SS2000-DP4 - Page 4

THINGS TO KNOW BEFORE USING THIS EQUIPMENT

Only qualified personnel should install or perform servicing procedures on this equipment.

Before performing any work on the unit, allow at least five minutes for the capacitors to discharge fully.

Voltage is present on unprotected pins when unit is operational.

Motors powered by this drive may develop extremely high torque. Be sure to disconnect power to this

drive before doing any mechanical work.

WARRANTY INFORMATION

Reconfiguration of the circuit in any fashion not shown in this manual will void the Warranty.

Failure to follow the installation guidelines as described in Section 3 will void the Warranty.

SECTION 1: INTRODUCTION

1.1 USING THIS MANUAL

It is important that you understand how this SLO-SYN SS2000-DP4 Translator/Drive is installed and

operated before you attempt to use it. We strongly recommend that you read this manual completely

before proceeding with the installation of this unit.

This manual is an installation and operating guide to the SLO-SYN SS2000-DP4 Translator/Drive.

Section 1 gives an overview of the Drive and its features. Section 2 describes the steps necessary to

place the drive into operation. General wiring guidelines as well as the physical mounting of the unit and

connections to the drive portion are covered in Section 3.

Complete specifications, listed in Section 4, provide easily referenced information concerning electrical,

mechanical and environmental specifications. The procedure for setting the motor current level is also

covered in this section.

Torque versus speed characteristics with all appropriate SLO-SYN Stepper Motors are given in Section 5.

Section 6, Troubleshooting, gives procedures to follow if the Translator/Drive fails to operate properly.

Appendix A provides procedures for troubleshooting electrical interference problems.

1.2 PRODUCT FEATURES

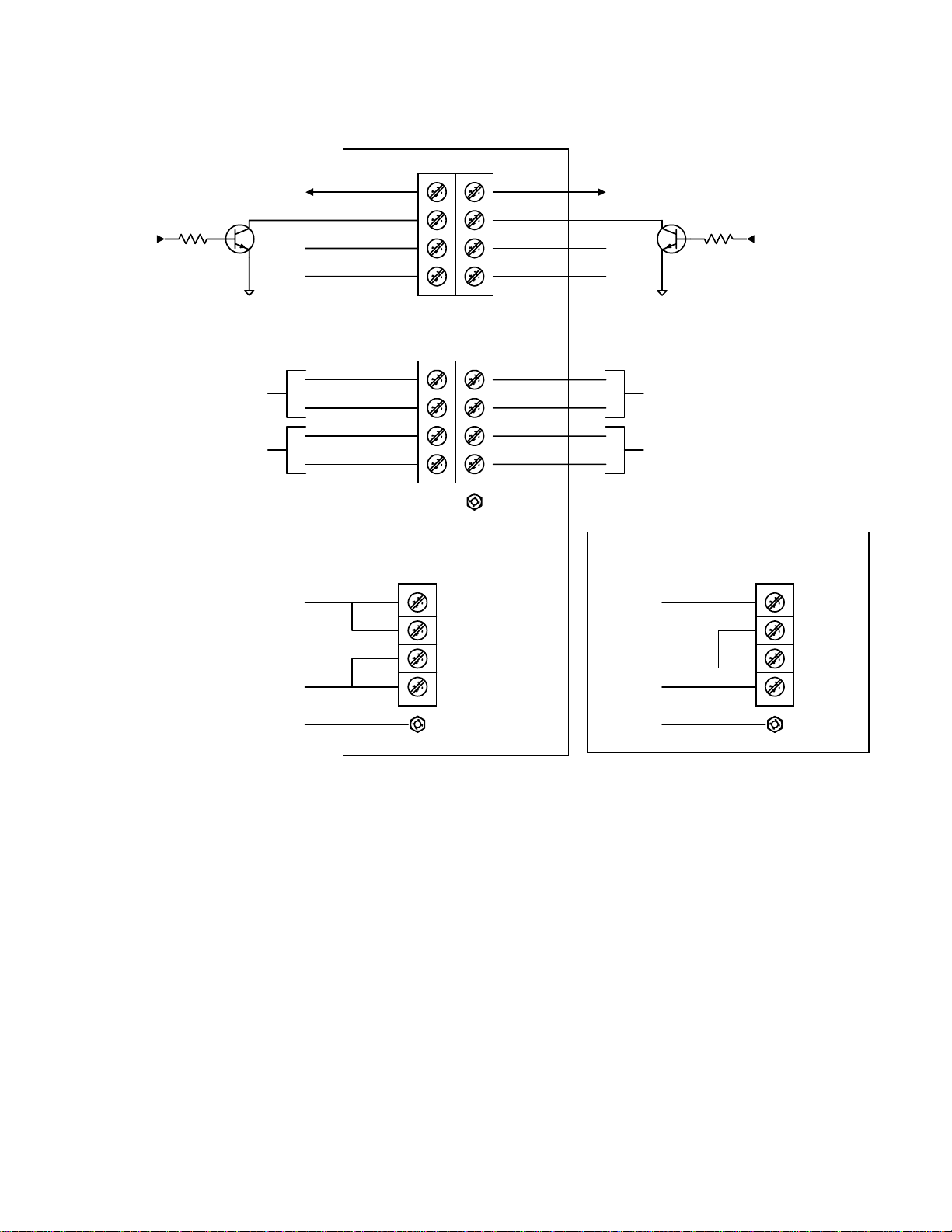

The SLO-SYN SS2000-DP4 Dual Packaged drive system includes two independent stepper motor drives

and their motor power supply in a single packaged unit. Each drive is a bipolar, adjustable speed,

two-phase PWM circuit which uses hybrid power devices. It can be set to operate a step motor in

microstep mode at up to 20,000 microsteps per revolution. The maximum running speed is 3,000 rpm. To

reduce the chances of electrical noise problems, the control signals are optically isolated from the drive

circuit. Features include:

•Switch selectable current levels of 0.5 through 3.5 amperes

•Choice of either Pulse/Direction or CW / CCW input capability

•Full short circuit protection (phase-to-phase and phase-to-ground)

•Undervoltage and transient overvoltage protection

•Overtemperature Protection

•Efficient thermal design

•Optically isolated inputs

•Windings Off capability

•Automatic Current Reduction (In –MM models)

•Switch selectable step resolution

•Compact size

•Sturdy cabinet with integral mounting flanges