DUCT LEAKAGE TESTER

Manual –V5.31-ES20160714

4

Pepparvägen 27

SE-123 56 Farsta, SWEDEN

www.swema.se

www.swema.com

SETTINGS

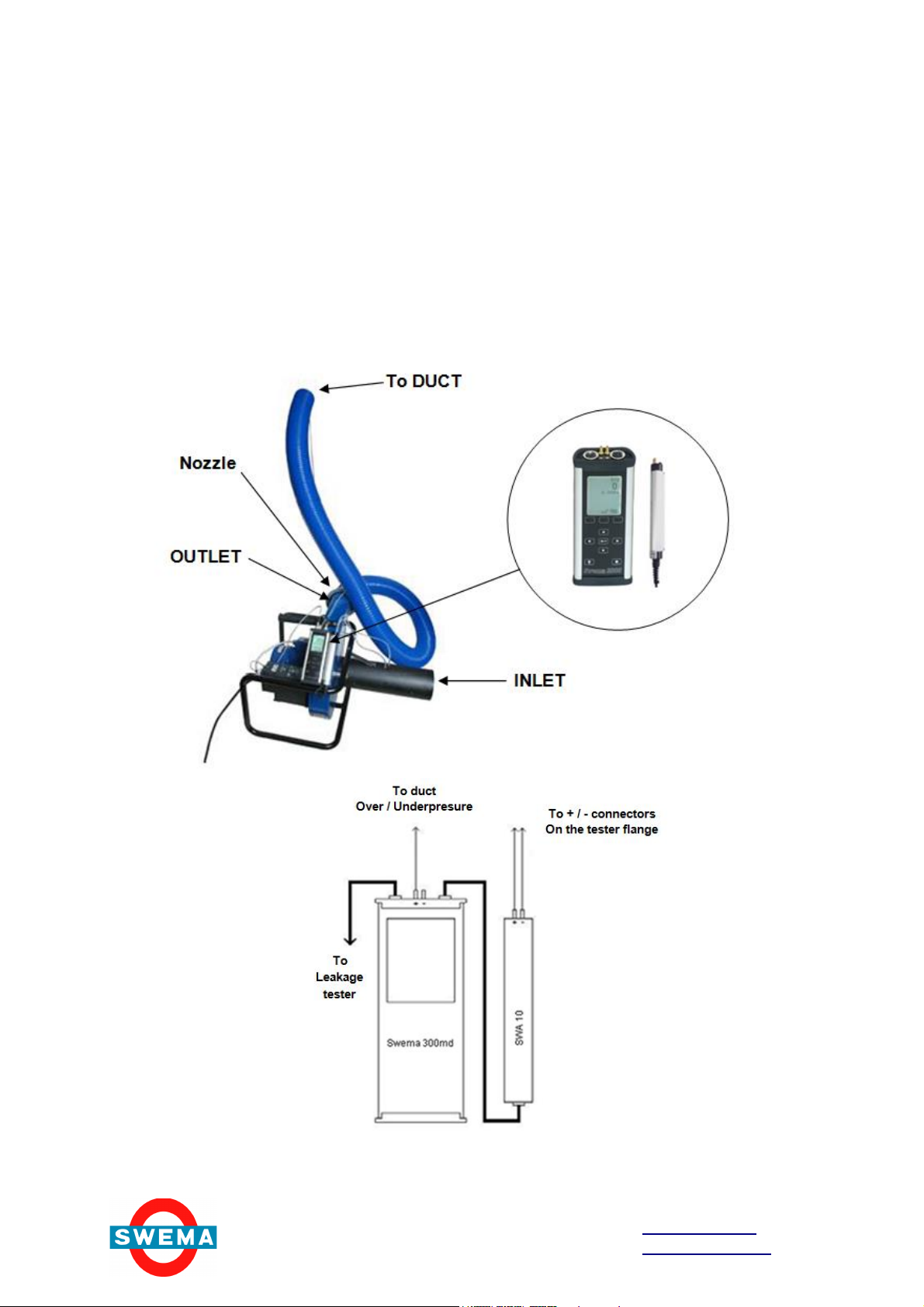

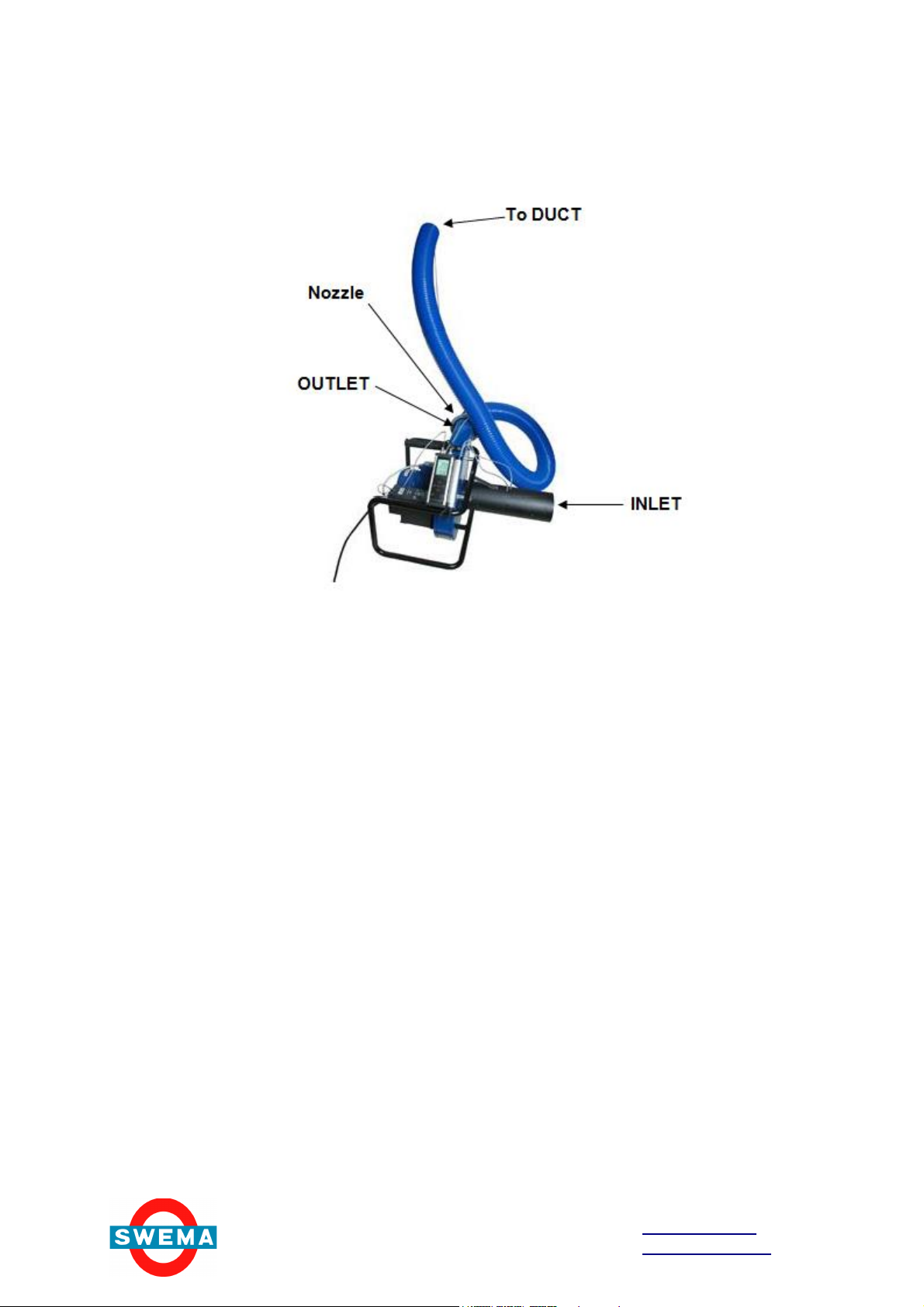

1. Control the leakage tester automatically with Swema 3000md and the sensor SWA 10.

2. The built-in differential pressure sensor in Swema 3000md measures over pressure and under

pressure in the duct. Connect the pressure hose (silicone hose) on the positive pressure

connector (marked with +).

3. Connect the valves of the probe SWA 10 to the valves on each side of the orifice plate in the

flange with the pressure hoses (silicone hoses) to measure the leakage flow. Follow the

convention + to + and –to -.

4. Connect the cable from the leakage tester to the RS232 contact on Swema 3000md.

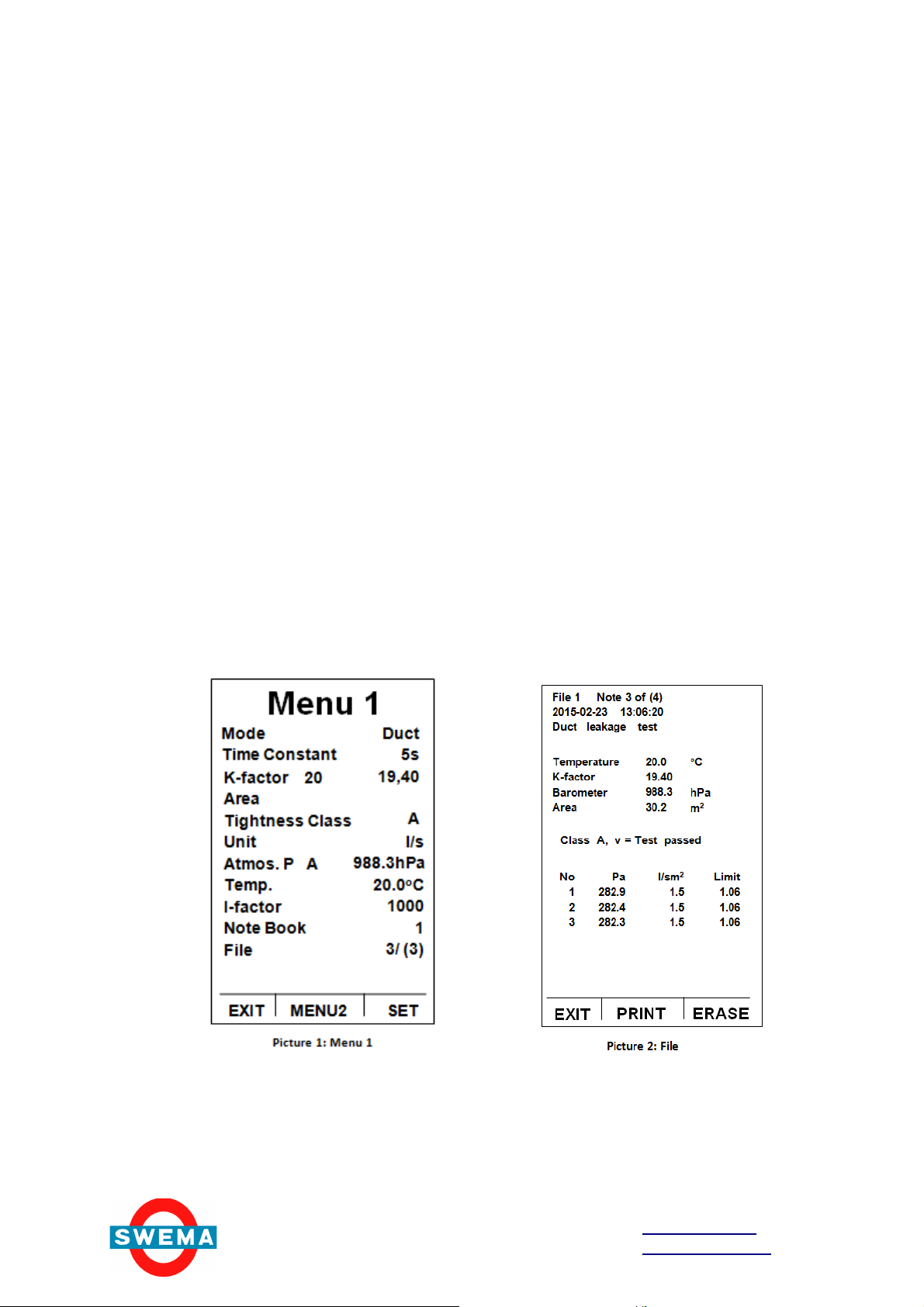

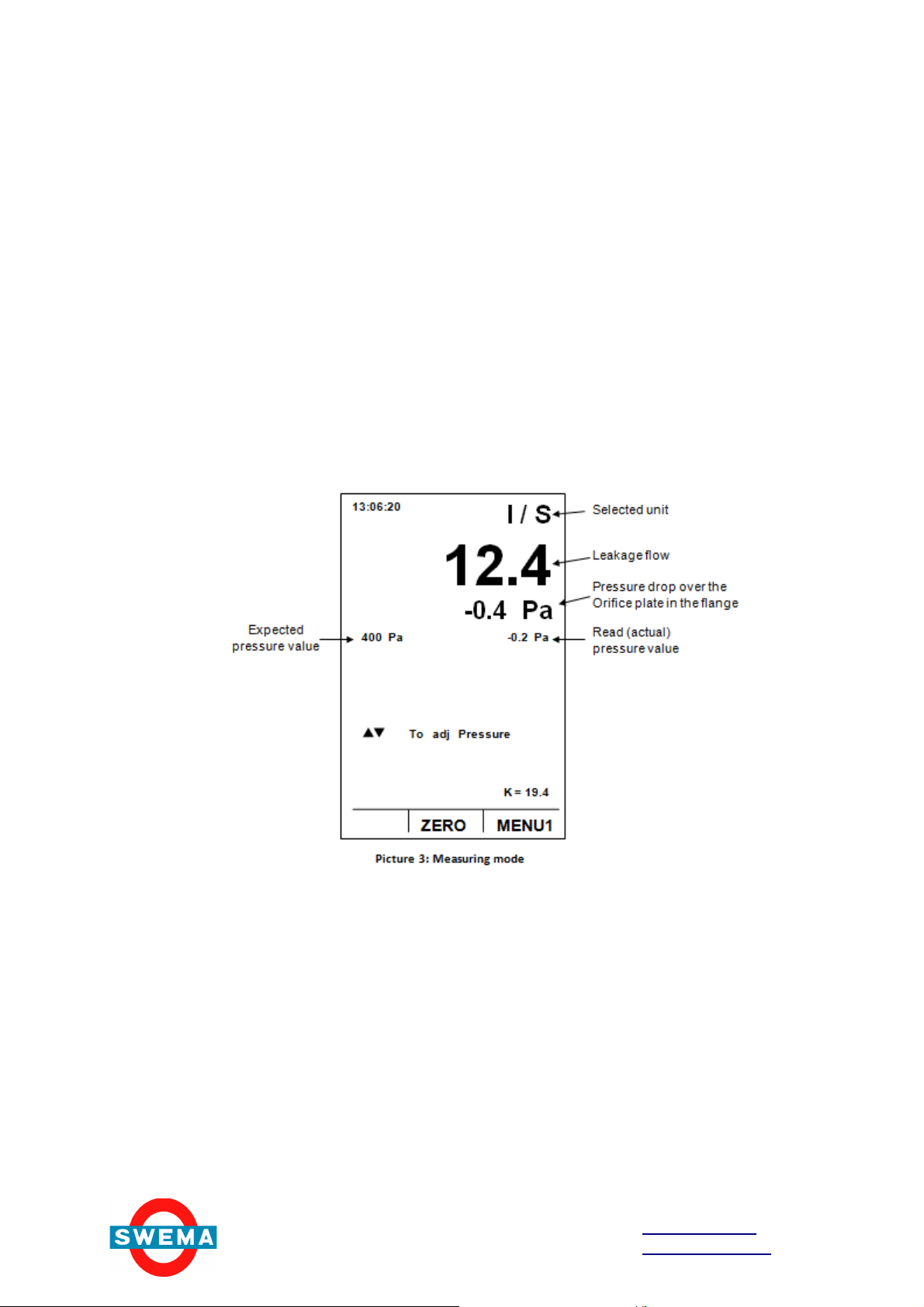

5. Turn Swema 3000md on and select measuring mode DUCT in MENU1 (See picture 1).

6. Set the K-factors on the label of the flange (See picture 1)..

7. Set the surface area of the duct to be tested. The selected area is used to calculate l/sm2and

m3/hm2if these units are selected (See picture 1).

8. Set the tightness (density) class to be used for the measurement of the leakage in the duct.

Select between classes A, B, C or D. In the saved protocol the selected class, used for

calculations, and the limit for the leakage on the test are shown. The limit depends on the

selected class and the pressure during the test (See picture 2).

9. Set the unit for the measurement, select between l/s, m3/h, l/sm2or m3/hm2. The unit l/sm2or

m3/hm2are calculated with the selected area of the duct (See picture 1).

10. Set the I-factor for duct leakage tester. 1000 is the standard factor for Swema 3000md to

control the fan with PID-regulation, however any other factor can be selected (See picture 1).

11. Set the actual ambient temperature. Swema 3000md compensates for air density calculating

with the selected temperature and the measured barometric pressure. The temperature can be

measured also with a thermocouple type-k connected to Swema 3000md (See picture 1).