SUREHATCH SH2000H User manual

USER MANUAL

MODEL:SH2000H HATCHER

DIGITAL EGG HATCHER

VERY IMPORTANT!

READ THIS USER MANUAL BEFORE USING YOUR

HATCHER

Table of Contents

Page 2 - 5:

Location and placement of your hatcher

What you will find inside your hatcher

How to use your Hatcher Control Panel

Page 6 - 9:

How to operate your hatcher

How to load eggs in your hatcher

Managing the hatching process

Page 9 - 15:

Daily Checklist for your hatcher

Incubation Problem Solving

________________________________________________________________________

Thank you for your choosing Surehatch!

Incubation and hatching is an exciting journey –thank you for trusting Surehatch as your hatcher

brand of choice in this endeavor. We wish you all the best and hope that you enjoy this journey as

much as we do!

Feel free to contact us for advice or assistance at the details below. Join the Surehatch Egg

Hatcher Owner’s Club on Facebook and meet some fellow Surehatch users!

Happy hatching!

Team Surehatch

Facebook: Surehatch Egg Hatcher Owner’s Club

Instagram: @surehatch

Website: www.surehatch.com

E-mail: sales@surehatch.com

Technical Specs: SH2000H Hatcher

Voltage: 120V AC, 60Hz Single Phase

For Indoor Use Only

Take caution when operating as moving parts can cause injury

Surehatch Hatchers have been designed for easy operation to produce the best possible

hatch rates taking all the variables of successful incubation into account.

All Surehatch hatchers and hatchers have been tested in our factory and are made to high

quality standards. Ultimately the success of your hatchery operation lies in the hands of the

hatchery manager/user and the quality of the hatching eggs. It is therefore critically important that

the hatchery manager ensures that he/she follows the best recommended practices for successful

incubation.

The information provided in this user manual aims to help ensure optimal functioning of the hatcher to

achieve the best possible incubation results. In addition to the contents of this user manual we also

recommend that you further your knowledge of incubation by studying additional hatchery

management info available on the internet.

NOTE: It is recommended that you operate the hatcher with a small quantity of inexpensive

eggs to be assured of your operating procedures and the performance of the hatcher before

attempting to hatch large quantities of eggs or expensive eggs.

Success in incubation has 3 main pillars which determines hatching results –these are:

1)

The hatcher (That is our part)

2)

The quality of the hatching eggs (That is up to the hen and cock)

3)

The inputs/management of the entire process (That is you)

All 3 pillars need to work together to produce a successful hatch. Below shows the interaction of all

the variables which determine incubation success:

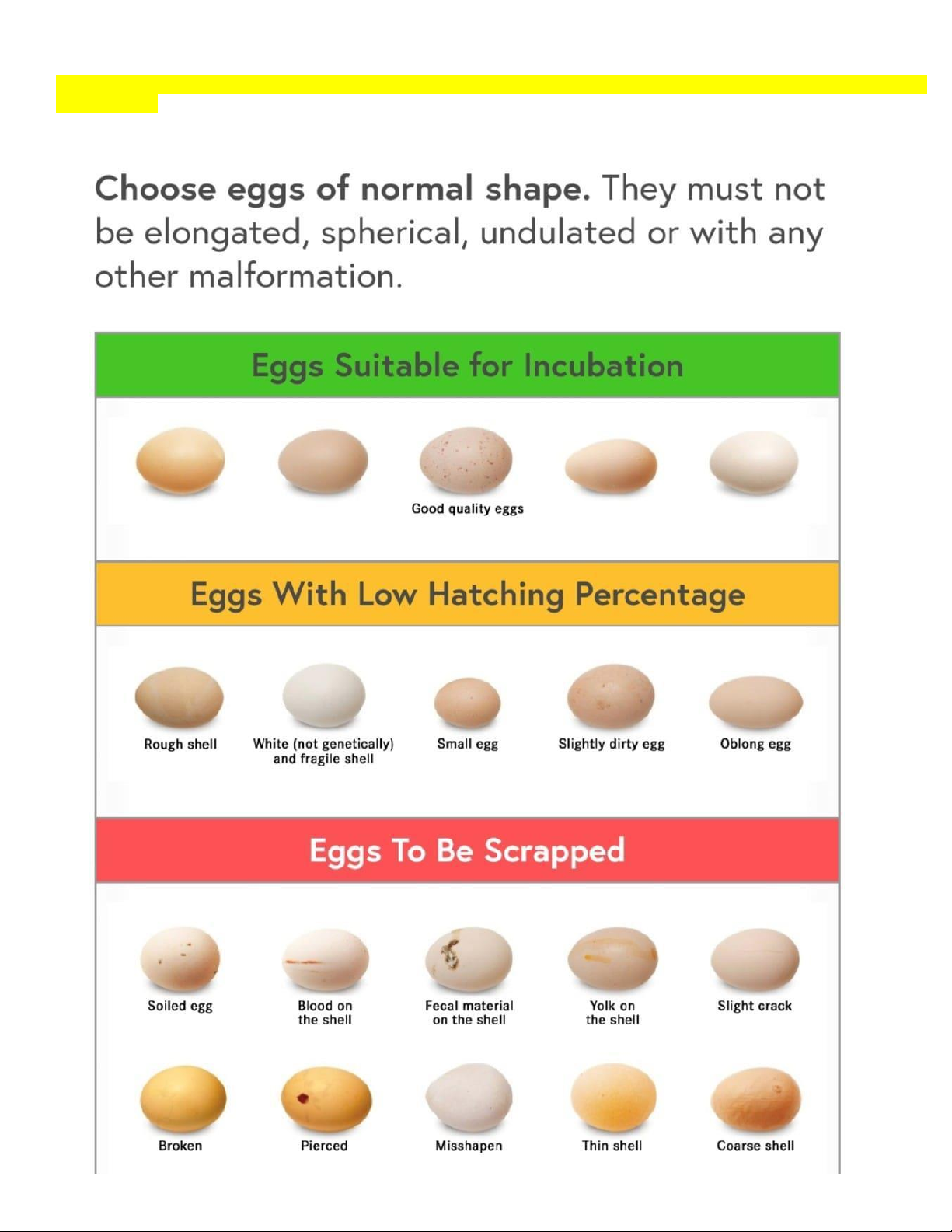

Hatching Egg quality and Pre-Incubation Egg Storage

It is important to note that the hatcher can only give good hatch rates if the eggs which are placed in it is of

good quality. Infertile eggs will never hatch, poor quality eggs will give low hatch rates. Good quality hatching

eggs havethe best chances of successful hatching. Shipped eggs have lower hatchability due to the

vibration/disturbances to the embryo and non-ideal temperature conditions during transport.

Only use good quality, clean fertile hatching eggs

-

Do not store eggs for longer than 7 days before incubating. On average, one day’s

storage adds one hour to incubation time. This must be taken into account when eggs are set, so

freshand stored eggs should be set at different times

-

The longer you store the eggs, the lower the hatch rate. Hatchability is depressed

by prolonged storage. The effect increases with storage time after the initial six-day period,

resulting in losses of 0.5 to 1.5% per day with the percent increasing as storage extends

further

-

Use eggs from good medium aged flock –young birds produce small eggs which are not ideal

for incubation. Older flock produce eggs which have lower hatchability

-

Only set eggs which are uniform and clean. Never set “dirty” eggs – eggs with visible

manureon, as you will introduce pathogens into the hatcher

-

Don’t wipe eggs before setting as you will close the egg pores which they need to breathe

through –rather use a brush to clean eggs

-

If you smell a bad egg, remove immediately and discard

-

Candle eggs after 10 days in the hatcher to check for fertility. Eggs cannot be checked

for fertility before 10 days in the hatcher

-

Remove eggs which are not fertile as they can potentially become “poppers” – eggs that

burstand release pathogens

-

Don’t use a permanent marker when marking eggs. The egg can absorb the toxic

chemicals inthe permanent marker which leads to potential early death. Rather write on the plastic

tray

-

Never mix waterfowl (like duck eggs) with dry or game fowl (like chickens) in the same

hatcher or hatcher. Waterfowl have potential pathogens on their shells which may negativelyaffect

chicken eggs and cause early deaths of embryos

-

Place eggs with their sharp end pointing downwards both in storage as well as when

placing inthe hatcher

Location/Placement of the hatcher

•Hatcher/hatcher must be placed INDOORS.

•Select a suitable room which has an average temperature of 68°F - 82°F

•Don’t let the room temperature exceed 86° F. The hatcher/hatcher cools down via the air

which it pulls in from the room. If the room temperature goes over 86°F the hatcher will struggle to

cool down and can potentially overheat the eggs

•Have a reliable source of electricity - (110V Household Electricity –Single Phase).

If you use a generator as a back-up make sure it’s an INVERTER GENERATOR. Any other type

of generator could damage the electronics.

•Ensure that the floor surface is level where you place the hatcher. The door of your

hatcher/hatcher will not shut properly if the floor is uneven.

•Place the hatcher/hatcher away from direct sunlight. You may place the hatcher on a table

or on the ground, whichever suits you best. Place the hatcher 2 feet away from a corneror wall so

that air can move around it freely.

•The room must have good ventilation. It’s important that there is always fresh air that

comes into the room.

•Depending on your room layout, we recommended that you make use of a wall/window

extractor fan to pull the air out of the room. As eggs develop into chicks, they release C02 (Carbon

Dioxide) which needs to be extracted out of the room. Ensure that fresh air (Oxygen)enters the

room. Ideally the air in the room needs to be replaced by fresh air every 4 to 6 hours.

•Try to maintain on average a 50% to 60% humidity in the ROOM. It is normal for humidity

to fluctuate day by day –this is fine as long as you don’t have extremes (Like 20% or 90% humidity

in the room). Your hatcher has been designed to be capable to regulate its humidityunder most

conditions –however, the more stable the room humidity, the easier it is for your hatcher to regulate.

•If you are in a very dry climate, place some water pans in the room to increase humidity. If you

maintain an average room temperature as suggested earlier then your room humidity usually results

in about 50%

•If you are in a very humid climate, you can remove the water pan/containers out of the

hatcher/hatcher to decrease humidity in the hatcher/hatcher

•Maintaining hygiene is particularly important in your hatcher/hatchers as well as in

the hatchery room. Do not keep chicks in same room as the hatcher/hatcher. Use a

separate room to placehatched chicks. This is done to maintain hygiene.

•We recommend having strict access control to the hatchery room. Do not let any unauthorized

persons tamper with the hatchers/hatchers while you are away.

Some basics about incubation you need to know

•Chicken eggs take 21 days to incubate

•For the first 18 days eggs are placed in plastic egg trays (Also called the setter)

•On the morning of day 18 the eggs must be moved from the plastic egg trays(setter) to

the hatcher (Hatching crates below the egg tray).

•The eggs must lay still in the hatcher. On day 21/22 the chicks will start hatching.Chicks can

be left inside the hatcher for up to 24 hours after they have hatched.

•DO NOT TO OPEN THE HATCHER/HATCHER FROM DAY 18 to 21 –opening the door causes

major moisture loss and may “shrink-wrap” the chicks inside the eggs

•Ideal incubation temperature is 99.5°F (Fluctuations between 96°F to 101°F is normal). Your

hatcher is pre-set to regulate the temperature to 99.5°F

•Ideal hatcher humidity: Day 1 to 18: 50-60%. Day 18 to 21: 60-65%

•Eggs must lose 12% of weight due to moisture loss in the first 18 days.

•Only eggs which are fertile can stand a chance to hatch. There are various reasons why

eggs don’t hatch –at the end of this manual you will find reasons why eggs fail to hatch. You

can check if the eggs are fertile after 10 days in the hatcher. You can’t check for fertility

before they are placed in the hatcher.

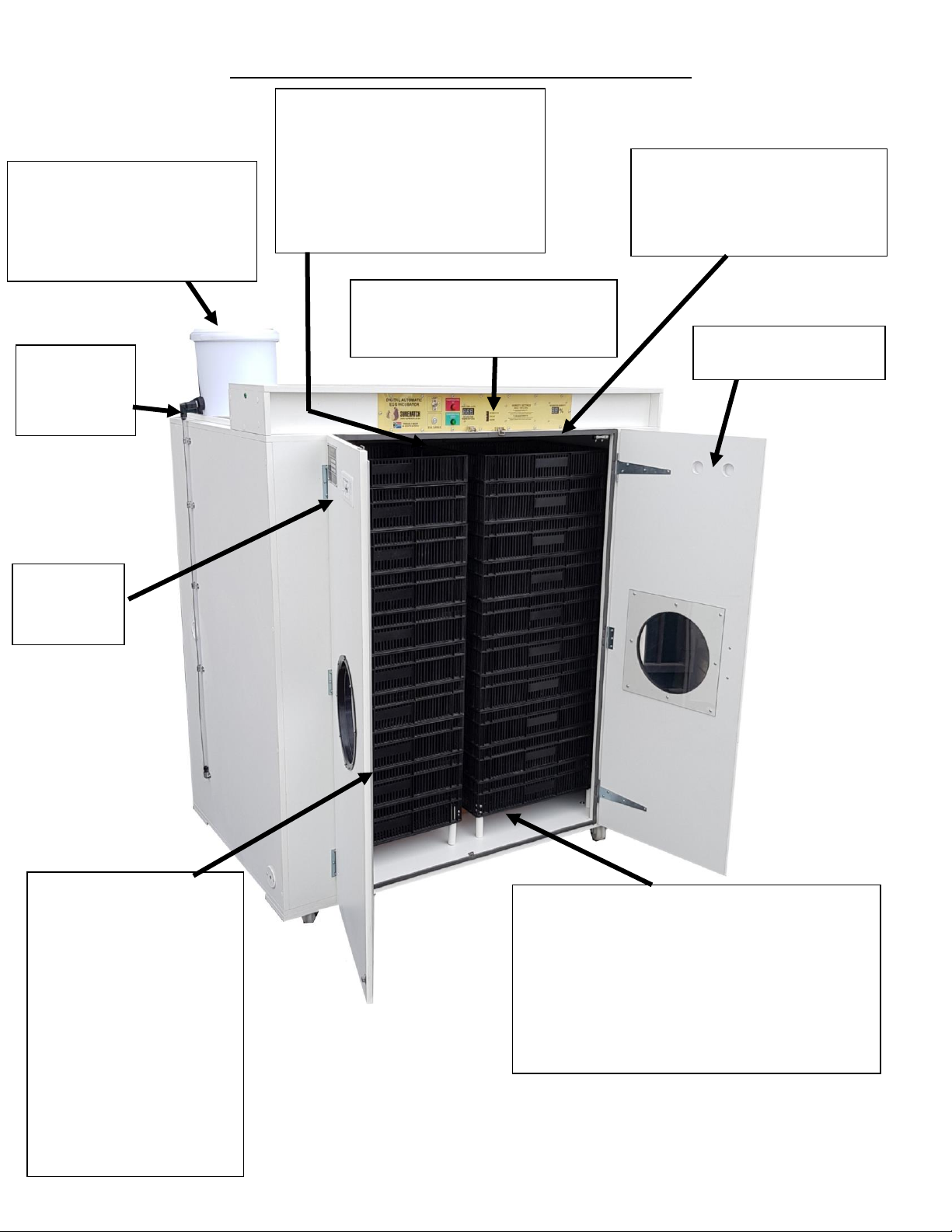

CONTENTS INSIDE YOUR HATCHER:

Plastic Hatching

crates:

Eggs are placed in the

hatcher on day 18.

Eggs will hatch on day

21/22.

DON’T OPEN THE

HATCHER FROM

DAY 18 to 21.

Remove chicks only

after most have

hatched after day 21

Plastic Water Pan:

(Located below hatching crates)

Water evaporating from the pan creates

humidity required for incubation.

The water pan will automatically fill itself

with water coming from the bucket on top

of the machine.

Hatcher Control Panel:

Shows hatcher Temperature

and Humidity %

Water Bucket:

Must be filled with clean

water. Bucket supplies

water to water pan inside.

Refill when empty

Temperature and humidity

Sensor:

Sensitive to water.

Don’t spray water directly

onto sensor when cleaning

machine!

Humidity Control

Air Vent

Connection

pipe for

water

bucket

Auto ON/OFF Switch:

Hatcher will switch off when

you open the door and back

on as you close it

Humidity

Control

Air Vent

STARTING UP YOUR HATCHER:

STEP 1: Plug in your hatcher:

Switch ON your hatcher by plugging it in to the wall plug.

STEP 2: Connect water bucket to hatcher and fill bucket with water

Your hatcher has an automatic float valve inside that will allow water to flow into the inside

water pan from the bucket on top of the machine. Make sure that you check the bucket

daily and fill with CLEAN WATER as required.

STEP 3: SETTING HATCHER TEMPERATURE: (This will take about 1 hour)

The hatcher has been factory set to heat up to 99.5°F (37.5 Degrees Celsius) when you switch it

on. The hatcher will take about 1 hour to heat up to 99.5°F

***You can change the temperature display from Fahrenheit to Celsius by pressingboth

TEMP UP and TEMP DOWN together at the same time and keeping it pressed for 6 seconds.

Next steps:

- Close hatcher door

- Wait for hatcher to reach 99.5°F

- To change the hatcher temperature set-point simply press the “Temp Up” or “Temp Down” Button

(Generally not required –only for advanced users

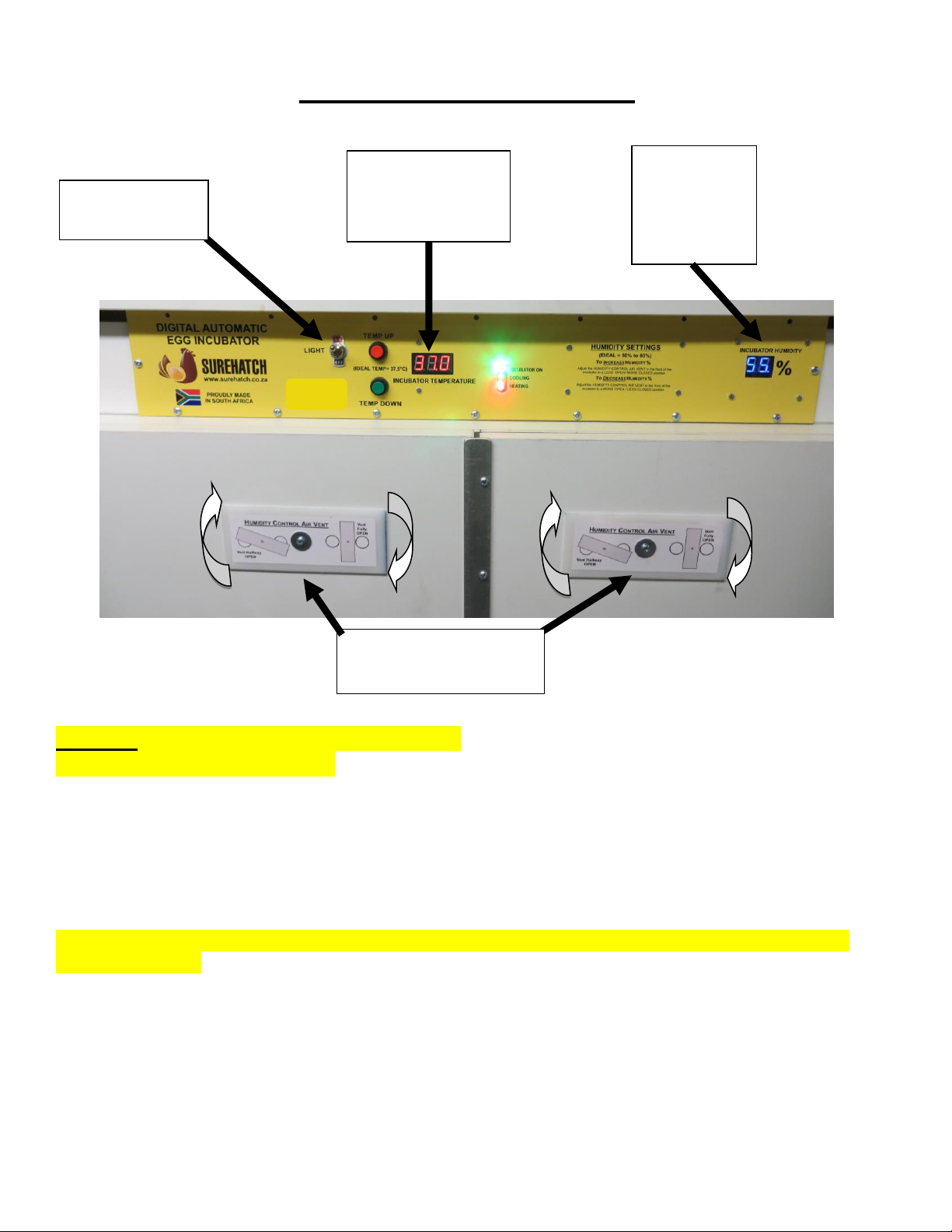

HATCHER Control Panel:

STEP 4: SETTING HATCHER HUMIDITY

(This will take 1 to 2 hours)

You can start adjusting humidity once the hatcher has been running at a temperature of 99.5°F for an at

least 1 hour.

The main way in which to change humidity on your hatcher is to adjust the Humidity Control Air Vents

on the front of the hatcher. (Slide these plastic vents up or down to open or close the vents).

*****The more open the vent is, the less the humidity will be. The less open, the higher the

humidity will be.

Never close the humidity control air vents completely –it’s always good to keep them slightly

open to assist in sufficient air exchanges for the eggs.

Set humidity by following the “Humidity Settings” instructions on the hatcher

Ideal humidity percentage is between 50% and 65%

Hatcher

Temperature

Ideal = 99.5°F

Hatcher

Humidity

(Ideal 50%

to 65%)

Hatcher

Light Switch

Humidity Control

Air Vents

HUMIDITY SETTINGS (IDEAL = 50% to 65%)

Humidity % is determined by the surface area of the water container/ pan and the amount of fresh air exchange in the hatcher.

You can regulate humidity % by decreasing or increasing the SURFACE AREA of the water and by regulating the fresh air that

comes into the hatcher

The ideal humidity % for incubation is between 50% and 65%

TO INCREASE HUMIDITY %

1)

Fill water container/pan with WARM WATER

2)

Adjust the HUMIDITY CONTROL AIR VENT in the front of the hatcher to a LESS OPEN/ MORE CLOSED position

If the above two steps fail to increase humidity, do the following in addition to the above:

3)

Place water pans and humidifier in the room where the hatcher is standing to increase room humidity

TO DECREASE HUMIDITY %

1)

Adjust the AIR VENT in front to a MORE OPEN / LESS CLOSED position

2)

Remove one of the water containers

If the above two steps fail to decrease humidity, do the following:

3)

Remove both water containers completely (Only in very humid / wet areas)

4)

Place a dehumidifier in the room (Only in very humid / wet areas)

After you are satisfied with the temperature and humidity you may place the eggs in the hatcher

Hatcher light:

Your hatcher has a light located on the inside of the hatcher. This light may be switched on in

order to view the eggs or chicks inside the hatcher.

VERY IMPORTANT: Don’t leave the light on as this will negatively effect the functioning of the

hatcher. Only use the light when necessary. Switch the light OFF after you have viewed the

eggs/chicks inside the hatcher.

CONGRATULATIONS!

YOU HAVE NOW SUCCESSFULLY SET UP YOUR SUREHATCH EGG HATCHER.

NEXT YOU NEED TO FOLLOW THE DAILY CHECKLIST

Remember to clean the hatcher after each hatch. Sanitation is CRITICALLY importantfor

successful hatching. Before loading any eggs, clean the hatcher by wiping the insides with a

cloth and hatcher sanitizer. It is essential that the hatcher and trays/crates be cleaned

thoroughly between hatches.

Before cleaning inside the hatcher, be sure to disconnect its electrical cord from theoutlet

to avoid possible electrical shock. Take care not to introduce moisture or waterinto the

electrical system of the hatcher and allow all surfaces to dry before again reconnecting the

electrical cord to the outlet.

BE CAREFUL not to spray water directly onto the temperature or humidity sensor

located inside the machine as this will damage the sensor.

DAILY CHECKLIST FOR YOUR SUREHATCH HATCHER:

Check the following once per day —Correct where necessary

-

CHECK Electricity - Electricity must always be ON. Power interruptions will negatively

affect the eggs.

-

CHECK Hatcher Temperature

Ideal temperature is 99.5°F (Fluctuation between 96°F to 101°F is normal)

-

CHECK Hatcher Humidity

Ideal humidity % for incubation is between 50% and 65%. Humidity takes hours to build

up and is quickly lost when the hatcher door is opened. It is normal for humidity to fluctuate 10% to

15% from day to day due to changes in outside humidity.

-

CHECK Hatcher Fan - Must always be ON and spinning

-

Check for smelly, rotten eggs —remove and throw away if any

-

Check that FRESH AIR is coming into the room

-

CHECK that nothing is blocking hatcher AIR VENT

-

CHECK that there’s NO DIRECT SUNLIGHT on the hatcher

-

CHECK ROOM TEMPERATURE —Ideal room temperature = 68°F - 82°F

-

Don’t let the room temperature exceed 86° F.

-

CLOSE hatcher DOOR after you have opened it.

-

Make sure no one can tamper with hatcher while you are away!

-

ONLY incubate CLEAN, FRESH, FERTILE eggs

MAINTAINING BIOSECURITY AND HYGIENE

-

WIPE CLEAN the insides of your hatcher after every hatch

-

WASH YOUR HANDS EVERY TIME BEFORE you work with the hatcher or touch the

eggs

-

WASH your hatching crate/s and egg trays after every hatch with disinfectant

-

Keep your incubation room clean and sanitized!

-

Throw away any eggs which are smelly, dirty or rotten

Trouble Shooting Failures with Egg Incubation

When incubation of eggs fails, indications are often available that a well trained

professionaluses for diagnosing the causes for failure. The information listed below

includes the more common symptoms for incubation failures, the causes for each symptom,

and the recommended corrective measures Symptoms of incubation/breeder management

problemsinclude:

•Clear eggs with no visible embryonic development.

•Blood rings in incubated eggs.

•Many dead embryos at an early stage.

•Chicks fully formed, but dead without pipping.

•Pipped eggs, but died without hatching.

•Early hatching.

•Late hatching or not hatching uniformly.

•Sticky embryos.

•Embryos sticking or adhering to shell.

•Crippled and malformed chicks.

•Abnormal, weak, or small chicks.

•Chicks with labored breathing.

•Large, soft-bodied mushy chicks.

•Rough or unhealed navels on chicks.

•Short down on chicks.

•Excessive yellow down color.

Symptoms

Probable Cause

Corrective Measures

Clear Eggs with no

embryonic

development

(infertiles)

Males undernourished

Follow a recommended feeding program to

provide adequate nutrition. Replace

underweight males with vigorous ones

Too few males

Increase the number of males in the flock.

Seasonal decline in fertility

Use young cockerels more resistant to

environmental stress.

Competition among breeding

males

Do not use too many males. Rear all males

together. Place temporary partitions within

large pens.

Diseased flock

Conduct an approved disease control

program.

Frozen combs and wattles

Provide comfortable housing. Properly select

and maintain drinking fountains.

Old males

Replace with younger males.

Selected mating in pens

Artificially inseminate infertile hens. Replace

males in the pen/house.

Male sterility

Replace males in the pen/house.

Crowded breeders

Provide recommended floor space, at least 3

ft²/bird.

Improper artificial

insemination techniques or

use of old/over-diluted

semen.

Follow recommendations of primary breeder

company.

Eggs damaged by

environment

Gather eggs frequently (at least once daily).

Eggs stored too long or

incorrectly

Store eggs at 50-60 degrees F. and 60%

relative humidity. Incubate eggs within 7

days of lay.

Symptoms

Probable Cause

Corrective Measures

Blood rings

Improper storage

Follow recommended egg storage and

gathering recommendations.

Improper incubation

temperatures

Check thermometer accuracy and hatcher

functions. Follow recommended temperature

settings.

Improper breeder nutrition

Feed breeders a diet with balanced nutrient

levels.

Improper fumigation

Follow fumigation recommendations.

Symptoms

Probable Cause

Corrective Measures

Many dead

embryos at early

stages

Improper incubation

temperatures (usually too

high)

Follow recommended incubation temperatures.

Improper egg turning

Turn at least 3 times daily.

Inherited low hatchability

Avoid cross breeding. May need to secure

different breeding stock.

Improper ventilation

Increase ventilation rate in hatcher and/or

room, but avoid drafts. Add oxygen at high

altitudes.

Pullorum disease or other

salmonelloses

Use eggs from disease-free sources. Have NPIP

representatives blood-test the breeder flock.

Improper nutrition of breeders

Provide a well-balanced nutritional diet to breeders

Symptoms

Probable Cause

Corrective Measures

Chicks fully formed,

but dead without

pipping

Low average humidity

Maintain recommended humidity for species ofbird

incubated.

Improper incubation

temperature

Check thermometer accuracy and hatcher

functions. Follow recommended temperature

settings.

Improper ventilation in

hatcher

Adjust ventilation to provide optimum moisture-

loss rate from egg during incubation.

Improper turning of eggs

Turn eggs at least three times daily until 3 days

prior to hatching.

Chilling of eggs

Gather eggs frequently and store under proper

conditions.

Diseased or poorly

conditioned breeder flock

Conduct a good disease control and breeder

management program. Use a well-balanced

nutritional diet.

Symptoms

Probable Cause

Corrective Measures

Pipped eggs, but

died without

hatching

Insufficient moisture

Increase humidity during the hatching period.

Improper ventilation

Increase ventilation rate in hatcher and/orroom,

but avoid drafts.

Improper setting of eggs

causing malpositioned

embryos

Set eggs with small end down. Turn eggs

properly but avoid turning within 3 days of

hatching.

Symptoms

Probable Cause

Corrective Measures

Early hatching (may

have bloody navels)

High incubation

temperatures

Follow recommended incubation temperatures.

Check equipment for proper function. Guard

against electrical surges or high hatcher room

temperatures.

Improper egg storage

Store eggs at 60 Degrees F. and 60% R.H. Turnat

least 3 times daily.

Symptoms

Probable Cause

Corrective Measures

Late hatching or not

hatching uniformly

Low incubation

temperatures

Follow recommended incubation temperatures.

Old or improperly stored

eggs

Gather eggs frequently, cool immediately and

store eggs properly. Do not store longer than 7

days.

Symptoms

Probable Cause

Corrective Measures

Sticky embryos

(embryos may be

smeared with egg

contents)

High average incubation

humidity

Follow recommended incubation humidity. Check

size of air cell as an indicator for adjusting humidity

condition.

Low incubation

temperature

Follow recommended temperature settings.

Lethal genes

Avoid cross breeding. May need to secure different

breeding stock.

Inadequate ventilation

Increase ventilation rate in hatcher and/or room,

but avoid drafts.

Improper fumigation ofeggs

Fumigate eggs by following the procedure

carefully.

Symptoms

Probable Cause

Corrective Measures

Embryos sticking or

adhering to shell

Low incubation humidity

(especially during

hatching)

Increase incubation humidity by increasing water

evaporation. Embryos dried too much.

Excessive ventilation rate

Reduce ventilation rate but maintain minimum air

exchange to prevent suffocation of embryos.

Symptoms

Probable Cause

Corrective Measures

Abnormal, weak, or

small chicks

High incubation or hatching

temperatures

Follow recommended incubation temperatures.

Small eggs hatch small

chicks

Set only standard or large sized eggs.

Insufficient incubation

humidity

Maintain recommended humidity for species of

bird incubated..

Improper ventilation in

hatcher unit

Increase ventilation rate, but avoid drafts.

Diseased or poorly

conditioned breeder flock

Use eggs from disease-free sources only. Have

NPIP representatives blood-test the breeder

flock.

Improper nutrition of breeders

Provide a well-balanced nutritional diet to

breeders (especially vitamin levels).

Excessive fumigation in

Fumigate using proper procedures.

Symptoms

Probable Cause

Corrective Measures

Crippled and

malformed chicks

Improper incubation

temperatures (usually too high)

Follow recommended incubation temperatures.

Low incubation humidity

Increase incubation humidity by increasing water

evaporation. Embryos dried too much.

Improper egg setting position or

turning during incubation

Set eggs with small ends down. Turn eggs atleast

3 times daily. Do not turn eggs within 3

days of hatching.

Heredity

Proper culling and breeding practices will reduce

problems.

Slick hatching trays

Use trays with wire floors or place crinoline on

hatching surface.

Improper nutrition of breeders

Provide a well-balanced nutritional diet to

breeders.

Symptoms

Probable Cause

Corrective Measures

Chicks with labored

breathing

Excessive use of fumigant

Follow recommended fumigation procedures.

Respiratory diseases

Check disease status of breeder flock. Conduct a

thorough cleanup and disinfection of hatcher and

hatching facilities.

Symptoms

Probable Cause

Corrective Measures

Rough or unhealed

navels

Improper incubation

temperatures

Follow recommended incubation temperatures.

High hatching humidity

Maintain proper humidity.

Navel infection (Omphalitis)

Clean and disinfect hatcher and hatching units

between settings of eggs. Maintain dry hatching

trays. Properly store and fumigate eggs.

Symptoms

Probable Cause

Corrective Measures

Short down on

chicks

High incubation

temperatures

Follow recommended incubation temperatures.

Low incubation humidity

Follow suggestions to correct insufficient

humidity.

Excessive ventilation

Reduce vent openings to restrict but maintain

adequate air exchange.

Holding chicks in hatcher toolong

after hatching

Remove all chicks as soon as fluffy but within 24

hours after hatching.

Symptoms

Probable Cause

Corrective Measures

Excessive yellow

coloring of down

Improper and excessive

fumigation in hatcher unit

Follow recommended fumigation procedures.

Trouble Shooting Failures with Surehatch Egg Hatchers

In general there is very little that will go wrong with your Surehatch hatcher. In the unlikely event that

something goes wrong, please contact us or consult the trouble shooting below. NB Always switch

off the hatcher when making repairs. ONLY ELECTRICIANS SHOULD MAKE REPAIRS dueto the

dangers of electrical shock.

Symptoms

Probable Cause

Corrective Measures

Hatcher not running

Hatcher not plugged in or electricity

not on. Auto off switch atdoor faulty

Make sure that all plugs are

correctly plugged in and that the

electricity is on. Check auto off

switch on door

Fan is working but Hatcher not

producing heat

Faulty Temperature Controller or

faulty heating elements

Replace Temperature Controller.

Once this is done and the problem

persists, consider replacing the

heating elements (Very unlikely to

happen)

Hatcher does not regulate

temperature

Faulty Temperature Controller or

temperature sensor

Replace temperature controller or

temperature sensor

Egg trays not turning

Egg Turner not switched on or eggs

loaded incorrectly

Make sure egg turner is switched on.

Load eggs in balance (Load equal

number of eggs in front and back of

the machine). If all eggs areloaded in

front or back then the turner will not

turn

Incorrect temperature

Someone adjusted temperature or

faulty temperature controller

Adjust temperature and monitor. If

not resolved consider replacing

temperature controller and

temperature probe

Humidity too high (Shows 99%

Reading)

Faulty Humidity Sensor due to water

spilled onto it

Dry out sensor with hair dryer (Blow

on sensor for 3 min on cold setting of

hair dryer). If reading does not go

back to normal replace humidity

sensor

20

Thank you for your support!

We wish you all the best and look forward

todoing business again.

Happy hatching!

The Surehatch Team

Facebook:

Surehatch Egg Hatcher Owner’s Club

Website: www.surehatch.com

E-mail: sales@surehatch.com

LIMITED WARRANTEE & LIMITED LIABILITY

Whereas Surehatch has no control over usage of equipment supplied, it assumes no responsibility for

losses or damage from their equipment. No guarantee on hatchability of eggs.

Do not expose electrical parts to water. Installation of replacement electrical parts should be done by

qualified electrician.

STANDARD TERMS AND CONDITIONS APPLY

Contact us via email to receive your copy.

Other SUREHATCH Farm Equipment manuals