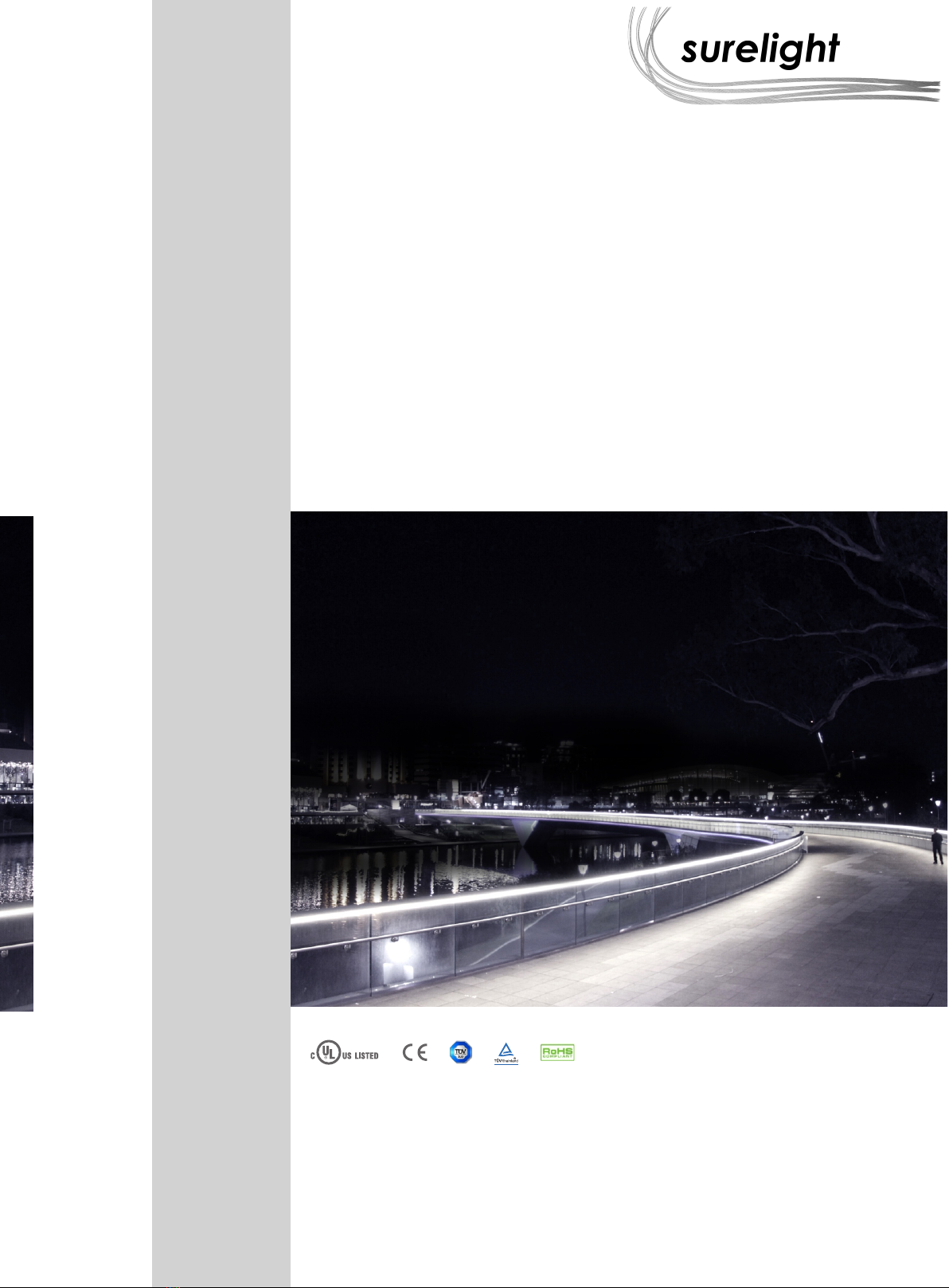

Surelight NE-MI User manual

ARTIST OF LIGHT

LED NEON FLEX RIBBON

NE-MI

USER MANUAL

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE

INSTALLATION. LEAVE A COPY FOR THE END USER/MAINTENANCE

ENGINEER FOR FUTURE REFERENCE.

Version No. : V2.0

Table

Of

Contents

02

USER MANUAL www.surelight.com

Unpacking

Basic Parameters

Cautions

Instructions for Cutting Light

Clasp Front Connector

Clasp End Cap

Snap Front Connector

Snap End Cap

Swivel Front Connector

Swivel End Cap

Diagram of Light Wiring

Mounting Profile Options

Troubleshooting

Limited Warranty

Appendix

03

06

07

08

09

13

16

20

24

27

28

30

40

41

42

1 2

3

5 6

78

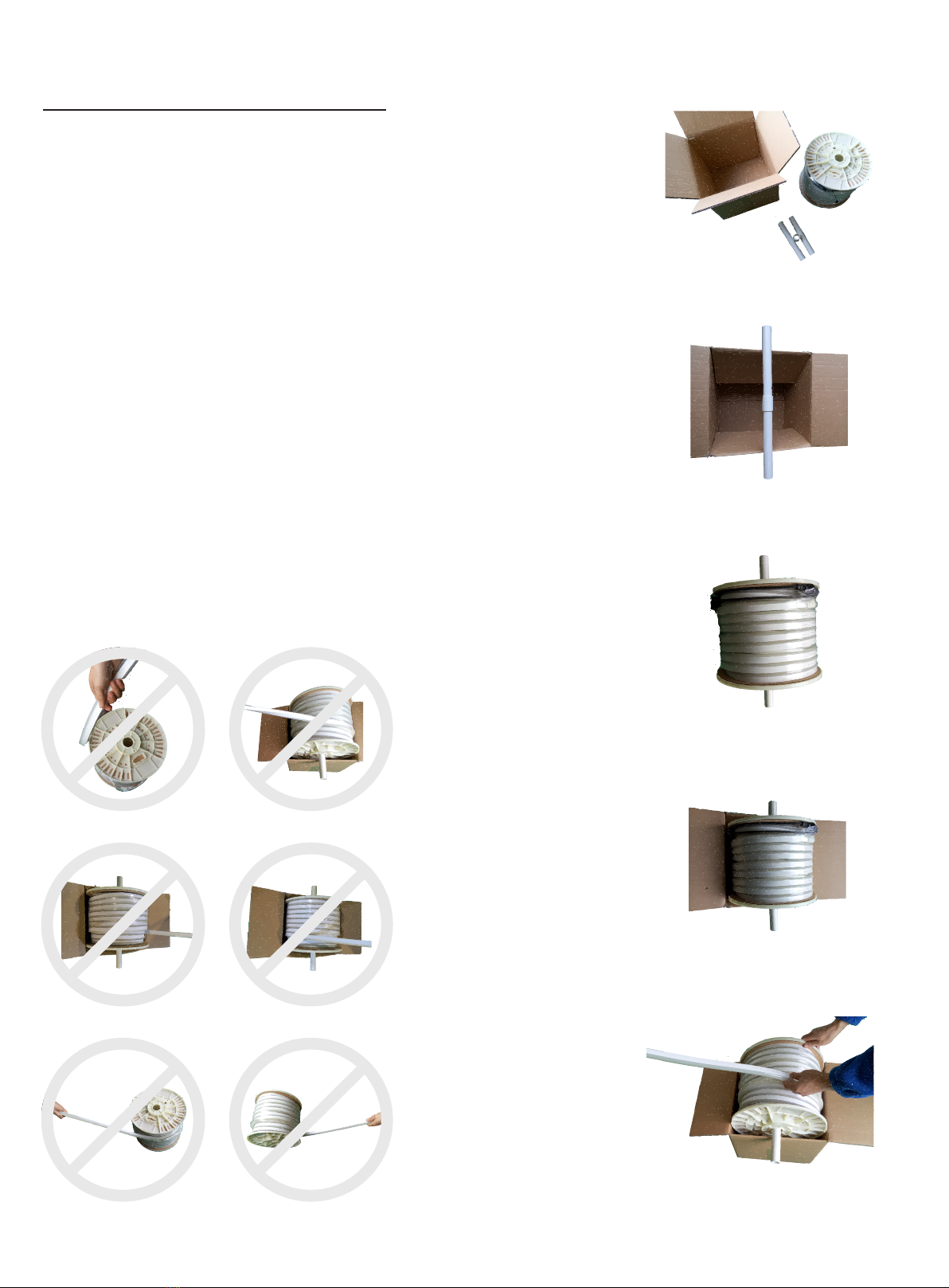

Unpacking

03

White Box Packaging

USER MANUAL www.surelight.com

Note: Two people are needed to uncoil the light.

Unpacking

04

Reel Packaging

1

2

3

4

5

USER MANUAL www.surelight.com

Unpacking

05

Uncoiling Roller

Uncoiling Roller (Optional Device)

USER MANUAL www.surelight.com

Roll up the rest of the light

Protect the light end and fix it

Use recommended cutter to cut

the light vertically

Rotate the roller edge to uncoil the

light with another hand

Put the light on the middle of

uncoiling roller

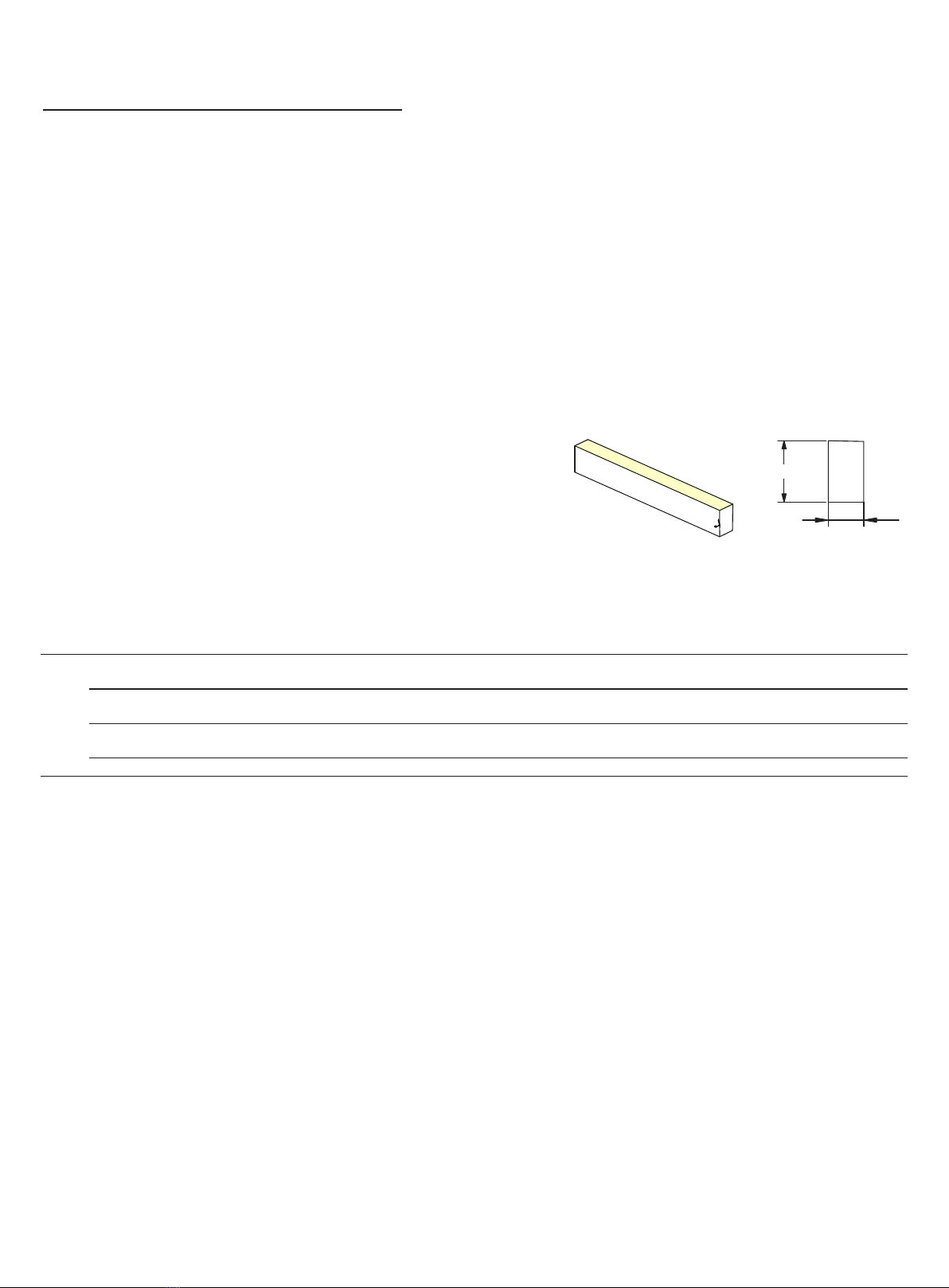

Basic

Parameters

06

1. Dimension: 9*18mm

2. Min. bend diameter: 90mm

3. Protection rate: IP68/IP67/IP65/IP20

4. IP68 protection rate: Protected against dust and submersion in water (1 meter above).

5.The product IP rate is ultimately in line with properly applied IP rated connectors.

Connector termination required after cutting to achieve appropriate IP Rating.

6. Easy to use, with a range of accessories for joining, terminating, mounting&powering.

7. Long Iifetime: 5 years.

8. Working ambient temperature: -20°C~45°C (High Voltage: -20°C~35°C ) .

9. Environmental Installation Tempeature: 0°C~45°C (High Voltage: -0°C~35°C ).

USER MANUAL www.surelight.com

01

9mm

18mm

Max.Running Length

20m for single end feed

40m for double ends feed

15m for single end feed

30m for double ends feed

7.5m for single end feed

15m for double ends feed

80m for single end feed

Min.Cutting Length

125mm(9LEDs)

83.3mm(6LEDs)

41.7mm(3LEDs)

1000mm(72LEDs)

LED Spacing

13.89mm

13.89mm

13.89mm

13.89mm

Rated Power/m

3.5W

4.5W

4.5W

5W

Working Voltage

D24CV

D24CV

D12CV

Ac230

LED Qty/mtr

72LEDs

72LEDs

72LEDs

72LEDs

Appearance of Cover*

WM

WM

WM

WM

Light Color

R/A

G/B/W

R/A/G/B/W

R/A/G/B/W

B

Light Type: NE-MI

Note: Unless otherwise stated, the tolerance of the light is ±0.3mm.

*

NOTE: Appearance of Cover

1 2

WM=White PVC Housing +Milky Light-emitting Surface

Note 1: Housing color is the light color except from the light-emitting surface.

Note 2: Light-emitting surface color is the color without light up.

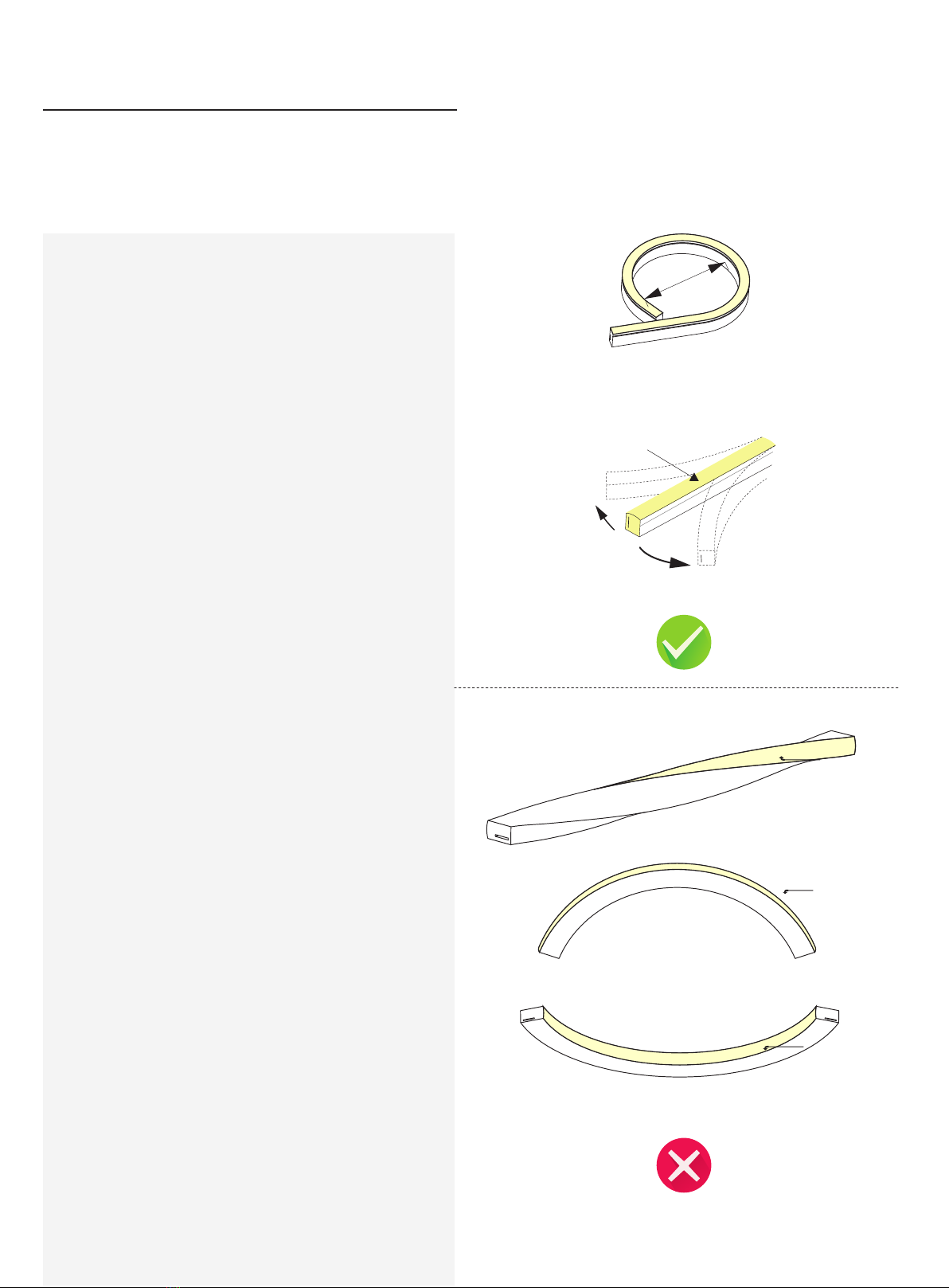

Twist the light

Light Surface

WARNING: The above wrong approaches will damage the light.

Light Surface

Light Surface

Do not bend smaller than allowed minimum bend diameter 90mm.

Cautions

07

USER MANUAL www.surelight.com

1. Before making any cuts, installation, maintenance or

connection, be sure the mains is disconnected!

2. Note: All connectors should be properly installed to achieve

the appropriate level of IP, IP rating can NOT be achieved

without connector termination.

3. Please operate this flex light by instructions, and confirm the

work voltage, it must be matched with product requirements.

4. Please confirm the polarity of connector before insertion front

connection cable.

5. Connect and cut this product correctly. Any wrong operation

will damage this product.

6. Using qualified DC power supply.

7. Please correctly use and bend this flex ribbon light, see the

figures on the right.

8.Do not operate light when ambient temperature exceeds the

range of specified temperature in User Manual.

9.Do not energize the light over 30 minutes in coil packaging.

90 mm

01 |0 2

(HB)Horizontal Bending

Light Surface

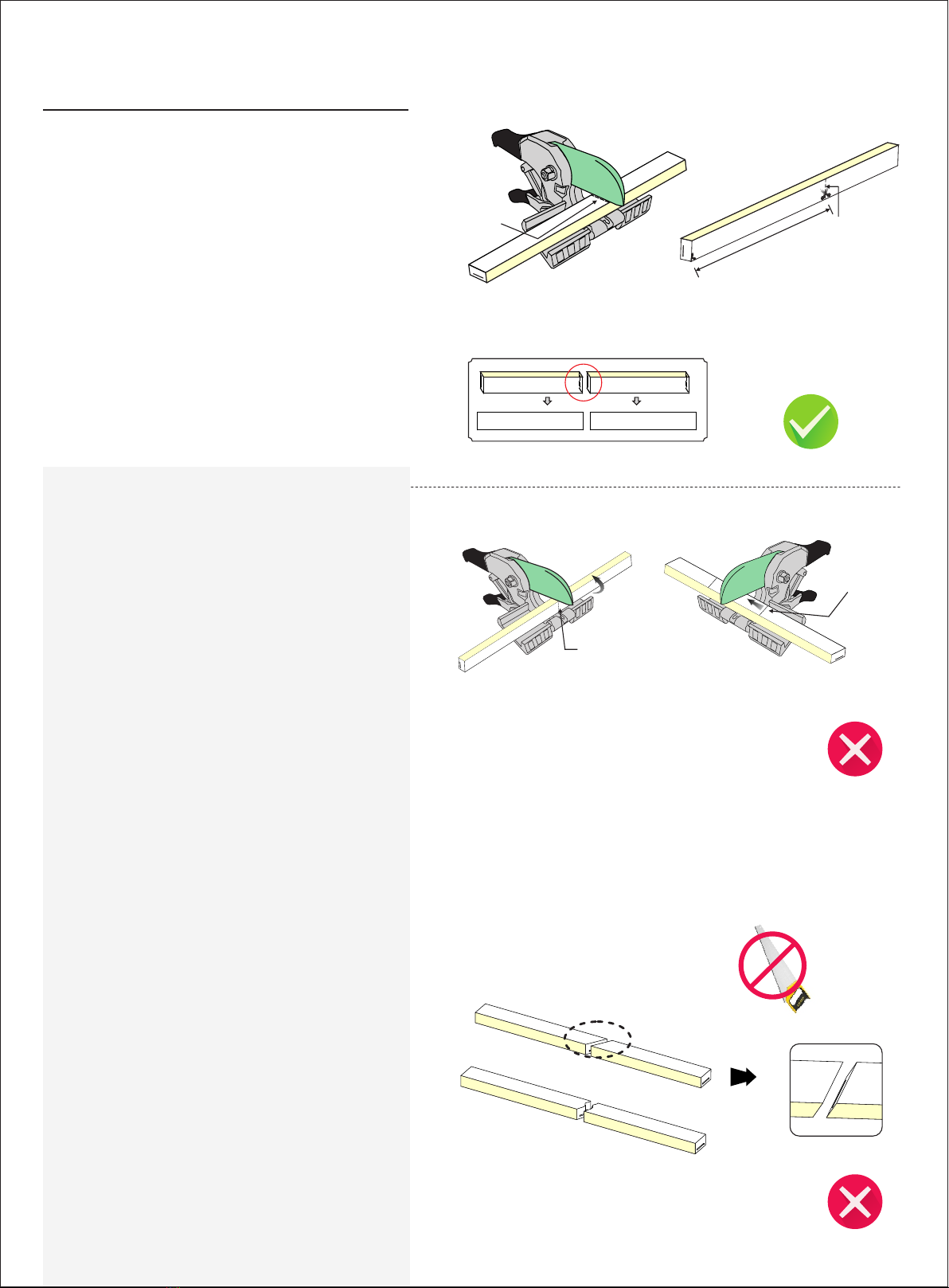

Instructions

for

light

cutting

08

The Min. cutting length

(see as the feature)

Cutting line

Don't cut slantingly

Note:

1. Place the light horizontally when cutting it.

2.Use only factory-recommended cutter.

3.Cut the light according to the following instructions.

Incorrect operation will damage the light

USER MANUAL www.surelight.com

Cutting line

02

01 02

02

Cut the light only at printed cutting line with

printing mark face upwards

The cutting surface must be flush

and smooth.

Printing mark should be faced

upwards

Cutting can only be made at the

printed cutting line

01 0 2

01 0 2

Cutting line

01

Cutting Line

Printing Mark

Please use a smooth and sharp cutter for cutting when the dedicated cutter is not

available, any rusty or jagged cutter is prohibited.

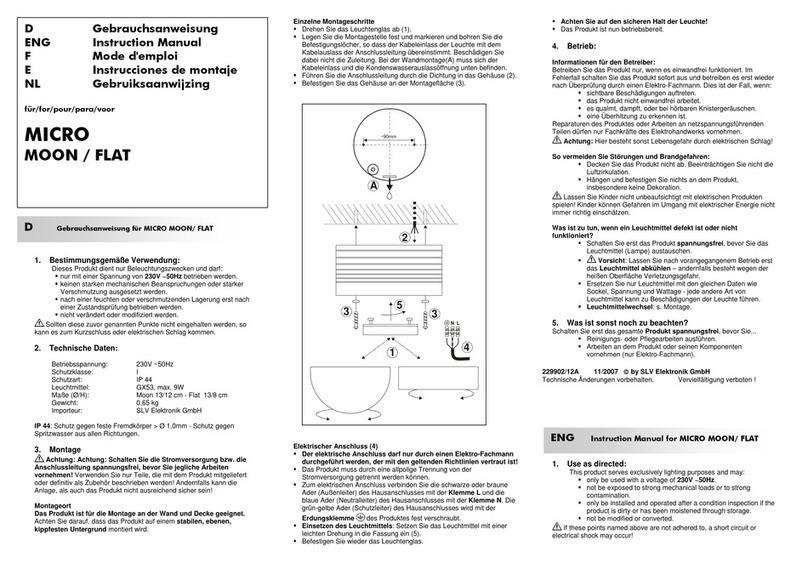

Note: Waterproof may not achieved with the following situations.

09

USER MANUAL www.surelight.com

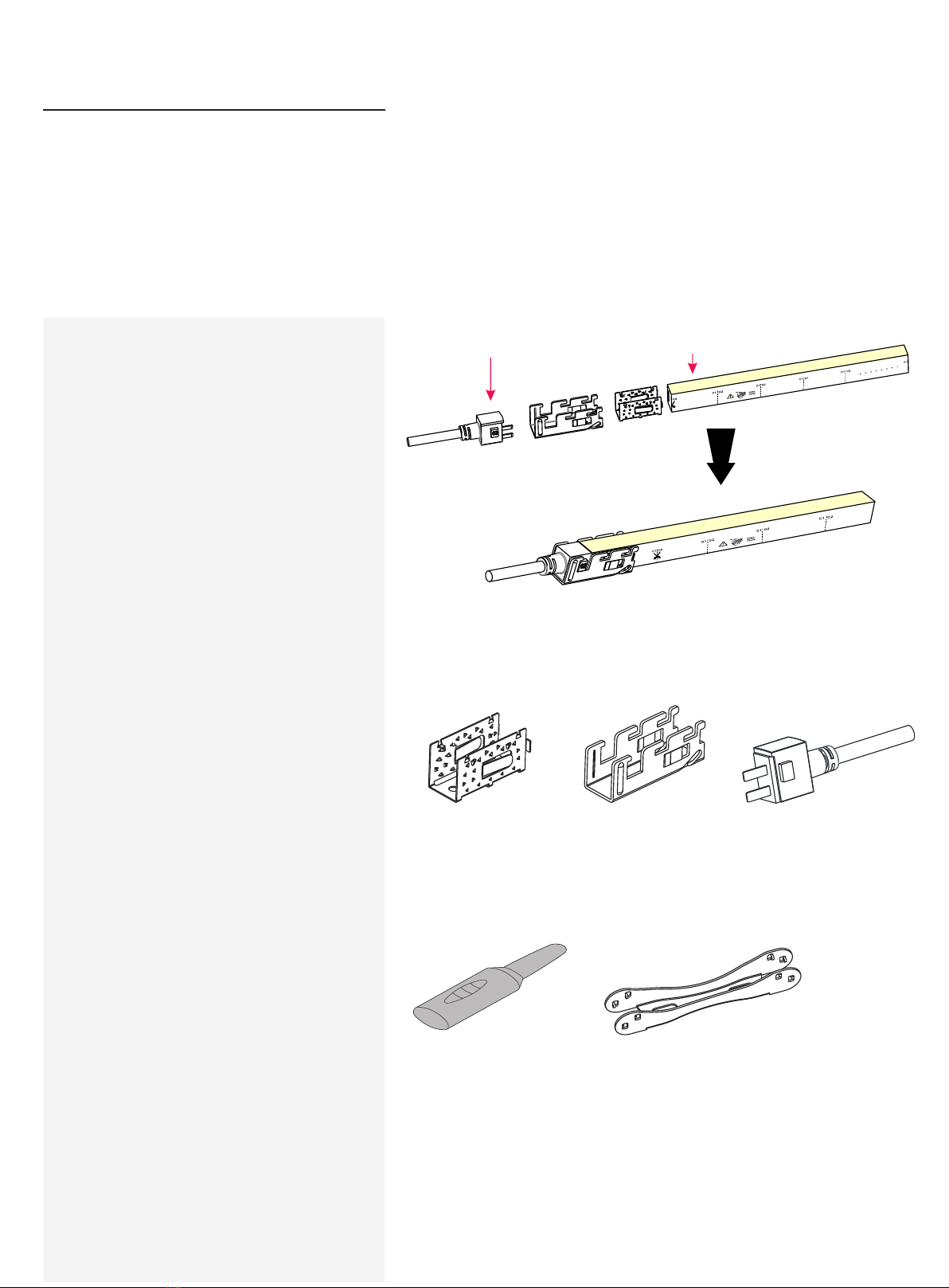

Clasp Front

Connector

Please ignore these steps if the front

connector has been assembled before

delivery.

Finished Assembly View

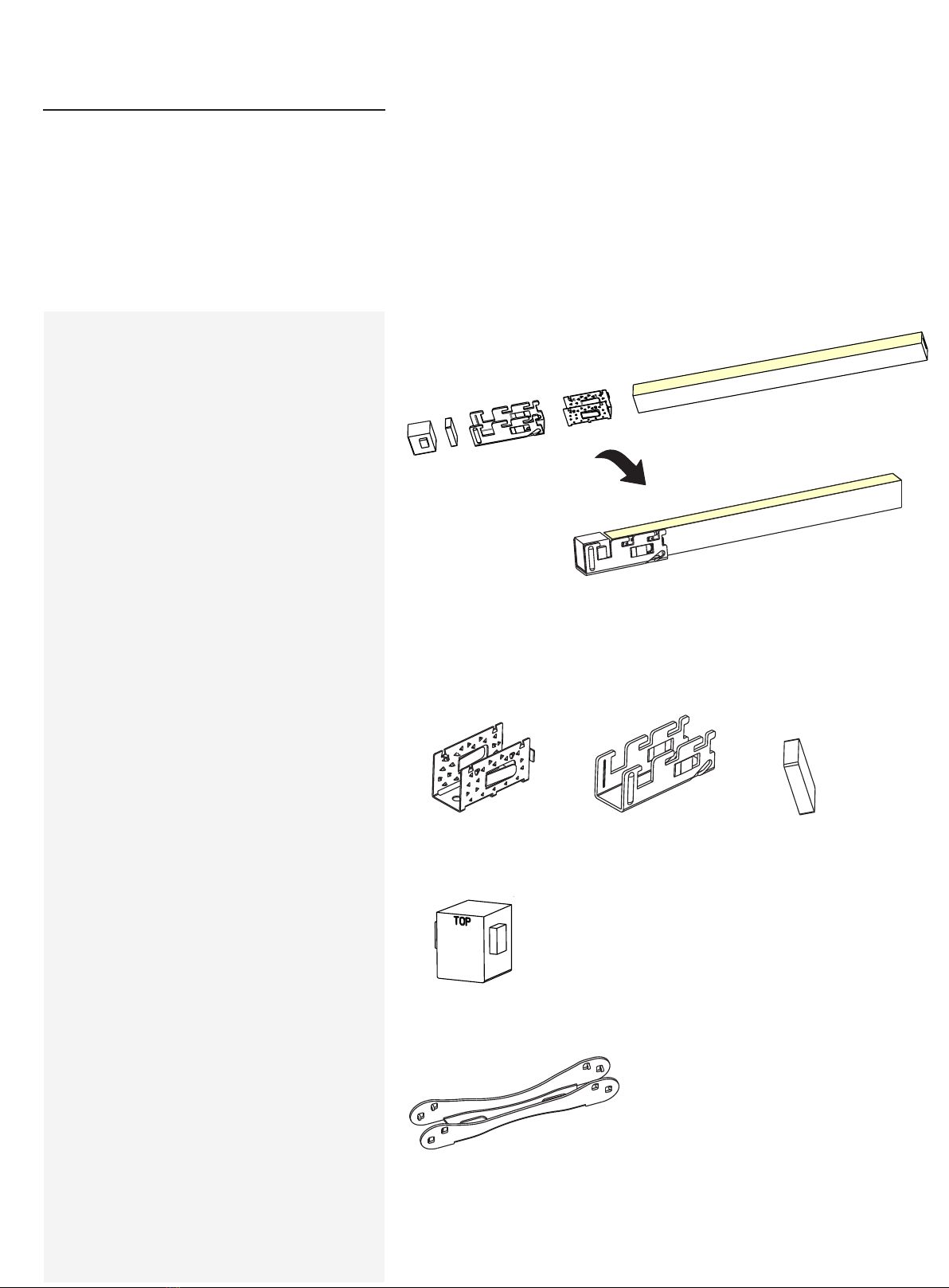

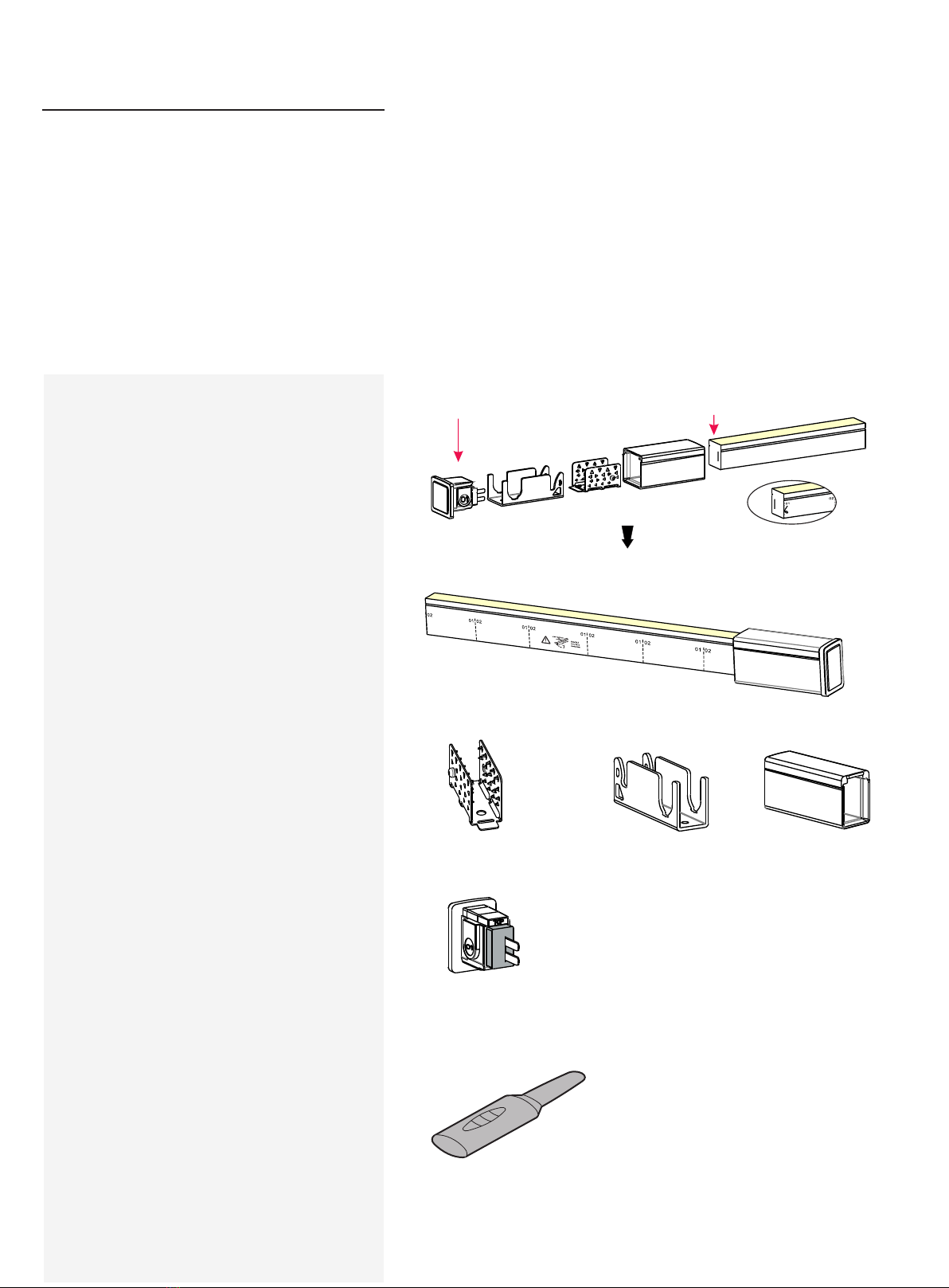

1.Components of Front

Connector

2.Tools

Feed Connector (1pc)

[Contain Silicone Gasket(1pc)]

Anti-skidding Clip (1pc) U Steel Plate (1pc)

Inducer Gripper

Explosive View

02

Note:

1. Never wet the assembly units or assemble with

wet hands.

2. Please use the tools correctly.

3. Please pay attention to personal security when

using tools.

4.Repeated assembly or reuse of the connector may

result in waterproof failure.

Note:

The light ends are marked with either an 01 or an 02. Always

make sure to use an identically labeled connector for the

appropriate direction.

02 Feed Connector 02 End of light

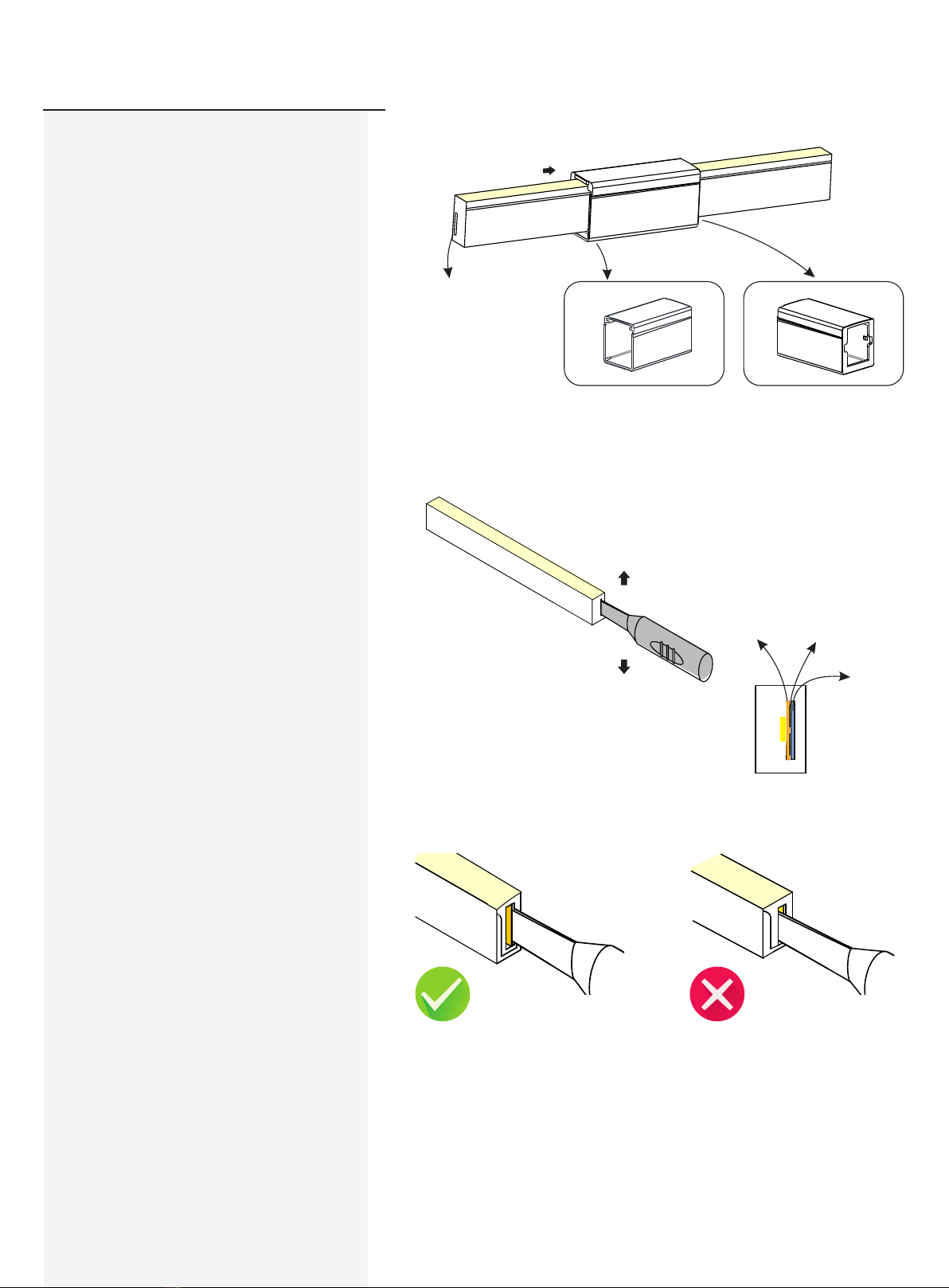

PCB Insertion Placement

PVC Tape

10

USER MANUAL www.surelight.com

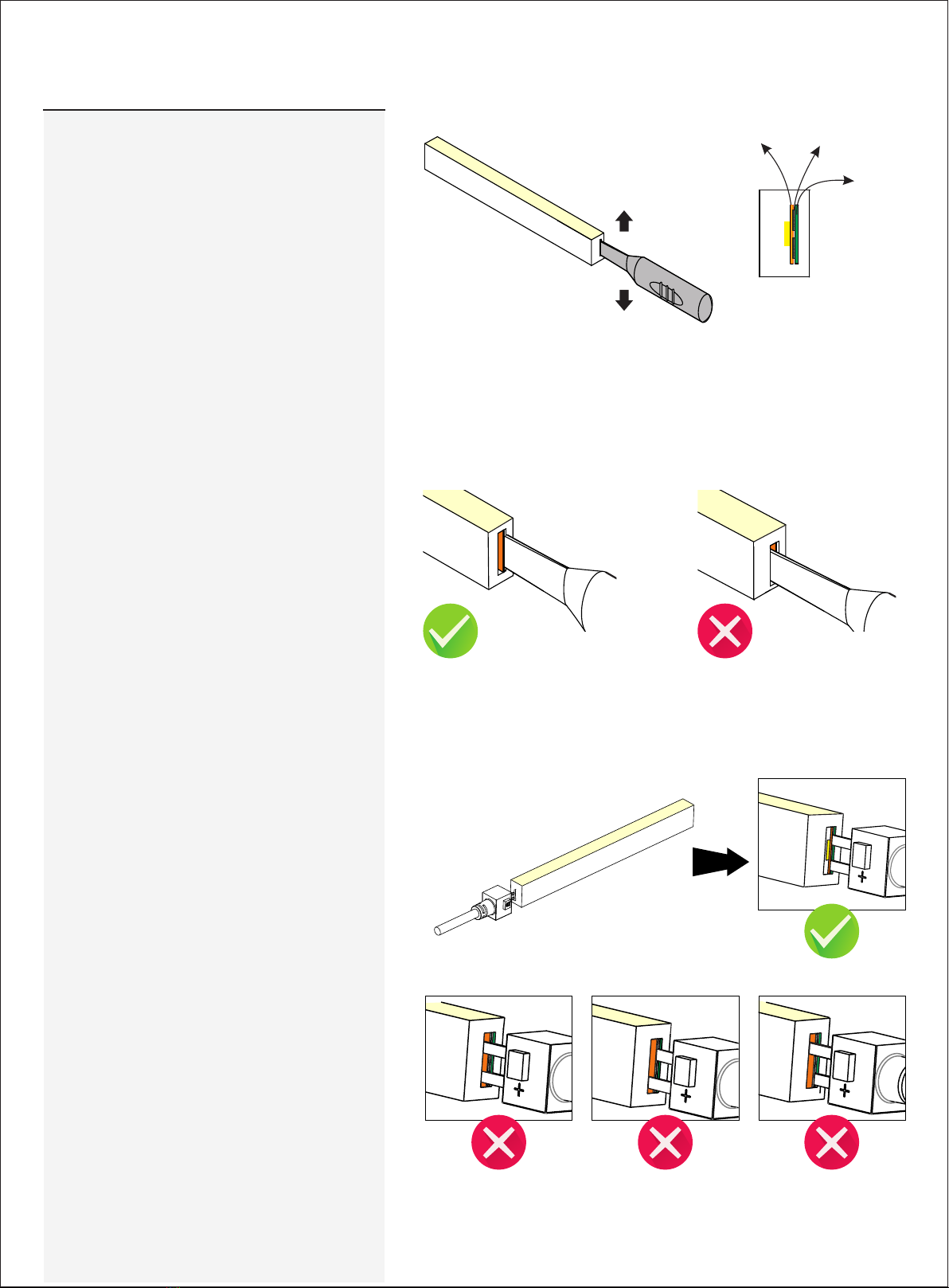

3.Installation Steps

3.1 Inducing a Cavity for Feed Connector

Insert the inducer to the backside of PCB around 10~12mm,

move the inducer up and down 3~5 times gently to create a

small cavity.

3.2 Insert the Feed Connector

Insert the inducer into the backside of PCB It will damage the light if insert into front

side of PCB

Insert the feed connector pins into the

cavity that you created with the

inducer (backside of PCB)

The following operations are prohibited:

Insert into the front side of the PCB

Insert crosswise into the PCB Insert crosswise into the PCB

NEVER insert into the front side

(LED side) of the PCB

11

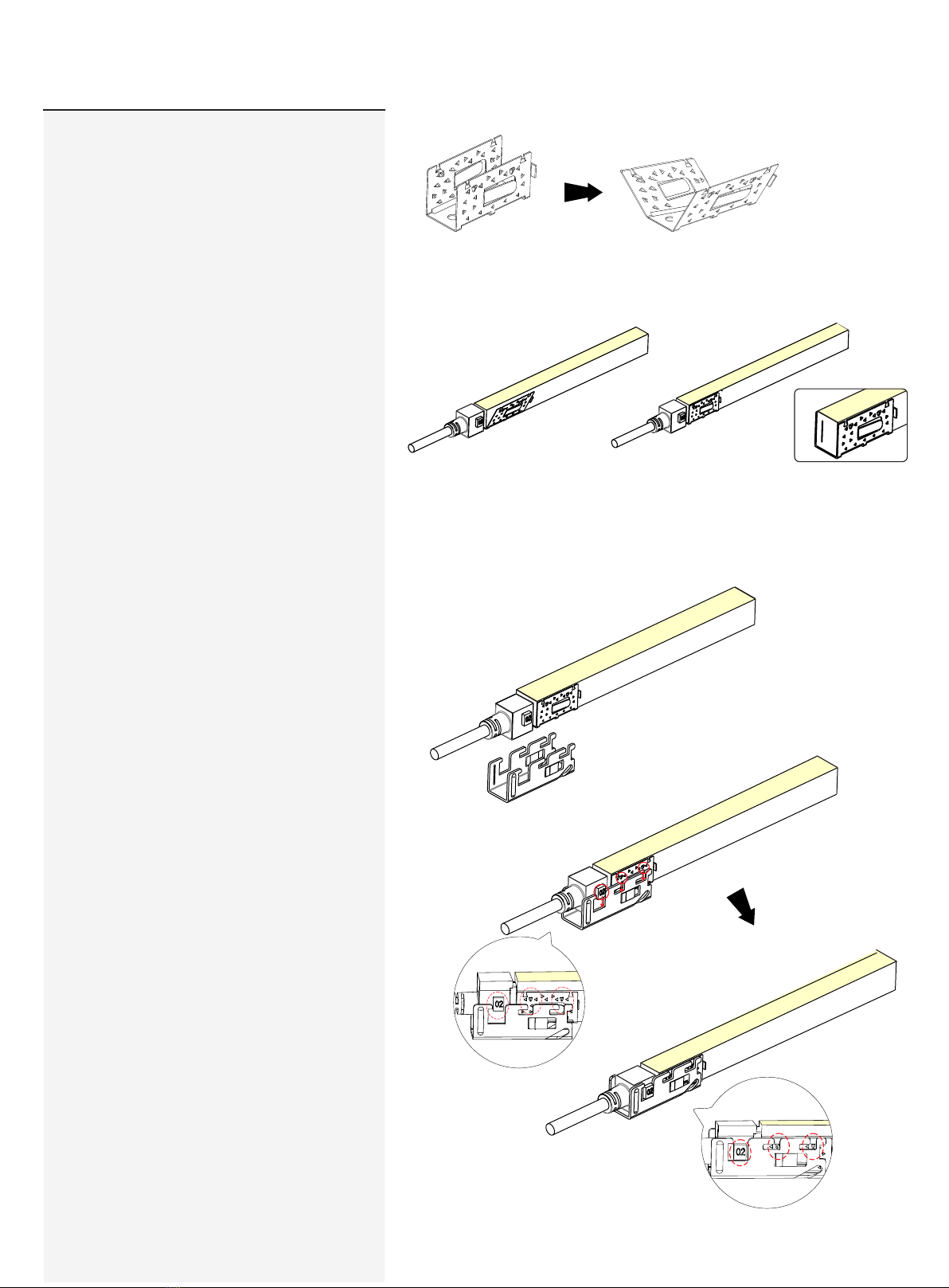

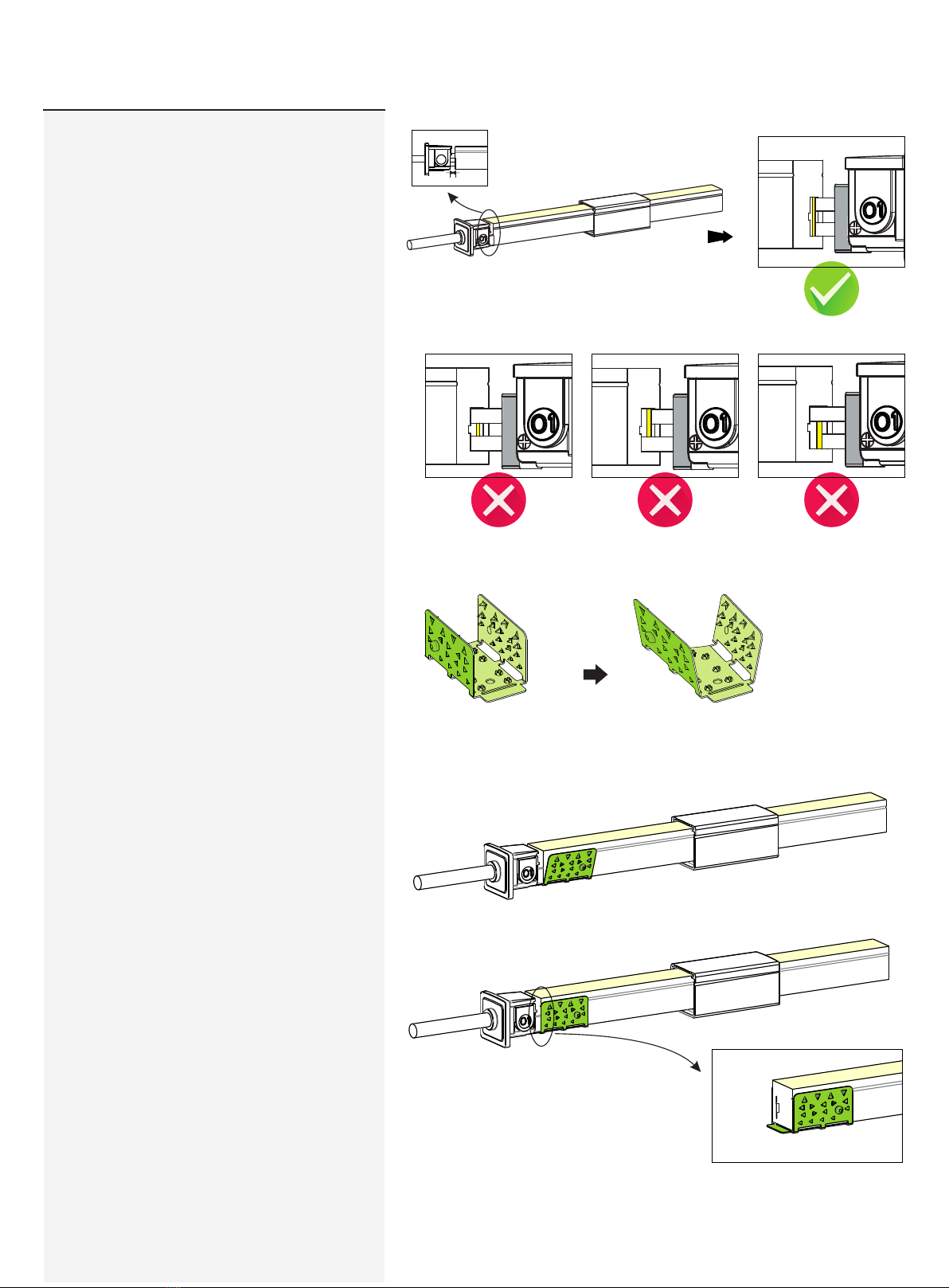

3.3 Treatment of Anti-skidding Clip

Unfold the anti-skidding clip about 20 degrees on both sides.

Fit the anti-skidding clip to the end of the light

tightly and align with the light end edge.

Place the anti-skidding clip

onto the end of the light. Notice

its installation direction.

3.4 Installation fo U Steel Plate

USER MANUAL www.surelight.com

Push the bulging points on the anti-skidding

clip into th slots on the U steel plate.

12

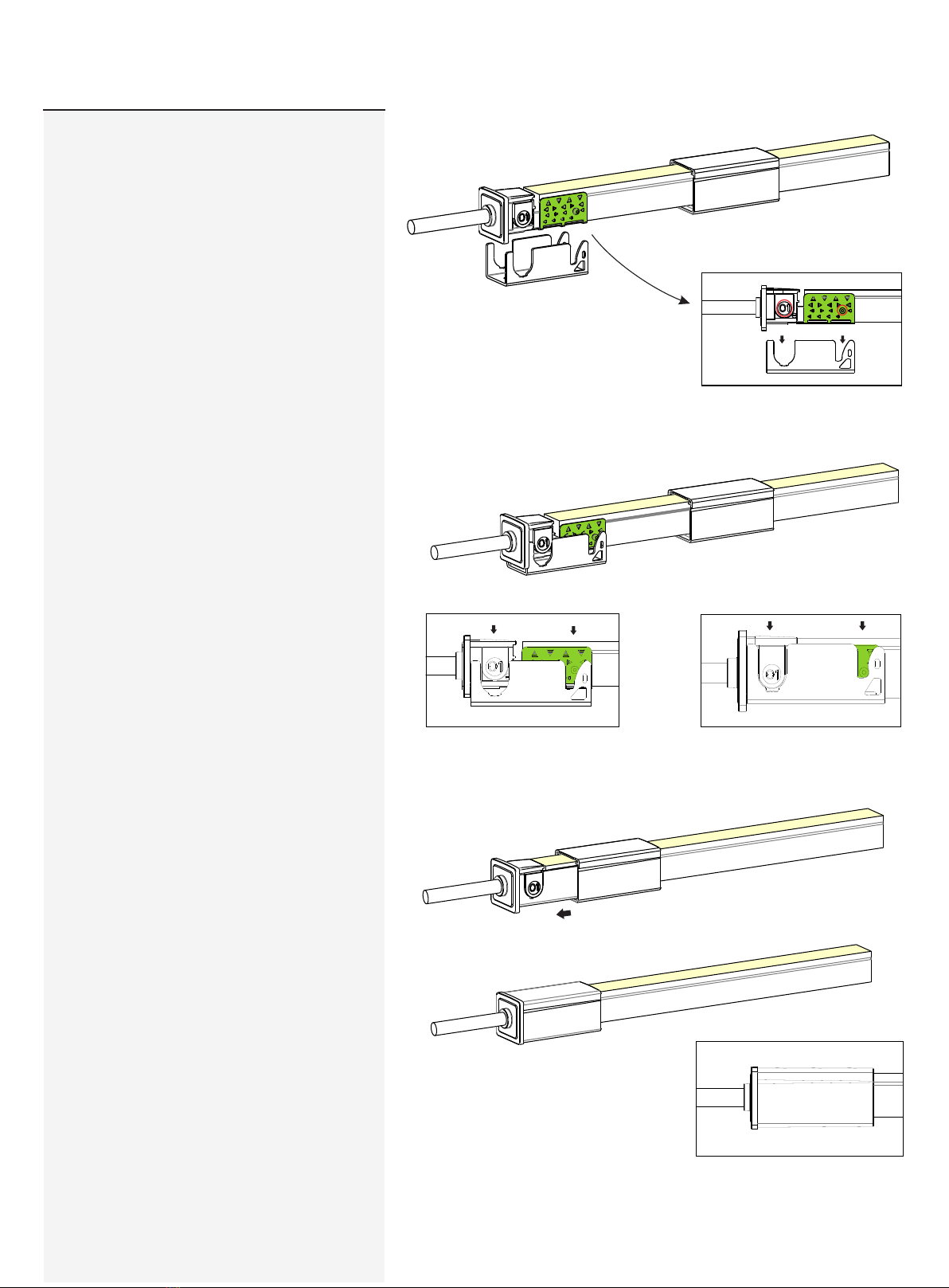

USER MANUAL www.surelight.com

3.5 Push the anti-skidding clip to the end

until the two hook splinters on each side pop

out to lock the U steel plate. Use the gripper

to help tighten the piece.

Please energize the light to check its

functionality and do waterproof

reliablity testing (refer to "waterproof

reliability testing instruction" video)

after connector assembly.

13

USER MANUAL www.surelight.com

Clasp

End Cap

Please ignore these steps if the end cap

has been assembled before delivery.

1.Components of End Cap

2.Tools

Tail Plug (1pc)

Silicone Gasket(1pc)

Anti-skidding Clip (1pc) U Steel Plate (1pc)

Gripper

Explosive View

Finished Assembly View

Note:

1. Never wet the assembly units or assemble with

wet hands.

2. Please use the tools correctly.

3. Please pay attention to personal security when

using tools.

4.Repeated assembly or reuse of the connector may

result in waterproof failure.

14

3.Installation Steps

3.1 Place the tail plug into the U steel plate

USER MANUAL www.surelight.com

3.2 Treatment of Anti-Skidding Clip

Unfold the anti-skidding clip about 20 degrees on both sides.

Place the anti-skidding clip onto the end of the light.

Notice its installation direction.

Fit the anti-skidding clip to the end of the light tightly

and align with the light end edge.

The silicone gasket is attached on the tail plug.

15

USER MANUAL www.surelight.com

3.3. Installation of Tail Plug

Push the bulging points on the anti-skidding

clip into the slots on the U steel plate.

3.4 Push the anti-skidding clip to the end

until the two hook splinters on each side pop

out to lock the U steel plate. Use the gripper

to help tighten the piece.

Please energize the light to check its

functionality and do waterproof

reliablity testing (refer to "waterproof

reliability testing instruction" video)

after connector assembly.

16

USER MANUAL www.surelight.com

Please ignore these steps if the front

connector has been assembled before

delivery.

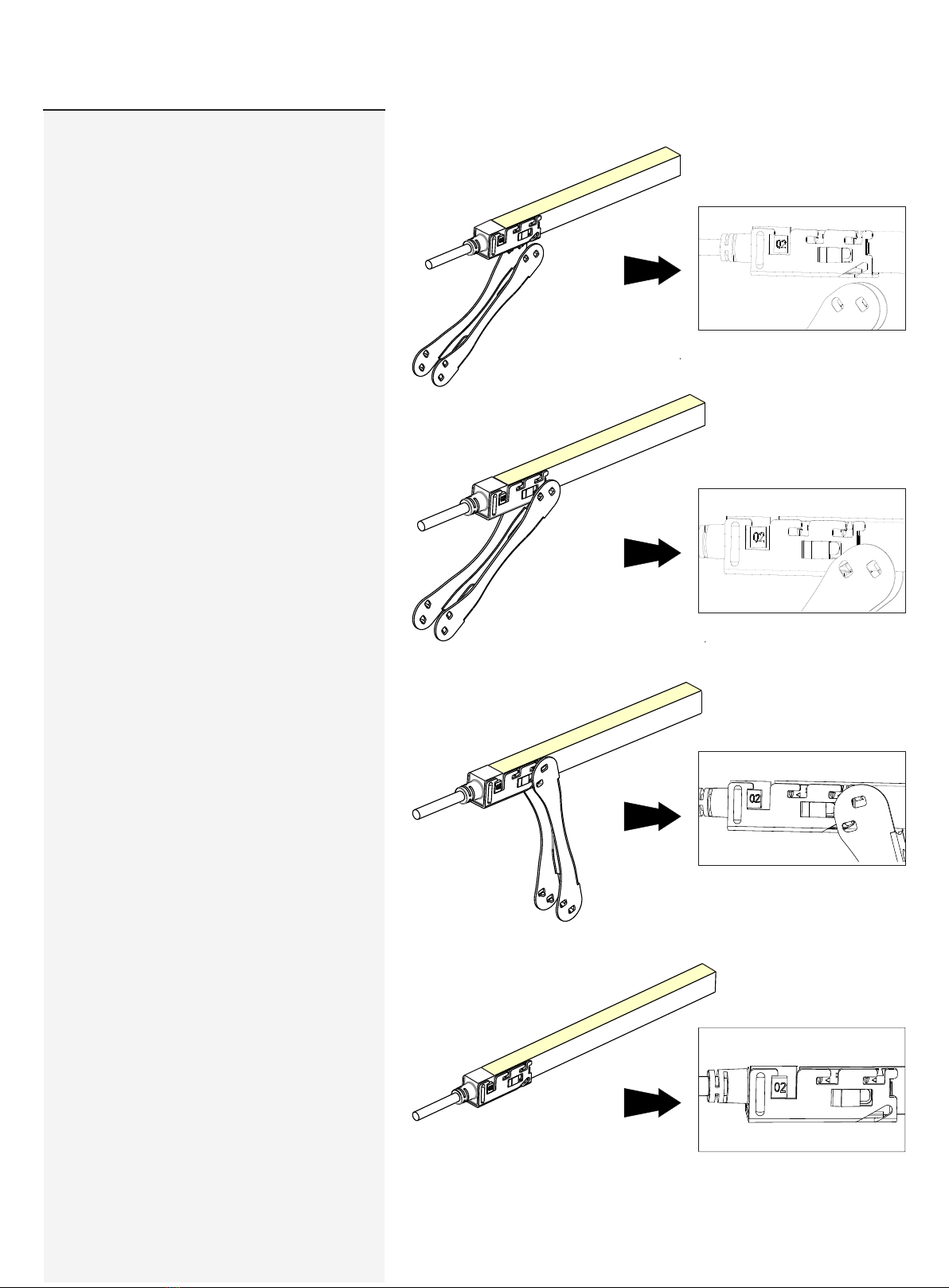

Snap

Front

Connector

Finished Assembly View

Explosive View

1.Components of Front Connector

Anti-skidding Clip (1pc) PC Cover (1pc)U Steel Plate (1pc)

2. Tools

Inducer

Note:

1. Never wet the assembly units or assemble with

wet hands.

2. Please use the tools correctly.

3. Please pay attention to personal security when

using tools.

4.Repeated assembly or reuse of the connector may

result in waterproof failure.

Note:

The light ends are marked with either an 01 or an

02. Always make sure to use an identically abeled

connector for the appropriate direction.

Feed Connector-top end (1pc) Feed Connector-side (1pc)

[Contain Silicone Gasket (1pc)] [Contain Silicone Gasket (1pc)]

Feed Connector-bottom (1pc)

[Contain Silicone Gasket (1pc)]

02 Feed Connector 02 End of light

Pay attention to the direction marked on the

bottom of PC cover.

17

3.2 Inducing a Cavity for Feed Connector

Insert the inducer to the backside of PCB around 10~12mm,

move the inducer up and down 3~5 times gently to create a

small cavity.

Insert the inducer into the backside of PCB It will damage the light if insert into front

side of PCB

NEVER insert into the front side

(LED side) of the PCB

3.1 Placing PC Cover

3.Installation Steps

Snap end of PC Cover Rear end of PC Cover

The assembly end

USER MANUAL www.surelight.com

PCB Insertion Placement

PVC Tape

18

The following operations are prohibited:

Insert into the front side of the PCB

Insert crosswise into the PCB Insert crosswise into the PCB

It will be a 2~5mm gap.

Unfold the anti-skidding clip about 20

degrees on both sides.

Place the anti-skidding clip onto the assembly end of the light.

Pay attention to its direction

Fit the anti-skidding clip to the end of the light so that it wraps

tightly and its brim is aligned with the cut edge on both sides.

3.3 Inserting the Feed Connector

3.4 Treatment of Anti-skidding Clip

3.5 Installation of Anti-Skidding Clip

USER MANUAL www.surelight.com

W=2~5mm

19

Slide back the PC cover till it snaps

in the feed connector.

Press the feed connector and light

downwards at the same time till

bottom.

Align the feed connector and anti-

skidding clip with the U steel

plate.

3.6 Installation of U Steel Plate and PC

Cover

Please energize the light to check its

functionality and do waterproof

reliablity testing (refer to "waterproof

reliability testing instruction" video)

after connector assembly.

USER MANUAL www.surelight.com

20

Please ignore these steps if the End Cap

has been assembled before delivery.

Snap

End Cap

Finished Assembly View

Explosive View Printing on opposite side of light

1.Components of End Cap

2. Tools

Tail Plug (1pc)

[Contain Silicone Gasket (1pc)]

Anti-skidding Clip (1pc) U Steel Plate (1pc) PC Cover (1pc)

Inducer

USER MANUAL www.surelight.com

Note:

1.Repeated assembly or reuse of the connector may

result in waterproof failure.

01 End Cap 01 End of light

Table of contents

Popular Outdoor Light manuals by other brands

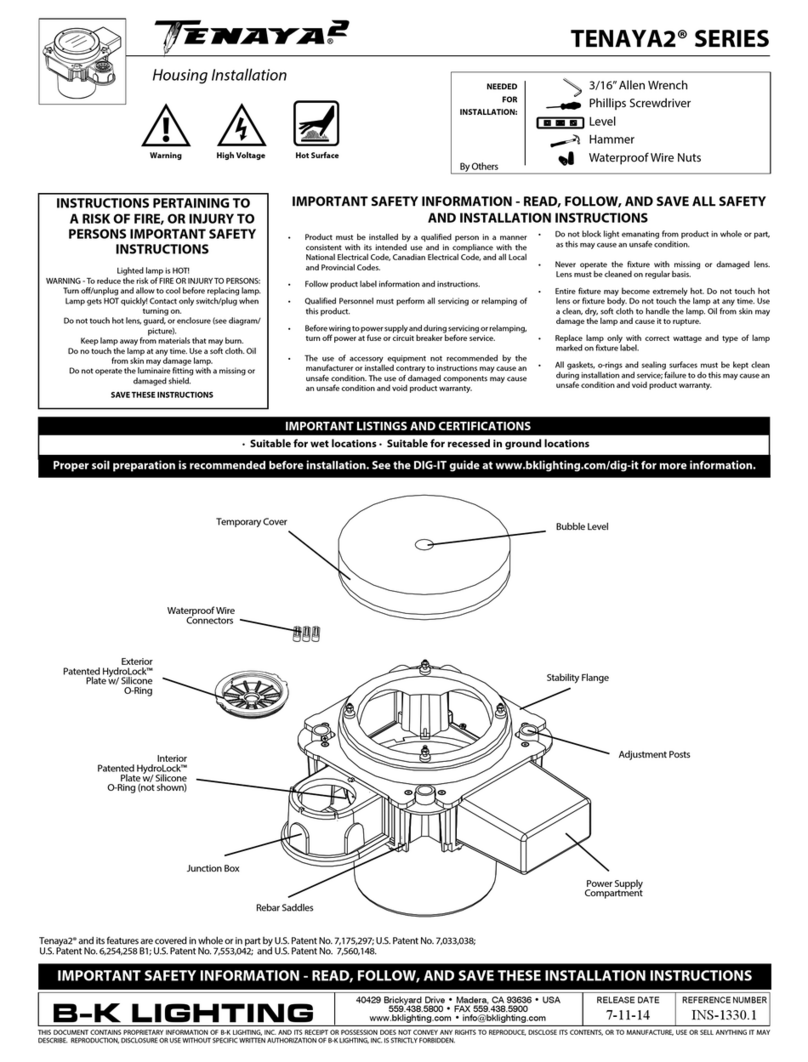

B-K lighting

B-K lighting TENAYA2 Series Housing Installation

Livoo

Livoo TEA247 user manual

Coopers of Stortford

Coopers of Stortford Solar Bird Welcome Stone Instructions for use

Pro-Elec

Pro-Elec PEL00589 instructions

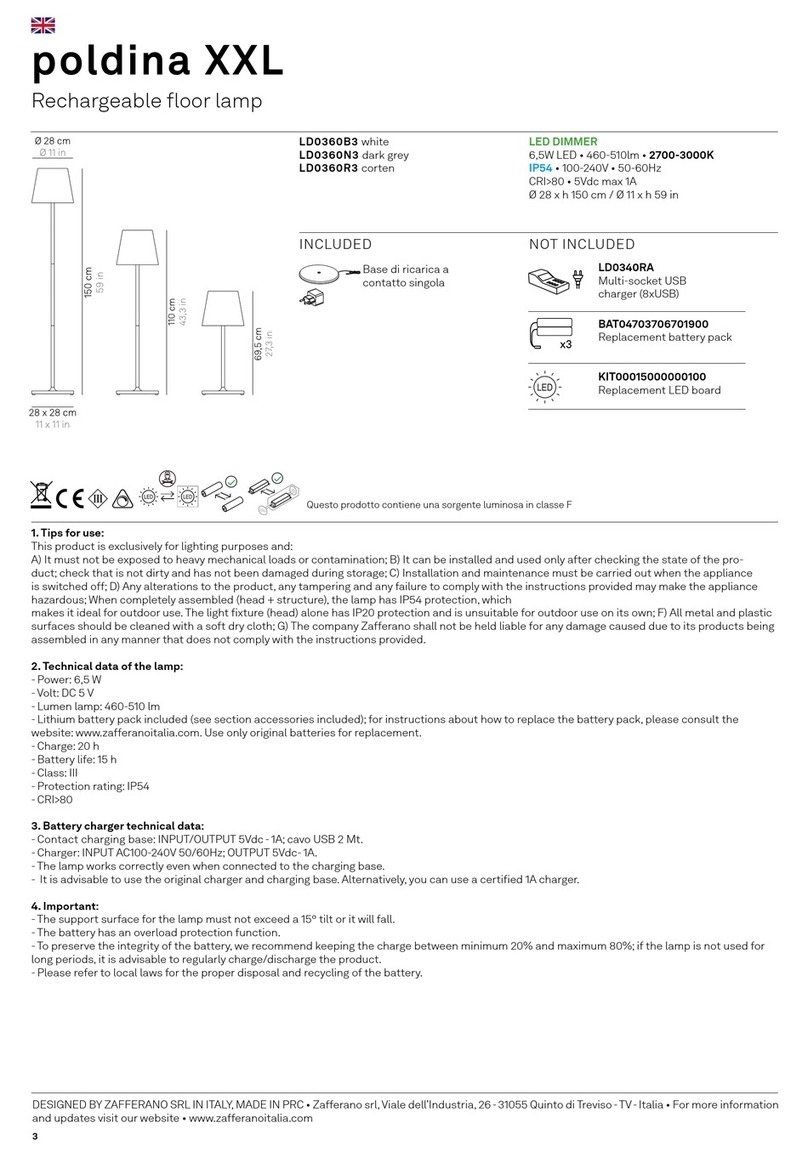

Zafferano

Zafferano poldina XXL quick start guide

Renkforce

Renkforce 1005226 operating instructions

GLUCKSTEIN ELEMENTS

GLUCKSTEIN ELEMENTS 39643-HBCLED Use and care guide

SLV Elektronik

SLV Elektronik KALU FLOOR 1 operating manual

Panlux

Panlux GARD NOO-E14 instructions

Hubbardton Forge

Hubbardton Forge Erlenmeyer Dark Sky Assembly/installation instructions

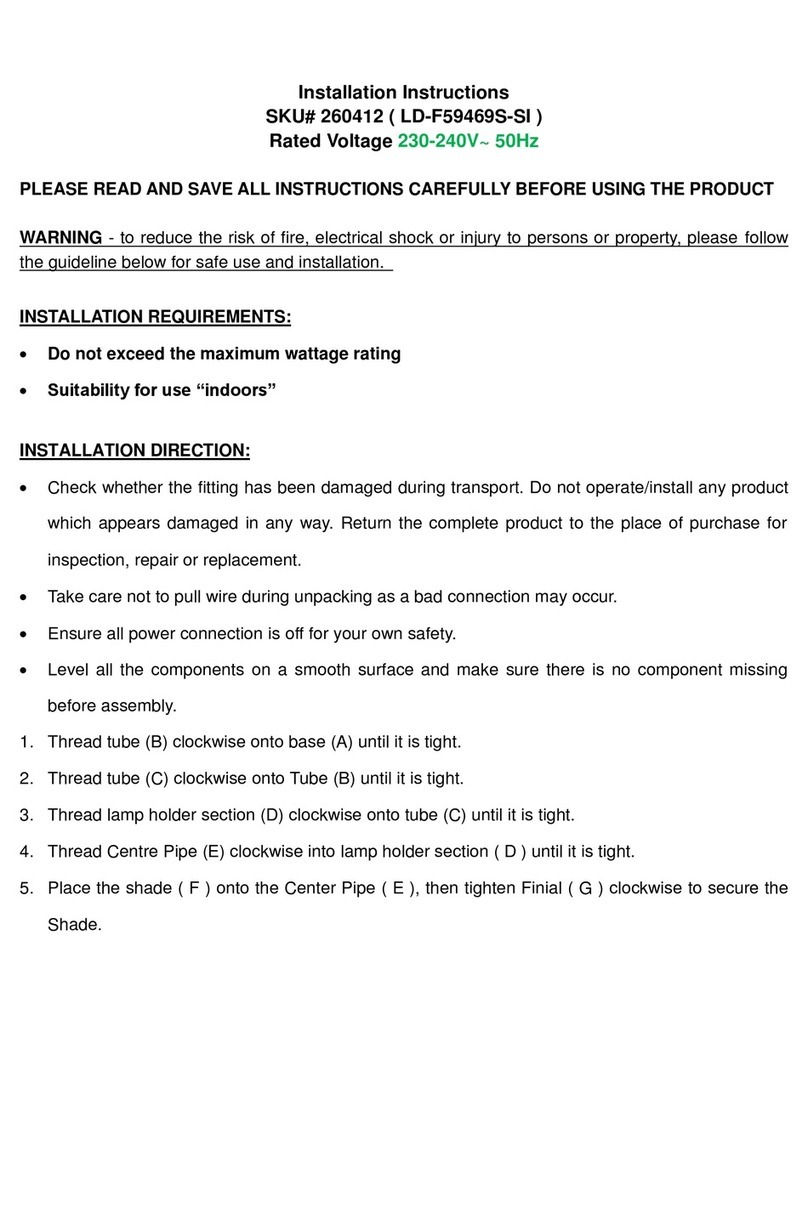

Lucci decor

Lucci decor Ava LD-F59469S-SI installation instructions

Maxim Lighting

Maxim Lighting Clyde VX manual