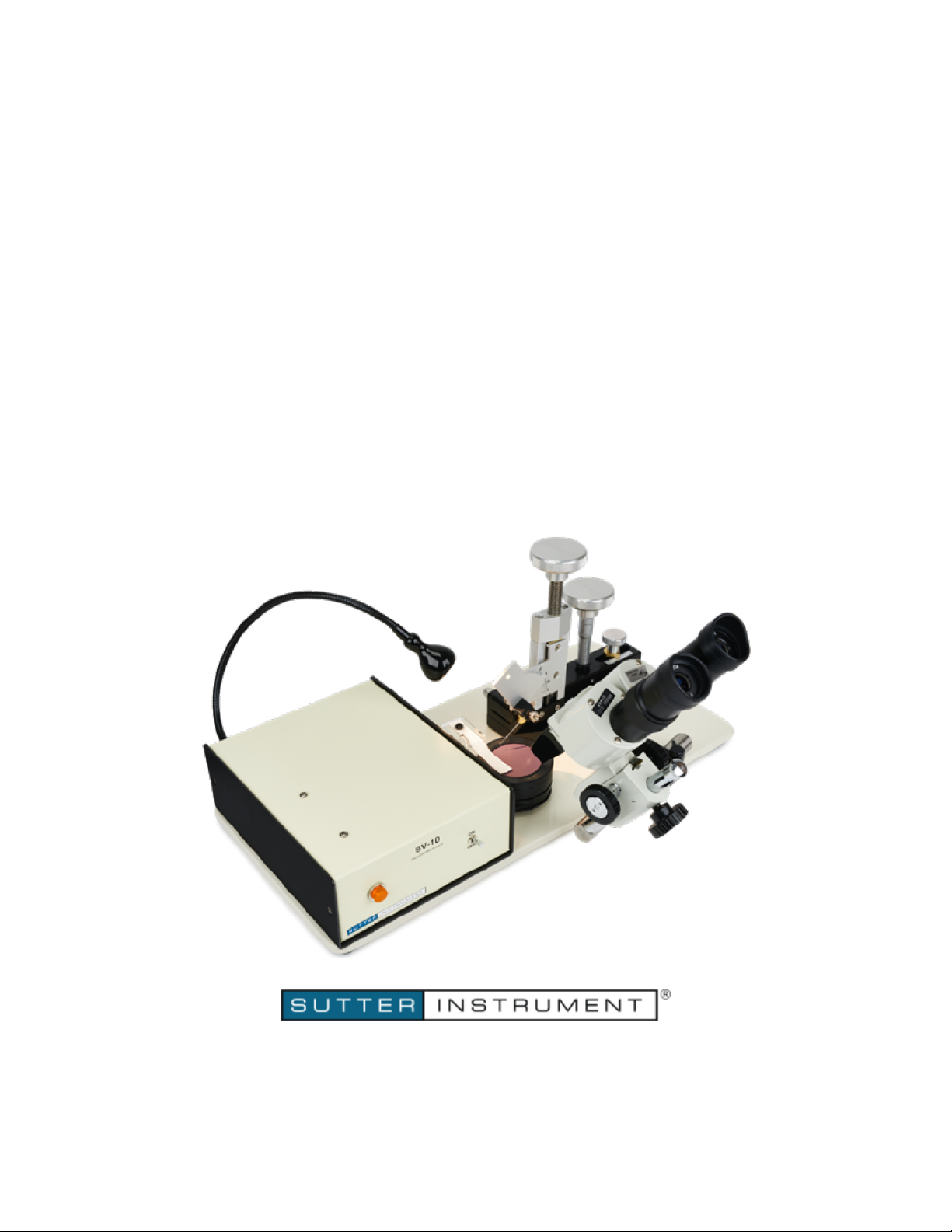

BV-10 OPERATION MANUAL – REV. 3.00 (20180423)

TABLE OF CONTENTS

DISCLAIMER .......................................................................................................................................3

SAFETY WARNINGS AND PRECAUTIONS....................................................................................3

Electrical ..................................................................................................................................................3

Avoiding Electrical Shock and Fire-related Injury..............................................................................3

Operational ..............................................................................................................................................4

1. GENERAL.........................................................................................................................................7

1.1 Introduction.......................................................................................................................................7

1.2 Features .............................................................................................................................................8

1.3 Models ................................................................................................................................................8

1.4 Technical Support.............................................................................................................................8

1.5 Description and Function of Components ..................................................................................... 8

1.5.1 Motorbase....................................................................................................................................8

1.5.2 Manipulator ................................................................................................................................9

1.5.3 Pedestal/Grinding Assembly...................................................................................................10

1.5.4 BVM-CE Electrode Impedance Meter (Optional).................................................................11

1.5.5 Optical Attachment (Optional)...............................................................................................12

2. INSTALLATION ............................................................................................................................13

2.1 Description of Package Contents ..................................................................................................13

2.2 Set-Up and Assembly Instructions ...............................................................................................14

3. OPERATION ..................................................................................................................................17

3.1 Grinding Procedure ........................................................................................................................17

3.1.1 General Information ................................................................................................................17

3.1.2 Control of Beveling by Measuring Electrical Resistance.....................................................18

3.1.3 Control of Beveling by Monitoring Bubble Size....................................................................18

3.2 Using the Resistance Meter...........................................................................................................19

3.2.1 Operation ..................................................................................................................................20

3.2.2 Ohms Law – Theory of Operation..........................................................................................20

3.2.3 Accuracy ....................................................................................................................................20

4. MAINTENANCE............................................................................................................................23

4.1 Cleaning the Grinding Place..........................................................................................................23

5. TROUBLESHOOTING..................................................................................................................25

5.1 Grinding Plate Won't Turn............................................................................................................25

5.2 Jerky Plate.......................................................................................................................................25

5.3 Beveling Takes a Long Time .........................................................................................................25

5.4 No Beveling Occurs.........................................................................................................................25

5.5 Meter Does Not Work.....................................................................................................................25

5.6 Pipettes Break During Beveling....................................................................................................25

APPENDIX A. LIMITED WARRANTY............................................................................................27

APPENDIX B. ACCESSORIES .........................................................................................................29

Accessories .............................................................................................................................................29

Replacement Parts................................................................................................................................29