substances on the machine.

• The machine operating temperature must be between 0°C and +40°C.

• The machine storage temperature must be between 0°C and +40°C.

• The humidity must be between 30% and 95%.

• When using detergents to clean the oor, follow the instructions and warnings on their containers.

• Use suitable gloves and protective devices when handling oor cleaning detergents.

• Do not use the machine as a transport vehicle.

• Do not let the brushes operate with the machine stopped to avoid damaging the oor.

• In case of re, use a powder extinguisher instead of a water one.

• Do not tamper with the protections provided for the machine under any circumstances; carefully follow

the routine maintenance instructions.

• Prevent any object from getting inside the machine openings. Do not use the machine if the openings

are blocked; keep the machine openings free from dust, lint, hair and any other foreign body that may

reduce air ow.

• Do not remove or tamper with the labels axed by the machine's Manufacturer.

• Release the electromagnetic brake to manually push the machine.

• Never use the machine if the electromagnetic brake is deactivated.

• If the machine is pushed (due to no batteries, at batteries, faults, etc.), never exceed a speed of 4 Km/h.

• This machine is not approved for use on public roads.

• When moving the machine with temperatures below the freezing point, be careful as the water in the

tanks or in the tubes may freeze and seriously damage the machine.

• Only use brushes and pads supplied with the machine and those specied in the Use and Maintenance

Manual. Use of other brushes or pads may compromise safety.

• If operating faults occur, make sure they are not due to insucient maintenance. Otherwise request

intervention by authorised personnel or by the Service Centre.

• For part replacement, request ORIGINAL spare parts from an authorised Dealer or Seller.

• For safety purposes as well as proper operation, planned maintenance must be carried out by autho-

rised personnel or an authorised Service Centre as indicated in the relevant chapter of this manual.

• Do not use direct or pressurised water jets or with corrosive substances to wash the machine.

• If lead batteries (WET) are installed in the machine, do not tilt it over 30° to the horizontal surface in

order to prevent any highly corrosive liquid leaks from the batteries. Remove the batteries before tilting

the machine for maintenance.

• The machine should not be abandoned at the end of its life cycle due to the presence of toxic and harm-

ful materials (batteries, etc.) inside, which are subject to standards that require disposal in special cen-

tres (see the Scrapping chapter in the Use and Maintenance Manual).

• In conditions of use compliant with the proper use provisions, vibrations are not liable to give rise to

dangerous situations. The machine vibration level falls within the limits provided by law.