4. Use the “Kent J-42188-B” tool to separate

upper ball joint taper.

CAUTION: Do not DAMAGE CV boot when lower-

ing, and closely watch ABS cable as well.

STEP 1: (Continued)

STEP 2A: For 1.75-2” of Lift

STEP 2B: For 2.25-2.5” of Lift (Recommended)

12. Reinstall strut with selected shims installed on

top. Prying down on the sway bar is required in the

same procedure as Step 10. Hand tighten three new

supplied short flanged nuts onto exposed threads on

top strut mount.

NOTICE: Repeat procedure 7-12 on both sides of the vehicle

before continuing.

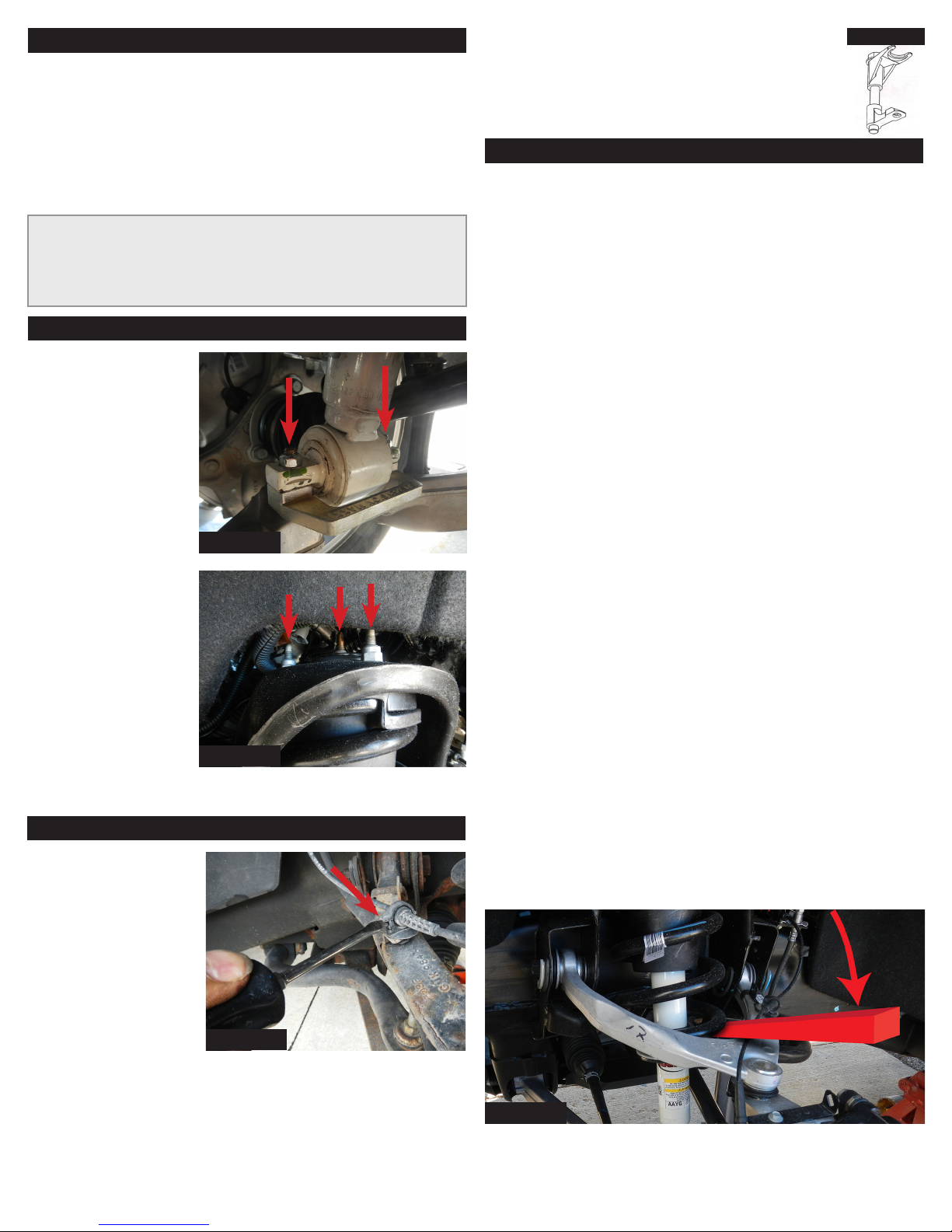

1. Pry down on sway

bar with pry bar

which will low-

er the control

arm allowing for

installation of

the Strut Mount

Extender.

“SUSPENSIONMAXX”

side facing up.

2. Align mount-

ing holes install

supplied bolt,

washers and nuts.

Torque to 35/lbs

(FIG 2A-1)

3. Torque 3 upper

strut mount nuts

to 25/lbs.

(FIG 2A-2) Reinstall wire loom clips.

1. Lightly support

lower A-arm with

bottle jack or foot

jack

2. Unlock the ABS

wire loom clip,

allowing the ABS

wire to be free

from the clip.

(FIG 2B-1)

3. Remove ball joint nut with 18mm wrench

1. NOTICE: For 1.75-2” you do not need to disconnect up-

per ball joint to complete installation. For customers li

their vehicle 2.25-2.5” disconnecting the upper ball joint

is required.

FIG. 2A-1

FIG. 2A-2

Kent J-42188-B

FIG. 2B-1

STEP 2B: For 2.25-2.5” of Lift (Alternative Method)

NOTICE: We recommend the procedure above. Use the

alternative method at your own risk.

1. Lightly support lower A-arm with bottle jack or foot

jack

2. Unlock the ABS wire loom clip, allowing the ABS wire

to be free from the clip. (FIG 2B-1)

3. Loosen upper ball joint nut with 18mm wrench,

3-5 threads, until an air gap is achieved and the nut

spins freely. Pry downward on the suspension, strike

the knuckle with a brass dri and hammer to shock

the taper and unseat the ball joint.

4. Pry down on sway bar with pry bar which will lower

the control arm allowing for installation of the Strut

Mount Extender. “SUSPENSIONMAXX” side facing up.

NOTICE: Use EXTREME Caution during the step above,

closely monitor ABS wire and CV Axel clearances to prevent

damage.

5. Align mounting holes install supplied bolt, washers

and nuts. Torque to 35/lbs (FIG 2A-1)

6. Reconnect ball-joint. Apply pressure by pumping the

bottle jack under the lower control arm.

7. Raise the lower A-Arm with the bottle jack on the

outermost point on the control arm.

NOTICE: Use caution when jacking under the lower control

arm as it may cause the vehicle to raise o jack stands.

8. Pry downward on the upper control arm realigning

the upper ball joint with the knuckle. Thread on

upper ball joint nut.

NOTICE: Prying downward on the upper A-Arm will seat

taper and hold the stud from rotating as you tighten the

18mm ball joint nut. Some ball joint tapers have Allen hex

to hold ball joint stud while seating the taper.

Torque to 37/lbs plus an additional 1/4 turn.

(FIG 2A-2)

FIG. 2B-2