Bench Top Bender User’s Manual 9

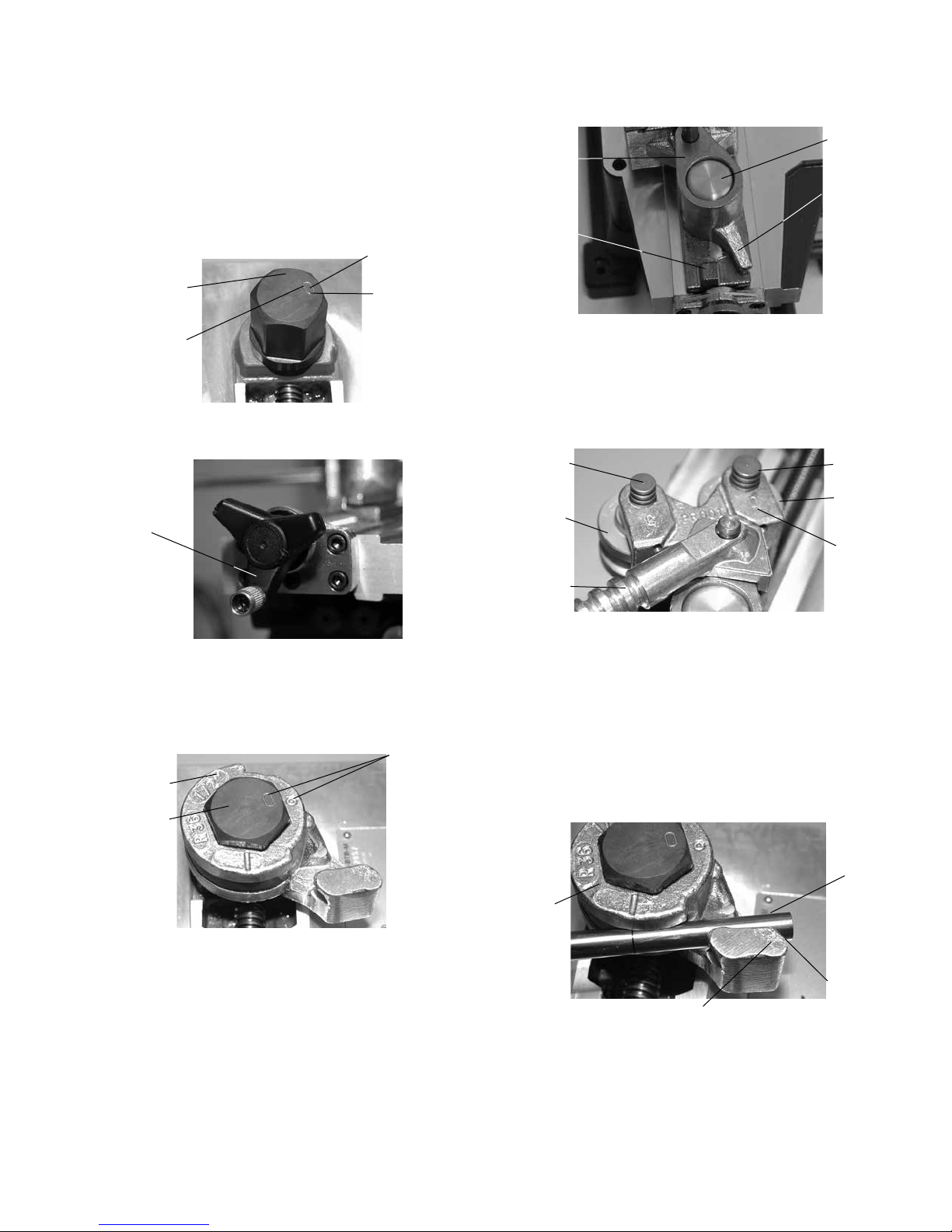

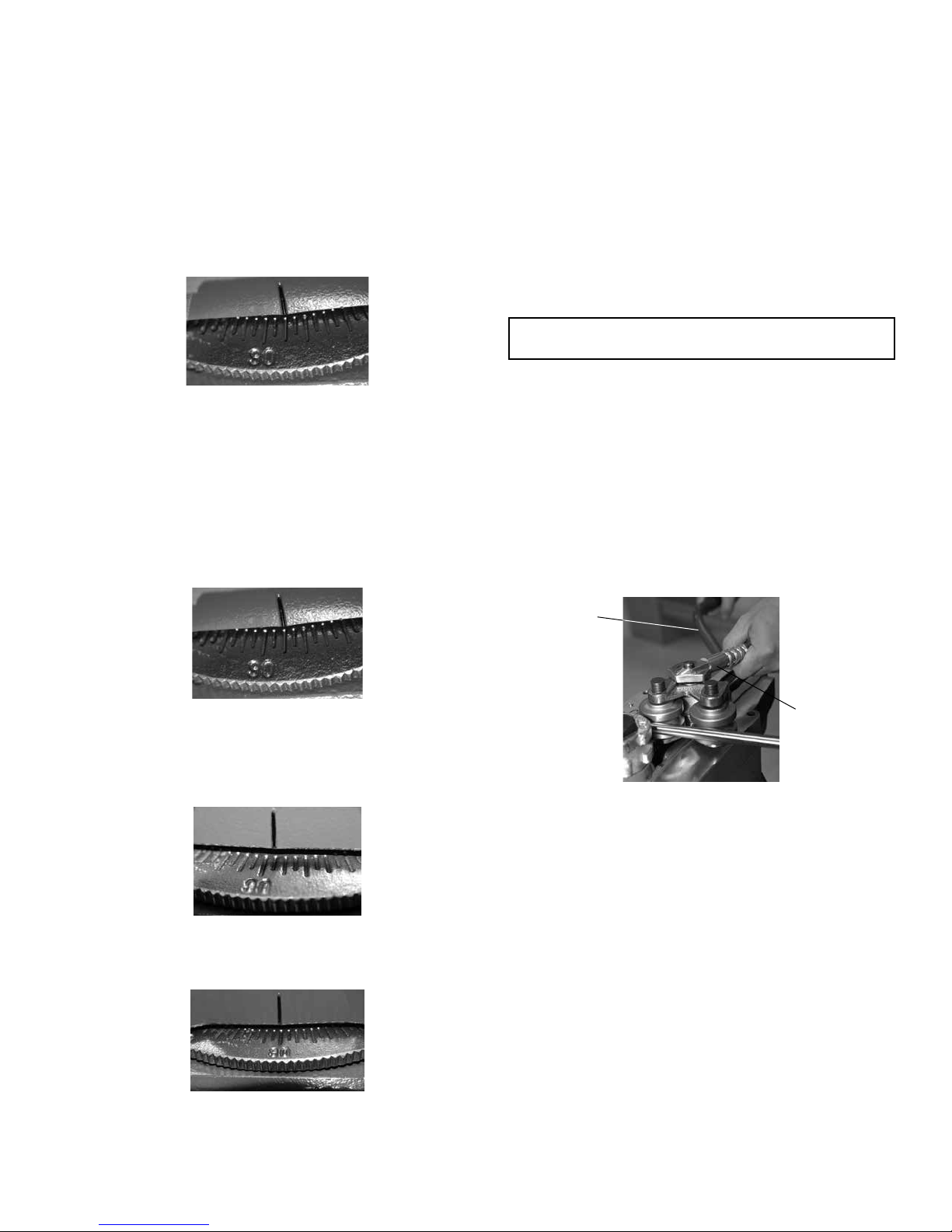

3. Keep the hand crank still and rotate the bend degree

wheel to zero.

Caution

Releasing the hand crank while tube is under

load may cause the hand crank to spin, possibly

leading to injury.

4. Rotate the hand crank until the bend wheel displays 5°

less than the desired bend angle. This will prevent setup

scrap due to overbending.

Example: For a desired bend angle of 90°, rotate the hand

crank until the bend degree wheel reads 85°.

5. Unload the bender (see Unloading the Bender) and

measure the bend angle of the tube (see Measuring

the Bend Angle). Make note of this measurement as it

is likely to be different than the angle displayed on the

bend wheel.

6. Reload the tube into the bender, lining up the bend mark

and the reference mark.

7. Rotate the hand crank until the bend degree wheel reads

the angle from step 4 (in example: 85°).

8. Keep the hand crank still and rotate the bend degree

wheel to the measurement noted in step 5 (in example:

88°). This calibrates the bend degree wheel by setting it

to display the actual bend angle being produced.

9. Continue to rotate the hand crank until the bend degree

wheel reads the desired bend angle.

10. Unload the bender (see Unloading the Bender) and

measure the bend angle of the tube.

The bend angle indicated on the bend degree wheel will

now be very close to the bend angle produced. If further

adjustment is desired repeat steps 6 through 10.

Note: Tube springback is cumulative. Depending on the tube

variables, a smaller bend angle builds up less tube

springback during the bending process than a larger

bend angle. For example, if a 30° bend is attempted

using a bender that was calibrated to make a 90°

bend, the resulting bend may be larger than desired.

Conversely, if a 150° bend is attempted on the same

bender, the resulting bend may be smaller than

desired. It is advised to verify each bend angle.

Unloading the Bender

Note: Do not turn the roller knob to unload the bender.

Doing so will affect bend consistency.

Caution

Releasing the hand crank while the tube is under

load may cause the hand crank to spin, possibly

leading to injury.

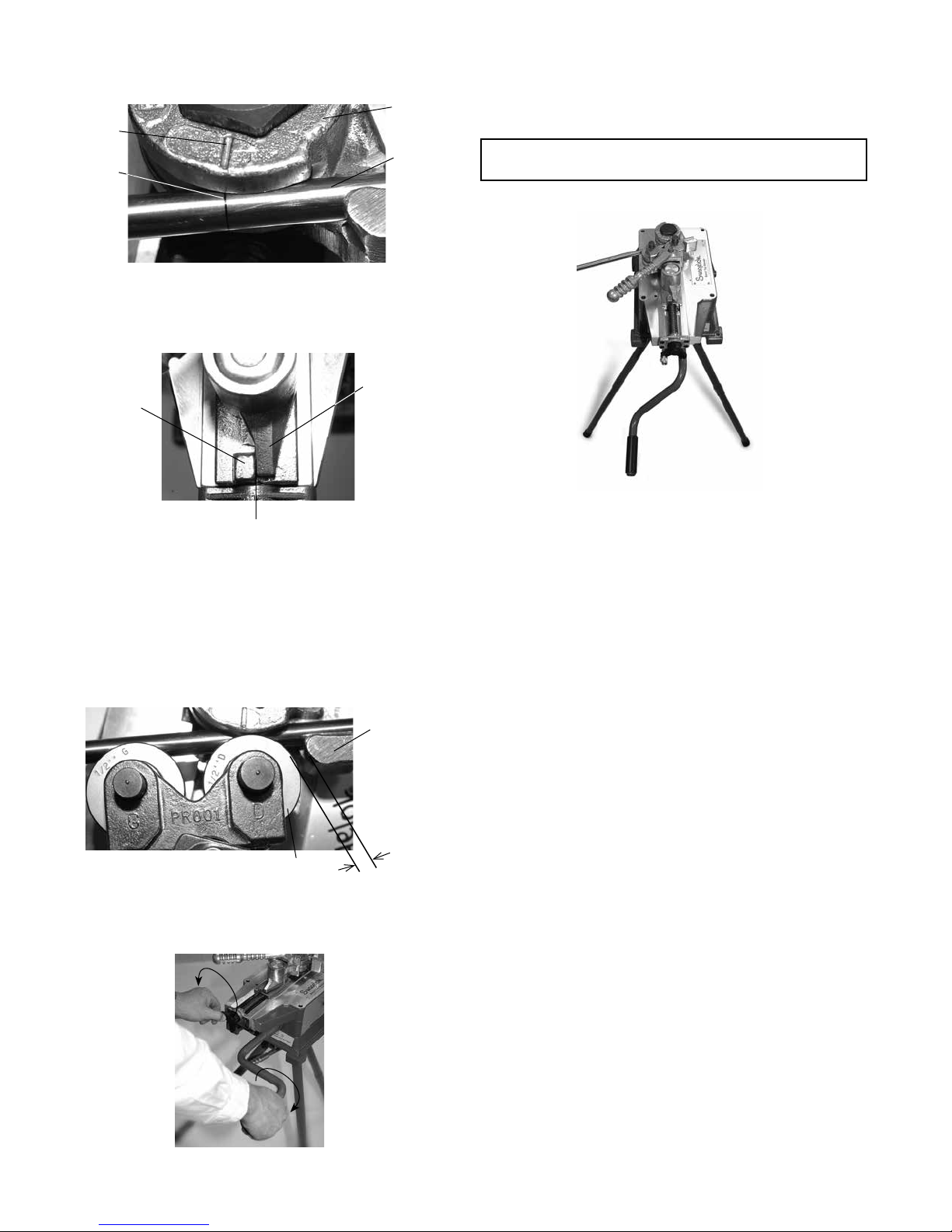

1. Rotate the hand crank in the direction opposite that

used to bend the tube.

2. As the hand crank is rotated, gently push the roller

bracket lever counter-clockwise until the rollers swing

away from the tube and the tube can be removed from

the bender.

Note: Do not force the roller bracket lever.

Hand crank

Roller bracket

lever