RMK-700 Operating Manual

Safety symbol and instructions

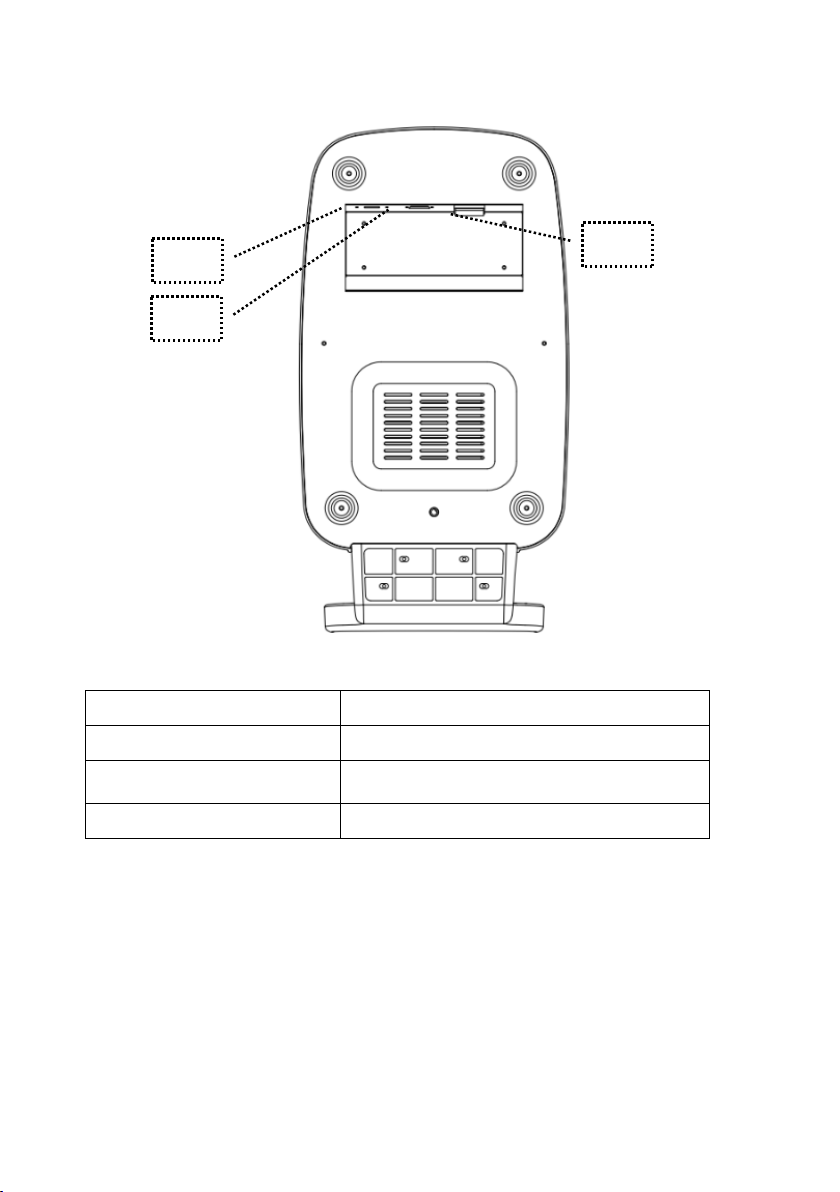

Note: Twist screws here before installation

Working condition :

1、 No hard light shoot directly

2、 No electromagnetic field of strong interference

3、 Temp e ra t ure : +5℃ ~ +40℃

4、 Relative Humidity : 30% ~ 75% RH

5、 Atmospheric pressure range : 700hpa~1060hpa

Working environment

1、 Do not hit or drop the instrument. The impact may cause damage to the function of this

instrument. Please handle with care.

2、 An exposure to the direct sunlight or bright indoor lights may influence the result of the

measurement. Please use the URK-800 in an appropriate optometry room.

3、 Please contact your dealer while connecting this to other associated equipment.

4、 A sudden heating will cause condensation on the protective glass in the monitor screen

and on optical parts inside the instrument. In this case, wait until condensation

disappears before performing measurements.

5、 Keep the objective glass on the examinee side clean. If smudged, it may cause an

ERROR or inaccurate measurements.

6、 In case there is smoke, strange odor or noise during operation, disconnect the power

supply and consult the distributor.

7、 Don’t use organic solvents such as alcohol, paint thinner, benzene, etc. to clean the

surface of this instrument. It may damage the instrument.

8、 When moving the RMK-700, Fix the stage by using stage holding knob and clamping

bolt, disconnect the power cable, and then lift the bottom of the unit with both hands.

9、 When the system is not in use for a longer period of time, disconnect the power supply

and cover with the dust cover.

10、 Some material using instructions touched directly with skin:when operating the

instrument, the customers need to use medical non-woven

fabrics(Specification:8cm*8cm)to separate the touching part between instruments and

patients, to avoid patients touch directly instrument surface.

11、 Don’t open the enclosure until our company agree.