GB.GOLDSKFCX.231015

We reserve the right to alter specifications.

4 www.swegon.com

2. General

2.1 Handling the air handling

unit before commissioning

The air handling unit and its duct connections should be pro-

tected against wetness and condensation until the unit is com-

missioned.

2.2 Range of Application

The GOLD units are designed for use in comfort ventilation appli-

cations. Depending on the variant selected, GOLD units can be

utilised in buildings such as office buildings, schools, day nurser-

ies, public buildings, shops, residential buildings, etc.

The GOLD CX units can also be used for the ventilation of mod-

erately humid buildings; however not where the humidity is

continuously high, such as in indoor swimming baths.

In order to fully obtain all the benefits the GOLD system has to

offer, it is important to take the special characteristics of the air

handling units into account when planning them into the pro-

ject, installing, commissioning and operating them.

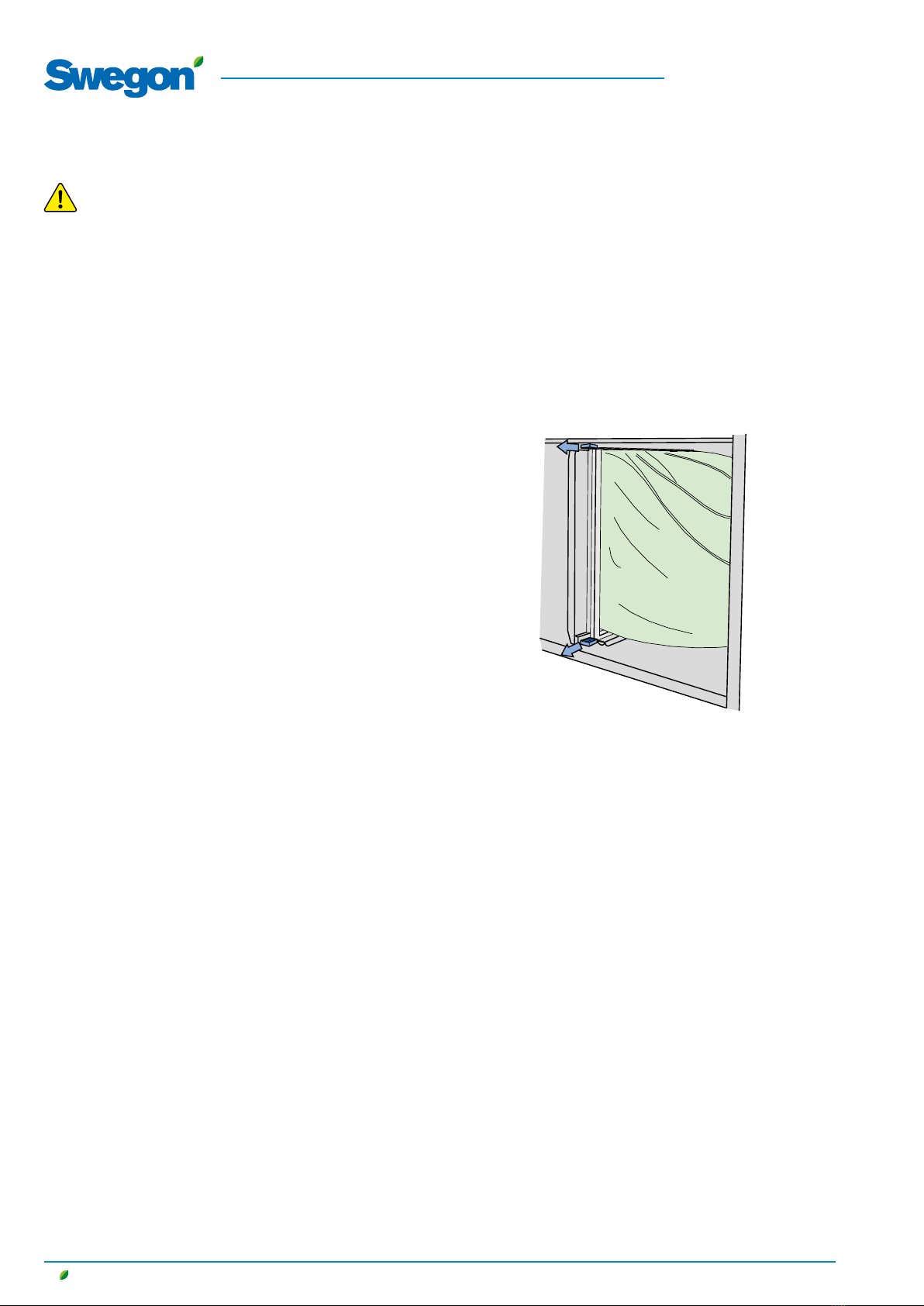

The air handling unit in its basic design should be installed

indoors. The TBTA/TBTB accessory should be used if the air

handling units are installed outdoors. If the duct accessories are

installed outdoors, they must be housed in an insulated casing

(type TCxx).

GOLD CX is designed and tested for temperatures, in the sur-

roundings and the air stream, from -40°C to +40°C. If the air

handling unit is placed outdoors, the expansion vessel must be

equipped with anti-freeze resistance and insulated when the

design outdoor temperature is lower than -10°C.

The fans are approved for continuous operation in temperatures

of up to 40°C.

The fans are tested for, and can manage operation for one hour

at 70°C.

Important!

Always read the safety instructions in Section 1 that

explain the risks involved in running the unit and desig-

nate who shall be permitted to operate and service the

unit, and carefully follow the installation instructions

provided in each paragraph.

The product identification plates are located on the inspection

side of the air handling unit and on a wall inside the fan section.

Refer to the particulars on the product identification plate when

you contact Swegon.

2.3 Mechanical Design

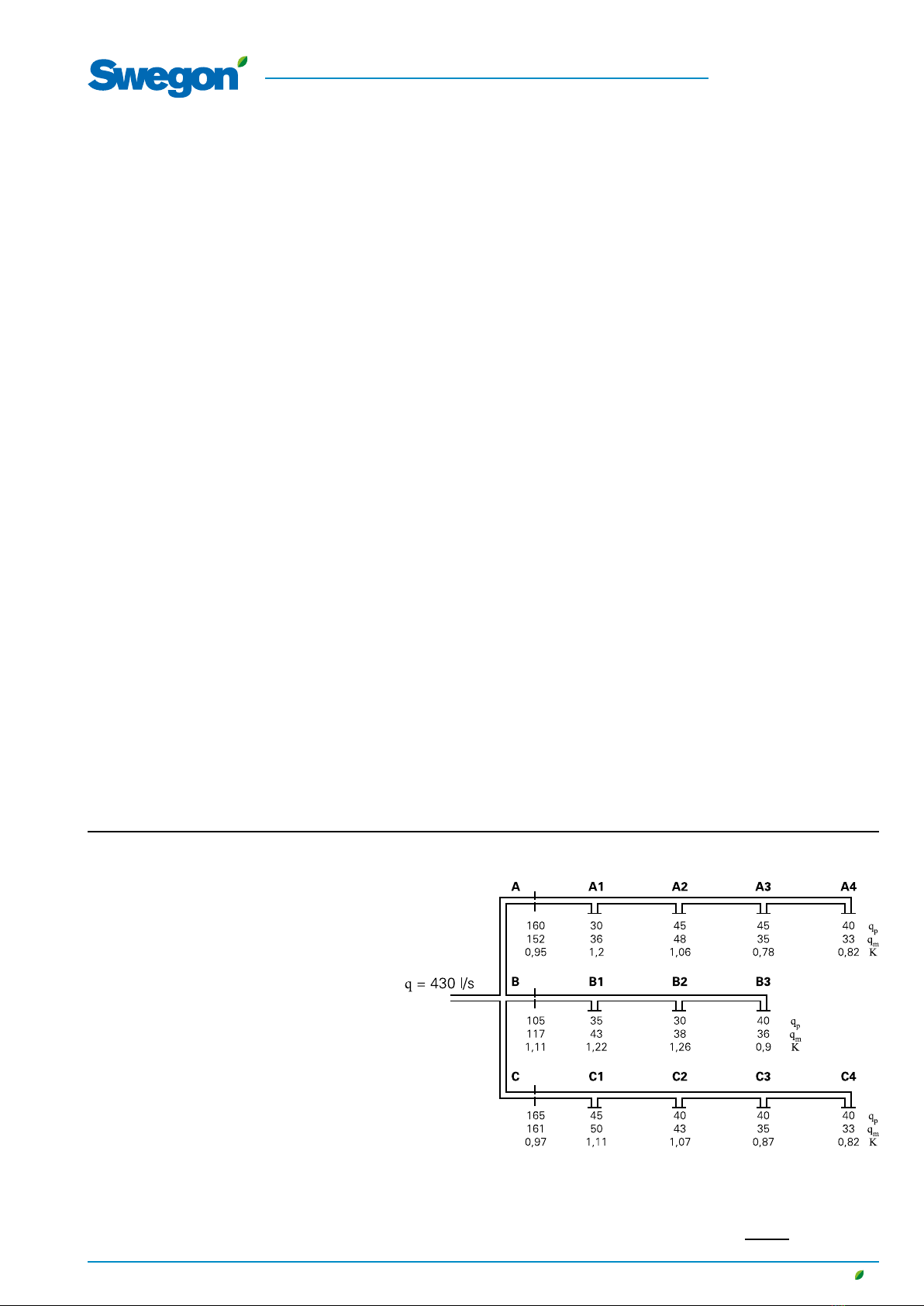

The GOLD CX units are available in 4 physical sizes and for 8

airflow ranges.

The outer sheet steel skin is painted in Swegon’s grey metallic

colour (closest RAL colour: 9007). The handles and decor strips

are black. Internal material: aluminium-zinc plated sheet steel

and Magnelis. Environmental Class C4. Panel thickness of 52

mm with intervening insulation consisting of mineral wool.

The GOLD CX units have class ePM10 60% (M5) or ePM1 50%

(F7) supply air and extract air filters made of glass fibre.

The coil heat exchangers in the size 035-080 one-piece GOLD CX

air handling units are supplied completely mounted from the fac-

tory; including mounted pipework package with all the necessary

components. The system is normally filled with liquid, vented,

commissioned and performance-tested prior to delivery, but can

also be ordered in unfilled condition e.g. for housing improve-

ment projects or if the application requires filling with another

mixture instead of 30 % ethylene glycol. A pipe coupling unit

supplied in unmounted condition is available as an accessory for

the size 100/120 units.

The supply air and extract air fans are of GOLD Wing+ type, an

axi-centrifugal fan with backward-curved blades. The fans are

direct-driven and have a motor control system for variable speed

control.

2.4 Control System

The IQlogic control system is microprocessor-based and is inte-

grated into the air handling unit. It controls and regulates the

fans, heat exchanger, temperatures, airflows, Operation times

and a large number of internal and external functions as well as

alarms.

2.5 Environmental

Documentation

For a complete Declaration of Construction Materials, see our

home page at www.swegon.com (applicable to Sweden only).

The air handling unit is designed in such a way that it can be

easily dismantled into its component parts. When the unit has

ended its useful product life, the services of an accredited recy-

cling company should be utilised for disposal.

The recyclable weight of the GOLD is about 94% of its initial

weight.

Swegon AB is associated with the REPA Register, No.

5560778465.

Contact Swegon AB, Phone: +46 (0)512-322 00, if you have

any questions regarding the dismantling instructions or the air

handling unit’s impact on the environment.