2010 Clermont Street, Antigo, WI, 54409 •

••

• Phone: 715-627-5500 or 800-448-2524 •

••

• Fa : 715-627-5554 Web: http://www.hydratight.com/

Operating Instruction

Page 1 of 2

REV: M

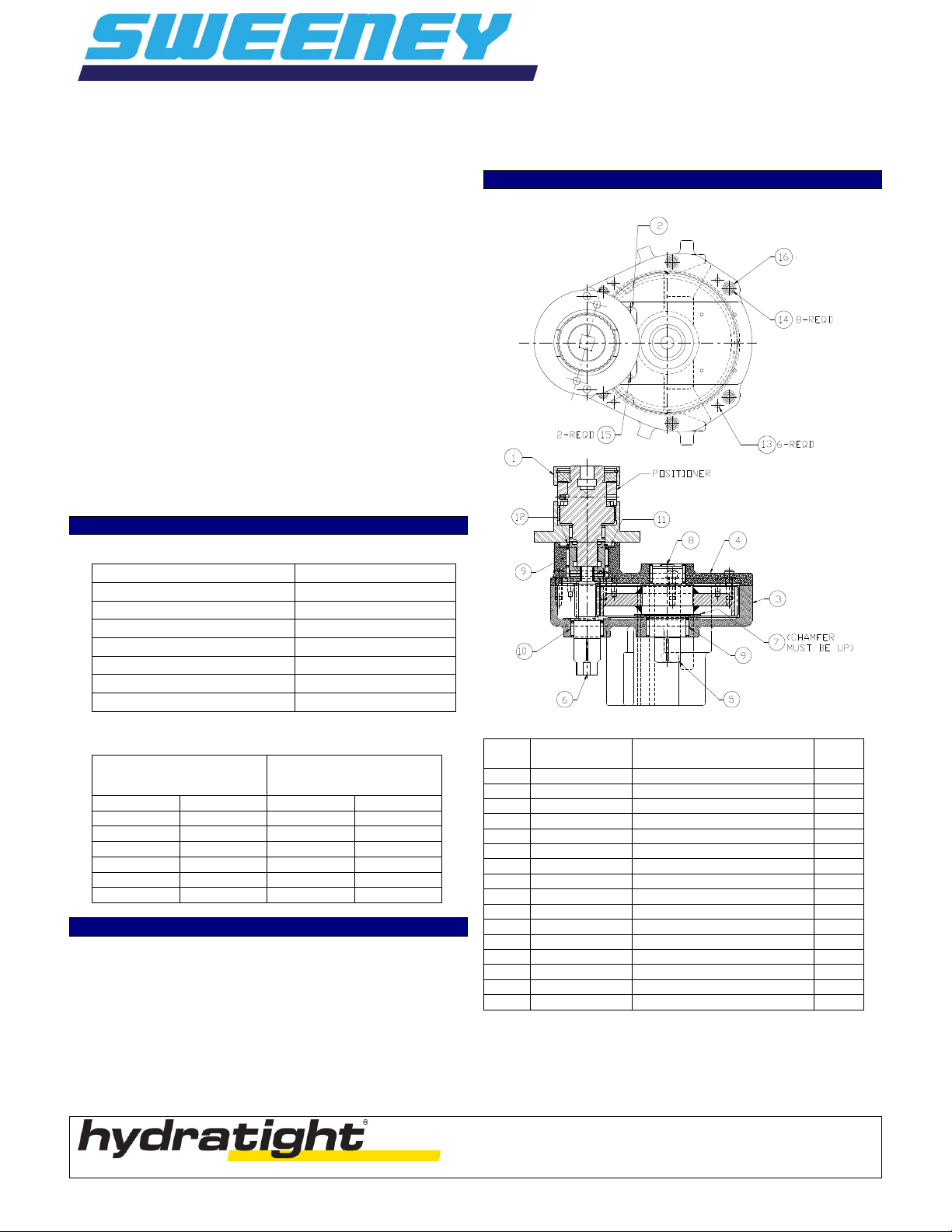

Model 8202-290A Torque Multiplier

WARNINGS

•

Do not exceed rated output of tool

•

Outputs turn in opposite directions. Verify direction before applying torque

•

Do not hold multiplier while applying torque. Normal multiplier deflection may pinch

fingers, especially in confined locations.

•

Maintain firm hand control of torque wrench or input handle when releasing multiplier

because recoil (wind up) will be experienced.

•

Remove input handle when not applying torque.

Model 8202-290A shown in use with model 8200

Model 8202-290A

1. INSTRUCTIONS

1.1 The model 8202-290A Torque Multiplier is a geared wrench

designed for use in conjunction with model 8200 8300 8111 or

8112 Torque Multiplier. The 8202-290A Torque Multiplier has a

torque ratio of 6.5:1 and a maximum output of 1 200 ft-lbs

torque. It has a 1/2” square female input and two 3/4” male

output drives.

1.2 The model 8202-290A Torque Multiplier has 360° continuous

rotation in either clockwise or counter clockwise direction. An

integral two-directional input torque holding device inhibits

accidental torque wind-up release. The torque multiplier has two

output drives. One turns at 6.5:1 (1/6.5 the speed of the input

wrench) to provide a high torque for torque breakaway. The

other output turns at 1:1 (the same speed as the input wrench)

to provide rapid tightening and loosening of fasteners

1.3 A positioner controls rotational direction for manually applied

input.

2. PROCEDURE

2.1 Select the proper anchor plate and socket to be used with the

attached torque multiplier (model 8200 8300 8111 or 8112).

2.2 Mount the anchor plate socket and torque multiplier in proper

position for the specific application.

2.3 To tighten: Mount the 8202-290A on the model 8200 8300

8111 or 8112 Torque Multiplier. Engage the appropriate 3/4”

male output drive of the 8202-290A Torque Multiplier (1:1 or

6.5:1 ratio drive) with the 3/4” female input drive of model 8200

8300 8111 or 8112 Torque Multiplier. The anchor plates of the

8202-290A Torque Multiplier will extend over the edge of the

attached torque multiplier. Rotation of the input square drive

may be required in order to match mating multiplier’s square

drive.

2.4 Rotate the positioner ring to the tighten position. Input and

output rotation directions are the same for the 1:1 drive.

(EXAMPLE: Input clockwise = output clockwise) Input and

output rotation directions are opposite for the 6.5:1 drive.

(EXAMPLE: Input clockwise = output counter-clockwise).

(See WARNING).