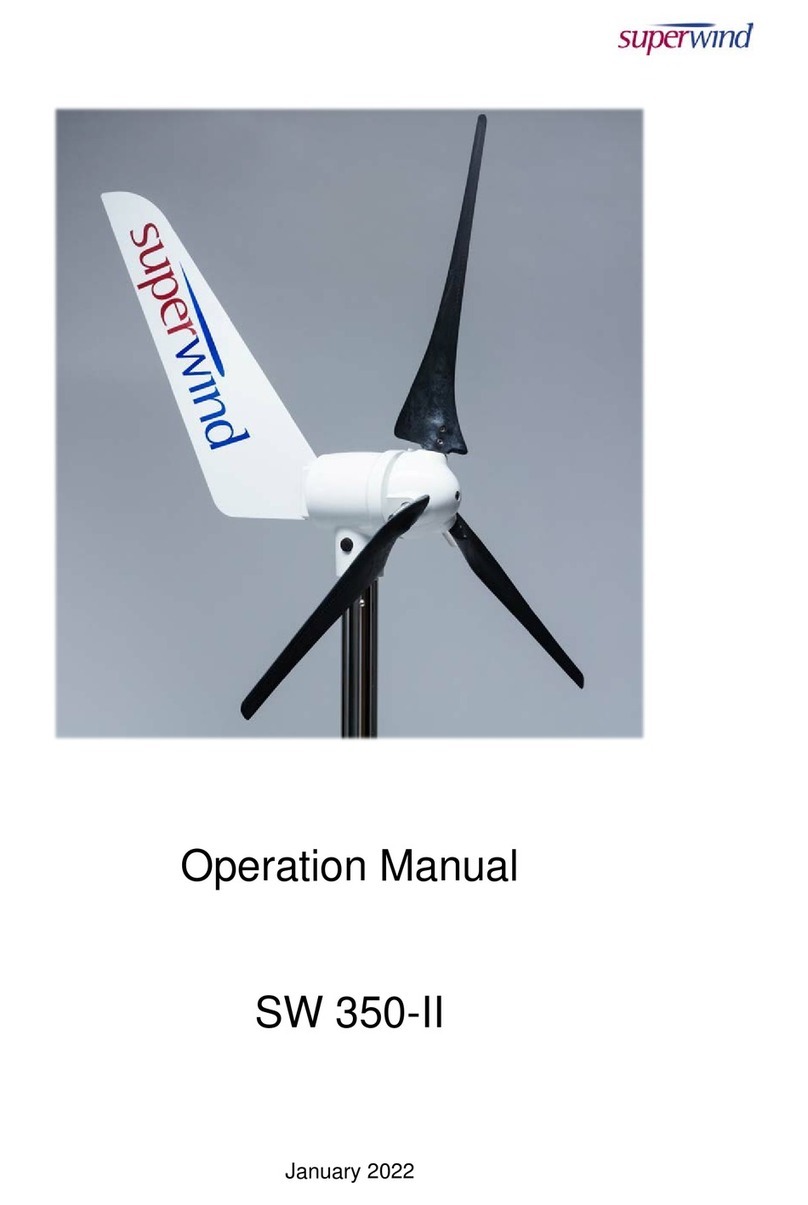

V 01-2017 www.superwind.com

3

Table of Contents

Section Description Page No.

OVERVIEW............................................................................................................... 2

Table of Contents.................................................................................................... 3

1. GENERAL INFORMATION AND REFERENCES

1.1. Company profile ............................................................................................ 5

1.2. Labelling ........................................................................................................ 5

1.3. Range of application ...................................................................................... 6

2. WARRANTY

2.1. Warranty......................................................................................................... 7

2.2. Warranty period ............................................................................................. 7

2.3. To obtain warranty service............................................................................. 7

2.4. Limitations...................................................................................................... 7

2.5. Others ............................................................................................................ 7

2.6. Expenses and Responsibilities ...................................................................... 8

2.7. Claims ............................................................................................................ 8

3. SAFETY INSTRUCTIONS

3.1. Potential sources of danger ........................................................................... 9

3.1.1. Mechanical dangers ....................................................................... 9

3.1.2. Electrical dangers........................................................................... 9

3.1.3. Dangers when mounting ...............................................................10

4. SPECIFICATIONS

4.1. Operational free space required ...................................................................12

4.1.1. Dimensions....................................................................................12

4.2. Technical data...............................................................................................13

4.3. Functional description / Special features ......................................................13

5. PREPARATIONS FOR ASSEMBLY

5.1. Packing list....................................................................................................15

5.2. Tools .............................................................................................................16

5.3. Optional accessories ....................................................................................16

5.4. Electrical components...................................................................................16

6. ELECTRICAL COMPONENTS AND CONNECTIONS

6.1. General information ......................................................................................17

6.2. Wiring diagrams ............................................................................................17

6.2.1. Recommended charge regulator....................................................17

6.2.1.1. SCR Marine Charge Regulator .......................................17

6.2.1.2. Diversion Load Resistor...................................................19

6.3. System components ....................................................................................19

6.3.1. Wires ..............................................................................................19

6.3.1.1 WAG Wire size chart for 12 Volt version .........................20

6.3.1.2 WAG Wire size chart for 24 Volt version .........................20

6.3.2. Strain relief ....................................................................................21

6.3.3. Polarity............................................................................................22

6.3.4. Batteries .........................................................................................22

6.3.4.1. Charging batteries ...........................................................22

6.3.4.2. SCR Marine charge regulator (with diversion load control). 24

6.3.4.3. Diversion load resistor .....................................................25

6.3.5. Fuses..............................................................................................25

6.3.6. Stop switch .....................................................................................25

6.4. Grounding .....................................................................................................26

7. SUPERWIND 350 GENERATOR ASSEMBLY

7.1. Precautions during mounting ........................................................................27