SS2000MD4M-O Page 1

TABLE OF CONTENTS

SECTION Page

THINGS TO KNOW BEFORE USING THIS

EQUIPMENT .............................................................................. 3

WARRANTY INFORMATION......................................................... 3

SECTION 1: INTRODUCTION ....................................................... 3

1.1 Using This Manual............................................................ 3

1.2 Product Features .............................................................. 4

SECTION 2: EXPRESS START UP PROCEDURE ........................... 5

SECTION 3: INSTALLATION GUIDELINES .................................... 6

3.1 Mounting ......................................................................... 6

3.2 Terminal Locations And Assignments................................. 7

3.2.1 Motor Connections................................................... 8

3.2.2 Power Input Connections .......................................... 10

SECTION 4: SPECIFICATIONS ..................................................... 11

4.1 Mechanical Specifications.................................................. 11

4.2 Electrical Specifications ..................................................... 11

4.3 Environmental Specifications.............................................. 11

4.4 Motor Compatibility ........................................................... 11

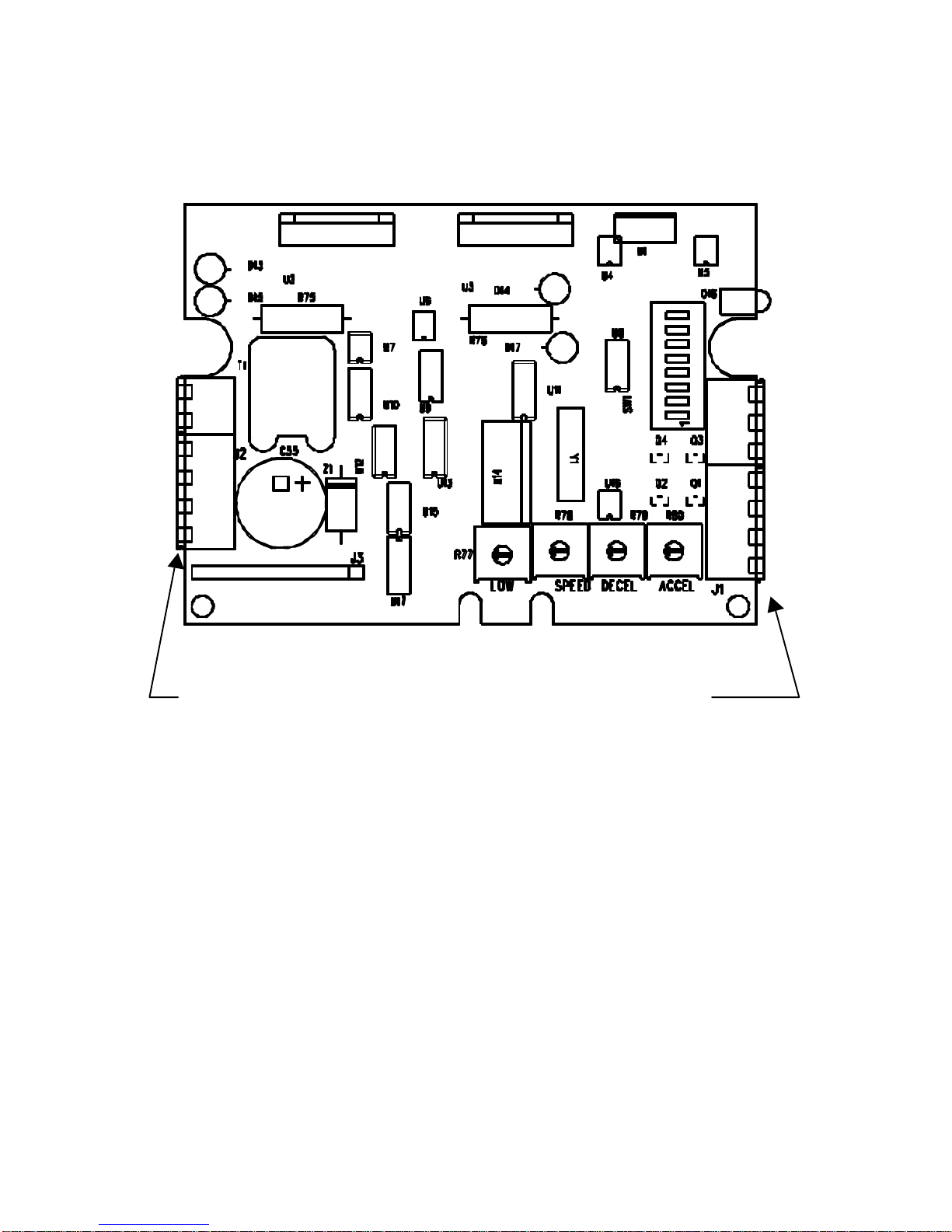

4.5 Switches and Potentiometers ............................................. 13

4.5.1 Motor Current Settings.............................................. 13

4.5.2 Automatic Current Reduction..................................... 13

4.5.3 Run Speed Source................................................... 13

4.5.4 External Speed Input Scaling..................................... 13

4.5.5 Potentiometers ........................................................ 14

4.6 Signal Specifications ......................................................... 15

4.7 Timing Considerations........................................................ 16

4.8 Indicator Lights................................................................. 18

SECTION 5: TORQUE VERSUS SPEED

CHARACTERISTICS .............................................................. 18

5.1 Motor Performance........................................................... 18

5.2 Typical Torque Vs. Speed Curves ....................................... 19

SECTION 6: TROUBLESHOOTING ............................................... 27

APPENDIX A: TROUBLESHOOTING ELECTRICAL

INTERFERENCE PROBLEMS........................................... 29