SureKap SK6000-BF6 User manual

INSTRUCTION MANUAL

MODEL SK6000-BF6 CAPPER

SUREKAP, INC.

579 BARROW PARK DR.

WINDER, GA 30680

770-867-5793

FAX: 770-867-5799

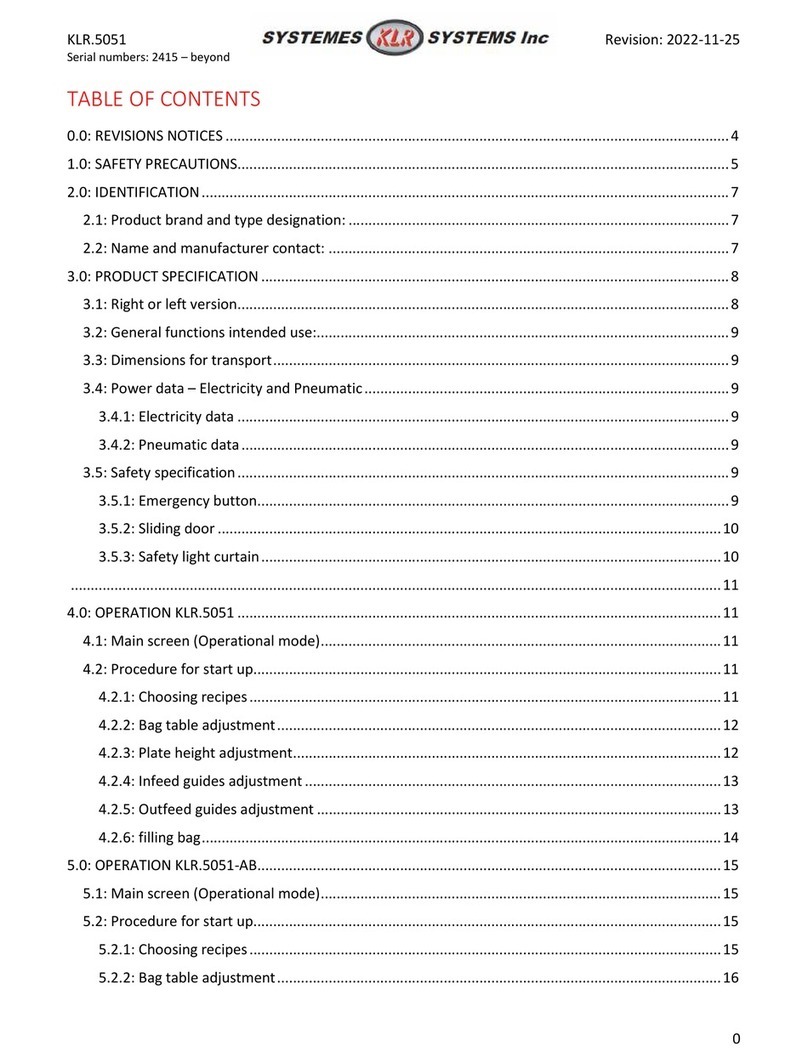

TABLE OF CONTENTS FOR SUREKAP SK6000-BF6

CAPPER INSTRUCTION MANUAL

Pages 1 –2 Instructions for Uncrating Your Capper

Pages 3 -5 Capper Preparation

Page 5 Set-Up & Changeover

Page 6 Blank Application Set-Up Data Sheet

Pages 7 –8 Floating Shoe Height

Page 8 Suggested Contact Patches (for most caps)

Pages 9 –10 Floating Shoe

Page 10 Chute Height

Page 11 Gripper Belt Height

Page 12 Gripper Belts In/Out

Page 13 Spindle Disc In/Out

Pages 13 - 14 Clutched Disc In/Out

Page 14 Chute In/Out

Page 15 Fingers In/Out

Pages 15 - 16 Floating Shoe In/Out

Page 16 Spindle Height

Pages 16 - 17 Spring Set Collar Height

Page 17 Cap Guides

Page 17 Container Separation

Page 17 Spindle Speed Dial Setting

Page 17 Gripper Belt Speed Dial Setting

Pages 18 –21 Instructions for BF6 Cap Feeder

Page 22 Pneumatic Parts Reject Circuit for BF6

Pages 23 –25 Clutch Option

Page 26 Silicone Belt Disclaimer

Page 26 Tightening Discs & Gripper Belts

Pages 27 –36 “A” through “E” Assembly Schematics

Page 37 –41 Chute & Chute Bracket Assembly Schematics

Page 42 Upper C-Chute Assembly Schematic

Page 43 Floating Shoe Assembly Schematic

Page 44 BF6 Cap Belt Conveyor Schematic

Pages 45 –47 SK04/06 Elevator Assembly Schematics

Page 48 Maintenance Schedule Outline

Pages 49 –53 Maintenance Guide

Pages 55 –55 Maintenance Schedule Checklist

Page 56 Dart DC Motor Control Schematic

Page 57 Fiber Optic Amplifier Instructions

Page 58 Electrical Schematic

Pages 59 –63 Gearbox Information

Page 64 Finalized Application Set-Up Data Sheet

Page 65 Hopper Low Level Assist (OPTIONAL; If Equipped)

Additional Pages Optional Equipment

Carla / My Documents 1Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

In the event of damage, please write down a complete description of the damage on the freight

bill and notify the claims department of the delivering carrier. They will inspect and handle your

claim.

The instructions herein are vital for the proper installation, operation and maintenance of this

equipment. Please see that these instructions are read carefully by the persons who will operate

and maintain the SUREKAP equipment.

UNCRATING CAPPER

1. Position the crate on three pieces of 4x4 lumber or equivalent (one under and parallel

with each skid runner). This will raise the crate approximately 3½" to allow access to the

four 1" bolts under the skid. Do not remove the bolts at this time.

2. Remove the wafer board skin from the top and all four sides of the crate. Use a pry bar

or claw hammer to remove the nails. CAUTION: Wear proper eye protection and gloves

when removing the wafer board and framed walls.

3. Remove the 2x4 framed walls from the skid. Use a pry bar or claw hammer to pry off the

framed walls.

4. Remove the box that contains the manual, leveling pads, and any accessories, if

applicable.

5. The machine is secured to the skid with four 1" bolts threaded from the bottom.. Use a

1½" wrench to loosen the retaining hex nuts on the top of the skid and then loosen the

four 1" bolts that are under the skid. Do not remove the 1" bolts at this time, just have

them loose.

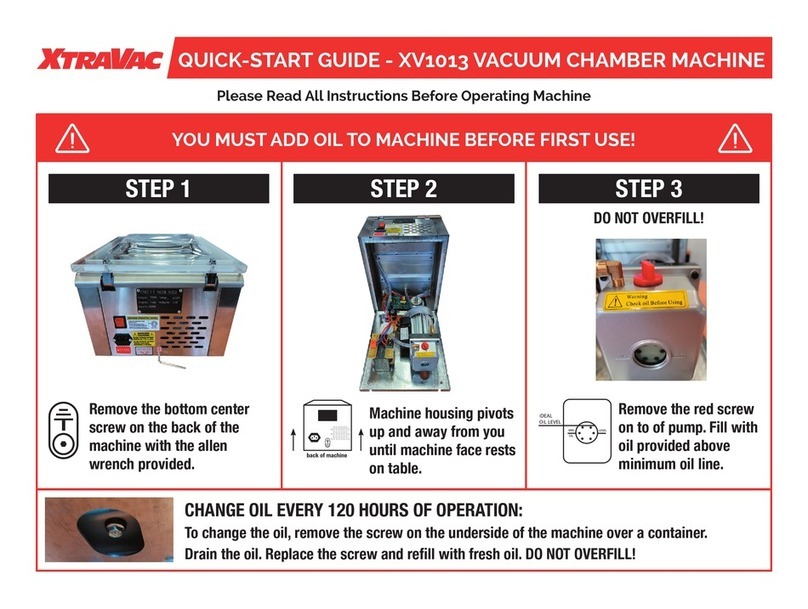

Figure 0.1B

Figure 0.1 A

Welded Hex Mounting Nut

1” Mounting Bolt

1 ½” Retaining Hex Nut & Washers

Carla / My Documents 2Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

Figure 0.1

1. Remove the four 1" bolts and hex nuts from the machine legs. Note: the bolts will still be

sticking up thru the skid at this time. Important: Save these bolts and the hex nuts, they

are used as the machine leveling bolts. The four large washers are used for crating

purposes only. CAUTION: Do not allow the machine to roll off of the skid.

2. Using a forklift with a minimum capacity of 3,000 lbs, slowly and carefully pick the

machine up off of the skid and place it on the floor.

For cappers and tighteners, it is recommended to approach the machine from the side and

position the forks below the legs of the frame and in between the casters. For cappers,

pick up from the side that does not have the cap feeding chute. CAUTION: Do not

damage the cap feeding chute or allow the machine roll off of the skid.

For tables with a feeder bowl and/or hopper, position the forks under the top of the table

and lift the table off of the skid. CAUTION: The feeder bowl is much heavier than the

hopper. Position the forks so that the table is properly balanced. CAUTION: Do not let

the machine roll off of the skid.

3. Install the four 1" leveling bolts down into the top of each leg. Install the hex nut on each

1" bolt from the underside of the leg. The aluminum leveling pads should be installed

below the 1" bolts after the machine is positioned over the conveyor. Refer to the

manual for detailed instructions on initial setup of machine.

Carla / My Documents 3Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

CAPPER PREPARATION

The purpose of this section is to familiarize you with the capper and to prepare it for set-up and

operation.

Step 1: Familiarize yourself with all on/off switches, speed adjustments, and the red emergency

stop button.

Step 2: Make sure all capper and related equipment switches are off. Check the color coded

plugs to the following: Bowl, Hopper, Air Jet Manifold Solenoid, Bowl/Hopper Limit Switch

(Red = Bowl; Blue = Hopper; Yellow = Limit Switch; Green = Air Jet Manifold). If you have a

BF6 Model, they will be Red = Cap Belt; Blue = Elevator.

Step 3: Plug in the power source (115/60 unless ordered differently). TWIST the

EMERGENCY STOP on/off button. Press the START button. Energize the gripper belts and

the spindles by turning on their individual control buttons. After viewing their operation, test the

EMERGENCY STOP by pushing the red button.

Step 4: Put some caps into the hopper, power up the machine and turn on the Bowl and Hopper

through their individual controls and view their operations. If you have a BF6 Model, turn on

the Cap Belt and Elevator. Hook up the air to the air jet manifold and familiarize yourself with

its function in relation to the bowl. If you have a BF6 Model, hook up the air and test the cap

reject system. Once you have become familiar with these functions, push all buttons off and

unplug the power cord and compressed air.

Step 5: Level your conveyor, front to back and side to side, in the area in which the capper is to

be installed. This step is important to achieve container stability and proper capper operation.

Step 6: Raise the capper head high enough so the gripper belts will clear your conveyor by

approximately 6 inches. The head of the machine can be raised or lowered using the jack built

onto the machine. Depending on machine orientation, the jack will either have its crank handle

1” Leveling Bolt

Hex Nut

Carla / My Documents 4Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

attached in the rear or will have a loop shaft attached in the front, which will require use of the

jack handle held to the side of the machine by a magnetic strip.

Step 7: Roll your capper over your leveled conveyor. The center line of your conveyor should

line up with the center of the two gripper belts, the chute, floating shoe, fixed hold-down, etc.

Step 8: For proper operation, the capper must be level front to rear and side to side. To level the

machine, there are (4) round

aluminum pads that are shipped

with the machine (there will be (8)

pads for a SK6000-SP model).

These pads are usually in the box

with your manual.

Place (1) pad under each leveling

bolt.

Place your level on the large top

plate of the capper. If your capper

is not level, screw one or more

levelers down to lift the necessary

corner or entire side. When

turning levelers, use a 1-1/2 inch

socket or open-end wrench and

make gradual adjustments. When

leveling, the casters should be off

the floor, but keep the capper as

low to the floor as possible.

NOTE: If your capper is far

enough out of level, front to rear,

when screwing the levelers you

might end up with the capper off

center of your conveyor.

Compensate for this by first rolling

the capper one or two inches

forward or backwards before

leveling. After the capper is level

and centered, raise the container

entry end of the capper by turning

the (2) leveler bolts (on the entry

side) one complete turn. This will

create a downward pressure on the container against the conveyor. If you have an SP Model,

move the Bowl and Hopper table into position so that the Bowl discharge and cap chute are in

alignment with each other. This will require the SP table to be raised or lowered accordingly to

the height of the capper and chute. There should be a gap (approximately 1/16" to 1/8") between

the bowl discharge and cap chute that will not allow the two to rub each other during operation,

but as close as possible. Use the leveling bolts and pads just as described in the leveling of the

Leveling Pad

©~PjQ»‰õtŽ ÿZà̦

Carla / My Documents 5Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

capper. CAUTION: Be careful not to crank the chute into the feeder discharge or the

feeder discharge into the chute.

SET-UP AND CHANGEOVER

Using the Application and Set-Up Data Sheet:

As parts of SUREKAP’s final testing and documentation procedure, your capper has been

performance tested with container and cap combinations provided to us. From each container

and cap combination tested and approved, a series of measurements are documented onto the

SUREKAP Application and Set-Up Data Sheet to allow you, the customer, to duplicate the set-

up with an established baseline for set-ups and changeovers to other caps and containers. With a

proper understanding of each measurement’s reference points, it is possible to duplicate the

factory recommended specifications that yield the highest operating performance. The following

information briefly defines the theories behind each adjustment and also defines from where

each measurement is scaled.

To begin using the SUREKAP Application and Set-Up Data Sheet, it is assumed that the capper

has been correctly and exactly placed over a container transport conveyor. The correct

relationship between the capper and conveyor is crucial for trouble-free operation. Do not

assume the capper will operate with any degree of success if the initial capper set-up procedures

have been neglected.

To begin, you will need the following:

1. The capper system correctly placed over the container transport conveyor.

2. A six and a twelve inch flexible steel rule, scaled in one thirty seconds of an inch. In

some cases, an eighteen or twenty-four inch scale is required. A metal scale provides a

much more accurate measurement than a ruler or a tape measure.

3. A set of hex keys (sometimes referred to as Allen or “L” wrenches). The set should

range from 1/8 to 5/16 of an inch.

4. The SUREKAP Application and Set-Up Data Sheet. Take a moment to get familiar with

the format of the sheet. The top of the Set-Up Data Sheet contains information such as:

customer, machine type and serial number of the tested machine. At the far left of the

page are the reference points (A through R), which run vertically (up and down). Notice

the first and second horizontal (left to right) row list the cap and container combinations

tested. Locate the vertical column that has the cap and container combination you wish

to adjust the capper to run. Following the column downward, adjust the capper to the

measurement specified in each window. It is recommended to follow the order as they

are listed; this is most important for the first three windows, as they are related to each

other. Once the first three measurements have been set, the order of the rest can be

varied to suit, in some cases they will have to be in an order to make room for the scale,

the tool or the hand.

Carla / My Documents 6Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

APPLICATION SET-UP DATA SHEET

Customer: ________________________________________

Date: ______________________________

Machine Type / Serial No: ___________________________

Prepared By: ________________________

Cap Size / Type: __________________________________

Bottle / Size / Type: __________________

A

Floating shoe block height

S

Conveyor speed (FPM)

B

Front floating shoe height (Locked)

□

T

Fixed hold down

C

Chute height

Y

Finger number

D

Gripper belt height (drop)

V

Floating Shoe number

E

Gripper belts in - out

W

Cap Alignment Cylinder

F

Spindle discs in - out *

X

Fiber Optic Trigger Level

G

Clutched discs in - out *

Y

Fiber Optic ON Delay

H

Chute in - out

Z

Fiber Optic OFF Delay

I

Fingers in - out

AA

2nd Floating Shoe height

J

Floating shoe in - out

BB

Flipper number

K

Spindle height - 1st set

QUICK CHANGE PACKAGE ONLY

L

Spring set collar height

Gripper belts in - out

M

Cap guides

Spindle discs in - out *

N

Bottle separation

Clutched discs in - out *

O

Spindle speed dial setting

Chute in - out

P

Gripper belt speed dial setting **

Capper Height Gauge

Q

Cap Belt / Bowl speed dial setting

Chute Bracket Scale

R

Elevator / Hopper speed dial setting

* The purpose of these measurements is to give you a starting point when setting up the machine. As your discs wear, these

measurements will change.

In most cases, the first set of discs should touch the cap just enough to start it onto the bottle. Any clutched sets should hit the cap just

hard enough to "kick out" the clutches.

** This is the speed dial setting that was used during in plant testing. The gripper belt speed should match your conveyor speed.

*** Please note that all measurements given are in inches (unless otherwise specified).

Carla / My Documents 7Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

CAPPER HEIGHT

Adjusting the height of the capper is important in order to achieve proper cap placement and cap

torque. The first dimension on the Application Set-Up Data Sheet is:

A. FLOATING SHOE BLOCK HEIGHT

Measure from the bottom of the aluminum block to the top of the conveyor belt. The

Floating Shoe Block Height is simply a reference point in which to define the capper’s height

over the bottle transport conveyor. The distance between the floating shoe block and the

conveyor is easily measured and in actuality is just a reference point in determining where

the spindle discs are in relationship to a cap installed on a bottle that is placed on the

conveyor. The floating shoe block height could technically be called the spindle disc height

because this is what you are actually setting. The spindle discs move up and down with the

entire capping head and are not adjustable in height from the conveyor except by moving the

entire capper head as a unit. The first set of spindle discs are the exception which is defined

later in the chapter. The floating shoe, the chute and the gripper belts are able to move

independently up and down, away or closer, to the capper head so it is imperative to set the

floating shoe block height first. In determining the proper relationship of the spindle discs to

a bottle cap (or floating shoe block height) one must examine the type of cap processed.

Different caps behave in different ways. For example, is it a flat cap or a deep skirted cap?

Is there a butterfly hinge protruding from the cap’s sidewall? These are the type of points

that have to be taken into consideration when determining the optimum location where the

spindle disc may properly contact a particular cap.

Before comparing the spindle disc contact patch to the bottle cap, it is recommended to fill

the bottle with product because with some types of containers the height of the cap could

slightly be different.

The cap should be seated and slightly torqued to the bottle. The last set of discs or 3rd set on

a SK6000, 4th set on an SK8000, should be referenced from when adjusting the floating shoe

block height.

1. To adjust the floating shoe block height.

2. Remove the crank handle from its storage magnet located on the discharge side of the

capper's C frame. Engage the loop end of the crank handle to the loop end of the jack

shaft.

3. Rotate the crank handle counterclockwise to increase the floating shoe block height

(or raise the capper). Rotating the jack handle clockwise will decrease the floating

shoe block height (or lower the capper).

GENERAL GUIDE LINES

1. Set the disc contact in relationship to the cap as high up on a cap as possible.

Typically, continuous threaded caps are stronger and more rigid towards the top than

the lower skirt side of the cap. Setting the disc to cap contact patch towards the lower

skirt end will tend to oval the cap, increasing the friction between the cap and bottle

threads resulting in lost cap torque.

2. Use as much of the spindle disc as practical. More contact between cap and disc

equals more friction which means more torque.

3. Avoid contacting areas on caps like “thumbnail catches”, “turret spouts”, “and sport

cap hoods”.

Carla / My Documents 8Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

4. Setting the disc height is only part of the picture in getting properly torqued cap on a

bottle. See also sections entitled “Spindle Disc Clutches”, “Spindle Disc Height, 1st

set”, “Spindle Disc In/Out”.

SUGGESTED CONTACT PATCHES FOR MOST CAPS

Typical 400 Style Flat Caps, Typical CRC In most cases, a flat cap is about the

same thickness as a spindle disc so

setting the disc evenly with the cap is the

best way. Some caps have a slight ring

at the cap’s skirt that will scuff easily. In

this case, it may be better to set the disc’s

bottom corner slightly above the cap’s

skirt.

Typical 410 Style Caps The 410 cap has a longer skirt or deeper

sidewall than a 400 series cap. In most

cases, a 410 style cap will be thicker than

a tightening disc thickness. It is

recommended to try and keep the disc’s

contact patch towards the top of this cap.

The cap is stronger towards its top than it

is towards its skirt.

Carla / My Documents 9Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

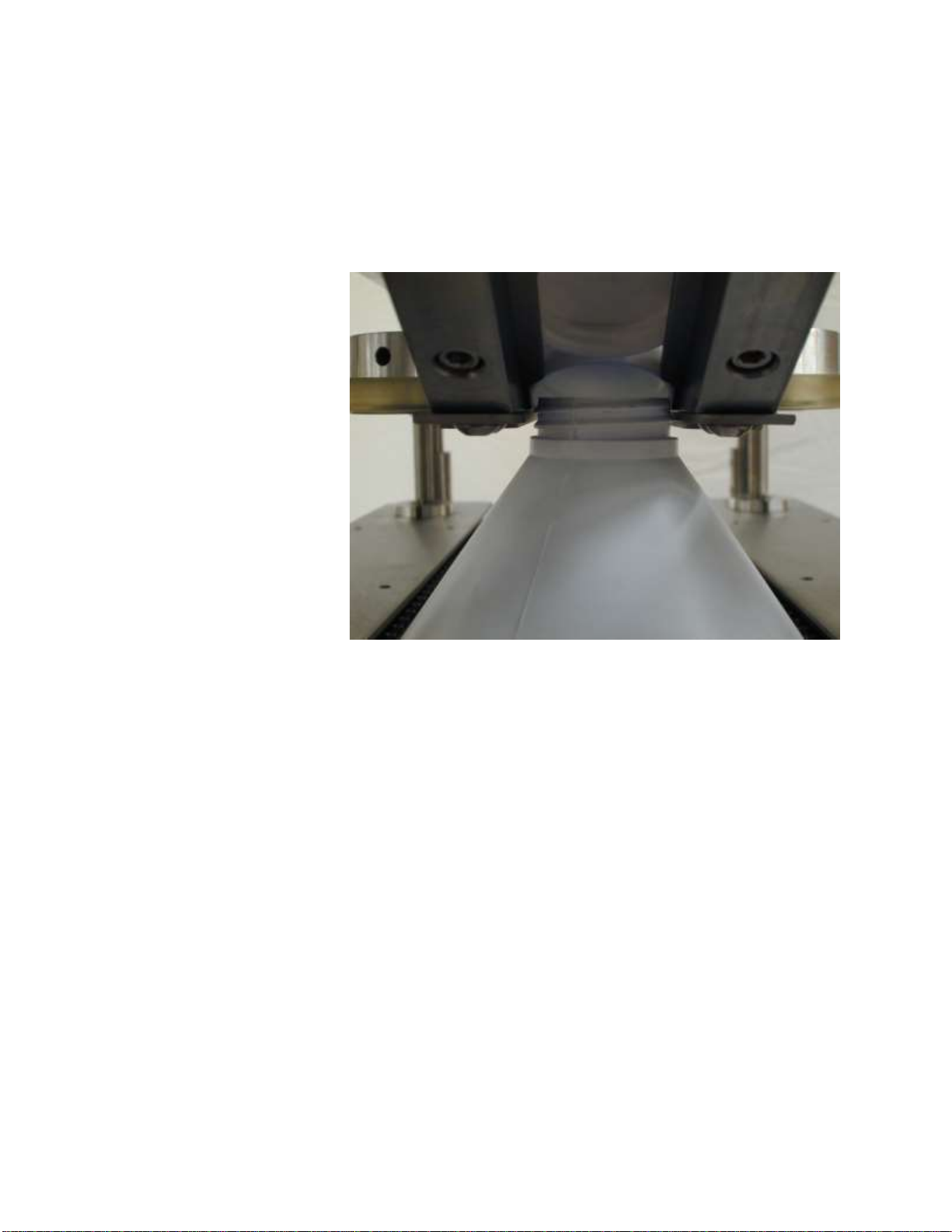

CONVEYOR

A

B

C

B. FLOATING SHOE Measure from the bottom of the front shoe to

the top of the conveyor belt. The purpose of

the floating shoe is to keep a light but constant

pressure on the cap until the first set of

spindles can start the cap and container

threads. The floating shoe is adjustable in

height by adjusting the set collar on the shaft

of the front shoe. It is also spring loaded and

spring tension can be increased or decreased

by raising or lowering the set collar

underneath the spring. You can also move the

floating shoe block (the block that holds the

floating shoe shafts) by loosening the socket

head cap screw at the bottom of the mount shaft.

STEP 1: Place a cap on top of the container

threads. Do not screw the cap down onto the

container. Place the container and cap on the

conveyor underneath the rear floating shoe,

turn the cap backwards on its threads until it

snaps down. Your cap will now be at its

lowest point. Adjust the set collar on the front

shoe shaft until there is about 1/16" to 1/8"

gap between the front and rear horseshoe

blocks on the floating shoe shaft. This will

give a light amount of pressure on the cap.

Carla / My Documents 10 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

Setting the shoe too high will allow the cap to fall off before it gets to the spindles or will

allow the first set of spindles to spin the cap off of the container. Setting the shoe too high

can also result in a cross-threaded cap. Setting the shoe too low will allow the shoe to knock

the cap off of the container upon impact.

C. CHUTE HEIGHT

Measure from the bottom

edge of the chute exit

block (or the top of the

cap guide if installed) to

the top of the conveyor

belt. In order for the

container to consistently

pull the cap out of the

chute (straight chute or

C-chute type), the chute

must be adjusted to the

proper height. Too high

or too low, or off-center,

will result in missed

and/or cross threaded

caps. To adjust the

height of the chute, first

open the gripper belts so

that a container can be passed underneath the chute by hand on top of the conveyor. There

are (2) bolts, (1) on each side of the slotted bracket that supports the chute. Loosen these

bolts. You can now raise or lower the chute by turning the knob on the chute bracket. The

neck, or threaded section of the container, should be able to pass through the notched section

of the chute rails at the bottom of the chute. Adjust the chute so that there is approximately

1/16" of clearance between the container and the chute.

Carla / My Documents 11 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

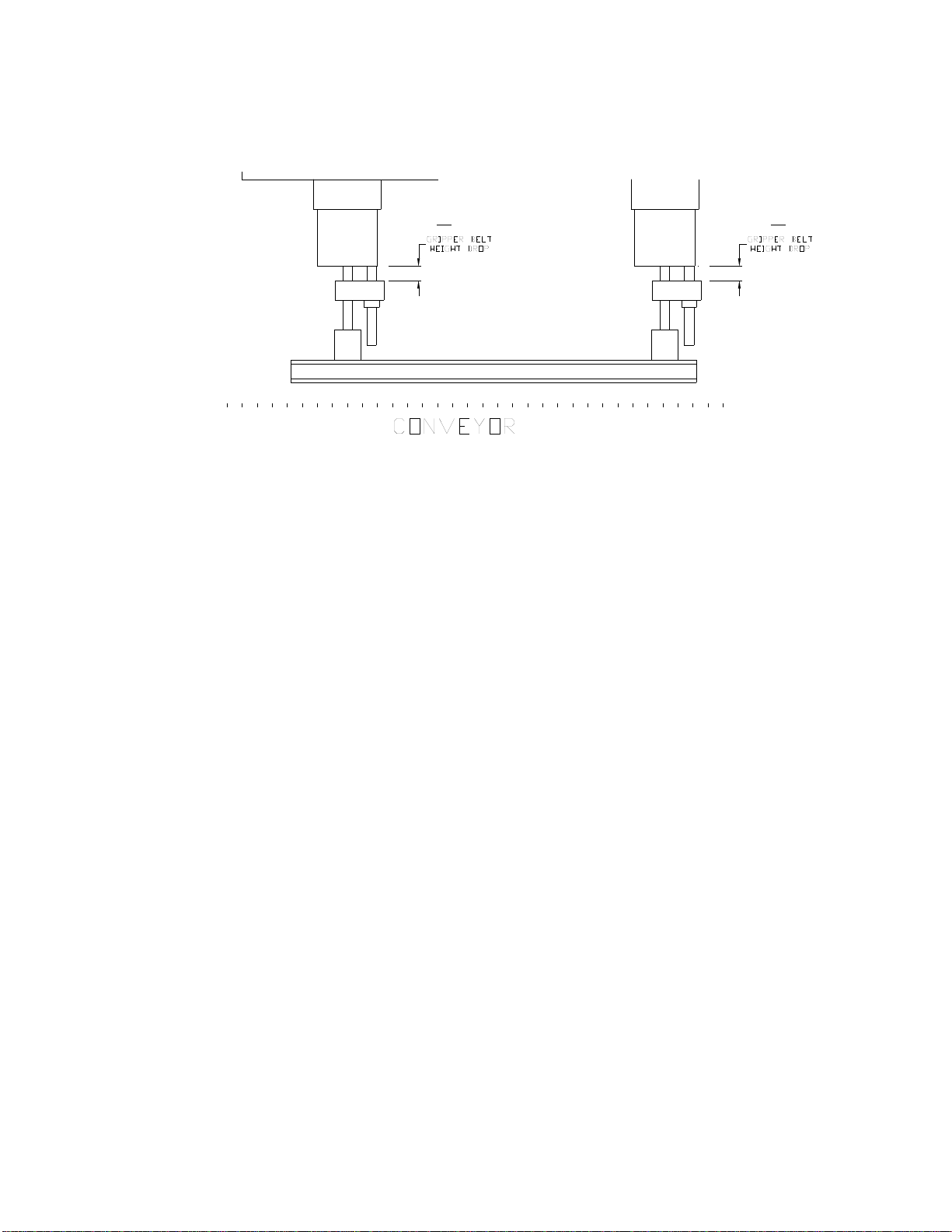

D D

D. GRIPPER BELT HEIGHT (Drop)

Measure from the top of the aluminum knuckle (cross block) to the bottom of the aluminum

slide block. The purpose of the gripper belts is to grab and stabilize the containers securely

while traveling through the capper. The belts should grab the container at the highest

position possible below the container threads for optimum container stability. If you are not

able to grab the container up high close to the threads (due to the shape/contour of the

container), than select the section of the container that is the most rigid, provides stability and

is as high as possible. When the gripper belts are near the center of the container, the

container may become unstable because this is close to the pivot point of the container.

Moving the gripper belts up or down is necessary, at times, due the various shapes and sizes

of containers.

Step 1: To raise or lower your belts, loosen the set collar and knuckle socket head cap

screws on both ends of one assembly. Slide the assembly up or down to the desired height.

Retighten the socket head cap screws on the knuckles and retighten the shaft set collar.

Step 2: Do the same for the other assembly. IMPORTANT: DO NOT loosen the tamper

proof torx fasteners. Also DO NOT allow the top end of the gripper belt drive SHAFT

to slide out of the tolomatic slide rite. There should be a snap ring on the top end of the

shaft to prevent this. Before lowering, inspect to make sure the snap rings are in place.

The front and rear gripper belt assemblies should be equal in distance from the measuring

points. Do not have one assembly lower than the other. The front and rear gripper belt

assemblies must be set to the same height.

Carla / My Documents 12 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

E

E. GRIPPER BELTS IN/OUT

Measure the distance between the top plates of the gripper belt assemblies on the infeed end

only. The gripper belts move in and out on center (to accommodate different container

diameters) with a crank handle on the front (or rear) of the machine. There is also a lock

knob that keeps the handle from being moved once it is set. Do not turn the crank handle if it

is locked. This can cause the flexible shaft coupling to rupture.

Step 1: Place your container on the conveyor.

Step 2: Adjust the (3) sets of spindles out enough so that your container can pass through

unrestricted.

Step 3: Open your gripper belt assemblies by turning the crank hndle clockwise. Slide your

container into the center of the assemblies. Now tighten the assemblies until they have a

firm, but not crushing, grip on the container.

Step 4: Turn the belts and conveyor on and run the container through a couple of times to

verify proper grip. You should not be collapsing the side of the container and the container

should not be slipping in the belts. Check the gripper belt tightness later on when you have

the spindles set at the proper torque levels, to check for container slippage. IMPORTANT:

The conveyor must run at a speed equal to the gripper belt speed. Check to make sure

the container stays in the same position on the conveyor while the gripper belts are in

contact with the container.

Carla / My Documents 13 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

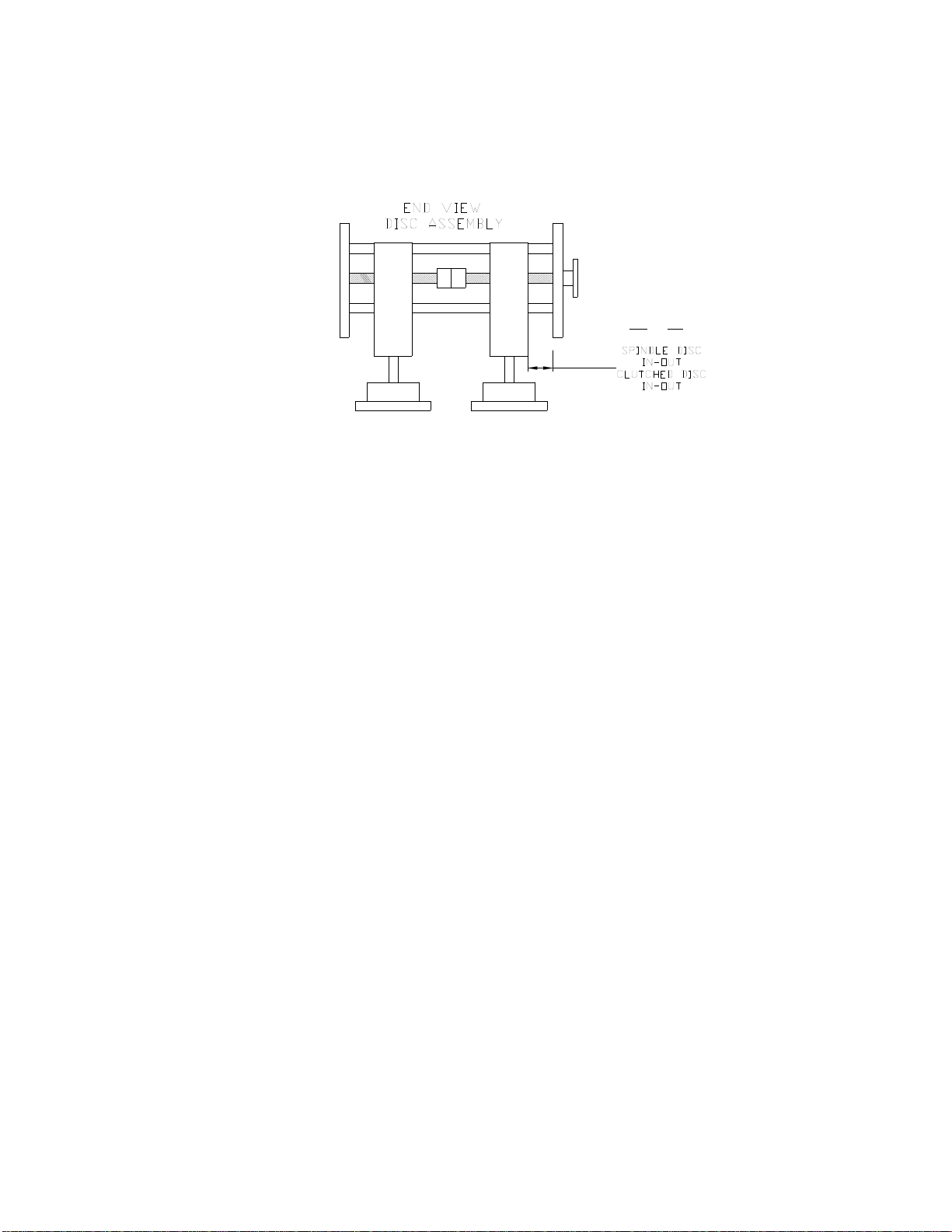

F & G

F. SPINDLE DISC IN/OUT (1st Set)

Measure the distance between the inside of the cage face plate and the cage block on the

operator’s side. The purpose of the 1st spindle set is to start the cap onto the container

threads. The spindle moves in and out, on center, by turning the appropriate knob. The

tightening discs only need to lightly touch the sides of the cap. If there is too much pressure,

you may not be able to start the cap on the threads. The spindle speed will need to be

adjusted so that the tightening disc spins the cap down completely until the cap is fully

seated.

Step 1: Adjust the 1st set of spindles (by turning the spindle knob) until the 1st set of

tightening discs lightly touch the sides of the cap.

Step 2: Turn on the conveyor and gripper belts. Turn on the spindles.

Step 3: Place your container on the conveyor and run it through the capper. The 1st set of

spindles should screw the cap down on the container (not tighten the cap). Adjust

accordingly, if needed. Secure the spindle knob with the lock knob.

G. CLUTCHED DISC IN/OUT

Measure the distance between the inside of the cage face plate and the cage block on the

operator’s side. Clutches have been installed on the 2nd and 3rd set of spindles. When

adjusted properly, the clutches will stop the spindle and tightening disc from spinning after

applying the desired amount of torque to the cap. Increased cap torque can be achieved by

adjusting the mechanical clutches (with the machine turned off) by turning the knurled ring

(with your fingers) clockwise to increase torque; counter-clockwise to decrease torque. A

small adjustment makes a big difference in performance. When turning the knurled ring, you

can feel it “click”. Count the “clicks” so you can set each side equally. CAUTION: Do not

attempt to adjust the clutch with the machine and/or spindles on.

Carla / My Documents 14 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

Step 1: Place the container on the conveyor and run it through the capper.

Step 2: Adjust the clutched spindles until the tightening disc touch the sides of the cap. The

2nd set should tighten the cap. The 3rd set should apply the final amount of torque to assure

the cap is tight. The 2nd set should appear to do most of the work.

Step 3: Adjust accordingly, if needed. Secure spindle knob with the lock knob.

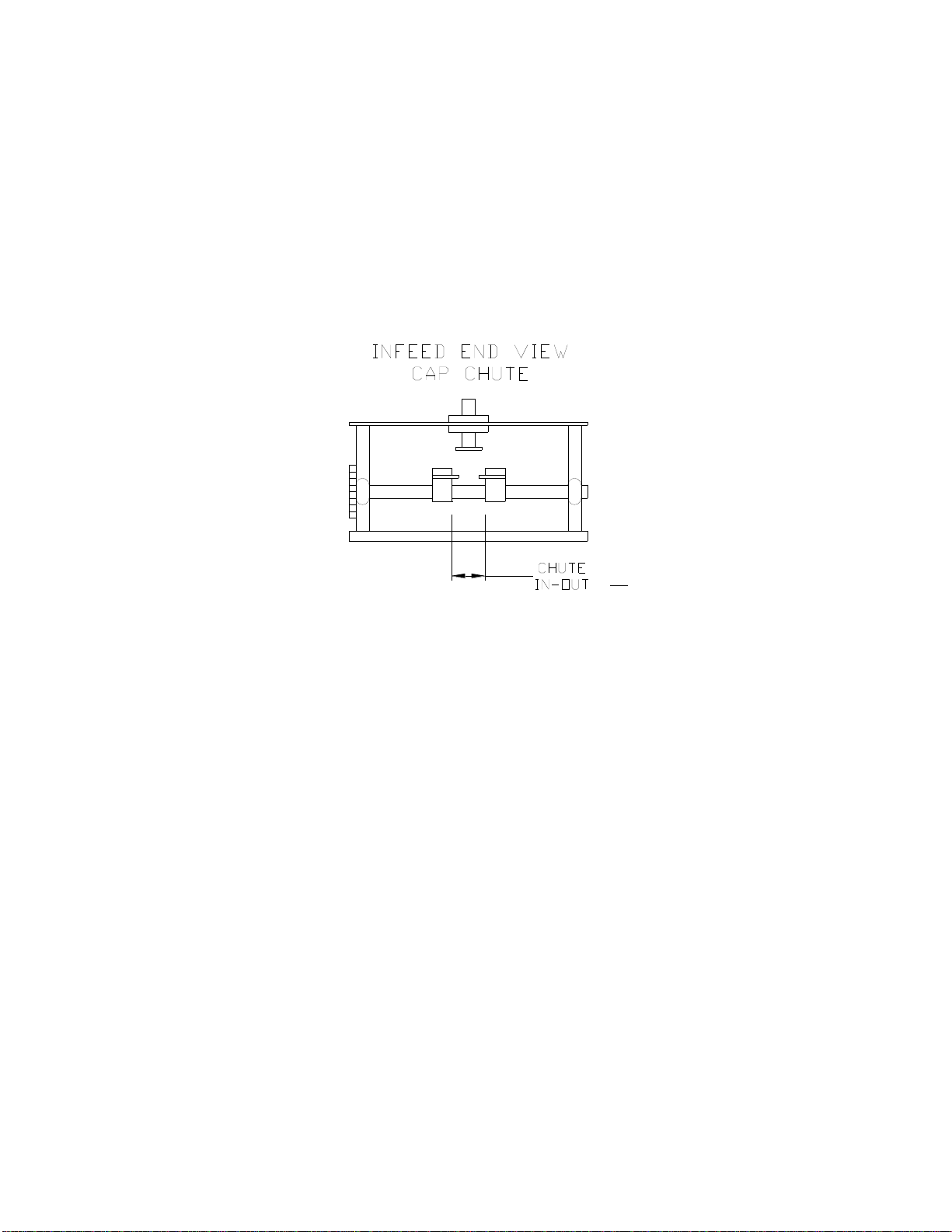

H

H. CHUTE IN/OUT

Measure between the inside edges of the 3/4" x 3/4" stainless steel cross blocks on the entry

end of the chute. SUREKAP manufactures two types of chutes: a straight chute and a “C”

chute. The purpose of both is to feed caps from your bowl to your container. The side rails

that confine the cap move in and out from center for different diameters of caps with a single

turn knob. The top confinement is adjustable up and down for different height caps.

Step 1: Adjust the chute for your cap diameter by turning the knob to open or close the side

rails, allowing the caps to slide from the entering end of the chute to the exit end unrestricted

all the way down to the chute fingers. There should be enough space to keep the caps from

jamming in the chute; approximately 1/32" to 1/16" on each side of the cap normally works

well.

Step 2: The top confinement rail should be adjusted up or down so there is approximately

1/16" clearance from the top of the cap to the rail. A cap should now slide freely from the

bowl discharge to the chute guide fingers. If not, make the necessary adjustments to free the

binding cap.

Carla / My Documents 15 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

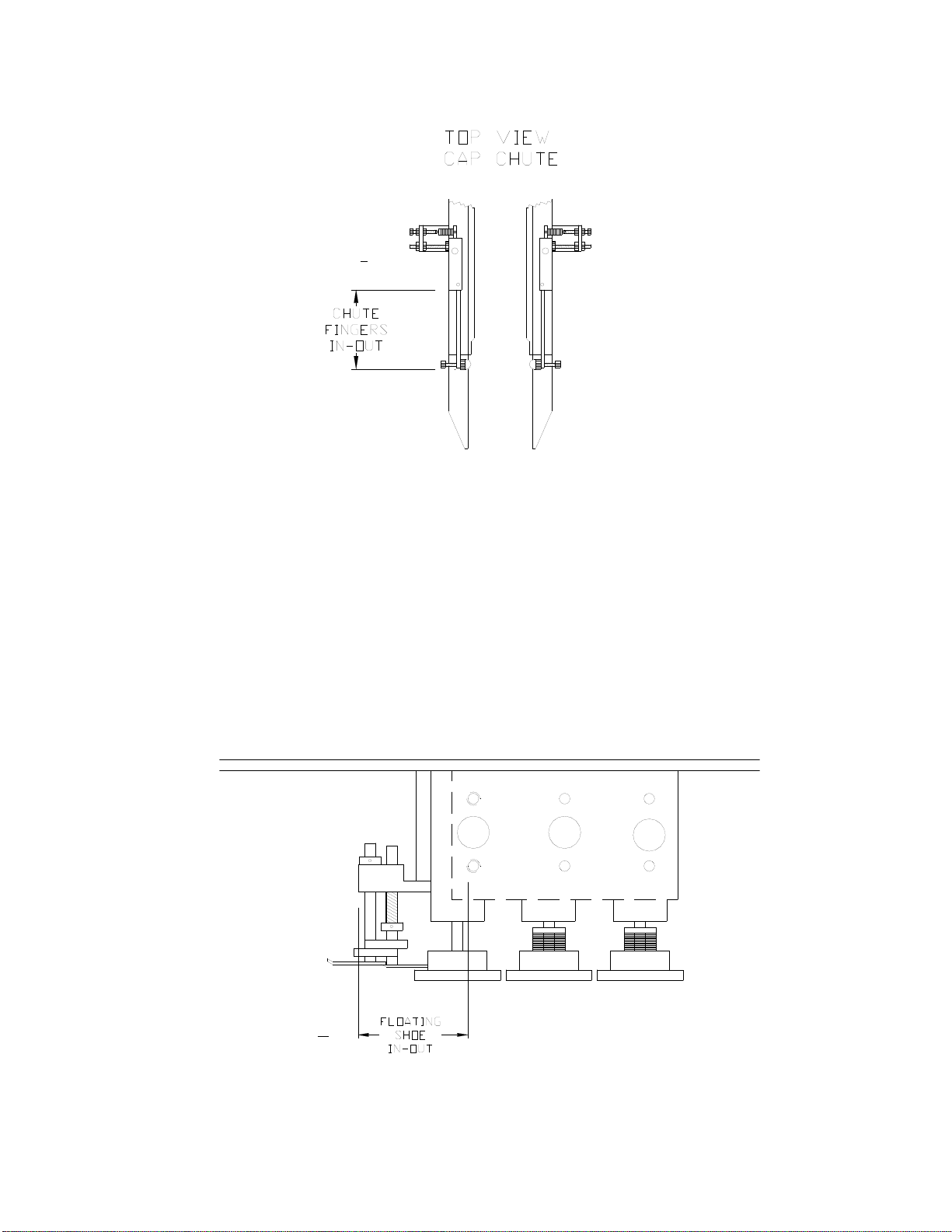

I

I. FINGERS IN/OUT

Distance that the rod fingers extend from the mounting block. Measure from the end of the

chute finger blocks to the end of the chute fingers (1/4" dia. stainless steel rod). The chute

fingers are located on the lower end (discharge) of the chute. The fingers are designed to

hold the caps in the chute. They are spring loaded so that the container can pull the cap out

of the chute when it passes and then springs back into place to continue holding the caps.

The nylon nut on the end of the fingers is sized to work with a wide range of cap diameters

and styles, therefore it is adjustable. At times, certain caps may require that the nylon nut is

not used because it wraps too far around a cap and preventing the cap from being pulled out

correctly (usually causes taller caps to tilt). The chute finger wrap is then changed by

rotating the finger 180º to the modified finger wrap. If non-standard chute finger wrap is

required, it will be indicated on the set-up sheet.

J

J. FLOATING SHOE IN/OUT

Carla / My Documents 16 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

Measure the distance from the front of the aluminum block to the leading edge of the 1st

horizontal cage shaft (3/4" stainless steel shaft). Different cap heights and diameters require

that the floating shoe be adjusted horizontally over the top of the cap as it exits the chute, so

that is lays down over the container threads correctly. The floating shoe is mounted in a

block that can be moved either closer to the cap and chute flipper, or further away. The

floating shoe height always affects this adjustment.

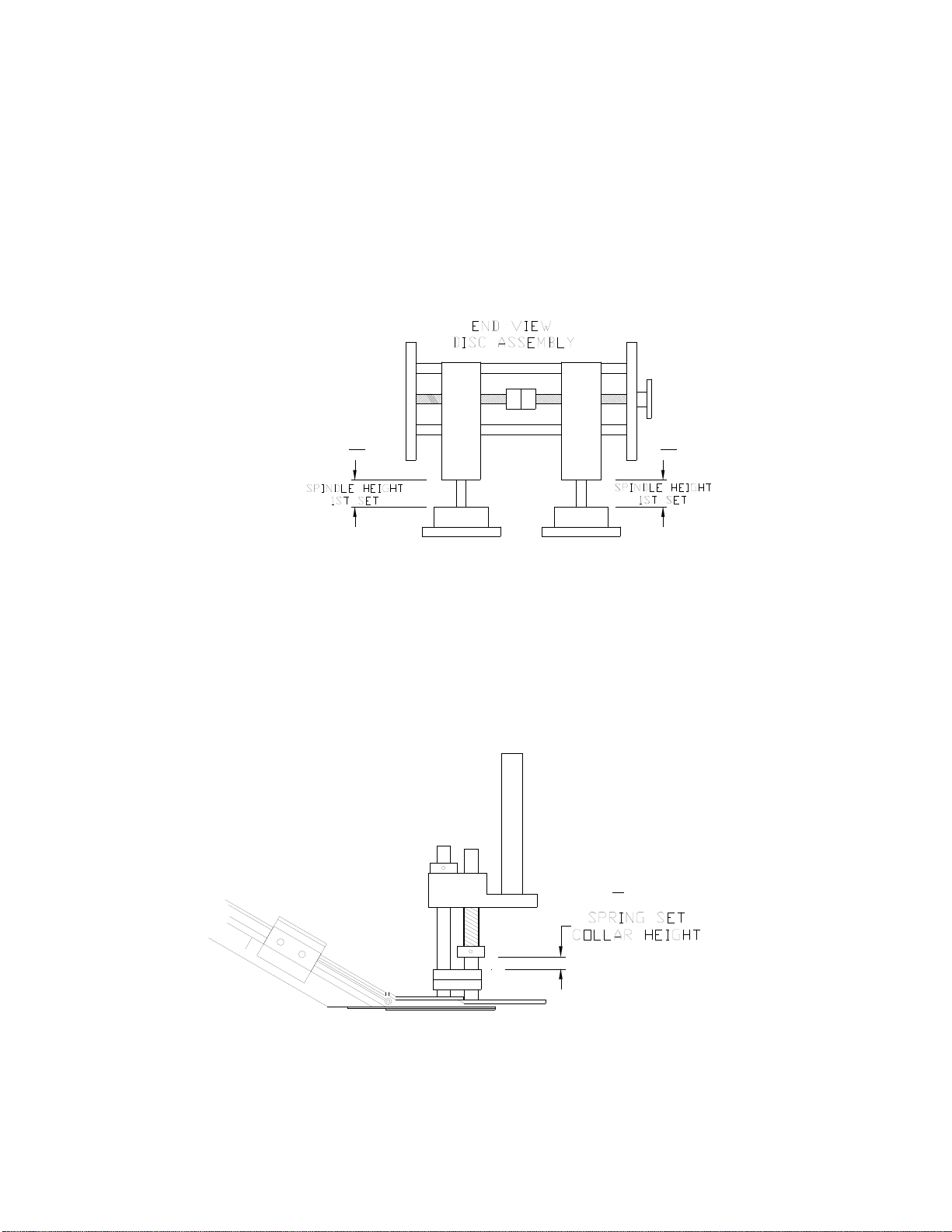

K K

K. SPINDLE HEIGHT

Measure the distance from the top of the disc hub to the bottom of the cage block. 1st Set:

The 1st set of spindle discs are used to spin and start the caps on the container threads.

Because the cap is at its highest position before starting on the threads, the tightening disc

must make contact with the cap properly at this point. Too low and they may squeeze the

bottom of the cap and not allow it to go on. Too high and it may not spin the cap on

completely.

L

Carla / My Documents 17 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

L. SPRING SET COLLAR HEIGHT

Measure from the top of the tie bar to the bottom of the shaft collar. This set collar is used to

adjust spring pressure for the floating shoes. It is located on the rear floating shoe shaft, just

above the horseshoe guide.

M

M. CAP GUIDES

Cap Guides are attached to the bottom of the chute and are used to guide caps in their

forward motion, so that they will seat properly on the container threads without cross-

threading. They are normally used on Flat caps (400’s), CRC’s or metal caps. If your cap

and container combination has been tested by SUREKAP, we will indicate whether or not

they are used. If you have a style of cap that may require them, please contact SUREKAP

for the correct application. Cap Guide Installation is covered in another section of this

manual.

N. CONTAINER SEPARATION

During testing, it is determined if containers can run touching, or if they require separation in

order to properly pull caps out of the chute, and for proper floating shoe movement. The

minimum distance between containers is indicated.

P. SPINDLE SPEED DIAL SETTING

Spindle speed can vary with cap diameter and cap torque requirements. Normally, the speed

is set so that the 1st set of discs (non-clutched) spins the cap completely onto the threads of

the container.

Q. GRIPPER BELT SPEED DIAL SETTING

The gripper belts are set to match the speed of the conveyor. Too fast, and containers will

lean or tilt forward and the base of the container will slide forward on the conveyor faster

than it is moving. Too slow, and the container will lean or tilt backward and the base of the

container will slide backward on the conveyor slower than the conveyor is moving.

Carla / My Documents 18 Rev. Date: 24 August 2018

“SK6000-BF6 Capper Manual-word document (master)”

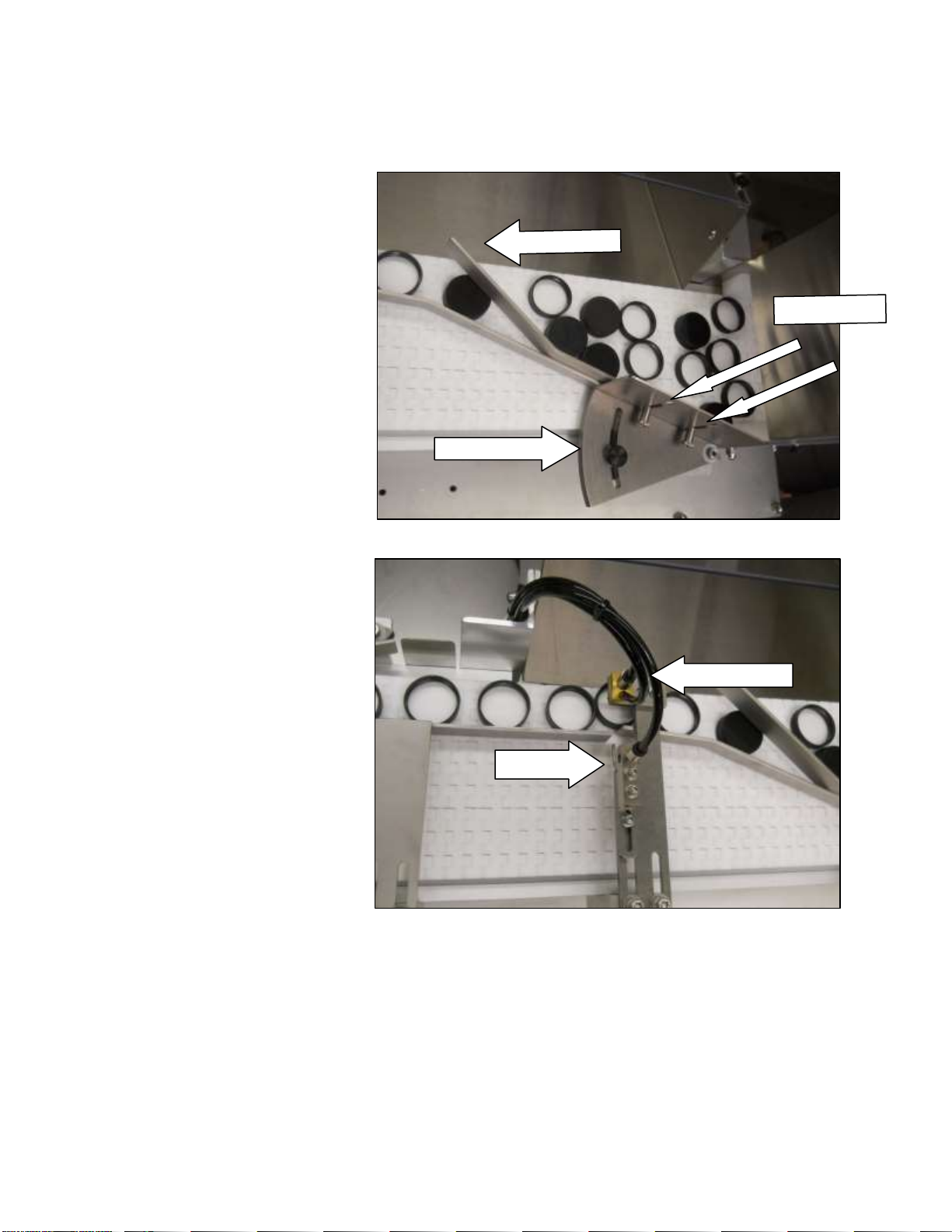

INSTRUCTIONS FOR BF6 CAP FEEDER:

1. Wiper Height: Set height

of the wiper blade (using

the thumbscrews) so that it

wipes off the layer of

double stacked caps into

the return chute.

2. 1st Deflector: Set the

deflector so that the single

layer of caps forms a single

line. The outside edge of

the cap should run as close

to the edge of the conveyor

as possible, without

bumping into the edge of

the return chute with the

belt running.

3. Sensor Tooling: Consists

of the following parts:

Cap Sensor and Cap Reject

Air Jet. Also consists of

the following adjustments:

Sensor Tooling Location,

Cap Sensor Height, Cap

Sensor Centering, Cap

Sensor Advance/Retard

and Cap Reject Air Jet

Positioning.

4. Sensor Tooling Location:

Generally the tooling will

be positioned so that the

sensor will be centered

between the edge of the 1st

deflector and the edge of

the return chute.

5. Cap Sensor Height: Adjust the tooling up or down so that caps will pass underneath the

sensor, without being obstructed. Sensor Height will also affect how sensitive the sensor

becomes. Best results are obtained by setting it close to the cap. The further it is from the

cap decreases the sensitivity. (see also Cap Sensor Regulator PSI)

Air Jet

1st Deflector

Wiper Blade

BladBlade

Thumbscrews

¡

Air Gap

Sen•h•è

Table of contents