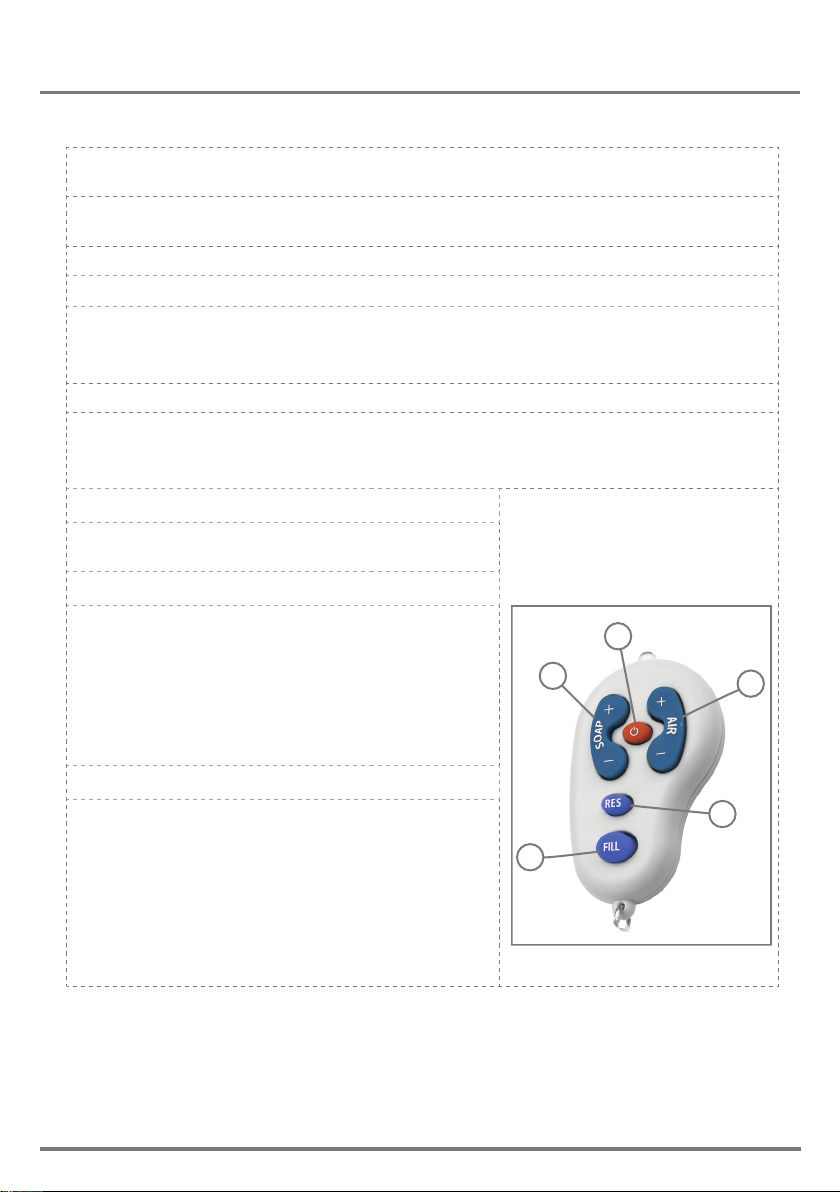

REMOTE CONTROL FUNCTIONS

If available, the foam dispenser remote control can adjust the dispenser’s settings. To

use the remote control hold it in front of the sensor at a distance of 10-15cm (4-6”).

Attention: The remote control will not operate out of the recommended range (too close

or too far).

The remote control can be used to adjust the following functions :

1-SOAP QUANTITY

Press the + sign on the SOAP button to increase the soap quantity by increasing the

dispensing time. Press the - button to decrease it.

Indication: continuous blinking blue light in the sensor eye.

2-AIR QUANTITY

To improve soap consistency (“foamability) change the amount air to be mixed. Press

the + sign on the AIR button to increase the air quantity and the - to

decrease it.

Indication: 2 blinks of the blue light in the sensor eye.

3-RESET

This function resets the sensor back to its factory

settings.

4-TEMPORARY OFF FUNCTION

This function temporary disables the dispenser. Use

this function to preform maintenance in front of the

sensor without activating the system (for example:

cleaning). The soap dispenser will shut o for one

minute after this button is pressed once.

To return to normal operation before the minute is

over, press the On/O button again

5-FILL THE SOAP TANK

Once the soap tank has been lled \ relled, press

the FILL button. The pump will run for one minute,

priming the piping with soap.

Once soap begins dispensing from the spout,

priming is complete. press the FILL button again to

stop the priming before the minute is over.

Indication: continuous solid blue light in the sensor

eye.

4

1

5

3

2

10