FORM#9922.02-05202019 PRINTED IN U.S.A. PAGE 3 OF 26

KitPartNumber K178 4.5"LiftKit KitPartNumber K179 6"LiftKit

PartNumber Qty.PartDescription PartNumber Qty.PartDescription

9922 1 KitBox,Knuckles 9922 1 KitBox,Knuckles

9926 1 KitBox,Crossmember,BellyPan&SwayBarDrop 9926 1 KitBox,Crossmember,BellyPan&SwayBarDrop

9927 1 KitBox,Differential,BumpStops&DriveshaftSpacer 9927 1 KitBox,Differential,BumpStops&DriveshaftSpacer

9929 1 KitBox,StrutSpacer 9928 1 KitBox,StrutSpacer

84057 1 KitBox,SUPERLIFTShocks 84057 1 KitBox,SUPERLIFTShocks

OR OR

KitPartNumber K178B 4.5"LiftKit KitPartNumber K179B 6"LiftKit

PartNumber Qty.PartDescription PartNumber Qty.PartDescription

9922 1 KitBox,Knuckles 9922 1 KitBox,Knuckles

9926 1 KitBox,Crossmember,BellyPan&SwayBarDrop 9926 1 KitBox,Crossmember,BellyPan&SwayBarDrop

9927 1 KitBox,Differential,BumpStops&DriveshaftSpacer 9927 1 KitBox,Differential,BumpStops&DriveshaftSpacer

9929 1 KitBox,StrutSpacer 9928 1 KitBox,StrutSpacer

84058 1 KitBox,BILSTEINShocks 84058 1 KitBox,BILSTEINShocks

KitPartNumber 9922 KitPartNumber 9928 6"LiftKit

PartNumber Qty.PartDescription PartNumber Qty.PartDescription

66‐01‐992

1 Knuckle,Driver10362 4 9/16"x3‐5/16"x12"Ubolts

66‐02‐992

1 Knuckle,Passenger 55‐09‐993

1 StrutSpacers(6"),Driver

55‐13‐992

1 StrutSpacers(6"),Passenger

KitPartNumber 9926 55‐31‐993

2 Block,Rear

PartNumber Qty.PartDescription 77‐1509 1 UboltNutsandWashers

55‐15‐992

1 Crossmember,Front

55‐16‐992

1 Crossmember,Rear KitPartNumber 9929 4.5"LiftKit

55‐07‐992

1 SwayBarDrop,DriverPartNumber Qty.PartDescription

55‐08‐992

1 SwayBarDrop,Passenger10352 4 9/16"x3‐5/16"x11"Ubolts

55‐10‐992

1 BellyPan 55‐11‐993

1 StrutSpacers(4.5"),Driver

77‐9922 1 HardwareBag,KnuckleSpacers,E‐Brake 55‐14‐992

1 StrutSpacers(4.5"),Passenger

77‐9926

1 HardwareBag,CamBolts 55‐30‐993

2 Block,Rear

77‐1509 1 UboltNutsandWashers

KitPartNumber 9927

PartNumber Qty.PartDescription KitPartNumber 84057

55‐03‐993

1 DifferentialDrop,DriverPartNumber Qty.PartDescription

55‐04‐993

1 DifferentialDrop,Passenger01‐8515

2 SUPERLIFTShockCylinder,Rear

55‐12‐993

2 BumpStop,Rear 77‐8703

2 HardwareBag,ShocksBushingsandSleeves

66‐11‐991

1 DriveshaftSpacer,Front

77‐993

1 HardwareBag,SUPERLIFTparts KitPartNumber 8405

77‐9932 1 HardwareBag,NutsandBolts PartNumber Qty.PartDescription

BE5‐6249‐H

2 BILSTEINShockCylinder,Rear

77‐8703

2 HardwareBag,ShocksBushingsandSleeves

KitPartNumber 77‐993

KitPartNumber 77‐993

PartNumber Qty.PartDescription PartNumber Qty.PartDescription

01‐6041

4 01‐60418,HourglassBushing 10MFN 6 10mmFlangeNut

21‐3205 1 5/16"x3‐1/2"VacuumHose 10MFW 2 10mmFlatWasher

23‐3205 1 5/16"HoseAdapter 10MX1.5X150C

2 10mmx1.5x150mmBolt

24‐570

4 24‐5704,0.75"ODx0.50"IDx1.54"L,Sleeve 10MX1.5X90SH

6 10mmx1.5x90mmBolt,sockethead

55‐16‐991

1 BrakeLineBracket,Rear 14X12STB 2 1/4"x1/2"Bolt,Self‐Tapping

55‐18‐991

1 BrakeLineBracket,FrontPassenger 18MFW 8 18mmFlatWasher

55‐19‐991

1 BrakeLineBracket,FrontDriver 18MLN 6 18mmStoverNut

18MX2.5X150C

2 18mmx2.5x150mmBolt

KitPartNumber 77‐992

38C5FN 4 3/8"FlangeNut

PartNumber Qty.PartDescription 38X1C5CB 4 3/8"x1"CarriageBolt,CoarseThread

55‐12‐992

1 EmergencyBrakeBracket 516C5NN 2 5/16"NylocNut

12X114C5CS 1 1/2"x1‐1/4"Bolt,CoarseThread 516C8SN 1 5/16"StoverNut

12SW 1 1/2"SAEWasher 516SW 3 5/16"SAEWasher

12C5NN 1 1/2"NylocNut 516X1C5CS 1 5/16"x1"Bolt,CoarseThread

516X1C5CS 1 5/16"x1"Bolt,CoarseThread 516X1STB 1 5/16"x1"Bolt,Self‐Tapping

516SW 2 5/16"SAEWasher 516X34C5CS 2 5/16"x3/4"Bolt,CoarseThread

516C5NN 1 5/16"NylocNut 716C8SN 4 7/16"StoverNut

716SW 4 7/16"SAEWasher

KitPartNumber 77‐9926

716X1C5CS 4 7/16"x1"Bolt,CoarseThread

PartNumber Qty.PartDescription 916C8SN 3 9/16"StoverNut

66‐23‐992

2 18mmx160mmCamBolt,CamWasher&NylocNut 916SW 3 9/16"SAEWasher

66‐22‐994

2 18mmx140mmCamBolt,CamWasher&NylocNut 916X334C5C

3 9/16"x3‐3/4"Bolt,CoarseThread

F470

2 F470L,ThreadLocker

KitPartNumber 77‐8703

PartNumber Qty.PartDescription KitPartNumber 77‐15‐992

01‐6041

2 01‐60418,HourglassBushing PartNumber Qty.PartDescription

24‐570

2 24‐5704,0.75"ODx0.50"IDx1.54"L,sleev

15‐9922 4 BrakeCaliperSleeve

KitPartNumber 77‐150

PartNumber Qty.PartDescription

1511-B09 8 9/16" High Nut, Fine Thread

1509 8 9/16" Ubolt Washer

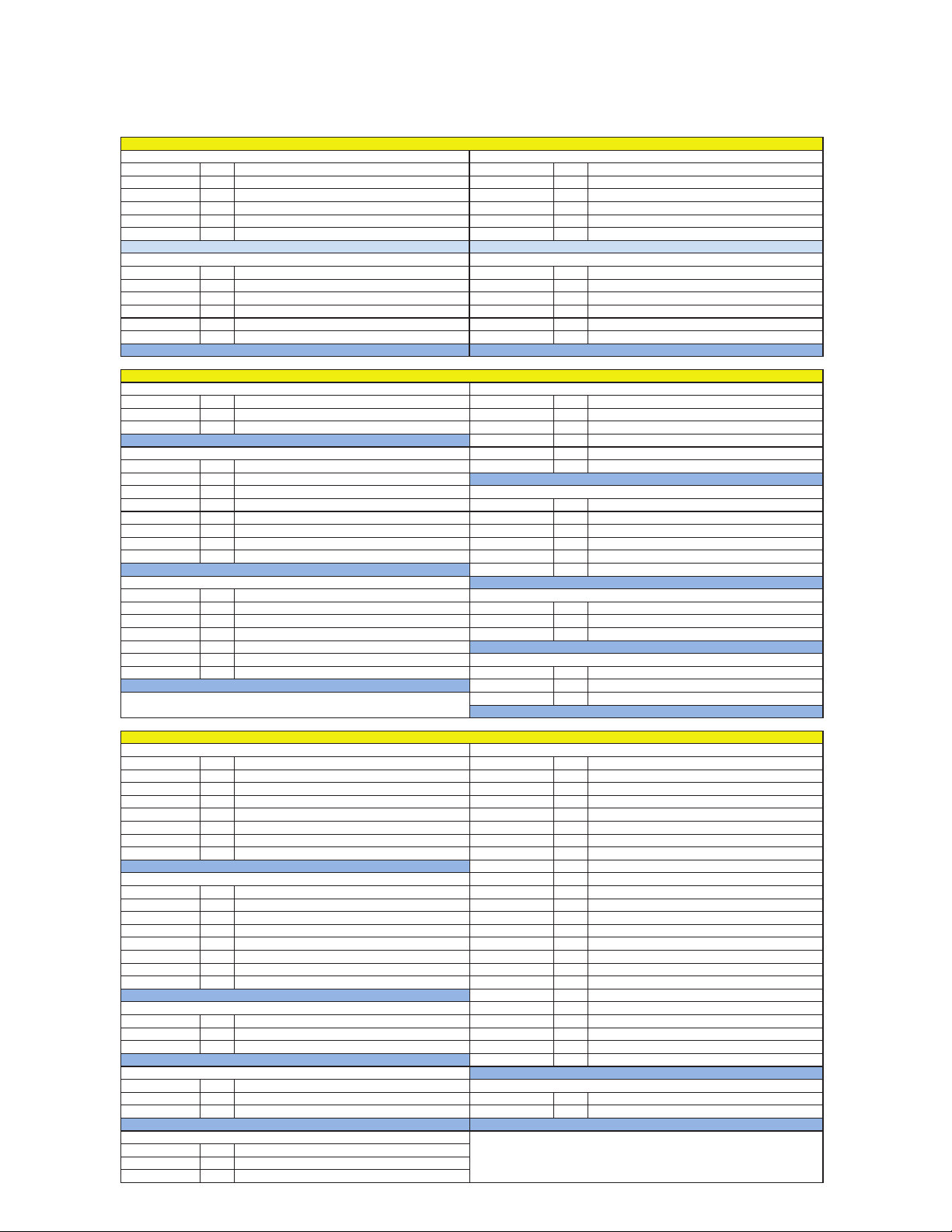

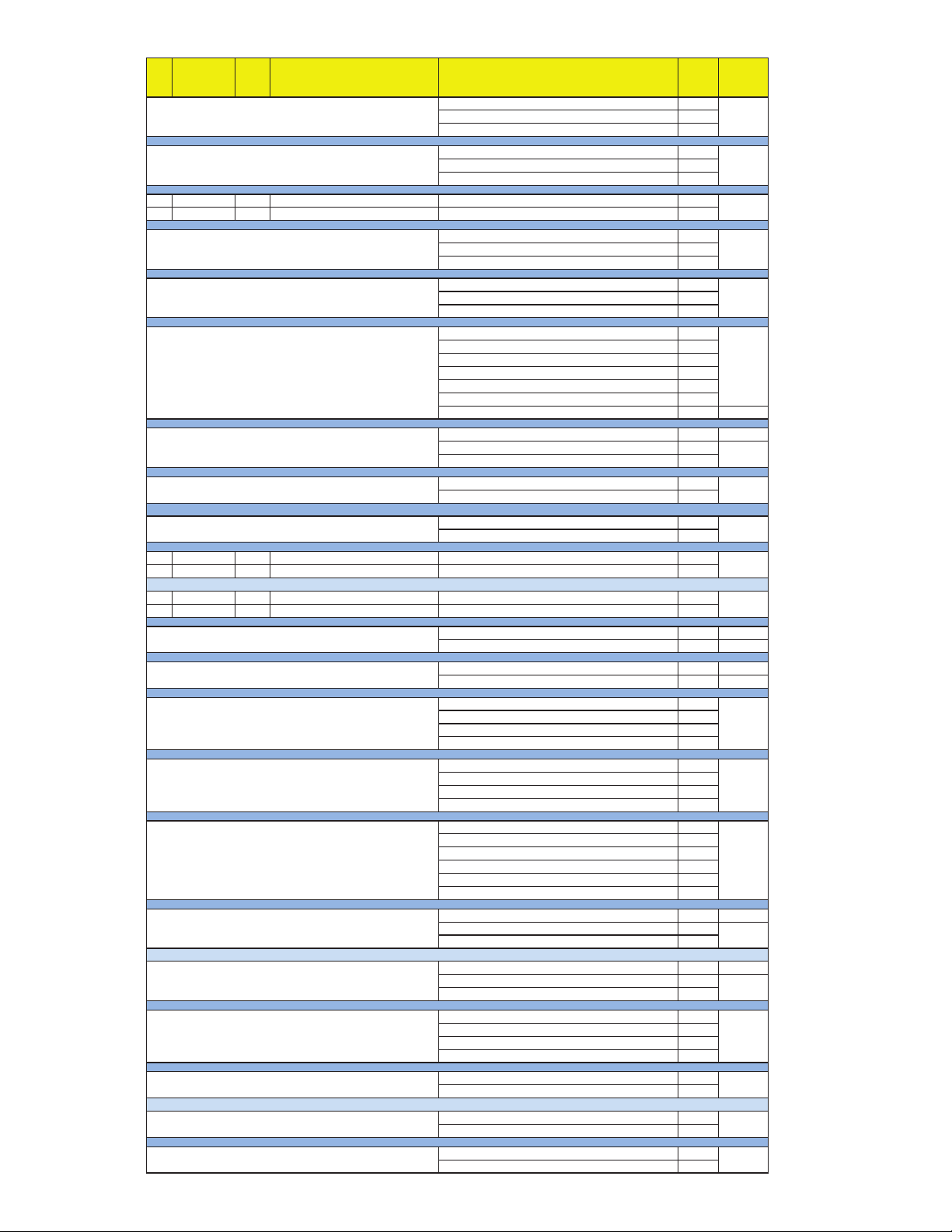

KKITBREAKDOWN

KITBOXBREAKDOWN

HARDWAREBAGBREAKDOWN

How to Read the Kit Breakdown Charts: The ‘K KIT BREAKDOWN’ lists the Part Numbers, Quantities & Part Description of

the Boxes that are included in the K KIT. The ‘KIT BREAKDOWN’ lists Part Numbers, Quantities & Part Description of the Individual

Components & Hardware Bags that are included in Each Box. The ‘HARDWARE BREAKDOWN’ lists the Part Numbers, Quantities

& Part Description of the Individual Components.